|

Tuyere

A tuyere or tuyère (; ) is a tube, nozzle or pipe allowing the blowing of air into a furnace or hearth.W. K. V. Gale, The iron and Steel industry: a dictionary of terms (David and Charles, Newton Abbot 1972), 216–217. Air or oxygen is injected into a hearth under pressure from bellows or a blowing engine or other devices. This causes the fire to become hotter in front of the blast than it would otherwise have been, enabling metals to be smelted or melted or made hot enough to be worked in a forge, though these are blown only with air. This applies to any process where a blast is delivered under pressure to make a fire hotter. Archeologists have discovered tuyeres dating from the Iron Age; one example dates from between 770 BCE and 515 BCE. Following the introduction of hot blast, tuyeres are often water-cooled. Around the year 1500 new ironmaking techniques, including the blast furnace and finery forge, were introduced into England from France, along with the French ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Blast Furnace

A blast furnace is a type of metallurgical furnace used for smelting to produce industrial metals, generally pig iron, but also others such as lead or copper. ''Blast'' refers to the combustion air being supplied above atmospheric pressure. In a blast furnace, fuel ( coke), ores, and flux (limestone) are continuously supplied through the top of the furnace, while a hot blast of (sometimes oxygen enriched) air is blown into the lower section of the furnace through a series of pipes called tuyeres, so that the chemical reactions take place throughout the furnace as the material falls downward. The end products are usually molten metal and slag phases tapped from the bottom, and flue gases exiting from the top. The downward flow of the ore along with the flux in contact with an upflow of hot, carbon monoxide-rich combustion gases is a countercurrent exchange and chemical reaction process. In contrast, air furnaces (such as reverberatory furnaces) are naturally aspirated, usu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Forge

A forge is a type of hearth used for heating metals, or the workplace (smithy) where such a hearth is located. The forge is used by the smith to heat a piece of metal to a temperature at which it becomes easier to shape by forging, or to the point at which work hardening no longer occurs. The metal (known as the "workpiece") is transported to and from the forge using tongs, which are also used to hold the workpiece on the smithy's anvil while the smith works it with a hammer. Sometimes, such as when hardening steel or cooling the work so that it may be handled with bare hands, the workpiece is transported to the slack tub, which rapidly cools the workpiece in a large body of water. However, depending on the metal type, it may require an oil quench or a salt brine instead; many metals require more than plain water hardening. The slack tub also provides water to control the fire in the forge. Types Coal/coke/charcoal forge A forge typically uses bituminous coal, indus ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bloomery

A bloomery is a type of metallurgical furnace once used widely for smelting iron from its iron oxides, oxides. The bloomery was the earliest form of smelter capable of smelting iron. Bloomeries produce a porous mass of iron and slag called a ''bloom''. The mix of slag and iron in the bloom, termed ''Direct reduced iron, sponge iron'', is usually consolidated and further forged into wrought iron. Blast furnaces, which produce pig iron, have largely superseded bloomeries. Process A bloomery consists of a wikt:pit, pit or chimney with heat-resistant walls made of earth, clay, or Rock (geology), stone. Near the bottom, one or more pipes (made of clay or metal) enter through the side walls. These pipes, called tuyeres, allow air to enter the furnace, either by natural draught or forced with bellows or a trompe. An opening at the bottom of the bloomery may be used to remove the bloom, or the bloomery can be tipped over and the bloom removed from the top. The first step taken b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nozzle

A nozzle is a device designed to control the direction or characteristics of a fluid flow (specially to increase velocity) as it exits (or enters) an enclosed chamber or pipe (material), pipe. A nozzle is often a pipe or tube of varying cross sectional area, and it can be used to direct or modify the flow of a fluid (liquid or gas). Nozzles are frequently used to control the rate of flow, speed, direction, mass, shape, and/or the pressure of the stream that emerges from them. In a nozzle, the velocity of fluid increases at the expense of its pressure energy. Types Jet A gas jet, fluid jet, or hydro jet is a nozzle intended to eject gas or fluid in a coherent stream into a surrounding medium. Gas jets are commonly found in gas stoves, ovens, or barbecues. Gas jets were commonly used for Gas lighting, light before the development of electric light. Other types of fluid jets are found in carburetors, where smooth calibrated orifices are used to regulate the flow of gasoline, fuel ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hot Blast

Hot blast is the preheated air blown into a blast furnace or other metallurgical process. This technology, which considerably reduces the fuel consumed, was one of the most important technologies developed during the Industrial Revolution. Hot blast also allowed higher furnace temperatures, which increased the capacity of furnaces. As first developed, it worked by alternately storing heat from the furnace flue gas in a firebrick-lined vessel with multiple chambers, then blowing combustion air through the hot chamber. This is known as regenerative heating. Hot blast was invented and patented for iron furnaces by James Beaumont Neilson in 1828 at Wilsontown Ironworks in Scotland, but was later applied in other contexts, including late bloomeries. Later the carbon monoxide in the flue gas was burned to provide additional heat. History Invention and spread James Beaumont Neilson, previously foreman at Glasgow gas works, invented the system of preheating the blast for a furna ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Steam Engine

A steam engine is a heat engine that performs Work (physics), mechanical work using steam as its working fluid. The steam engine uses the force produced by steam pressure to push a piston back and forth inside a Cylinder (locomotive), cylinder. This pushing force can be transformed by a connecting rod and Crank (mechanism), crank into rotational force for work. The term "steam engine" is most commonly applied to reciprocating engines as just described, although some authorities have also referred to the steam turbine and devices such as Hero's aeolipile as "steam engines". The essential feature of steam engines is that they are external combustion engines, where the working fluid is separated from the combustion products. The ideal thermodynamic cycle used to analyze this process is called the Rankine cycle. In general usage, the term ''steam engine'' can refer to either complete steam plants (including Boiler (power generation), boilers etc.), such as railway steam locomot ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

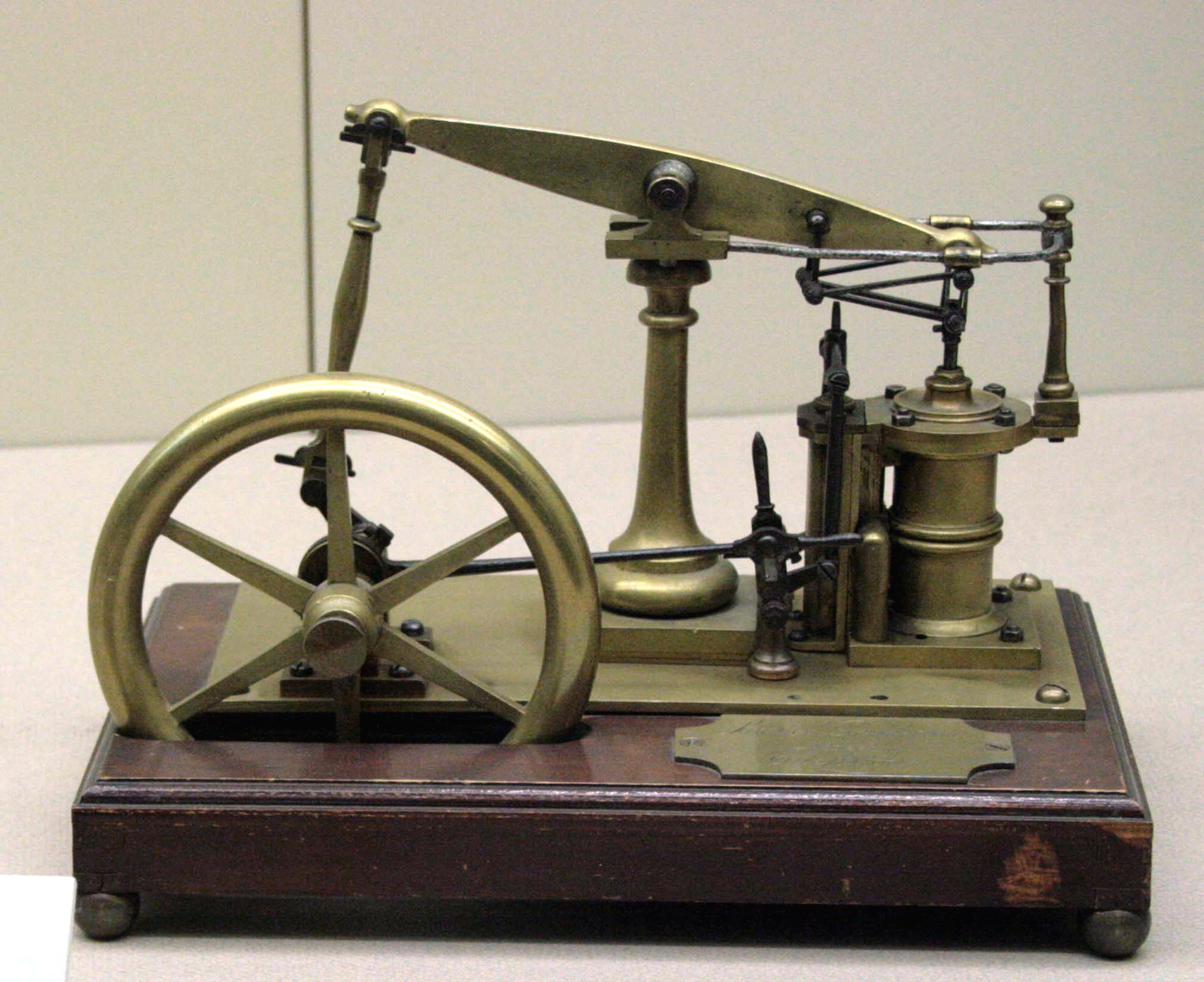

Watt Engine

The Watt steam engine design was an invention of James Watt that became synonymous with steam engines during the Industrial Revolution, and it was many years before significantly new designs began to replace the basic Watt design. The first steam engines, introduced by Thomas Newcomen in 1712, were of the "atmospheric" design. At the end of the power stroke, the weight of the object being moved by the engine pulled the piston to the top of the cylinder as steam was introduced. Then the cylinder was cooled by a spray of water, which caused the steam to condense, forming a partial vacuum in the cylinder. Atmospheric pressure on the top of the piston pushed it down, lifting the work object. James Watt noticed that it required significant amounts of heat to warm the cylinder back up to the point where steam could enter the cylinder without immediately condensing. When the cylinder was warm enough that it became filled with steam the next power stroke could commence. Watt realise ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cast Iron

Cast iron is a class of iron–carbon alloys with a carbon content of more than 2% and silicon content around 1–3%. Its usefulness derives from its relatively low melting temperature. The alloying elements determine the form in which its carbon appears: Cast iron#White cast iron, white cast iron has its carbon combined into an iron carbide named cementite, which is very hard, but brittle, as it allows cracks to pass straight through; Grey iron, grey cast iron has graphite flakes which deflect a passing crack and initiate countless new cracks as the material breaks, and Ductile iron, ductile cast iron has spherical graphite "nodules" which stop the crack from further progressing. Carbon (C), ranging from 1.8 to 4 wt%, and silicon (Si), 1–3 wt%, are the main alloying elements of cast iron. Iron alloys with lower carbon content are known as steel. Cast iron tends to be brittle, except for malleable iron, malleable cast irons. With its relatively low melting point, g ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Blacksmith

A blacksmith is a metalsmith who creates objects primarily from wrought iron or steel, but sometimes from #Other metals, other metals, by forging the metal, using tools to hammer, bend, and cut (cf. tinsmith). Blacksmiths produce objects such as gates, grilles, railings, light fixtures, furniture, sculpture, tools, agricultural implements, decorative and religious items, cooking utensils, and weapons. There was a historical distinction between the heavy work of the blacksmith and the more delicate operations of a whitesmith, who usually worked in Goldsmith, gold, Silversmith, silver, pewter, or the finishing steps of fine steel. The place where a blacksmith works is variously called a smithy, a forge, or a blacksmith's shop. While there are many professions who work with metal, such as farriers, wheelwrights, and Armourer, armorers, in former times the blacksmith had a general knowledge of how to make and repair many things, from the most complex of weapons and armor to simple ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chafery

A chafery is a variety of hearth used in ironmaking for reheating a bloom of iron, in the course of its being drawn out into a bar of wrought iron. The equivalent term for a bloomery was string hearth, except in 17th century Cumbria, where the terminology was that of the finery forge. A finery forge for the Walloon process would typically have one chafery to work two fineries (but sometimes one or three fineries). Chaferies were also used in the potting and stamping forges of the Industrial Revolution. Metallurgy References {{Reflist ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lead

Lead () is a chemical element; it has Chemical symbol, symbol Pb (from Latin ) and atomic number 82. It is a Heavy metal (elements), heavy metal that is density, denser than most common materials. Lead is Mohs scale, soft and Ductility, malleable, and also has a relatively low melting point. When freshly cut, lead is a shiny gray with a hint of blue. It tarnishes to a dull gray color when exposed to air. Lead has the highest atomic number of any stable nuclide, stable element and three of its isotopes are endpoints of major nuclear decay chains of heavier elements. Lead is a relatively unreactive post-transition metal. Its weak metallic character is illustrated by its Amphoterism, amphoteric nature; lead and lead oxides react with acids and base (chemistry), bases, and it tends to form covalent bonds. Lead compounds, Compounds of lead are usually found in the +2 oxidation state rather than the +4 state common with lighter members of the carbon group. Exceptions are mostly limited ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |