Blast Furnace on:

[Wikipedia]

[Google]

[Amazon]

A blast furnace is a type of

Blast furnaces operate on the principle of chemical reduction whereby carbon monoxide converts iron oxides to elemental iron.

Blast furnaces differ from bloomeries and reverberatory furnaces in that in a blast furnace, flue gas is in direct contact with the ore and iron, allowing carbon monoxide to diffuse into the ore and reduce the iron oxide. The blast furnace operates as a

Blast furnaces operate on the principle of chemical reduction whereby carbon monoxide converts iron oxides to elemental iron.

Blast furnaces differ from bloomeries and reverberatory furnaces in that in a blast furnace, flue gas is in direct contact with the ore and iron, allowing carbon monoxide to diffuse into the ore and reduce the iron oxide. The blast furnace operates as a

Cast iron has been found in

Cast iron has been found in

'Henry "Stamped Out Industrial Revolution"'

, ''

Due to the increased demand for iron for casting cannons, the blast furnace came into widespread use in France in the mid 15th century.

The direct ancestor of those used in France and England was in the

Due to the increased demand for iron for casting cannons, the blast furnace came into widespread use in France in the mid 15th century.

The direct ancestor of those used in France and England was in the

Stone wool or

Stone wool or

Modern furnaces are equipped with an array of supporting facilities to increase efficiency, such as ore storage yards where barges are unloaded. The raw materials are transferred to the stockhouse complex by ore bridges, or rail hoppers and ore transfer cars. Rail-mounted scale cars or computer controlled weight hoppers weigh out the various raw materials to yield the desired hot metal and slag chemistry. The raw materials are brought to the top of the blast furnace via a skip car powered by winches or conveyor belts.American Iron and Steel Institute (2005)

Modern furnaces are equipped with an array of supporting facilities to increase efficiency, such as ore storage yards where barges are unloaded. The raw materials are transferred to the stockhouse complex by ore bridges, or rail hoppers and ore transfer cars. Rail-mounted scale cars or computer controlled weight hoppers weigh out the various raw materials to yield the desired hot metal and slag chemistry. The raw materials are brought to the top of the blast furnace via a skip car powered by winches or conveyor belts.American Iron and Steel Institute (2005)

How a Blast Furnace Works

steel.org. There are different ways in which the raw materials are charged into the blast furnace. Some blast furnaces use a "double bell" system where two "bells" are used to control the entry of raw material into the blast furnace. The purpose of the two bells is to minimize the loss of hot gases in the blast furnace. First, the raw materials are emptied into the upper or small bell which then opens to empty the charge into the large bell. The small bell then closes, to seal the blast furnace, while the large bell rotates to provide specific distribution of materials before dispensing the charge into the blast furnace. A more recent design is to use a "bell-less" system. These systems use multiple hoppers to contain each raw material, which is then discharged into the blast furnace through valves. These valves are more accurate at controlling how much of each constituent is added, as compared to the skip or conveyor system, thereby increasing the efficiency of the furnace. Some of these bell-less systems also implement a discharge chute in the throat of the furnace (as with the Paul Wurth top) in order to precisely control where the charge is placed. The iron making blast furnace itself is built in the form of a tall structure, lined with

File:Alto horno antiguo Sestao.jpg, Abandoned blast furnace in Sestao, Spain. The furnace itself is inside the central girderwork.

File:Old blast furnace gas cleaning plant 2012-05-02.jpg, Part of the gas cleaning system of a blast furnace in Monclova, Mexico. This one is about to be de-commissioned and replaced.

American Iron and Steel InstituteBlast Furnace animation Extensive picture gallery about all methods of making and shaping of iron and steel in North America and Europe. In German and English.Schematic diagram of blast furnace and Cowper stove

{{DEFAULTSORT:Blast Furnace Chinese inventions Firing techniques Industrial buildings and structures Industrial furnaces Industrial Revolution Metallurgy Smelting Steelmaking

metallurgical furnace

A metallurgical furnace, often simply referred to as a furnace when the context is known, is an industrial furnace used to heat, melt, or otherwise process metals. Furnaces have been a central piece of equipment throughout the history of metallurg ...

used for smelting

Smelting is a process of applying heat and a chemical reducing agent to an ore to extract a desired base metal product. It is a form of extractive metallurgy that is used to obtain many metals such as iron-making, iron, copper extraction, copper ...

to produce industrial metals, generally pig iron

Pig iron, also known as crude iron, is an intermediate good used by the iron industry in the production of steel. It is developed by smelting iron ore in a blast furnace. Pig iron has a high carbon content, typically 3.8–4.7%, along with si ...

, but also others such as lead

Lead () is a chemical element; it has Chemical symbol, symbol Pb (from Latin ) and atomic number 82. It is a Heavy metal (elements), heavy metal that is density, denser than most common materials. Lead is Mohs scale, soft and Ductility, malleabl ...

or copper

Copper is a chemical element; it has symbol Cu (from Latin ) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pinkish-orang ...

. ''Blast'' refers to the combustion air being supplied above atmospheric pressure

Atmospheric pressure, also known as air pressure or barometric pressure (after the barometer), is the pressure within the atmosphere of Earth. The standard atmosphere (symbol: atm) is a unit of pressure defined as , which is equivalent to 1,013. ...

.

In a blast furnace, fuel ( coke), ores, and flux (limestone

Limestone is a type of carbonate rock, carbonate sedimentary rock which is the main source of the material Lime (material), lime. It is composed mostly of the minerals calcite and aragonite, which are different Polymorphism (materials science) ...

) are continuously supplied through the top of the furnace, while a hot blast of (sometimes oxygen

Oxygen is a chemical element; it has chemical symbol, symbol O and atomic number 8. It is a member of the chalcogen group (periodic table), group in the periodic table, a highly reactivity (chemistry), reactive nonmetal (chemistry), non ...

enriched) air is blown into the lower section of the furnace through a series of pipes called tuyeres, so that the chemical reactions take place throughout the furnace as the material falls downward. The end products are usually molten metal and slag phases tapped from the bottom, and flue gases exiting from the top. The downward flow of the ore along with the flux in contact with an upflow of hot, carbon monoxide

Carbon monoxide (chemical formula CO) is a poisonous, flammable gas that is colorless, odorless, tasteless, and slightly less dense than air. Carbon monoxide consists of one carbon atom and one oxygen atom connected by a triple bond. It is the si ...

-rich combustion gases is a countercurrent exchange

Countercurrent exchange is a mechanism between two flowing bodies flowing in opposite directions to each other, in which there is a transfer of some property, usually heat or some chemical. The flowing bodies can be liquids, gases, or even solid ...

and chemical reaction process.

In contrast, air furnaces (such as reverberatory furnaces) are naturally aspirated, usually by the convection

Convection is single or Multiphase flow, multiphase fluid flow that occurs Spontaneous process, spontaneously through the combined effects of material property heterogeneity and body forces on a fluid, most commonly density and gravity (see buoy ...

of hot gases in a chimney flue. According to this broad definition, bloomeries for iron, blowing houses for tin, and smelt mills for lead

Lead () is a chemical element; it has Chemical symbol, symbol Pb (from Latin ) and atomic number 82. It is a Heavy metal (elements), heavy metal that is density, denser than most common materials. Lead is Mohs scale, soft and Ductility, malleabl ...

would be classified as blast furnaces. However, the term has usually been limited to those used for smelting iron ore

Iron ores are rocks and minerals from which metallic iron can be economically extracted. The ores are usually rich in iron oxides and vary in color from dark grey, bright yellow, or deep purple to rusty red. The iron is usually found in the f ...

to produce pig iron

Pig iron, also known as crude iron, is an intermediate good used by the iron industry in the production of steel. It is developed by smelting iron ore in a blast furnace. Pig iron has a high carbon content, typically 3.8–4.7%, along with si ...

, an intermediate material used in the production of commercial iron and steel

Steel is an alloy of iron and carbon that demonstrates improved mechanical properties compared to the pure form of iron. Due to steel's high Young's modulus, elastic modulus, Yield (engineering), yield strength, Fracture, fracture strength a ...

, and the shaft furnaces used in combination with sinter plants in base metals smelting.

Blast furnaces are estimated to have been responsible for over 4% of global greenhouse gas emissions

Greenhouse gas (GHG) emissions from human activities intensify the greenhouse effect. This contributes to climate change. Carbon dioxide (), from burning fossil fuels such as coal, petroleum, oil, and natural gas, is the main cause of climate chan ...

between 1900 and 2015, and are difficult to decarbonize.

Process engineering and chemistry

Blast furnaces operate on the principle of chemical reduction whereby carbon monoxide converts iron oxides to elemental iron.

Blast furnaces differ from bloomeries and reverberatory furnaces in that in a blast furnace, flue gas is in direct contact with the ore and iron, allowing carbon monoxide to diffuse into the ore and reduce the iron oxide. The blast furnace operates as a

Blast furnaces operate on the principle of chemical reduction whereby carbon monoxide converts iron oxides to elemental iron.

Blast furnaces differ from bloomeries and reverberatory furnaces in that in a blast furnace, flue gas is in direct contact with the ore and iron, allowing carbon monoxide to diffuse into the ore and reduce the iron oxide. The blast furnace operates as a countercurrent exchange

Countercurrent exchange is a mechanism between two flowing bodies flowing in opposite directions to each other, in which there is a transfer of some property, usually heat or some chemical. The flowing bodies can be liquids, gases, or even solid ...

process whereas a bloomery does not. Another difference is that bloomeries operate as a batch process whereas blast furnaces operate continuously for long periods. Continuous operation is also preferred because blast furnaces are difficult to start and stop. Also, the carbon in pig iron lowers the melting point below that of steel or pure iron; in contrast, iron does not melt in a bloomery.

Silica

Silicon dioxide, also known as silica, is an oxide of silicon with the chemical formula , commonly found in nature as quartz. In many parts of the world, silica is the major constituent of sand. Silica is one of the most complex and abundant f ...

has to be removed from the pig iron. It reacts with calcium oxide (burned limestone) and forms silicates, which float to the surface of the molten pig iron as slag. Historically, iron was produced with charcoal to prevent sulfur contamination.

In a blast furnace, a downward-moving column of ore, flux, coke (or charcoal) and their reaction products must be sufficiently porous for the flue gas to pass through, upwards. To ensure this permeability the particle size of the coke or charcoal is of great relevance. Therefore, the coke must be strong enough so it will not be crushed by the weight of the material above it. Besides the physical strength of its particles, the coke must also be low in sulfur, phosphorus

Phosphorus is a chemical element; it has Chemical symbol, symbol P and atomic number 15. All elemental forms of phosphorus are highly Reactivity (chemistry), reactive and are therefore never found in nature. They can nevertheless be prepared ar ...

, and ash.

The main chemical reaction producing the molten iron is:

:Fe2O3 + 3CO → 2Fe + 3CO2

This reaction might be divided into multiple steps, with the first being that preheated air blown into the furnace reacts with the carbon in the form of coke to produce carbon monoxide

Carbon monoxide (chemical formula CO) is a poisonous, flammable gas that is colorless, odorless, tasteless, and slightly less dense than air. Carbon monoxide consists of one carbon atom and one oxygen atom connected by a triple bond. It is the si ...

and heat:

:2 C(s) + O2(g) → 2 CO(g)

Hot carbon monoxide is the reducing agent

In chemistry, a reducing agent (also known as a reductant, reducer, or electron donor) is a chemical species that "donates" an electron to an (called the , , , or ).

Examples of substances that are common reducing agents include hydrogen, carbon ...

for the iron ore and reacts with the iron oxide

An iron oxide is a chemical compound composed of iron and oxygen. Several iron oxides are recognized. Often they are non-stoichiometric. Ferric oxyhydroxides are a related class of compounds, perhaps the best known of which is rust.

Iron ...

to produce molten iron and carbon dioxide

Carbon dioxide is a chemical compound with the chemical formula . It is made up of molecules that each have one carbon atom covalent bond, covalently double bonded to two oxygen atoms. It is found in a gas state at room temperature and at norma ...

. Depending on the temperature in the different parts of the furnace (warmest at the bottom) the iron is reduced in several steps. At the top, where the temperature usually is in the range between 200 °C and 700 °C, the iron oxide is partially reduced to iron(II,III) oxide, Fe3O4.

:3 Fe2O3(s) + CO(g) → 2 Fe3O4(s) + CO2(g)

The temperatures 850 °C, further down in the furnace, the iron(II,III) is reduced further to iron(II) oxide:

:Fe3O4(s) + CO(g) → 3 FeO(s) + CO2(g)

Hot carbon dioxide, unreacted carbon monoxide, and nitrogen

Nitrogen is a chemical element; it has Symbol (chemistry), symbol N and atomic number 7. Nitrogen is a Nonmetal (chemistry), nonmetal and the lightest member of pnictogen, group 15 of the periodic table, often called the Pnictogen, pnictogens. ...

from the air pass up through the furnace as fresh feed material travels down into the reaction zone. As the material travels downward, the counter-current gases both preheat the feed charge and decompose the limestone to calcium oxide and carbon dioxide:

:CaCO3(s) → CaO(s) + CO2(g)

The calcium oxide formed by decomposition reacts with various acidic impurities in the iron (notably silica

Silicon dioxide, also known as silica, is an oxide of silicon with the chemical formula , commonly found in nature as quartz. In many parts of the world, silica is the major constituent of sand. Silica is one of the most complex and abundant f ...

), to form a fayalitic slag which is essentially calcium silicate, :

:SiO2 + CaO → CaSiO3

As the iron(II) oxide moves down to the area with higher temperatures, ranging up to 1200 °C degrees, it is reduced further to iron metal:

:FeO(s) + CO(g) → Fe(s) + CO2(g)

The carbon dioxide formed in this process is re-reduced to carbon monoxide by the coke:

:C(s) + CO2(g) → 2 CO(g)

The temperature-dependent equilibrium controlling the gas atmosphere in the furnace is called the Boudouard reaction:

::2CO CO2 + C

The pig iron

Pig iron, also known as crude iron, is an intermediate good used by the iron industry in the production of steel. It is developed by smelting iron ore in a blast furnace. Pig iron has a high carbon content, typically 3.8–4.7%, along with si ...

produced by the blast furnace has a relatively high carbon content of around 4–5% and usually contains too much sulphur, making it very brittle, and of limited immediate commercial use. Some pig iron is used to make cast iron

Cast iron is a class of iron–carbon alloys with a carbon content of more than 2% and silicon content around 1–3%. Its usefulness derives from its relatively low melting temperature. The alloying elements determine the form in which its car ...

. The majority of pig iron produced by blast furnaces undergoes further processing to reduce the carbon and sulphur content and produce various grades of steel used for construction materials, automobiles, ships and machinery. Desulphurisation usually takes place during the transport of the liquid steel to the steelworks. This is done by adding ''calcium oxide'', which reacts with the iron sulfide contained in the pig iron to form calcium sulfide (called ''lime desulfurization''). In a further process step, the so-called basic oxygen steelmaking, the carbon is oxidized by blowing oxygen onto the liquid pig iron to form ''crude steel''.

History

Cast iron has been found in

Cast iron has been found in China

China, officially the People's Republic of China (PRC), is a country in East Asia. With population of China, a population exceeding 1.4 billion, it is the list of countries by population (United Nations), second-most populous country after ...

dating to the 5th century BC, but the earliest extant blast furnaces in China date to the 1st century AD and in the West from the High Middle Ages

The High Middle Ages, or High Medieval Period, was the periodization, period of European history between and ; it was preceded by the Early Middle Ages and followed by the Late Middle Ages, which ended according to historiographical convention ...

. They spread from the region around Namur

Namur (; ; ) is a city and municipality in Wallonia, Belgium. It is the capital both of the province of Namur and of Wallonia, hosting the Parliament of Wallonia, the Government of Wallonia and its administration.

Namur stands at the confl ...

in Wallonia

Wallonia ( ; ; or ), officially the Walloon Region ( ; ), is one of the three communities, regions and language areas of Belgium, regions of Belgium—along with Flemish Region, Flanders and Brussels. Covering the southern portion of the c ...

(Belgium) in the late 15th century, being introduced to England in 1491. The fuel used in these was invariably charcoal. The successful substitution of coke for charcoal is widely attributed to British inventor Abraham Darby in 1709. The efficiency of the process was further enhanced by the practice of preheating the combustion air ( hot blast), patented by British inventor James Beaumont Neilson in 1828.

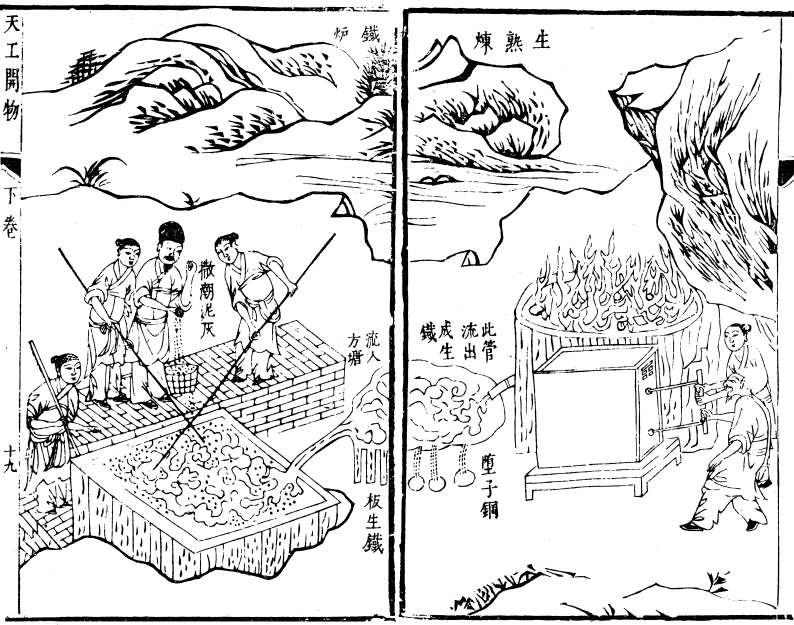

China

Archaeological evidence shows that iron-smelting techniques and bloomeries were brought to China by nomadic peoples around 800 BC. Wrought iron artifacts were originally only found in the northwest, but by the 6th century BC, luxury items such as wrought iron swords and knives were widespread in China. Bloomery iron co-existed with blast furnaces and cast iron, which were invented shortly after wrought iron technology entered China, for quite some time. Cast iron pieces have been found alongside wrought iron in Shanxi Province dating to the 9th-8th centuries BC, however it is uncertain if these cast iron pieces were accidental byproducts of the iron smelting process. Adzes made using cast iron with a decarburised layer of steel have been found inLuoyang

Luoyang ( zh, s=洛阳, t=洛陽, p=Luòyáng) is a city located in the confluence area of the Luo River and the Yellow River in the west of Henan province, China. Governed as a prefecture-level city, it borders the provincial capital of Zheng ...

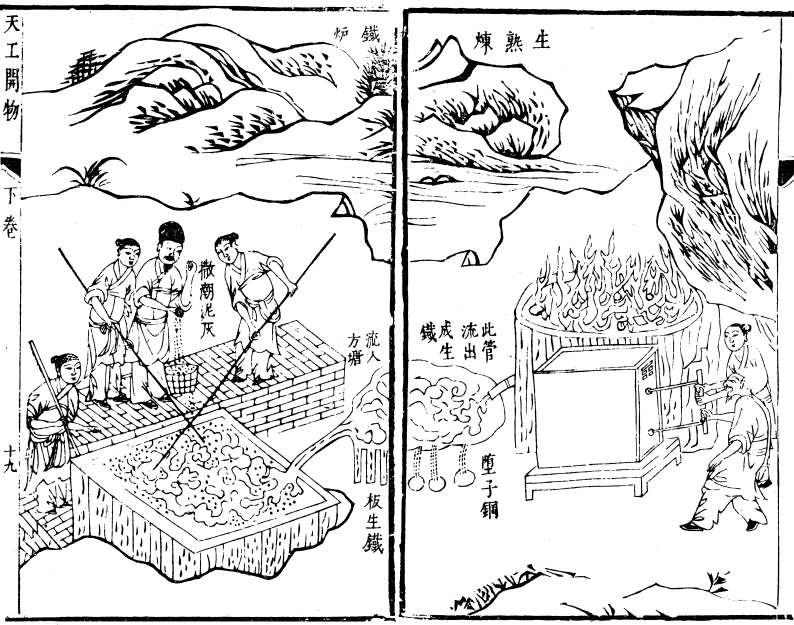

dating to the 5th century BC. Cast iron farming tools that had undergone an annealing process to decrease brittleness were found in burials and smelting cites dating to the 4th century BC. Bloomery iron disappeared in China after the 3rd century AD with the exception of Xinjiang, where bloomery iron objects could be found as late as the 9th century AD. In China, blast furnaces produced cast iron, which was then either converted into finished implements in a cupola furnace, or turned into wrought iron in a fining hearth.

Although cast iron

Cast iron is a class of iron–carbon alloys with a carbon content of more than 2% and silicon content around 1–3%. Its usefulness derives from its relatively low melting temperature. The alloying elements determine the form in which its car ...

farm tools and weapons were widespread in China by the 5th century BC, employing workforces of over 200 men in iron smelters from the 3rd century onward, the earliest blast furnaces constructed were attributed to the Han dynasty

The Han dynasty was an Dynasties of China, imperial dynasty of China (202 BC9 AD, 25–220 AD) established by Liu Bang and ruled by the House of Liu. The dynasty was preceded by the short-lived Qin dynasty (221–206 BC ...

in the 1st century AD.Ebrey, p. 30. These early furnaces had clay walls and used phosphorus

Phosphorus is a chemical element; it has Chemical symbol, symbol P and atomic number 15. All elemental forms of phosphorus are highly Reactivity (chemistry), reactive and are therefore never found in nature. They can nevertheless be prepared ar ...

-containing minerals as a flux. Chinese blast furnaces ranged from around two to ten meters in height, depending on the region. The largest ones were found in modern Sichuan

Sichuan is a province in Southwestern China, occupying the Sichuan Basin and Tibetan Plateau—between the Jinsha River to the west, the Daba Mountains to the north, and the Yunnan–Guizhou Plateau to the south. Its capital city is Cheng ...

and Guangdong

) means "wide" or "vast", and has been associated with the region since the creation of Guang Prefecture in AD 226. The name "''Guang''" ultimately came from Guangxin ( zh, labels=no, first=t, t= , s=广信), an outpost established in Han dynasty ...

, while the 'dwarf" blast furnaces were found in Dabieshan. In construction, they are both around the same level of technological sophistication.

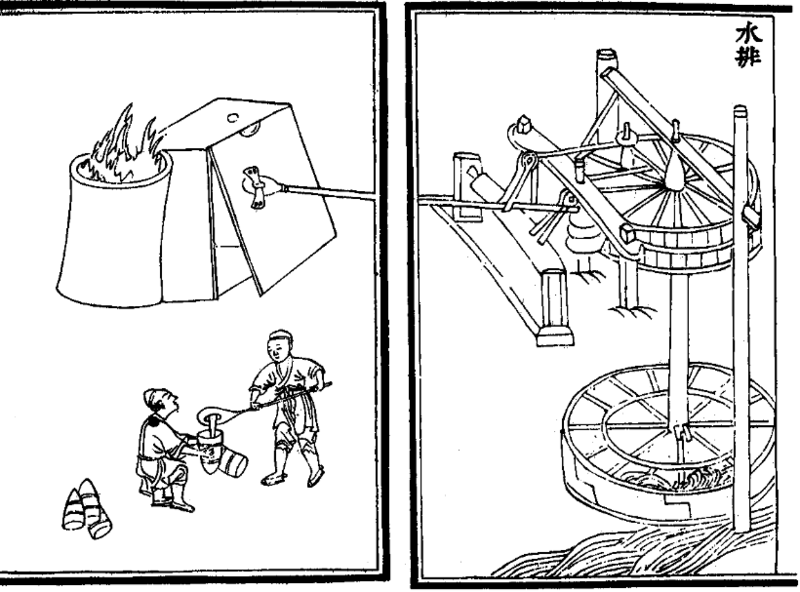

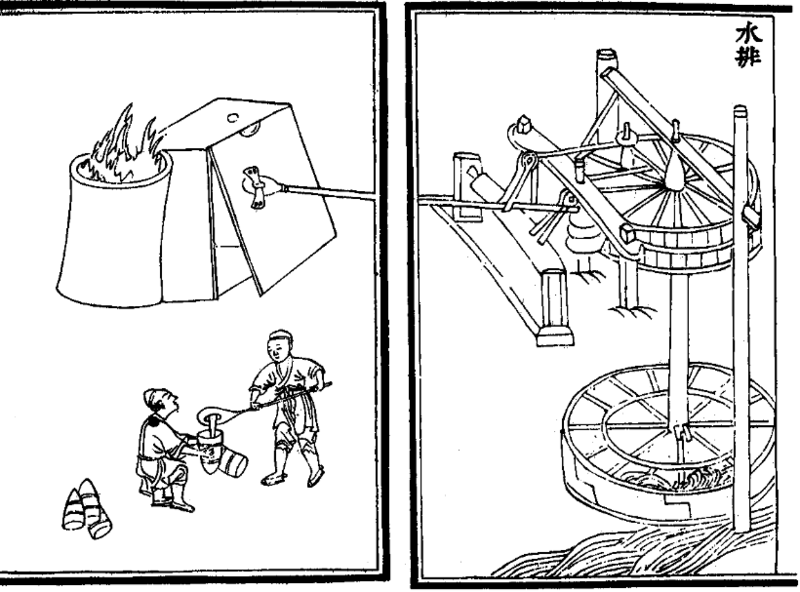

The effectiveness of the Chinese human and horse powered blast furnaces was enhanced during this period by the engineer Du Shi

Du Shi (, d. 38'' Book of Later Han'', vol. 31Crespigny, 183.) was a Chinese hydrologist, inventor, mechanical engineer, metallurgist, and politician of the Eastern Han dynasty. Du Shi is credited with being the first to apply hydraulic power ...

(c. AD 31), who applied the power of waterwheels to piston- bellows in forging cast iron. Early water-driven reciprocators for operating blast furnaces were built according to the structure of horse powered reciprocators that already existed. That is, the circular motion of the wheel, be it horse driven or water driven, was transferred by the combination of a belt drive, a crank-and-connecting-rod, other connecting rods, and various shafts, into the reciprocal motion necessary to operate push bellows.. Donald Wagner suggests that early blast furnace and cast iron production evolved from furnaces used to melt bronze

Bronze is an alloy consisting primarily of copper, commonly with about 12–12.5% tin and often with the addition of other metals (including aluminium, manganese, nickel, or zinc) and sometimes non-metals (such as phosphorus) or metalloid ...

. Certainly, though, iron was essential to military success by the time the State of Qin had unified China (221 BC). Usage of the blast and cupola furnace remained widespread during the Song

A song is a musical composition performed by the human voice. The voice often carries the melody (a series of distinct and fixed pitches) using patterns of sound and silence. Songs have a structure, such as the common ABA form, and are usu ...

and Tang dynasties. By the 11th century, the Song dynasty

The Song dynasty ( ) was an Dynasties of China, imperial dynasty of China that ruled from 960 to 1279. The dynasty was founded by Emperor Taizu of Song, who usurped the throne of the Later Zhou dynasty and went on to conquer the rest of the Fiv ...

Chinese iron industry made a switch of resources from charcoal to coke in casting iron and steel, sparing thousands of acres of woodland from felling. This may have happened as early as the 4th century AD.

The primary advantage of the early blast furnace was in large scale production and making iron implements more readily available to peasants. Cast iron is more brittle than wrought iron or steel, which required additional fining and then cementation or co-fusion to produce, but for menial activities such as farming it sufficed. By using the blast furnace, it was possible to produce larger quantities of tools such as ploughshares more efficiently than the bloomery. In areas where quality was important, such as warfare, wrought iron and steel were preferred. Nearly all Han period weapons are made of wrought iron or steel, with the exception of axe-heads, of which many are made of cast iron.

Blast furnaces were also later used to produce gunpowder

Gunpowder, also commonly known as black powder to distinguish it from modern smokeless powder, is the earliest known chemical explosive. It consists of a mixture of sulfur, charcoal (which is mostly carbon), and potassium nitrate, potassium ni ...

weapons such as cast iron bomb shells and cast iron cannon

A cannon is a large-caliber gun classified as a type of artillery, which usually launches a projectile using explosive chemical propellant. Gunpowder ("black powder") was the primary propellant before the invention of smokeless powder during th ...

s during the Song dynasty

The Song dynasty ( ) was an Dynasties of China, imperial dynasty of China that ruled from 960 to 1279. The dynasty was founded by Emperor Taizu of Song, who usurped the throne of the Later Zhou dynasty and went on to conquer the rest of the Fiv ...

.

Medieval Europe

The simplest forge, known as the Corsican, was used prior to the advent ofChristianity

Christianity is an Abrahamic monotheistic religion, which states that Jesus in Christianity, Jesus is the Son of God (Christianity), Son of God and Resurrection of Jesus, rose from the dead after his Crucifixion of Jesus, crucifixion, whose ...

. Examples of improved bloomeries are the Stuckofen, sometimes called wolf-furnace, which remained until the beginning of the 19th century. Instead of using natural draught, air was pumped in by a '' trompe'', resulting in better quality iron and an increased capacity. This pumping of air in with bellows is known as ''cold blast'', and it increases the fuel efficiency

Fuel efficiency (or fuel economy) is a form of thermal efficiency, meaning the ratio of effort to result of a process that converts chemical energy, chemical potential energy contained in a carrier (fuel) into kinetic energy or Mechanical work, w ...

of the bloomery and improves yield. They can also be built bigger than natural draught bloomeries.

Oldest European blast furnaces

The oldest known blast furnaces in the West were built in Durstel inSwitzerland

Switzerland, officially the Swiss Confederation, is a landlocked country located in west-central Europe. It is bordered by Italy to the south, France to the west, Germany to the north, and Austria and Liechtenstein to the east. Switzerland ...

, the Märkische Sauerland in Germany

Germany, officially the Federal Republic of Germany, is a country in Central Europe. It lies between the Baltic Sea and the North Sea to the north and the Alps to the south. Its sixteen States of Germany, constituent states have a total popu ...

, and at Lapphyttan in Sweden

Sweden, formally the Kingdom of Sweden, is a Nordic countries, Nordic country located on the Scandinavian Peninsula in Northern Europe. It borders Norway to the west and north, and Finland to the east. At , Sweden is the largest Nordic count ...

, where the complex was active between 1205 and 1300. At Noraskog in the Swedish parish of Järnboås, traces of even earlier blast furnaces have been found, possibly from around 1100. These early blast furnaces, like the Chinese examples, were very inefficient compared to those used today. The iron from the Lapphyttan complex was used to produce balls of wrought iron known as osmonds, and these were traded internationally – a possible reference occurs in a treaty with Novgorod

Veliky Novgorod ( ; , ; ), also known simply as Novgorod (), is the largest city and administrative centre of Novgorod Oblast, Russia. It is one of the oldest cities in Russia, being first mentioned in the 9th century. The city lies along the V ...

from 1203 and several certain references in accounts of English customs from the 1250s and 1320s. Other furnaces of the 13th to 15th centuries have been identified in Westphalia.

The technology required for blast furnaces may have either been transferred from China, or may have been an indigenous innovation. Al-Qazvini in the 13th century and other travellers subsequently noted an iron industry in the Alburz Mountains to the south of the Caspian Sea

The Caspian Sea is the world's largest inland body of water, described as the List of lakes by area, world's largest lake and usually referred to as a full-fledged sea. An endorheic basin, it lies between Europe and Asia: east of the Caucasus, ...

. This is close to the silk route, so that the use of technology derived from China is conceivable. Much later descriptions record blast furnaces about three metres high. As the Varangian Rus' people

The Rus, also known as Russes, were a people in early medieval Eastern Europe. The scholarly consensus holds that they were originally Norsemen, mainly originating from present-day Sweden, who settled and ruled along the river-routes between t ...

from Scandinavia

Scandinavia is a subregion#Europe, subregion of northern Europe, with strong historical, cultural, and linguistic ties between its constituent peoples. ''Scandinavia'' most commonly refers to Denmark, Norway, and Sweden. It can sometimes also ...

traded with the Caspian (using their Volga trade route), it is possible that the technology reached Sweden by this means. The Vikings are known to have used double bellows, which greatly increases the volumetric flow of the blast.

The Caspian region may also have been the source for the design of the furnace at Ferriere, described by Filarete, involving a water-powered bellows at Semogo in Valdidentro in northern Italy in 1226. In a two-stage process the molten iron was tapped twice a day into water, thereby granulating it.

Cistercian contributions

The General Chapter of theCistercian

The Cistercians (), officially the Order of Cistercians (, abbreviated as OCist or SOCist), are a Catholic religious order of monks and nuns that branched off from the Benedictines and follow the Rule of Saint Benedict, as well as the contri ...

monks spread some technological advances across Europe. This may have included the blast furnace, as the Cistercians are known to have been skilled metallurgists.Woods, p. 34. According to Jean Gimpel, their high level of industrial technology facilitated the diffusion of new techniques: "Every monastery had a model factory, often as large as the church and only several feet away, and waterpower drove the machinery of the various industries located on its floor." Iron ore deposits were often donated to the monks along with forges to extract the iron, and after a time surpluses were offered for sale. The Cistercians became the leading iron producers in Champagne

Champagne (; ) is a sparkling wine originated and produced in the Champagne wine region of France under the rules of the appellation, which demand specific vineyard practices, sourcing of grapes exclusively from designated places within it, spe ...

, France, from the mid-13th century to the 17th century,Gimpel, p. 67. also using the phosphate

Phosphates are the naturally occurring form of the element phosphorus.

In chemistry, a phosphate is an anion, salt, functional group or ester derived from a phosphoric acid. It most commonly means orthophosphate, a derivative of orthop ...

-rich slag from their furnaces as an agricultural fertilizer.

Archaeologists are still discovering the extent of Cistercian technology.Woods, p. 36. At Laskill, an outstation of Rievaulx Abbey and the only medieval blast furnace so far identified in Britain, the slag produced was low in iron content.Woods, p. 37. Slag from other furnaces of the time contained a substantial concentration of iron, whereas Laskill is believed to have produced cast iron quite efficiently.David Derbyshire'Henry "Stamped Out Industrial Revolution"'

, ''

The Daily Telegraph

''The Daily Telegraph'', known online and elsewhere as ''The Telegraph'', is a British daily broadsheet conservative newspaper published in London by Telegraph Media Group and distributed in the United Kingdom and internationally. It was found ...

'' (21 June 2002); cited by Woods. Its date is not yet clear, but it probably did not survive until Henry VIII's Dissolution of the Monasteries in the late 1530s, as an agreement (immediately after that) concerning the "smythes" with the Earl of Rutland in 1541 refers to blooms. Nevertheless, the means by which the blast furnace spread in medieval Europe has not finally been determined.

Origin and spread of early modern blast furnaces

Namur

Namur (; ; ) is a city and municipality in Wallonia, Belgium. It is the capital both of the province of Namur and of Wallonia, hosting the Parliament of Wallonia, the Government of Wallonia and its administration.

Namur stands at the confl ...

region, in what is now Wallonia

Wallonia ( ; ; or ), officially the Walloon Region ( ; ), is one of the three communities, regions and language areas of Belgium, regions of Belgium—along with Flemish Region, Flanders and Brussels. Covering the southern portion of the c ...

(Belgium). From there, they spread first to the Pays de Bray on the eastern boundary of Normandy

Normandy (; or ) is a geographical and cultural region in northwestern Europe, roughly coextensive with the historical Duchy of Normandy.

Normandy comprises Normandy (administrative region), mainland Normandy (a part of France) and insular N ...

and from there to the Weald of Sussex

Sussex (Help:IPA/English, /ˈsʌsɪks/; from the Old English ''Sūþseaxe''; lit. 'South Saxons'; 'Sussex') is an area within South East England that was historically a kingdom of Sussex, kingdom and, later, a Historic counties of England, ...

, where the first furnace (called Queenstock) in Buxted was built in about 1491, followed by one at Newbridge in Ashdown Forest in 1496. They remained few in number until about 1530 but many were built in the following decades in the Weald, where the iron industry perhaps reached its peak about 1590. Most of the pig iron from these furnaces was taken to finery forges for the production of bar iron.

The first British furnaces outside the Weald appeared during the 1550s, and many were built in the remainder of that century and the following ones. The output of the industry probably peaked about 1620, and was followed by a slow decline until the early 18th century. This was apparently because it was more economic to import iron from Sweden

Sweden, formally the Kingdom of Sweden, is a Nordic countries, Nordic country located on the Scandinavian Peninsula in Northern Europe. It borders Norway to the west and north, and Finland to the east. At , Sweden is the largest Nordic count ...

and elsewhere than to make it in some more remote British locations. Charcoal that was economically available to the industry was probably being consumed as fast as the wood to make it grew.

The first blast furnace in Russia

Russia, or the Russian Federation, is a country spanning Eastern Europe and North Asia. It is the list of countries and dependencies by area, largest country in the world, and extends across Time in Russia, eleven time zones, sharing Borders ...

opened in 1637 near Tula and was called the Gorodishche Works. The blast furnace spread from there to central Russia and then finally to the Urals.

Coke blast furnaces

In 1709, at Coalbrookdale in Shropshire, England, Abraham Darby began to fuel a blast furnace with coke instead of charcoal. Coke's initial advantage was its lower cost, mainly because making coke required much less labor than cutting trees and making charcoal, but using coke also overcame localized shortages of wood, especially in Britain and elsewhere in Europe. Metallurgical grade coke will bear heavier weight than charcoal, allowing larger furnaces. A disadvantage is that coke contains more impurities than charcoal, with sulfur being especially detrimental to the iron's quality. Coke's impurities were more of a problem before hot blast reduced the amount of coke required and before furnace temperatures were hot enough to make slag from limestone free flowing. (Limestone ties up sulphur. Manganese may also be added to tie up sulphur.) Coke iron was initially only used for foundry work, making pots and other cast iron goods. Foundry work was a minor branch of the industry, but Darby's son built a new furnace at nearby Horsehay, and began to supply the owners of finery forges with coke pig iron for the production of bar iron. Coke pig iron was by this time cheaper to produce than charcoal pig iron. The use of a coal-derived fuel in the iron industry was a key factor in the BritishIndustrial Revolution

The Industrial Revolution, sometimes divided into the First Industrial Revolution and Second Industrial Revolution, was a transitional period of the global economy toward more widespread, efficient and stable manufacturing processes, succee ...

. However, in many areas of the world charcoal was cheaper while coke was more expensive even after the Industrial Revolution: e. g., in the US charcoal-fueled iron production fell in share to about a half but still continued to increase in absolute terms until , while in João Monlevade in the Brazilian Highlands charcoal-fired blast furnaces were built as late as the 1930s and only phased out in 2000.

Darby's original blast furnace has been archaeologically excavated and can be seen in situ at Coalbrookdale, part of the Ironbridge Gorge Museums. Cast iron from the furnace was used to make girders for the world's first cast iron bridge in 1779. The Iron Bridge crosses the River Severn

The River Severn (, ), at long, is the longest river in Great Britain. It is also the river with the most voluminous flow of water by far in all of England and Wales, with an average flow rate of at Apperley, Gloucestershire. It rises in t ...

at Coalbrookdale and remains in use for pedestrians.

Steam-powered blast

The steam engine was applied to power blast air, overcoming a shortage of water power in areas where coal and iron ore were located. This was first done at Coalbrookdale where asteam engine

A steam engine is a heat engine that performs Work (physics), mechanical work using steam as its working fluid. The steam engine uses the force produced by steam pressure to push a piston back and forth inside a Cylinder (locomotive), cyl ...

replaced a horse-powered pump in 1742. Such engines were used to pump water to a reservoir above the furnace. The first engines used to blow cylinders directly was supplied by Boulton and Watt to John Wilkinson's New Willey Furnace. This powered a cast iron blowing cylinder, which had been invented by his father Isaac Wilkinson. He patented such cylinders in 1736, to replace the leather bellows, which wore out quickly. Isaac was granted a second patent, also for blowing cylinders, in 1757. The steam engine and cast iron blowing cylinder led to a large increase in British iron production in the late 18th century.

Hot blast

Hot blast was the single most important advance in fuel efficiency of the blast furnace and was one of the most important technologies developed during theIndustrial Revolution

The Industrial Revolution, sometimes divided into the First Industrial Revolution and Second Industrial Revolution, was a transitional period of the global economy toward more widespread, efficient and stable manufacturing processes, succee ...

. Hot blast was patented by James Beaumont Neilson at Wilsontown Ironworks in Britain in 1828. Within a few years of the introduction, hot blast was developed to the point where fuel consumption was cut by one-third using coke or two-thirds using coal, while furnace capacity was also significantly increased. Within a few decades, the practice was to have a "stove" as large as the furnace next to it into which the waste gas (containing CO) from the furnace was directed and burnt. The resultant heat was used to preheat the air blown into the furnace.Birch, pp. 181–189.

Hot blast enabled the use of raw anthracite coal, which was difficult to light, in the blast furnace. Anthracite was first tried successfully by George Crane at Ynyscedwyn Ironworks in south Wales in 1837. It was taken up in America by the Lehigh Crane Iron Company at Catasauqua, Pennsylvania, in 1839. Anthracite use declined when very high capacity blast furnaces requiring coke were built in the 1870s.

Modern applications of the blast furnace

Iron blast furnaces

The blast furnace remains an important part of modern iron production. Modern furnaces are highly efficient, including Cowper stoves to pre-heat the blast air and employ recovery systems to extract the heat from the hot gases exiting the furnace. Competition in industry drives higher production rates. The largest blast furnace in the world is in South Korea, with a volume around . It can produce around of iron per year. This is a great increase from the typical 18th-century furnaces, which averaged about per year. Variations of the blast furnace, such as the Swedish electric blast furnace, have been developed in countries which have no native coal resources. According to '' Global Energy Monitor'', the blast furnace is likely to become obsolete to meetclimate change

Present-day climate change includes both global warming—the ongoing increase in Global surface temperature, global average temperature—and its wider effects on Earth's climate system. Climate variability and change, Climate change in ...

objectives of reducing carbon dioxide emission, but BHP disagrees. An alternative process involving direct reduced iron (DRI) is likely to succeed it, but this also needs to use a blast furnace to melt the iron and remove the gangue (impurities) unless the ore is very high quality.

Oxygen blast furnace

The oxygen blast furnace (OBF) process, developed from the 1970s to the 1990s, has been extensively studied theoretically because of the potentials of promising energy conservation and emission reduction. This type may be the most suitable for use with CCS. The main blast furnace has of three levels; the reduction zone (), slag formation zone (), and the combustion zone (). OBFs are usually combined with top gas recycling. The problem with this, besides significant oxygen expenditures, is the uneven distribution of gas recycled from the top of the furnace to the middle, which collides with the hot gas from below. As of 2023, the technology is only practiced on the experimental level in Sweden, Japan and China.Blast furnaces in copper and lead smelting

Blast furnaces are currently rarely used in copper smelting, but modern lead smelting blast furnaces are much shorter than iron blast furnaces and are rectangular in shape.R J Sinclair, ''The Extractive Metallurgy of Lead'' (The Australasian Institute of Mining and Metallurgy: Melbourne, 2009), 77. Modern lead blast furnaces are constructed using water-cooled steel or copper jackets for the walls, and have no refractory linings in the side walls.R J Sinclair, ''The Extractive Metallurgy of Lead'' (The Australasian Institute of Mining and Metallurgy: Melbourne, 2009), 75. The base of the furnace is a hearth of refractory material (bricks or castable refractory). Lead blast furnaces are often open-topped rather than having the charging bell used in iron blast furnaces. The blast furnace used at the NyrstarPort Pirie

Port Pirie is a small city on the east coast of the Spencer Gulf in South Australia, north of the state capital, Adelaide. Port Pirie is the largest city and the main retail centre of the Mid North region of South Australia. The city has an ex ...

lead smelter differs from most other lead blast furnaces in that it has a double row of tuyeres rather than the single row normally used. The lower shaft of the furnace has a chair shape with the lower part of the shaft being narrower than the upper. The lower row of tuyeres being located in the narrow part of the shaft. This allows the upper part of the shaft to be wider than the standard.

Zinc blast furnaces

The blast furnaces used in the Imperial Smelting Process ("ISP") were developed from the standard lead blast furnace, but are fully sealed.R J Sinclair, ''The Extractive Metallurgy of Lead'' (The Australasian Institute of Mining and Metallurgy: Melbourne, 2009), 89. This is because the zinc produced by these furnaces is recovered as metal from the vapor phase, and the presence of oxygen in the off-gas would result in the formation of zinc oxide. Blast furnaces used in the ISP have a more intense operation than standard lead blast furnaces, with higher air blast rates per m2 of hearth area and a higher coke consumption. Zinc production with the ISP is more expensive than with electrolytic zinc plants, so several smelters operating this technology have closed in recent years. However, ISP furnaces have the advantage of being able to treat zinc concentrates containing higher levels of lead than can electrolytic zinc plants.Manufacture of stone wool

Stone wool or

Stone wool or rock wool

Rock most often refers to:

* Rock (geology), a naturally occurring solid aggregate of minerals or mineraloids

* Rock music, a genre of popular music

Rock or Rocks may also refer to:

Places United Kingdom

* Rock, Caerphilly, a location in Wale ...

is a spun mineral fibre used as an insulation product and in hydroponics. It is manufactured in a blast furnace fed with diabase rock which contains very low levels of metal oxides. The resultant slag is drawn off and spun to form the rock wool product. Very small amounts of metals are also produced which are an unwanted by-product

A by-product or byproduct is a secondary product derived from a production process, manufacturing process or chemical reaction; it is not the primary product or service being produced.

A by-product can be useful and marketable or it can be cons ...

.

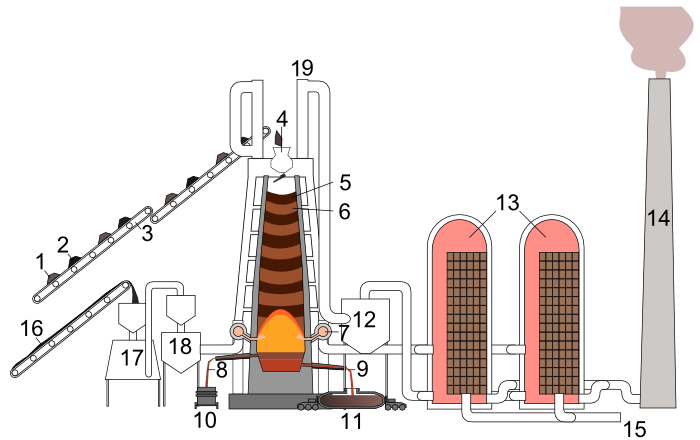

Modern iron process

Modern furnaces are equipped with an array of supporting facilities to increase efficiency, such as ore storage yards where barges are unloaded. The raw materials are transferred to the stockhouse complex by ore bridges, or rail hoppers and ore transfer cars. Rail-mounted scale cars or computer controlled weight hoppers weigh out the various raw materials to yield the desired hot metal and slag chemistry. The raw materials are brought to the top of the blast furnace via a skip car powered by winches or conveyor belts.American Iron and Steel Institute (2005)

Modern furnaces are equipped with an array of supporting facilities to increase efficiency, such as ore storage yards where barges are unloaded. The raw materials are transferred to the stockhouse complex by ore bridges, or rail hoppers and ore transfer cars. Rail-mounted scale cars or computer controlled weight hoppers weigh out the various raw materials to yield the desired hot metal and slag chemistry. The raw materials are brought to the top of the blast furnace via a skip car powered by winches or conveyor belts.American Iron and Steel Institute (2005)How a Blast Furnace Works

steel.org. There are different ways in which the raw materials are charged into the blast furnace. Some blast furnaces use a "double bell" system where two "bells" are used to control the entry of raw material into the blast furnace. The purpose of the two bells is to minimize the loss of hot gases in the blast furnace. First, the raw materials are emptied into the upper or small bell which then opens to empty the charge into the large bell. The small bell then closes, to seal the blast furnace, while the large bell rotates to provide specific distribution of materials before dispensing the charge into the blast furnace. A more recent design is to use a "bell-less" system. These systems use multiple hoppers to contain each raw material, which is then discharged into the blast furnace through valves. These valves are more accurate at controlling how much of each constituent is added, as compared to the skip or conveyor system, thereby increasing the efficiency of the furnace. Some of these bell-less systems also implement a discharge chute in the throat of the furnace (as with the Paul Wurth top) in order to precisely control where the charge is placed. The iron making blast furnace itself is built in the form of a tall structure, lined with

refractory

In materials science, a refractory (or refractory material) is a material that is resistant to decomposition by heat or chemical attack and that retains its strength and rigidity at high temperatures. They are inorganic, non-metallic compound ...

brick, and profiled to allow for expansion of the charged materials as they heat during their descent, and subsequent reduction in size as melting starts to occur. Coke, limestone

Limestone is a type of carbonate rock, carbonate sedimentary rock which is the main source of the material Lime (material), lime. It is composed mostly of the minerals calcite and aragonite, which are different Polymorphism (materials science) ...

flux, and iron ore (iron oxide) are charged into the top of the furnace in a precise filling order which helps control gas flow and the chemical reactions inside the furnace. Four "uptakes" allow the hot, dirty gas high in carbon monoxide content to exit the furnace throat, while "bleeder valves" protect the top of the furnace from sudden gas pressure surges. The coarse particles in the exhaust gas settle in the "dust catcher" and are dumped into a railroad car or truck for disposal, while the gas itself flows through a venturi scrubber and/or electrostatic precipitators and a gas cooler to reduce the temperature of the cleaned gas.

The "casthouse" at the bottom half of the furnace contains the bustle pipe (a large-diameter annular pipe to deliver heated air under pressure to the tuyeres) and the equipment for casting the liquid iron and slag. Once a "taphole" is drilled through the refractory clay plug, liquid iron and slag flow down a trough through a "skimmer" opening, separating the iron and slag. Modern, larger blast furnaces may have as many as four tapholes and two casthouses. Once the pig iron and slag has been tapped, the taphole is again plugged with refractory clay.

The tuyeres are used to implement a hot blast, which is used to increase the efficiency of the blast furnace. The hot blast is directed into the furnace through water-cooled copper nozzles called tuyeres near the base. The hot blast temperature can be from depending on the stove design and condition. The temperatures they deal with may be . Oil, tar, natural gas

Natural gas (also fossil gas, methane gas, and gas) is a naturally occurring compound of gaseous hydrocarbons, primarily methane (95%), small amounts of higher alkanes, and traces of carbon dioxide and nitrogen, hydrogen sulfide and helium ...

, powdered coal

Coal is a combustible black or brownish-black sedimentary rock, formed as rock strata called coal seams. Coal is mostly carbon with variable amounts of other Chemical element, elements, chiefly hydrogen, sulfur, oxygen, and nitrogen.

Coal i ...

and oxygen

Oxygen is a chemical element; it has chemical symbol, symbol O and atomic number 8. It is a member of the chalcogen group (periodic table), group in the periodic table, a highly reactivity (chemistry), reactive nonmetal (chemistry), non ...

can also be injected into the furnace at tuyere level to combine with the coke to release additional energy and increase the percentage of reducing gases present which is necessary to increase productivity.

The exhaust gasses of a blast furnace are generally cleaned in the dust collector

A dust collector is a system used to enhance the quality of air released from industrial and commercial processes by collecting dust particle and other impurities from air or gas. Designed to handle high-volume dust loads, a dust collector syste ...

– such as an inertia

Inertia is the natural tendency of objects in motion to stay in motion and objects at rest to stay at rest, unless a force causes the velocity to change. It is one of the fundamental principles in classical physics, and described by Isaac Newto ...

l separator, a baghouse

A baghouse, also known as a baghouse filter, bag filter, or fabric filter is an air pollution control device and dust collector that removes particulates entrained in gas released from commercial processes. Power plants, steel mills, pharmaceutical ...

, or an electrostatic precipitator. Each type of dust collector has strengths and weaknesses – some collect fine particles, some coarse particles, some collect electrically charged particles. Effective exhaust clearing relies on multiple stages of treatment. Waste heat is usually collected from the exhaust gases, for example by the use of a Cowper stove, a variety of heat exchanger.

Environmental impact

Fossil fuel (coke, natural gas) use in blast furnaces is a source ofgreenhouse gas emissions

Greenhouse gas (GHG) emissions from human activities intensify the greenhouse effect. This contributes to climate change. Carbon dioxide (), from burning fossil fuels such as coal, petroleum, oil, and natural gas, is the main cause of climate chan ...

and the blast furnace is the most emission intensive stage of the steel making process.IEA-GHG, 2000. Greenhouse Gas Emissions from Major Industrial Sources – Iron and Steel Production. Report no. PH3/30. Cheltenham, UK, IEA Greenhouse Gas R&D Programme. https://ieaghg.org/docs/General_Docs/Reports/PH3-30%20iron-steel.pdf Accessed 30 July 2021. Fuels and reductants such as plastic waste, biomass and hydrogen are being used by steelmakers as possible alternatives to fossil fuels, although cost and availability remain a challenge and deployment is limited.

Electric arc furnaces (EAF) are cited as an alternative steel production path which avoids the use of blast furnaces, however, depending on the characteristics of the steel product required the two furnace types are not always interchangeable. Furthermore, EAFs utilize steel scrap as a feedstock but estimates suggest that there will not be enough scrap available to meet future steel demand. Using hydrogen gas as a reductant to produce DRI (so called H2-DRI) from iron ore, which is then used as a feedstock for an EAF provides a technologically feasible, low emission alternative to blast furnaces. The H2-DRI EAF production route is in a fledgling state, with just one plant in operation.

A 2000 report from the International Energy Agency

The International Energy Agency (IEA) is a Paris-based autonomous intergovernmental organization, established in 1974, that provides policy recommendations, analysis and data on the global energy sector. The 31 member countries and 13 associatio ...

Greenhouse Gas Technical Collaboration Programme (IEAGHG) shows that 70% of the emissions from integrated steel plants arise directly from the blast furnace gas (BFG). By treating BFG with carbon capture technology prior to use for heat exchange and energy recovery within the plant, a portion of these emissions can be abated. The report estimates that chemical absorption would cost $35/t of , plus $8–20/t for transportation and storage. At the time, this would have increased steel production costs by 15–20%, presenting a barrier to decarbonisation for steelmakers which typically operate with margins of 8–10%. As of 2024 no blast furnaces have been equipped with carbon capture technology.

ULCOS (Ultra Low CO2 Steelmaking) was a European programme exploring processes to reduce blast furnace emissions by at least 50%. Technologies identified include carbon capture and storage (CCS) and alternative energy sources and reductants such as hydrogen, electricity and biomass.ICIT-Revue de Métallurgie, September and October issues, 2009

Preserved historic blast furnaces

Historically it was normal procedure for a decommissioned blast furnace to be demolished and either replaced with a newer, improved one, or to have the entire site demolished and treated for follow-up use of the area. In recent decades, several countries have realized the historic value of blast furnaces and have transformed them into museums. Examples can be found in theCzech Republic

The Czech Republic, also known as Czechia, and historically known as Bohemia, is a landlocked country in Central Europe. The country is bordered by Austria to the south, Germany to the west, Poland to the northeast, and Slovakia to the south ...

, France, Germany, Japan, Luxembourg

Luxembourg, officially the Grand Duchy of Luxembourg, is a landlocked country in Western Europe. It is bordered by Belgium to the west and north, Germany to the east, and France on the south. Its capital and most populous city, Luxembour ...

, Poland

Poland, officially the Republic of Poland, is a country in Central Europe. It extends from the Baltic Sea in the north to the Sudetes and Carpathian Mountains in the south, bordered by Lithuania and Russia to the northeast, Belarus and Ukrai ...

, Romania

Romania is a country located at the crossroads of Central Europe, Central, Eastern Europe, Eastern and Southeast Europe. It borders Ukraine to the north and east, Hungary to the west, Serbia to the southwest, Bulgaria to the south, Moldova to ...

, Mexico

Mexico, officially the United Mexican States, is a country in North America. It is the northernmost country in Latin America, and borders the United States to the north, and Guatemala and Belize to the southeast; while having maritime boundar ...

, Russia

Russia, or the Russian Federation, is a country spanning Eastern Europe and North Asia. It is the list of countries and dependencies by area, largest country in the world, and extends across Time in Russia, eleven time zones, sharing Borders ...

, Spain, United Kingdom

The United Kingdom of Great Britain and Northern Ireland, commonly known as the United Kingdom (UK) or Britain, is a country in Northwestern Europe, off the coast of European mainland, the continental mainland. It comprises England, Scotlan ...

, and United States

The United States of America (USA), also known as the United States (U.S.) or America, is a country primarily located in North America. It is a federal republic of 50 U.S. state, states and a federal capital district, Washington, D.C. The 48 ...

.

Gallery

See also

* Basic oxygen furnace * Blast furnace zinc smelting process * Crucible steel * Extraction of iron * Water gas, produced by a "steam blast" * FINEX * Krupp-Renn Process * Flodin process * Steelmaking * Ironworks and steelworks in England, which covers ironworks of all kinds. * Shaft furnace breather * Direct reduction * Direct reduction (blast furnace) * Coking factory * Water jacket furnaceReferences

Bibliography

* * * * * * * * *External links

American Iron and Steel Institute

{{DEFAULTSORT:Blast Furnace Chinese inventions Firing techniques Industrial buildings and structures Industrial furnaces Industrial Revolution Metallurgy Smelting Steelmaking