|

Polishing

Polishing is the process of creating a smooth and shiny surface by rubbing it or by applying a chemical treatment, leaving a clean surface with a significant specular reflection (still limited by the index of refraction of the material according to the Fresnel equations). In some materials (such as metals, glasses, black or transparent stones), polishing is also able to reduce diffuse reflection to minimal values. When an unpolished surface is magnified thousands of times, it usually looks like a succession of mountains and valleys. By repeated abrasion, those "mountains" are worn down until they are flat or just small "hills". The process of polishing with abrasives starts with a coarse grain size and gradually proceeds to the finer ones to efficiently flatten the surface imperfections and to obtain optimal results. Mechanical properties The strength of polished products can be higher than their unpolished counterparts owing to the removal of stress concentrations pres ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chemical-mechanical Polishing

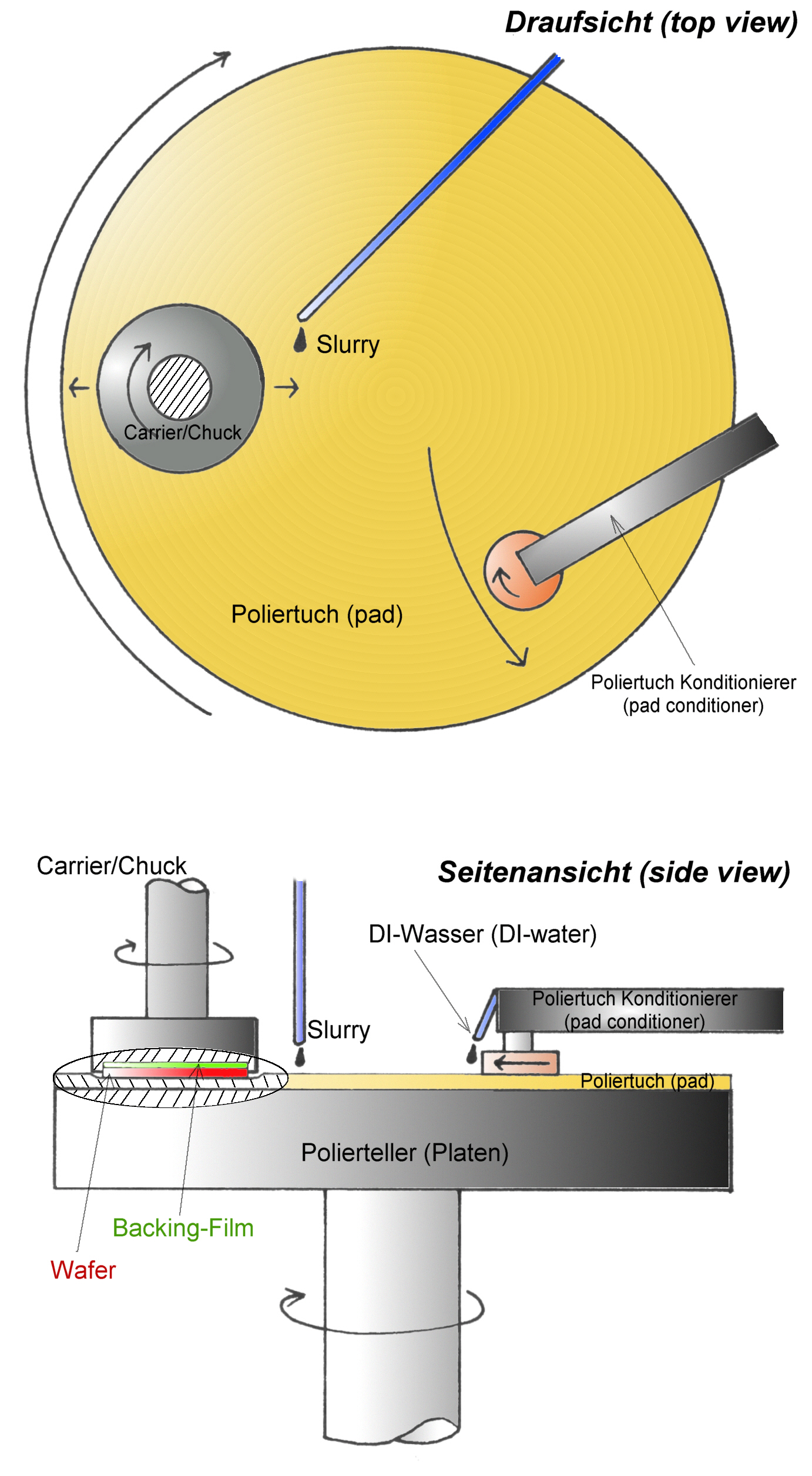

Chemical mechanical polishing (CMP) (also called chemical mechanical planarization) is a process of smoothing surfaces with the combination of chemical and mechanical forces. It can be thought of as a wikt:hybrid, hybrid of chemical etching and free abrasive polishing. It is used in the semiconductor industry to polish semiconductor wafers as part of the integrated circuit manufacturing process. Description The process uses an abrasive and corrosive chemical slurry (commonly a colloid) in conjunction with a polishing pad and retaining ring, typically of a greater diameter than the wafer. The pad and wafer are pressed together by a dynamic polishing head and held in place by a plastic retaining ring. The dynamic polishing head is rotated with different axes of rotation (i.e., not wiktionary:concentric, concentric). This removes material and tends to even out any irregular topography, making the wafer flat or planar. This may be necessary to set up the wafer for the formation of ad ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

French Polishing

French polishing is a wood finishing technique that results in a very high gloss surface, with a deep colour and chatoyancy. French polishing consists of applying many thin coats of shellac dissolved in denatured alcohol using a rubbing pad lubricated with one of a variety of oils. The rubbing pad is made of absorbent cotton or wool cloth wadding inside of a piece of fabric (usually soft cotton cloth) and is commonly referred to as a ''fad'', also called a rubber, tampon, or (Spanish for 'rag doll'). French polish is a process, not a material. The main material is shellac, although there are several other shellac-based finishes, not all of which classify as French polishing. The French polish technique is an effective method to accent exotic wood grain. The finish is softer than modern varnishes and lacquers, and is particularly sensitive to spills of water or alcohol, which may produce white cloudy marks, as does heat damage. On the other hand, French polish is simpler to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Flame Polishing

Flame polishing, also known as fire polishing, is a method of polishing a material, usually glass or thermoplastics, by exposing it to a flame or heat. When the surface of the material briefly melts, surface tension smooths the surface. Operator skill is critical with this method. When done properly, flame plastic polishing produces the clearest finish, especially when polishing acrylic. This method is most applicable to flat external surfaces. Flame polishing is frequently used in acrylic plastic fabrication because of its high speed compared to abrasive methods. In this application, an oxyhydrogen torch is typically used, one reason being that the flame chemistry is unlikely to contaminate the plastic. Flame polishing is essential to creation of the glass pipettes used for the patch clamp The patch clamp technique is a laboratory technique in electrophysiology used to study ionic currents in individual Cell isolation, isolated living cells, tissue sections, or patches of ce ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Abrasive

An abrasive is a material, often a mineral, that is used to shape or finish a workpiece through rubbing which leads to part of the workpiece being worn away by friction. While finishing a material often means polishing it to gain a smooth, reflective surface, the process can also involve roughening as in satin, matte or beaded finishes. In short, the ceramics which are used to cut, grind and polish other softer materials are known as abrasives. Abrasives are extremely commonplace and are used very extensively in a wide variety of industrial, domestic, and technological applications. This gives rise to a large variation in the physical and chemical composition of abrasives as well as the shape of the abrasive. Some common uses for abrasives include grinding, polishing, buffing, honing, cutting, drilling, sharpening, lapping, and sanding (see abrasive machining). (For simplicity, "mineral" in this article will be used loosely to refer to both minerals and mineral-like substances ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tumble Finishing

Tumble finishing, also known as tumbling or rumbling, is a technique for smoothing and polishing a rough surface on relatively small parts. In the field of metalworking, a similar process called barreling, or barrel finishing,Degarmo, p. 781. works upon the same principles. Tumbled stones are made with rock tumblers in a process very similar to the natural processes that produce "sea glass" or "beach glass". Stones Tumbling of rocks as a lapidary technique for rock polishing usually requires a plastic or rubber-lined barrel loaded with a consignment of rocks, all of similar or the same hardness, some abrasive grit, and a liquid lubricant. Silicon carbide grit is commonly used, and water is a universal lubricant. The barrel is then placed upon slowly rotating rails so that it rotates. The optimal speed of rotation depends on the size of the tumbler barrel and materials involved. Vibratory finishing process can be used instead. A well-chosen speed for stone polishing causes t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Vapor Polishing

Vapor polishing is a method of polishing plastics to reduce the surface roughness or improve clarity. Typically, a component is exposed to a chemical vapor causing the surface to flow thereby improving the surface finish. This method of polishing is frequently used to return clear materials to an optical quality finish after machining. Vapor polishing works well in the internal features of components. Feature size changes of the plastic component generally do not occur. Post stress relieving is usually required as vapor polishing sets up surface stresses that can cause crazing. Plastics that respond well to vapor polishing are polycarbonate, acrylic, polysulfone, PEI, and ABS. The technique is also being used to improve the surface of objects created with 3D printing 3D printing, or additive manufacturing, is the construction of a three-dimensional object from a CAD model or a digital 3D model. It can be done in a variety of processes in which material is deposited, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Industrial Processes

Industrial processes are procedures involving chemical, physical, electrical, or mechanical steps to aid in the manufacturing of an item or items, usually carried out on a very large scale. Industrial processes are the key components of heavy industry. Chemical processes by main basic material Certain chemical process yield important basic materials for society, e.g., (cement, steel, aluminum, and fertilizer). However, these chemical reactions contribute to climate change by emitting carbon dioxide, a greenhouse gas, through chemical reactions, as well as through the combustion of fossil fuels to generate the high temperatures needed to reach the activation energies of the chemical reactions. Cement (the paste within concrete) * Calcination – Limestone, which is largely composed of fossilized calcium carbonate (CaCO3), breaks down at high temperatures into useable calcium oxide (CaO) and carbon dioxide gas (), which gets released as a by-product. This chemical reaction, c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Diffuse Reflection

Diffuse reflection is the reflection of light or other waves or particles from a surface such that a ray incident on the surface is scattered at many angles rather than at just one angle as in the case of specular reflection. An ''ideal'' diffuse reflecting surface is said to exhibit Lambertian reflection, meaning that there is equal luminance when viewed from all directions lying in the half-space adjacent to the surface. A surface built from a non-absorbing powder such as plaster, or from fibers such as paper, or from a polycrystalline material such as white marble, reflects light diffusely with great efficiency. Many common materials exhibit a mixture of specular and diffuse reflection. The visibility of objects, excluding light-emitting ones, is primarily caused by diffuse reflection of light: it is diffusely-scattered light that forms the image of the object in an observer's eye over a wide range of angles of the observer with respect to the object. Mechanism Di ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Burnishing (metal)

Burnishing is the deformation (engineering), plastic deformation of a surface due to friction, sliding contact with another object. It smooths the surface and makes it shinier. Burnishing may occur on any sliding surface if the contact stress locally exceeds the yield (engineering), yield strength of the material. The phenomenon can occur both unintentionally as a failure mode, and intentionally as part of a metalworking or manufacturing process. It is a squeezing operation under cold working. Failure mode (unintentionally) The action of a hardened ball against a softer, flat plate illustrates the process of burnishing. If the ball is pushed directly into the plate, stresses develop in both objects around the area where they contact. As this normal force increases, both the ball and the plate's surfaces deform. The deformation caused by the hardened ball increases with the magnitude of the force pressing against it. If the force on it is small, when the force is released both ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mass Finishing

Mass finishing is a group of manufacturing processes that allow large quantities of parts to be simultaneously finished. The goal of this type of finishing is to burnish, deburr, clean, radius, de-flash, descale, remove rust, polish, brighten, surface harden, prepare parts for further finishing, or break off die cast runners. The two main types of mass finishing are tumble finishing, also known as barrel finishing, and vibratory finishing.Degarmo, pp. 781–784. Both involve the use of a cyclical action to create grinding contact between surfaces. Sometimes the workpieces are finished against each other; however, usually a finishing medium is used. Mass finishing can be performed dry or wet; wet processes have liquid lubricants, cleaners, or abrasives, while dry processes do not. Cycle times can be as short as 10 minutes for nonferrous workpieces or as long as 2 hours for hardened steel. Mass finishing processes can be configured as either batch systems, in ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Vibratory Finishing

Vibratory finishing is a type of mass finishing manufacturing Manufacturing is the creation or production of goods with the help of equipment, labor, machines, tools, and chemical or biological processing or formulation. It is the essence of the secondary sector of the economy. The term may refer ... process used to deburr, radius, descale, burnish, clean, and brighten a large number of relatively small workpieces.Degarmo, p. 783. In this batch-type operation, specially shaped pellets of media and the workpieces are placed into the tub of a vibratory tumbler. The tub of the vibratory tumbler and all of its contents are then vibrated. The vibratory action causes the media to rub against the workpieces which yield the desired result. Depending on the application this can be either a dry or wet process. Unlike rotary tumbling this process can finish internal features, such as holes. It is also quicker and quieter. The process is performed in an open tub so the operat ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wood Finishing

Wood finishing refers to the process of refining or protecting a wooden surface, especially in the production of furniture where typically it represents between 5 and 30% of manufacturing costs. Finishing is the final step of the manufacturing process that gives wood surfaces desirable characteristics, including enhanced appearance and increased resistance to moisture and other environmental agents. Finishing can also make wood easier to clean and keep it sanitized, sealing pores that can be breeding grounds for bacteria. Finishing can also influence other wood properties, for example tonal qualities of musical instruments and hardness of flooring. In addition, finishing provides a way of giving low-value woods the appearance of ones that are expensive and difficult to obtain. Planning the finish Finishing of wood requires careful planning to ensure that the finished piece looks attractive, performs well in service and meets safety and environmental requirements. Planning for ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |