Ceramography on:

[Wikipedia]

[Google]

[Amazon]

Ceramography is the art and science of preparation, examination and evaluation of

Image:Etch_A999.jpg, Fig. 1: Thermally etched 99.9% alumina

Image:Thin_A999.jpg, Fig. 2: Thin section of 99.9% alumina

Alternatively, non-cubic ceramics can be prepared as

Alternatively, non-cubic ceramics can be prepared as

Leco Met-Tips No. 19

2008. * ''Sample Preparation of Ceramic Material''

Buehler Ltd.

1990. * ''Structure'', Volume 33

Struers A/S

1998, p 3–20.

Struers Metalog Guide

* S. Binkowski, R. Paul & M. Woydt, "Comparing Preparation Techniques Using Microstructural Images of Ceramic Materials," ''Structure'', Vol 39, 2002, p 8–19. * R.E. Chinn, ''Ceramography'',

Digital Library of Ceramic Microstructures

University of Dayton, 2003. * G. Elssner, H. Hoven, G. Kiessler & P. Wellner, translated by R. Wert, ''Ceramics and Ceramic Composites: Materialographic Preparation'', Elsevier Science Inc., 1999, . * R.M. Fulrath & J.A. Pask, ed., ''Ceramic Microstructures: Their Analysis, Significance, and Production'', Robert E. Krieger Publishing Co., 1968, . * K. Geels in collaboration with D.B. Fowler, W-U Kopp & M. Rückert, ''Metallographic and Materialographic Specimen Preparation, Light Microscopy, Image Analysis and Hardness Testing'', ASTM International, 2007, . * H. Insley & V.D. Fréchette, ''Microscopy of Ceramics and Cements'', Academic Press Inc., 1955. * W.E. Lee and W.M. Rainforth, ''Ceramic Microstructures: Property Control by Processing'', Chapman & Hall, 1994. * I.J. McColm, ''Ceramic Hardness'', Plenum Press, 2000, .

Micrograph Center

ASM International, 2005. * H. Mörtel, "Microstructural Analysis," ''Engineered Materials Handbook, Volume 4: Ceramics and Glasses'', ASM International, 1991, p 570–579, . * G. Petzow, ''Metallographic Etching, 2nd Edition'', ASM International, 1999, . * G.D. Quinn, "Indentation Hardness Testing of Ceramics," ''ASM Handbook, Volume 8: Mechanical Testing and Evaluation'', ASM International, 2000, p 244–251, . * A.T. Santhanam, "Metallography of Cemented Carbides," ''ASM Handbook Volume 9: Metallography and Microstructures'', ASM International, 2004, p 1057–1066, . * U. Täffner, V. Carle & U. Schäfer, "Preparation and Microstructural Analysis of High-Performance Ceramics," ''ASM Handbook Volume 9: Metallography and Microstructures'', ASM International, 2004, p 1057–1066, {{ISBN, 0-87170-706-3. * D.C. Zipperian, ''Metallographic Handbook'', PACE Technologies, 2011. Ceramic engineering Metallurgy Microscopy Materials science Materials testing

ceramic

A ceramic is any of the various hard, brittle, heat-resistant, and corrosion-resistant materials made by shaping and then firing an inorganic, nonmetallic material, such as clay, at a high temperature. Common examples are earthenware, porcela ...

microstructure

Microstructure is the very small scale structure of a material, defined as the structure of a prepared surface of material as revealed by an optical microscope above 25× magnification. The microstructure of a material (such as metals, polymer ...

s. Ceramography can be thought of as the metallography

Metallography is the study of the physical structure and components of metals, by using microscopy.

Ceramic and polymeric materials may also be prepared using metallographic techniques, hence the terms ceramography, plastography and, collecti ...

of ceramics. The microstructure is the structure level of approximately 0.1 to 100 μm

The micrometre (Commonwealth English as used by the International Bureau of Weights and Measures; SI symbol: μm) or micrometer (American English), also commonly known by the non-SI term micron, is a unit of length in the International System ...

, between the minimum wavelength

In physics and mathematics, wavelength or spatial period of a wave or periodic function is the distance over which the wave's shape repeats.

In other words, it is the distance between consecutive corresponding points of the same ''phase (waves ...

of visible light

Light, visible light, or visible radiation is electromagnetic radiation that can be perceived by the human eye. Visible light spans the visible spectrum and is usually defined as having wavelengths in the range of 400–700 nanometres (nm ...

and the resolution limit of the naked eye. The microstructure includes most grains, secondary phases, grain boundaries

In materials science, a grain boundary is the interface between two grains, or crystallites, in a polycrystalline material. Grain boundaries are two-dimensional crystallographic defect, defects in the crystal structure, and tend to decrease the ...

, pores, micro-cracks and hardness microindentations. Most bulk mechanical, optical, thermal, electrical

Electricity is the set of physical phenomena associated with the presence and motion of matter possessing an electric charge. Electricity is related to magnetism, both being part of the phenomenon of electromagnetism, as described by Maxwel ...

and magnetic properties are significantly affected by the microstructure. The fabrication method and process conditions are generally indicated by the microstructure. The root cause of many ceramic failures is evident in the microstructure. Ceramography is part of the broader field of materialography, which includes all the microscopic techniques of material analysis, such as metallography, petrography

Petrography is a branch of petrology that focuses on detailed descriptions of rocks. Someone who studies petrography is called a petrographer. The mineral content and the textural relationships within the rock are described in detail. The clas ...

and plastography. Ceramography is usually reserved for high-performance ceramics for industrial applications, such as 85–99.9% alumina

Aluminium oxide (or aluminium(III) oxide) is a chemical compound of aluminium and oxygen with the chemical formula . It is the most commonly occurring of several aluminium oxides, and specifically identified as aluminium oxide. It is commonly ...

(Al2O3) in Fig. 1, zirconia

Zirconium dioxide (), sometimes known as zirconia (not to be confused with zirconium silicate or zircon), is a white crystalline oxide of zirconium. Its most naturally occurring form, with a monoclinic crystalline structure, is the mineral ba ...

(ZrO2), silicon carbide

Silicon carbide (SiC), also known as carborundum (), is a hard chemical compound containing silicon and carbon. A wide bandgap semiconductor, it occurs in nature as the extremely rare mineral moissanite, but has been mass-produced as a powder a ...

(SiC), silicon nitride

Silicon nitride is a chemical compound of the elements silicon and nitrogen. (''Trisilicon tetranitride'') is the most thermodynamically stable and commercially important of the silicon nitrides, and the term ″''Silicon nitride''″ commonly re ...

(Si3N4), and ceramic-matrix composites. It is seldom used on whiteware ceramics

A ceramic is any of the various hard, brittle, heat-resistant, and corrosion-resistant materials made by shaping and then firing an inorganic, nonmetallic material, such as clay, at a high temperature. Common examples are earthenware, porce ...

such as sanitaryware, wall tiles and dishware.

History

Ceramography evolved along with other branches of materialography andceramic engineering

Ceramic engineering is the science and technology of creating objects from inorganic, non-metallic materials. This is done either by the action of heat, or at lower temperatures using precipitation reactions from high-purity chemical solutions ...

. Alois de Widmanstätten of Austria etched a meteorite in 1808 to reveal proeutectoid

A eutectic system or eutectic mixture ( ) is a type of a homogeneous mixture that has a melting point lower than those of the constituents. The lowest possible melting point over all of the mixing ratios of the constituents is called the ''eutec ...

ferrite bands that grew on prior austenite

Austenite, also known as gamma-phase iron (γ-Fe), is a metallic, non-magnetic allotrope of iron or a solid solution of iron with an alloying element. In plain-carbon steel, austenite exists above the critical eutectoid temperature of 1000 ...

grain boundaries. Geologist Henry Clifton Sorby

Henry Clifton Sorby (10 May 1826 – 9 March 1908) was an English amateur microscopist and geologist. His major contribution was the development of techniques for thin sectioning of rocks and minerals with polarized light under a microscope whi ...

, the "father of metallography", applied petrographic techniques to the steel industry in the 1860s in Sheffield, England. French geologist Auguste Michel-Lévy devised a chart that correlated the optical properties of minerals to their transmitted color and thickness in the 1880s. Swedish metallurgist J.A. Brinell invented the first quantitative hardness scale in 1900. Smith and Sandland developed the first microindentation hardness test at Vickers

Vickers was a British engineering company that existed from 1828 until 1999. It was formed in Sheffield as a steel foundry by Edward Vickers and his father-in-law, and soon became famous for casting church bells. The company went public in 18 ...

Ltd. in London in 1922. Swiss-born microscopist A.I. Buehler started the first metallographic equipment manufacturer near Chicago in 1936. Frederick Knoop and colleagues at the National Bureau of Standards

The National Institute of Standards and Technology (NIST) is an agency of the United States Department of Commerce whose mission is to promote American innovation and industrial competitiveness. NIST's activities are organized into physical sc ...

developed a less-penetrating (than Vickers) microindentation test in 1939. Struers A/S of Copenhagen introduced the electrolytic

An electrolyte is a substance that conducts electricity through the movement of ions, but not through the movement of electrons. This includes most soluble salts, acids, and bases, dissolved in a polar solvent like water. Upon dissolving, the ...

polisher to metallography in 1943. George Kehl of Columbia University

Columbia University in the City of New York, commonly referred to as Columbia University, is a Private university, private Ivy League research university in New York City. Established in 1754 as King's College on the grounds of Trinity Churc ...

wrote a book that was considered the bible of materialography until the 1980s. Kehl co-founded a group within the Atomic Energy Commission that became the International Metallographic Society in 1967.

Preparation of ceramographic specimens

The preparation of ceramic specimens for microstructural analysis consists of five broad steps:saw

A saw is a tool consisting of a tough blade, Wire saw, wire, or Chainsaw, chain with a hard toothed edge used to cut through material. Various terms are used to describe toothed and abrasive saws.

Saws began as serrated materials, and when man ...

ing, embedding, grinding, polishing

Polishing is the process of creating a smooth and shiny surface by rubbing it or by applying a chemical treatment, leaving a clean surface with a significant specular reflection (still limited by the index of refraction of the material accordi ...

and etching

Etching is traditionally the process of using strong acid or mordant to cut into the unprotected parts of a metal surface to create a design in intaglio (incised) in the metal. In modern manufacturing, other chemicals may be used on other type ...

. The tools and consumables for ceramographic preparation are available worldwide from metallography equipment vendors and laboratory

A laboratory (; ; colloquially lab) is a facility that provides controlled conditions in which scientific or technological research, experiments, and measurement may be performed. Laboratories are found in a variety of settings such as schools ...

supply companies.Sawing

Most ceramics are extremely hard and must be wet-sawed with a circular blade embedded with diamond particles. A metallography orlapidary

Lapidary () is the practice of shaping rock (geology), stone, minerals, or gemstones into decorative items such as cabochons, engraved gems (including cameo (carving), cameos), and faceted designs. A person who practices lapidary techniques of ...

saw equipped with a low-density diamond blade

A diamond blade is a saw blade which has diamonds fixed on its edge for cutting hard or abrasive materials. There are many types of diamond blade, and they have many uses, including cutting stone, concrete, asphalt, bricks, coal balls, glass, an ...

is usually suitable.D.C. Zipperian, ''Metallographic Handbook'', PACE Technologies, 2011, p 34-43. The blade must be cooled by a continuous liquid spray.

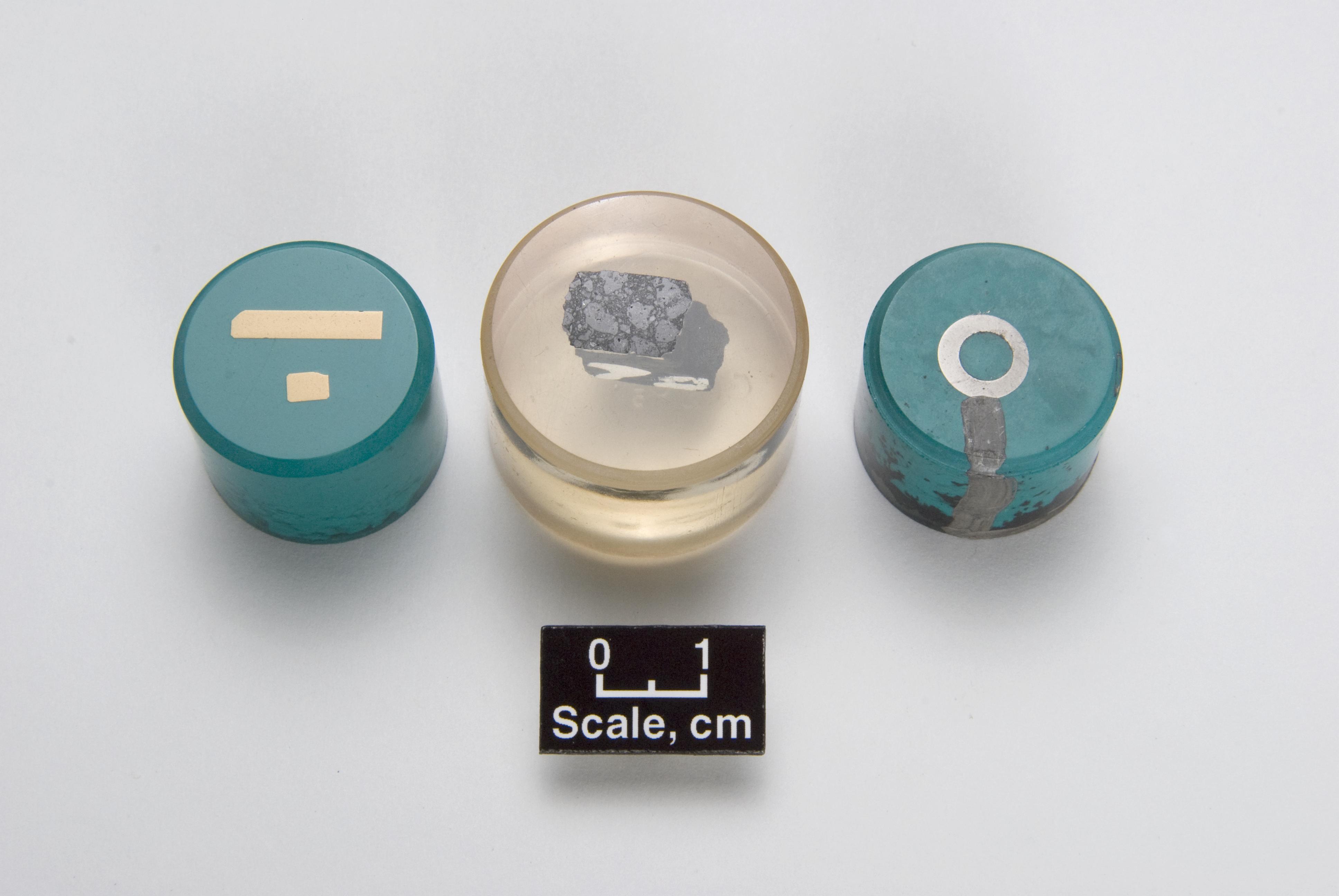

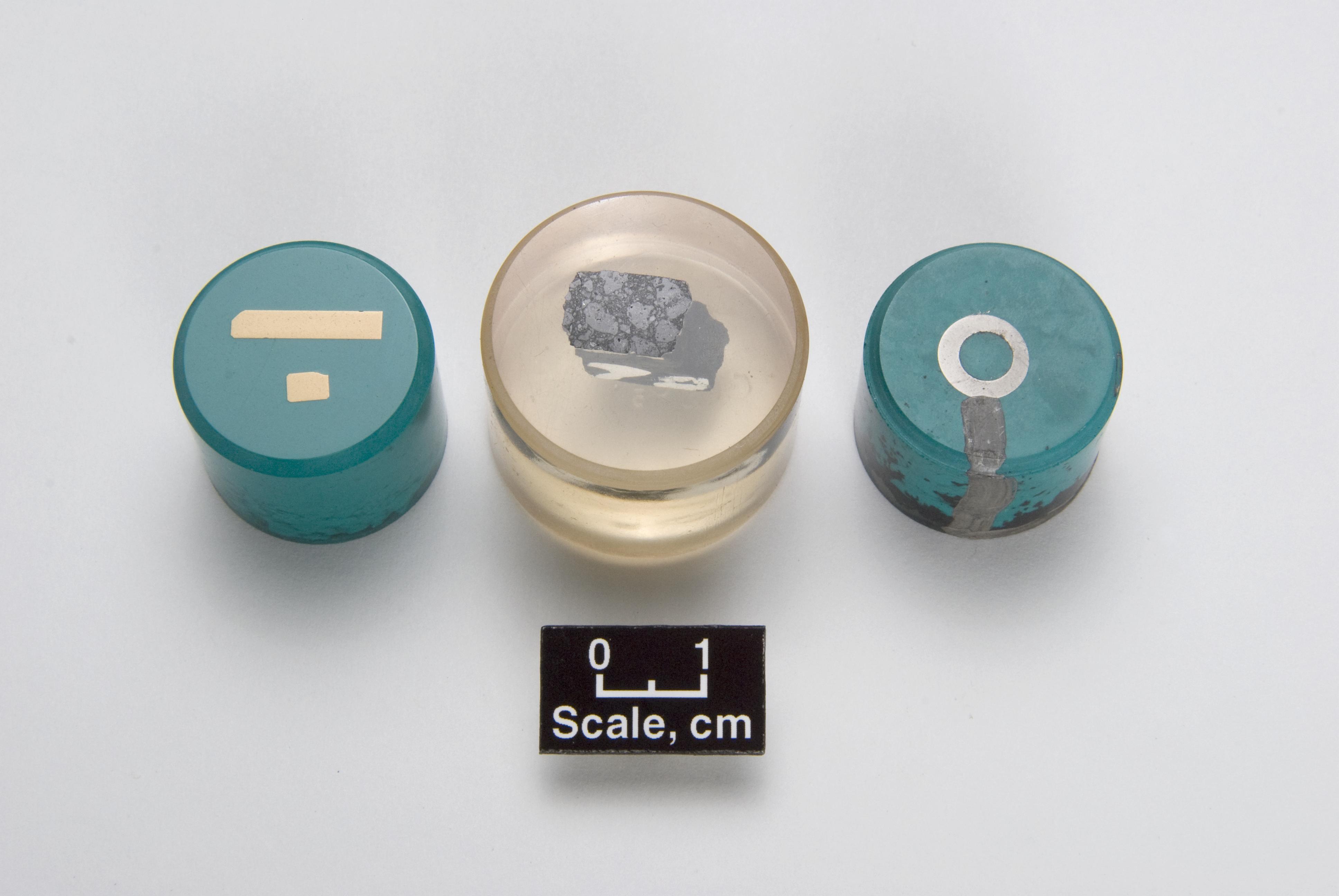

Embedding

To facilitate further preparation, the sawed specimen is usually embedded (or mounted or encapsulated) in a plastic disc, 25, 32 or 38 mm in diameter."Mounting of Specimens," ''ASM Handbook, Volume 9: Metallography and Microstructures'', ASM International, 1985, ISBN 0-87170-015-8, DOI: https://doi.org/10.31399/asm.hb.v09.a0003786, p 28. Athermosetting

In materials science, a thermosetting polymer, often called a thermoset, is a polymer that is obtained by irreversibly hardening (" curing") a soft solid or viscous liquid prepolymer (resin). Curing is induced by heat or suitable radiation and m ...

solid resin

A resin is a solid or highly viscous liquid that can be converted into a polymer. Resins may be biological or synthetic in origin, but are typically harvested from plants. Resins are mixtures of organic compounds, predominantly terpenes. Commo ...

, activated by heat and compression

Compression may refer to:

Physical science

*Compression (physics), size reduction due to forces

*Compression member, a structural element such as a column

*Compressibility, susceptibility to compression

* Gas compression

*Compression ratio, of a ...

, e.g. mineral-filled epoxy

Epoxy is the family of basic components or Curing (chemistry), cured end products of epoxy Resin, resins. Epoxy resins, also known as polyepoxides, are a class of reactive prepolymers and polymers which contain epoxide groups. The epoxide fun ...

, is best for most applications. A castable (liquid) resin such as unfilled epoxy, acrylic or polyester

Polyester is a category of polymers that contain one or two ester linkages in every repeat unit of their main chain. As a specific material, it most commonly refers to a type called polyethylene terephthalate (PET). Polyesters include some natura ...

may be used for porous refractory

In materials science, a refractory (or refractory material) is a material that is resistant to decomposition by heat or chemical attack and that retains its strength and rigidity at high temperatures. They are inorganic, non-metallic compound ...

ceramics or microelectronic

Microelectronics is a subfield of electronics. As the name suggests, microelectronics relates to the study and manufacture (or microfabrication) of very small electronic designs and components. Usually, but not always, this means micrometre- ...

devices. The castable resins are also available with fluorescent

Fluorescence is one of two kinds of photoluminescence, the emission of light by a substance that has absorbed light or other electromagnetic radiation. When exposed to ultraviolet radiation, many substances will glow (fluoresce) with color ...

dyes that aid in fluorescence microscopy

A fluorescence microscope is an optical microscope that uses fluorescence instead of, or in addition to, scattering, reflection, and attenuation or absorption, to study the properties of organic or inorganic substances. A fluorescence micro ...

. The left and right specimens in Fig. 3 were embedded in mineral-filled epoxy. The center refractory in Fig. 3 was embedded in castable, transparent acrylic.

Grinding

Grinding is abrasion of the surface of interest byabrasive

An abrasive is a material, often a mineral, that is used to shape or finish a workpiece through rubbing which leads to part of the workpiece being worn away by friction. While finishing a material often means polishing it to gain a smooth, reflec ...

particles, usually diamond, that are bonded to paper or a metal disc. Grinding erases saw marks, coarsely smooths the surface, and removes stock to a desired depth. A typical grinding sequence for ceramics is one minute on a 240- grit metal-bonded diamond

Diamond is a Allotropes of carbon, solid form of the element carbon with its atoms arranged in a crystal structure called diamond cubic. Diamond is tasteless, odourless, strong, brittle solid, colourless in pure form, a poor conductor of e ...

wheel rotating at 240 rpm and lubricated by flowing water, followed by a similar treatment on a 400-grit wheel. The specimen is washed in an ultrasonic bath after each step.

Polishing

Polishing is abrasion by free abrasives that are suspended in a lubricant and can roll or slide between the specimen and paper. Polishing erases grinding marks and smooths the specimen to a mirror-like finish. Polishing on a bare metallic platen is calledlapping

Lapping is a machining process in which two surfaces are rubbed together with an abrasive between them, by hand movement or using a machine.

Lapping often follows other subtractive processes with more aggressive material removal as a first ste ...

. A typical polishing sequence for ceramics is 5–10 minutes each on 15-, 6- and 1-μm diamond paste or slurry on napless paper rotating at 240 rpm. The specimen is again washed in an ultrasonic bath after each step. The three sets of specimens in Fig. 3 have been sawed, embedded, ground and polished.

Etching

Etching reveals and delineates grain boundaries and other microstructural features that are not apparent on the as-polished surface. The two most common types of etching in ceramography are selective chemical corrosion, and a thermal treatment that causesrelief

Relief is a sculpture, sculptural method in which the sculpted pieces remain attached to a solid background of the same material. The term ''wikt:relief, relief'' is from the Latin verb , to raise (). To create a sculpture in relief is to give ...

. As an example, alumina can be chemically etched by immersion in boiling concentrated phosphoric acid

Phosphoric acid (orthophosphoric acid, monophosphoric acid or phosphoric(V) acid) is a colorless, odorless phosphorus-containing solid, and inorganic compound with the chemical formula . It is commonly encountered as an 85% aqueous solution, ...

for 30–60 s, or thermally etched in a furnace for 20–40 min at in air. The plastic encapsulation must be removed before thermal etching. The alumina in Fig. 1 was thermally etched.

Alternatively, non-cubic ceramics can be prepared as

Alternatively, non-cubic ceramics can be prepared as thin section

In optical mineralogy and petrography, a thin section (or petrographic thin section) is a thin slice of a rock or mineral sample, prepared in a laboratory, for use with a polarizing petrographic microscope, electron microscope and electron ...

s, also known as petrography, for examination by polarized transmitted light microscopy. In this technique, the specimen is sawed to ~1 mm thick, glued to a microscope slide

A microscope slide is a thin flat piece of glass, typically 75 by 26 mm (3 by 1 inches) and about 1 mm thick, used to hold objects for examination under a microscope. Typically the object is mounted (secured) on the slide, and then ...

, and ground or sawed (e.g., by microtome

A microtome (from the Greek ''mikros'', meaning "small", and ''temnein'', meaning "to cut") is a cutting tool used to produce extremely thin slices of material known as ''sections'', with the process being termed microsectioning. Important in sc ...

) to a thickness (''x'') approaching 30 μm. A cover slip is glued onto the exposed surface. The adhesives, such as epoxy or Canada balsam

Canada balsam, also called Canada turpentine or balsam of fir, is the oleoresin of the balsam fir tree (''Abies balsamea'') of boreal North America. The resin, dissolved in essential oils, is a viscous, sticky, colourless or yellowish liquid t ...

resin, must have approximately the same refractive index

In optics, the refractive index (or refraction index) of an optical medium is the ratio of the apparent speed of light in the air or vacuum to the speed in the medium. The refractive index determines how much the path of light is bent, or refrac ...

(η ≈ 1.54) as glass. Most ceramics have a very small absorption coefficient

The linear attenuation coefficient, attenuation coefficient, or narrow-beam attenuation coefficient characterizes how easily a volume of material can be penetrated by a beam of light, sound, particles, or other energy or matter. A coefficient val ...

(α ≈ 0.5 cm −1 for alumina in Fig. 2) in the Beer–Lambert law

The Beer–Bouguer–Lambert (BBL) extinction law is an empirical relationship describing the attenuation in intensity of a radiation beam passing through a macroscopically homogenous medium with which it interacts. Formally, it states that the ...

below, and can be viewed in transmitted light. Cubic

Cubic may refer to:

Science and mathematics

* Cube (algebra), "cubic" measurement

* Cube, a three-dimensional solid object bounded by six square faces, facets or sides, with three meeting at each vertex

** Cubic crystal system, a crystal system w ...

ceramics, e.g. yttria-stabilized zirconia and spinel

Spinel () is the magnesium/aluminium member of the larger spinel group of minerals. It has the formula in the cubic crystal system. Its name comes from the Latin word , a diminutive form of ''spine,'' in reference to its pointed crystals.

Prop ...

, have the same refractive index in all crystallographic

Crystallography is the branch of science devoted to the study of molecular and crystalline structure and properties. The word ''crystallography'' is derived from the Ancient Greek word (; "clear ice, rock-crystal"), and (; "to write"). In J ...

directions and appear, therefore, black when the microscope's polarizer

A polarizer or polariser is an optical filter that lets light waves of a specific polarization (waves), polarization pass through while attenuation, blocking light waves of other polarizations. It can filter a beam of light of undefined or mixed ...

is 90° out of phase with its analyzer

An analyser (British English) or analyzer (American English; see spelling differences) is a tool used to analyze data. For example, a gas analyzer tool is used to analyze gases. It examines the given data and tries to find patterns and relationsh ...

.

: (Beer–Lambert eqn)

Ceramographic specimens are electrical insulators in most cases, and must be coated with a conductive ~10-nm layer of metal or carbon for electron microscopy, after polishing and etching. Gold or Au-Pd alloy from a sputter coater or evaporative coater also improves the reflection of visible light from the polished surface under a microscope, by the Fresnel formula below. Bare alumina (η ≈ 1.77, ''k'' ≈ 10 −6) has a negligible extinction coefficient and reflects only 8% of the incident light from the microscope, as in Fig. 1. Gold-coated (''η'' ≈ 0.82, ''k'' ≈ 1.59 @ λ = 500 nm) alumina reflects 44% in air, 39% in immersion oil.

: (Fresnel eqn)..

Ceramographic analysis

Ceramic microstructures are most often analyzed by reflected visible-lightmicroscopy

Microscopy is the technical field of using microscopes to view subjects too small to be seen with the naked eye (objects that are not within the resolution range of the normal eye). There are three well-known branches of microscopy: optical mic ...

in brightfield. Darkfield is used in limited circumstances, e.g., to reveal cracks. Polarized transmitted light is used with thin sections, where the contrast between grains comes from birefringence

Birefringence, also called double refraction, is the optical property of a material having a refractive index that depends on the polarization and propagation direction of light. These optically anisotropic materials are described as birefrin ...

. Very fine microstructures may require the higher magnification

Magnification is the process of enlarging the apparent size, not physical size, of something. This enlargement is quantified by a size ratio called optical magnification. When this number is less than one, it refers to a reduction in size, so ...

and resolution of a scanning electron microscope

A scanning electron microscope (SEM) is a type of electron microscope that produces images of a sample by scanning the surface with a focused beam of electrons. The electrons interact with atoms in the sample, producing various signals that ...

(SEM) or confocal laser scanning microscope

Confocal microscopy, most frequently confocal laser scanning microscopy (CLSM) or laser scanning confocal microscopy (LSCM), is an optical imaging technique for increasing optical resolution and contrast (vision), contrast of a micrograph by me ...

(CLSM). The cathodoluminescence microscope

Cathodoluminescence is an Optical phenomenon, optical and Electromagnetism, electromagnetic phenomenon in which electrons impacting on a Luminescence, luminescent material such as a phosphor, cause the emission of photons which may have waveleng ...

(CLM) is useful for distinguishing phases of refractories. The transmission electron microscope

Transmission electron microscopy (TEM) is a microscopy technique in which a beam of electrons is transmitted through a specimen to form an image. The specimen is most often an ultrathin section less than 100 nm thick or a suspension on a gr ...

(TEM) and scanning acoustic microscope

A scanning acoustic microscope (SAM) is a device which uses focused sound to investigate, measure, or image an object (a process called scanning acoustic tomography). It is commonly used in failure analysis and non-destructive evaluation. It a ...

(SAM) have specialty applications in ceramography.

Ceramography is often done qualitatively, for comparison of the microstructure of a component to a standard for quality control

Quality control (QC) is a process by which entities review the quality of all factors involved in production. ISO 9000 defines quality control as "a part of quality management focused on fulfilling quality requirements".

This approach plac ...

or failure analysis

Failure analysis is the process of collecting and analyzing data to determine the cause of a failure, often with the goal of determining corrective actions or liability.

According to Bloch and Geitner, ”machinery failures reveal a reaction chain ...

purposes. Three common quantitative analyses of microstructures are grain size, second-phase

Phase or phases may refer to:

Science

*State of matter, or phase, one of the distinct forms in which matter can exist

*Phase (matter), a region of space throughout which all physical properties are essentially uniform

*Phase space, a mathematica ...

content and porosity

Porosity or void fraction is a measure of the void (i.e. "empty") spaces in a material, and is a fraction of the volume of voids over the total volume, between 0 and 1, or as a percentage between 0% and 100%. Strictly speaking, some tests measure ...

. Microstructures are measured by the principles of stereology

Stereology is the three-dimensional interpretation of two-dimensional cross sections of materials or tissues. It provides practical techniques for extracting quantitative information about a three-dimensional material from measurements made on two ...

, in which three-dimensional objects are evaluated in 2-D by projections or cross-sections. Microstructures exhibiting heterogeneous grain sizes, with certain grains growing very large, occur in diverse ceramic systems and this phenomenon is known as abnormal grain growth

In materials science, abnormal or discontinuous grain growth, also referred to as exaggerated or secondary recrystallisation grain growth, is a grain growth phenomenon in which certain energetically favorable grains (crystallites) grow rapidly i ...

or AGG. The occurrence of AGG

Agg or AGG may refer to:

As an acronym:

* Anti-Grain Geometry, computer graphics rendering library

* Aesthetic group gymnastics, gymnastics in a group

* Abnormal grain growth, materials science phenomenon

* Arctic Gateway Group, owner-operators of ...

has consequences, positive or negative, on mechanical and chemical properties of ceramics and its identification is often the goal of ceramographic analysis.

Grain size can be measured by the line-fraction or area-fraction methods of ASTM

ASTM International, formerly known as American Society for Testing and Materials, is a standards organization that develops and publishes voluntary consensus technical international standards for a wide range of materials, products, systems and s ...

E112. In the line-fraction methods, a statistical grain size is calculated from the number of grains or grain boundaries intersecting a line of known length or circle of known circumference. In the area-fraction method, the grain size is calculated from the number of grains inside a known area. In each case, the measurement is affected by secondary phases, porosity, preferred orientation, exponential distribution

In probability theory and statistics, the exponential distribution or negative exponential distribution is the probability distribution of the distance between events in a Poisson point process, i.e., a process in which events occur continuousl ...

of sizes, and non-equiaxed grains. Image analysis

Image analysis or imagery analysis is the extraction of meaningful information from images; mainly from digital images by means of digital image processing techniques. Image analysis tasks can be as simple as reading barcode, bar coded tags or a ...

can measure the shape factors of individual grains by ASTM E1382.

Second-phase content and porosity are measured the same way in a microstructure, such as ASTM E562. Procedure E562 is a point-fraction method based on the stereological principle of point fraction = volume fraction, i.e., ''P''p = ''V''v. Second-phase content in ceramics, such as carbide whiskers in an oxide matrix, is usually expressed as a mass

Mass is an Intrinsic and extrinsic properties, intrinsic property of a physical body, body. It was traditionally believed to be related to the physical quantity, quantity of matter in a body, until the discovery of the atom and particle physi ...

fraction. Volume

Volume is a measure of regions in three-dimensional space. It is often quantified numerically using SI derived units (such as the cubic metre and litre) or by various imperial or US customary units (such as the gallon, quart, cubic inch) ...

fractions can be converted to mass fractions if the density

Density (volumetric mass density or specific mass) is the ratio of a substance's mass to its volume. The symbol most often used for density is ''ρ'' (the lower case Greek letter rho), although the Latin letter ''D'' (or ''d'') can also be u ...

of each phase is known. Image analysis can measure porosity, pore-size distribution and volume fractions of secondary phases by ASTM E1245. Porosity measurements do not require etching. Multi-phase microstructures do not require etching if the contrast between phases is adequate, as is usually the case.

Grain size, porosity and second-phase content have all been correlate

In statistics, correlation or dependence is any statistical relationship, whether causal or not, between two random variables or bivariate data. Although in the broadest sense, "correlation" may indicate any type of association, in statistics ...

d with ceramic properties such as mechanical strength σ by the Hall–Petch equation. Hardness

In materials science, hardness (antonym: softness) is a measure of the resistance to plastic deformation, such as an indentation (over an area) or a scratch (linear), induced mechanically either by Pressing (metalworking), pressing or abrasion ...

, toughness

In materials science and metallurgy, toughness is the ability of a material to absorb energy and plastically deform without fracturing.dielectric constant

The relative permittivity (in older texts, dielectric constant) is the permittivity of a material expressed as a ratio with the electric permittivity of a vacuum. A dielectric is an insulating material, and the dielectric constant of an insul ...

and many other properties are microstructure-dependent.

Microindentation hardness and toughness

The hardness of a material can be measured in many ways. TheKnoop hardness test

The Knoop hardness test is a microhardness test – a test for mechanical hardness used particularly for very brittle materials or thin sheets, where only a small indentation may be made for testing purposes. A pyramidal diamond point is pressed ...

, a method of microindentation hardness, is the most reproducible for dense ceramics. The Vickers hardness test

The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell scale, Brinell method to measure the hardness of materials. The Vickers test is often easier to use than ot ...

and superficial Rockwell scale

The Rockwell hardness test is a hardness test based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor loa ...

s (e.g., 45N) can also be used, but tend to cause more surface damage than Knoop. The Brinell test is suitable for ductile metals, but not ceramics. In the Knoop test, a diamond indenter in the shape of an elongated pyramid is forced into a polished (but not etched) surface under a predetermined load, typically 500 or 1000 g. The load is held for some amount of time, say 10 s, and the indenter is retracted. The indention long diagonal (''d'', μm

The micrometre (Commonwealth English as used by the International Bureau of Weights and Measures; SI symbol: μm) or micrometer (American English), also commonly known by the non-SI term micron, is a unit of length in the International System ...

, in Fig. 4) is measured under a microscope, and the Knoop hardness (HK) is calculated from the load (P, g) and the square of the diagonal length in the equations below. The constants account for the projected area of the indenter and unit conversion factors. Most oxide ceramics have a Knoop hardness in the range of 1000–1500 kgf/mm2 (10 – 15 G Pa), and many carbides are over 2000 (20 GPa). The method is specified in ASTM C849, C1326 & E384. Microindentation hardness is also called microindentation hardness

Indentation hardness tests are used in mechanical engineering to determine the hardness of a material to deformation. Several such tests exist, wherein the examined material is indented until an impression is formed; these tests can be performed o ...

or simply microhardness. The hardness of very small particles and thin films of ceramics, on the order of 100 nm, can be measured by nanoindentation methods that use a Berkovich indenter.

: (kgf/mm2) and (GPa)

The toughness of ceramics can be determined from a Vickers test under a load of 10 – 20 kg. Toughness

In materials science and metallurgy, toughness is the ability of a material to absorb energy and plastically deform without fracturing.propagation

Propagation can refer to:

*Chain propagation in a chemical reaction mechanism

*Crack propagation, the growth of a crack during the fracture of materials

*Propaganda, non-objective information used to further an agenda

*Reproduction, and other forms ...

. Several calculations have been formulated from the load (P), elastic modulus

An elastic modulus (also known as modulus of elasticity (MOE)) is a quantity that describes an object's or substance's resistance to being deformed elastically (i.e., non-permanently) when a stress is applied to it.

Definition

The elastic modu ...

(E), microindentation hardness (H), crack length (''c'' in Fig. 5) and flexural strength

Flexural strength, also known as modulus of rupture, or bend strength, or transverse rupture strength is a material property, defined as the Stress (mechanics), stress in a material just before it Yield (engineering), yields in a flexure test. T ...

(σ). Modulus of rupture (MOR) bars with a rectangular cross-section are indented in three places on a polished surface. The bars are loaded in 4-point bending with the polished, indented surface in tension, until fracture. The fracture normally originates at one of the indentions. The crack lengths are measured under a microscope. The toughness of most ceramics is 2–4 MPa, but toughened zirconia is as much as 13, and cemented carbide

Cemented carbides are a class of hard materials used extensively for cutting tool material, cutting tools, as well as in other industrial applications. It consists of fine particles of carbide cemented into a composite material, composite by a ...

s are often over 20. The toughness-by-indention methods have been discredited recently and are being replaced by more rigorous methods that measure crack growth in a notched beam in bending.G.D. Quinn & R.C. Bradt, "On the Vickers Indentation Fracture Toughness Test," ''J. Am. Ceram. Soc.'', 90 p 673–680 (Mar 2007).

: initial crack length

: indention strength in bending

References

Further reading and external links

* ''Expert Guide: Materialography/Metallography'', QATM Academy, ATM Qness GmbH, 2022. * ''Metallographic Preparation of Ceramic and Cermet Materials''Leco Met-Tips No. 19

2008. * ''Sample Preparation of Ceramic Material''

Buehler Ltd.

1990. * ''Structure'', Volume 33

Struers A/S

1998, p 3–20.

Struers Metalog Guide

* S. Binkowski, R. Paul & M. Woydt, "Comparing Preparation Techniques Using Microstructural Images of Ceramic Materials," ''Structure'', Vol 39, 2002, p 8–19. * R.E. Chinn, ''Ceramography'',

ASM International

ASM International N.V. (with ASM standing for Advanced Semiconductor Materials) is a Dutch-headquartered multinational corporation that designs, manufactures, sells, and services equipment used in the fabrication of semiconductor devices. Its ...

and the American Ceramic Society

The American Ceramic Society (ACerS) is a nonprofit organization of professionals for the ceramics community, with a focus on scientific research, emerging technologies, and applications in which ceramic materials are an element. ACerS is located ...

, 2002, .

* D.J. Clinton, ''A Guide to Polishing and Etching of Technical and Engineering Ceramics'', The Institute of Ceramics, 1987.

Digital Library of Ceramic Microstructures

University of Dayton, 2003. * G. Elssner, H. Hoven, G. Kiessler & P. Wellner, translated by R. Wert, ''Ceramics and Ceramic Composites: Materialographic Preparation'', Elsevier Science Inc., 1999, . * R.M. Fulrath & J.A. Pask, ed., ''Ceramic Microstructures: Their Analysis, Significance, and Production'', Robert E. Krieger Publishing Co., 1968, . * K. Geels in collaboration with D.B. Fowler, W-U Kopp & M. Rückert, ''Metallographic and Materialographic Specimen Preparation, Light Microscopy, Image Analysis and Hardness Testing'', ASTM International, 2007, . * H. Insley & V.D. Fréchette, ''Microscopy of Ceramics and Cements'', Academic Press Inc., 1955. * W.E. Lee and W.M. Rainforth, ''Ceramic Microstructures: Property Control by Processing'', Chapman & Hall, 1994. * I.J. McColm, ''Ceramic Hardness'', Plenum Press, 2000, .

Micrograph Center

ASM International, 2005. * H. Mörtel, "Microstructural Analysis," ''Engineered Materials Handbook, Volume 4: Ceramics and Glasses'', ASM International, 1991, p 570–579, . * G. Petzow, ''Metallographic Etching, 2nd Edition'', ASM International, 1999, . * G.D. Quinn, "Indentation Hardness Testing of Ceramics," ''ASM Handbook, Volume 8: Mechanical Testing and Evaluation'', ASM International, 2000, p 244–251, . * A.T. Santhanam, "Metallography of Cemented Carbides," ''ASM Handbook Volume 9: Metallography and Microstructures'', ASM International, 2004, p 1057–1066, . * U. Täffner, V. Carle & U. Schäfer, "Preparation and Microstructural Analysis of High-Performance Ceramics," ''ASM Handbook Volume 9: Metallography and Microstructures'', ASM International, 2004, p 1057–1066, {{ISBN, 0-87170-706-3. * D.C. Zipperian, ''Metallographic Handbook'', PACE Technologies, 2011. Ceramic engineering Metallurgy Microscopy Materials science Materials testing