|

Siemens-Martin

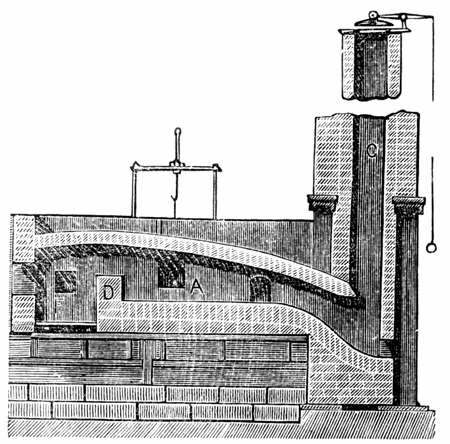

An open-hearth furnace or open hearth furnace is any of several kinds of industrial furnace in which excess carbon and other impurities are burnt out of pig iron to produce steel. Because steel is difficult to manufacture owing to its high melting point, normal fuels and furnaces were insufficient for mass production of steel, and the open-hearth type of furnace was one of several technologies developed in the nineteenth century to overcome this difficulty. Compared with the Bessemer process, which it displaced, its main advantages were that it did not embrittle the steel from excessive nitrogen exposure, was easier to control, and permitted the melting and refining of large amounts of scrap iron and steel. The open-hearth furnace was first developed by German/British engineer Carl Wilhelm Siemens. In 1865, the French engineer Pierre-Émile Martin took out a licence from Siemens and first applied his regenerative furnace for making steel. Their process was known as the Sieme ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Carl Wilhelm Siemens

Sir Carl Wilhelm Siemens (4 April 1823 – 19 November 1883), anglicised to Charles William Siemens, was a German-British electrical engineer and businessman. autobiography Sir Carl Wilhelm Siemens FRS FRSA, anglicised to Charles William Siemens, was a German-British electrical engineer and businessman. He was born on April 4, 1823, in the Kingdom of Hanover and died on 19 November 1883 at the age of 60 years in London. Nationality: British, German He had siblings: Carl Heinrich von Siemens, Werner von Siemens, and his parents were Christian Ferdinand Siemens and Eleonore Deichmann. He received the Albert Medal in 1874, the Royal Society Bakeries Medal in 1871, and was elected Fellow of the Royal Society in 1862. The regenerative furnace is the greatest single invention of Charles William Siemens, using a process known as the Siemens-Martin process. The early years In the autumn of 1838 when William was fifteen years old, he began his studies to become an engineer. He atten ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

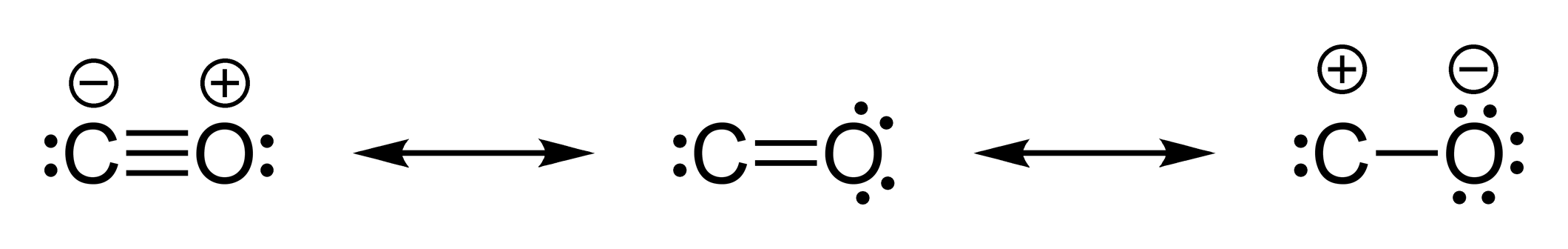

Carbon Monoxide

Carbon monoxide (chemical formula CO) is a poisonous, flammable gas that is colorless, odorless, tasteless, and slightly less dense than air. Carbon monoxide consists of one carbon atom and one oxygen atom connected by a triple bond. It is the simplest oxocarbon, carbon oxide. In coordination complexes, the carbon monoxide ligand is called ''metal carbonyl, carbonyl''. It is a key ingredient in many processes in industrial chemistry. The most common source of carbon monoxide is the partial combustion of carbon-containing compounds. Numerous environmental and biological sources generate carbon monoxide. In industry, carbon monoxide is important in the production of many compounds, including drugs, fragrances, and fuels. Indoors CO is one of the most acutely toxic contaminants affecting indoor air quality. CO may be emitted from tobacco smoke and generated from malfunctioning fuel-burning stoves (wood, kerosene, natural gas, propane) and fuel-burning heating systems (wood, oil, n ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pierre-Émile Martin

Pierre-Émile Martin (; 18 August 1824, Bourges, Cher – 23 May 1915, Fourchambault) was a French industrial engineer. He applied the principle of recovery of the hot gas in an open hearth furnace, a process invented by Carl Wilhelm Siemens. In 1865, based on the Siemens process, he implemented the process which bears his name for producing steel in a hearth by remelting scrap steel with the addition of cast iron for the dilution of impurities. His work earned him the award of the Bessemer Gold Medal of the Iron and Steel Institute in 1915 and of the French nation (knight in 1878 then Officer of the Legion of Honour The National Order of the Legion of Honour ( ), formerly the Imperial Order of the Legion of Honour (), is the highest and most prestigious French national order of merit, both military and civil. Currently consisting of five classes, it was ... in 1910). Martin steel The metal obtained using Martin's process has been called Martin steel. This steel conta ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Steelmaking

Steelmaking is the process of producing steel from iron ore and/or scrap. Steel has been made for millennia, and was commercialized on a massive scale in the 1850s and 1860s, using the Bessemer process, Bessemer and open hearth furnace, Siemens-Martin processes. Currently, two major commercial processes are used. Basic oxygen steelmaking (BOS) uses liquid Pig iron, pig-iron from a blast furnace and scrap steel as the main feed materials. Electric arc furnace (EAF) steelmaking uses scrap steel or direct reduced iron (DRI). Oxygen steelmaking has become more popular over time. Steelmaking is one of the most carbon emission-intensive industries. In 2020, the steelmaking industry was reported to be responsible for 7% of energy sector greenhouse gas emissions. The industry is seeking significant emission reductions. Steel Steel is made from iron and carbon. Cast iron is a hard, brittle material that is difficult to work, whereas steel is malleable, relatively easily formed and v ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Steel

Steel is an alloy of iron and carbon that demonstrates improved mechanical properties compared to the pure form of iron. Due to steel's high Young's modulus, elastic modulus, Yield (engineering), yield strength, Fracture, fracture strength and low raw material cost, steel is one of the most commonly manufactured materials in the world. Steel is used in structures (as concrete Rebar, reinforcing rods), in Bridge, bridges, infrastructure, Tool, tools, Ship, ships, Train, trains, Car, cars, Bicycle, bicycles, Machine, machines, Home appliance, electrical appliances, furniture, and Weapon, weapons. Iron is always the main element in steel, but other elements are used to produce various grades of steel demonstrating altered material, mechanical, and microstructural properties. Stainless steels, for example, typically contain 18% chromium and exhibit improved corrosion and Redox, oxidation resistance versus its carbon steel counterpart. Under atmospheric pressures, steels generally ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Blast Furnace

A blast furnace is a type of metallurgical furnace used for smelting to produce industrial metals, generally pig iron, but also others such as lead or copper. ''Blast'' refers to the combustion air being supplied above atmospheric pressure. In a blast furnace, fuel ( coke), ores, and flux (limestone) are continuously supplied through the top of the furnace, while a hot blast of (sometimes oxygen enriched) air is blown into the lower section of the furnace through a series of pipes called tuyeres, so that the chemical reactions take place throughout the furnace as the material falls downward. The end products are usually molten metal and slag phases tapped from the bottom, and flue gases exiting from the top. The downward flow of the ore along with the flux in contact with an upflow of hot, carbon monoxide-rich combustion gases is a countercurrent exchange and chemical reaction process. In contrast, air furnaces (such as reverberatory furnaces) are naturally aspirated, usu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Finery Forge

A finery forge is a forge used to produce wrought iron from pig iron by decarburization in a process called "fining" which involved liquifying cast iron in a fining hearth and decarburization, removing carbon from the molten cast iron through Redox, oxidation. Finery forges were used as early as the 3rd century BC in China. The finery forge process was replaced by the puddling (metallurgy), puddling process and the roller mill, both developed by Henry Cort in 1783–4, but not becoming widespread until after 1800. History A finery forge was used to refine wrought iron at least by the 3rd century BC in ancient China, based on the earliest archaeological specimens of Cast iron, cast and pig iron fined into wrought iron and steel found at the early Han dynasty (202 BC – 220 AD) site at Tieshengguo.Pigott, Vincent C. (1999). ''The Archaeometallurgy of the Asian Old World''. Philadelphia: University of Pennsylvania Museum of Archaeology and Anthropology. , p. 186-187. Pigott spec ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Puddling Furnace

Puddling is the process of converting pig iron to bar (wrought) iron in a coal fired reverberatory furnace. It was developed in England during the 1780s. The molten pig iron was stirred in a reverberatory furnace, in an Redox, oxidizing environment to burn the carbon, resulting in wrought iron. It was one of the most important processes for making the first appreciable volumes of valuable and useful wrought iron, bar iron (malleable wrought iron) without the use of charcoal. Eventually, the furnace would be used to make small quantities of specialty steels. Though it was not the first process to produce bar iron without charcoal, puddling was by far the most successful, and replaced the earlier potting and stamping processes, as well as the much older charcoal finery forge, finery and bloomery processes. This enabled a great expansion of iron production to take place in Great Britain, and shortly afterwards, in North America. That expansion constitutes the beginnings of the Ind ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Batch Production

Batch production is a method of manufacturing in which products are made as specified groups or amounts, within a time frame. A batch can go through a series of steps in a large manufacturing process to make the final desired product. Batch production is used for many types of manufacturing that may need smaller amounts of production at a time to ensure specific quality standards or changes in the process. This is opposed to large mass production Mass production, also known as mass production, series production, series manufacture, or continuous production, is the production of substantial amounts of standardized products in a constant flow, including and especially on assembly lines ... or continuous production methods, where the product or process does not need to be checked or changed as frequently or periodically. Characteristics In the manufacturing batch production process, the machines are in chronological order directly related to the manufacturing process. The ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Oxygen

Oxygen is a chemical element; it has chemical symbol, symbol O and atomic number 8. It is a member of the chalcogen group (periodic table), group in the periodic table, a highly reactivity (chemistry), reactive nonmetal (chemistry), nonmetal, and a potent oxidizing agent that readily forms oxides with most elements as well as with other chemical compound, compounds. Oxygen is abundance of elements in Earth's crust, the most abundant element in Earth's crust, making up almost half of the Earth's crust in the form of various oxides such as water, carbon dioxide, iron oxides and silicates.Atkins, P.; Jones, L.; Laverman, L. (2016).''Chemical Principles'', 7th edition. Freeman. It is abundance of chemical elements, the third-most abundant element in the universe after hydrogen and helium. At standard temperature and pressure, two oxygen atoms will chemical bond, bind covalent bond, covalently to form dioxygen, a colorless and odorless diatomic gas with the chemical formula ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bloomery

A bloomery is a type of metallurgical furnace once used widely for smelting iron from its iron oxides, oxides. The bloomery was the earliest form of smelter capable of smelting iron. Bloomeries produce a porous mass of iron and slag called a ''bloom''. The mix of slag and iron in the bloom, termed ''Direct reduced iron, sponge iron'', is usually consolidated and further forged into wrought iron. Blast furnaces, which produce pig iron, have largely superseded bloomeries. Process A bloomery consists of a wikt:pit, pit or chimney with heat-resistant walls made of earth, clay, or Rock (geology), stone. Near the bottom, one or more pipes (made of clay or metal) enter through the side walls. These pipes, called tuyeres, allow air to enter the furnace, either by natural draught or forced with bellows or a trompe. An opening at the bottom of the bloomery may be used to remove the bloom, or the bloomery can be tipped over and the bloom removed from the top. The first step taken b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |