Bloomery on:

[Wikipedia]

[Google]

[Amazon]

A bloomery is a type of

A bloomery consists of a pit or

A bloomery consists of a pit or

The onset of the

The onset of the

Early European bloomeries were relatively small, primarily due to the mechanical limits of human-powered bellows and the amount of force possible to apply with hand-driven sledge hammers. Those known archaeologically from the pre-Roman Iron Age tend to be in the 2 kg range, produced in low shaft furnaces. Roman-era production often used furnaces tall enough to create a natural draft effect (into the range of 200 cm tall), and increasing bloom sizes into the range of 10–15 kg. Contemporary experimenters had routinely made blooms using Northern European-derived "short-shaft" furnaces with blown air supplies in the 5–10 kg range The use of

Early European bloomeries were relatively small, primarily due to the mechanical limits of human-powered bellows and the amount of force possible to apply with hand-driven sledge hammers. Those known archaeologically from the pre-Roman Iron Age tend to be in the 2 kg range, produced in low shaft furnaces. Roman-era production often used furnaces tall enough to create a natural draft effect (into the range of 200 cm tall), and increasing bloom sizes into the range of 10–15 kg. Contemporary experimenters had routinely made blooms using Northern European-derived "short-shaft" furnaces with blown air supplies in the 5–10 kg range The use of

Experimental Iron Smelting (at the Wareham Forge)

Viking-Era Norse techniques by DARC

The Catalan process for the direct production of malleable iron and its spread to Europe and the Americas PDF

by Estanislau Tomàs (retrieved 23 March 2010) * A Practical Treatise on the Smelting and Smithing of Bloomery ''Iron'' https://hmsjournal.org/index.php/home/article/view/268/257 * An Update on "A Practical Treatise" https://www.researchgate.net/publication/285737243_An_American_bloomery_in_Sussex#fullTextFileContent {{Authority control Industrial furnaces Steelmaking Iron Archaeometallurgy Smelting Iron Age Europe

metallurgical furnace

A metallurgical furnace, often simply referred to as a furnace when the context is known, is an industrial furnace used to heat, melt, or otherwise process metals. Furnaces have been a central piece of equipment throughout the history of metallurg ...

once used widely for smelting

Smelting is a process of applying heat and a chemical reducing agent to an ore to extract a desired base metal product. It is a form of extractive metallurgy that is used to obtain many metals such as iron-making, iron, copper extraction, copper ...

iron from its oxides

An oxide () is a chemical compound containing at least one oxygen atom and one other element in its chemical formula. "Oxide" itself is the dianion (anion bearing a net charge of −2) of oxygen, an O2− ion with oxygen in the oxidation state o ...

. The bloomery was the earliest form of smelter

Smelting is a process of applying heat and a chemical reducing agent to an ore to extract a desired base metal product. It is a form of extractive metallurgy that is used to obtain many metals such as iron, copper, silver, tin, lead and zin ...

capable of smelting iron. Bloomeries produce a porous mass of iron

Iron is a chemical element; it has symbol Fe () and atomic number 26. It is a metal that belongs to the first transition series and group 8 of the periodic table. It is, by mass, the most common element on Earth, forming much of Earth's o ...

and slag

The general term slag may be a by-product or co-product of smelting (pyrometallurgical) ores and recycled metals depending on the type of material being produced. Slag is mainly a mixture of metal oxides and silicon dioxide. Broadly, it can be c ...

called a ''bloom''. The mix of slag and iron in the bloom, termed '' sponge iron'', is usually consolidated and further forged into wrought iron

Wrought iron is an iron alloy with a very low carbon content (less than 0.05%) in contrast to that of cast iron (2.1% to 4.5%), or 0.25 for low carbon "mild" steel. Wrought iron is manufactured by heating and melting high carbon cast iron in an ...

. Blast furnace

A blast furnace is a type of metallurgical furnace used for smelting to produce industrial metals, generally pig iron, but also others such as lead or copper. ''Blast'' refers to the combustion air being supplied above atmospheric pressure.

In a ...

s, which produce pig iron

Pig iron, also known as crude iron, is an intermediate good used by the iron industry in the production of steel. It is developed by smelting iron ore in a blast furnace. Pig iron has a high carbon content, typically 3.8–4.7%, along with si ...

, have largely superseded bloomeries.

Process

A bloomery consists of a pit or

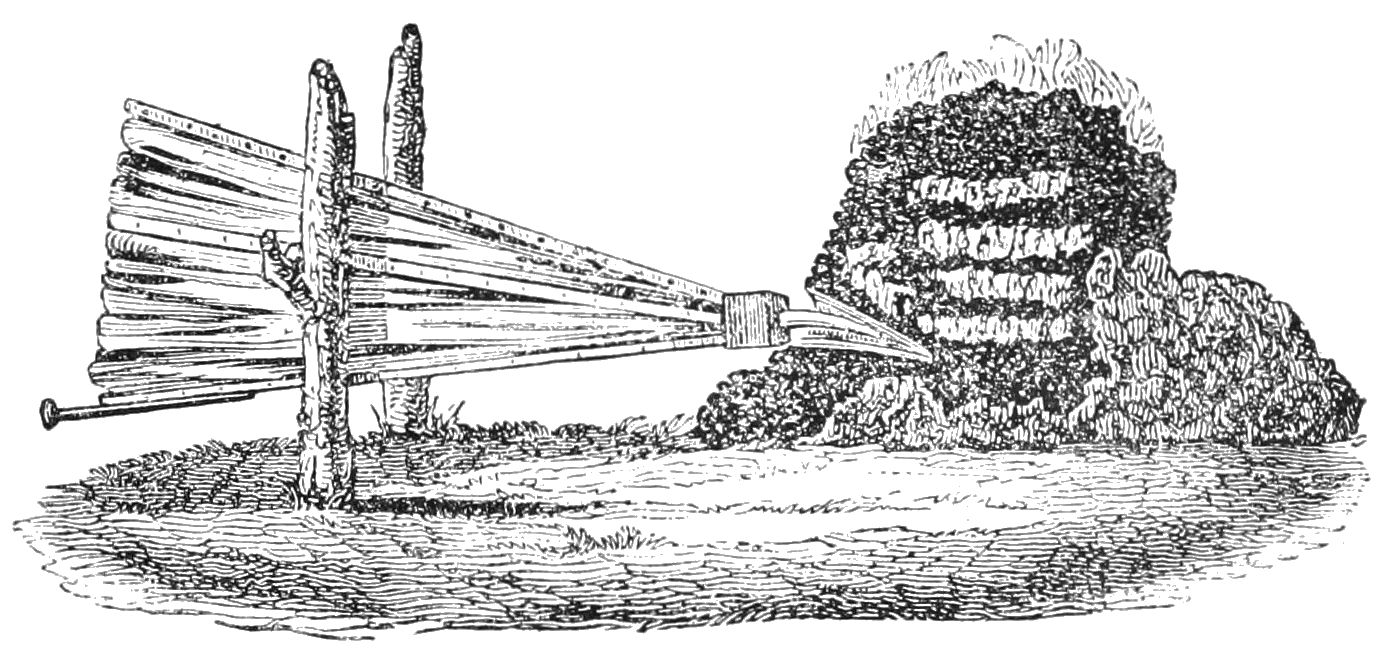

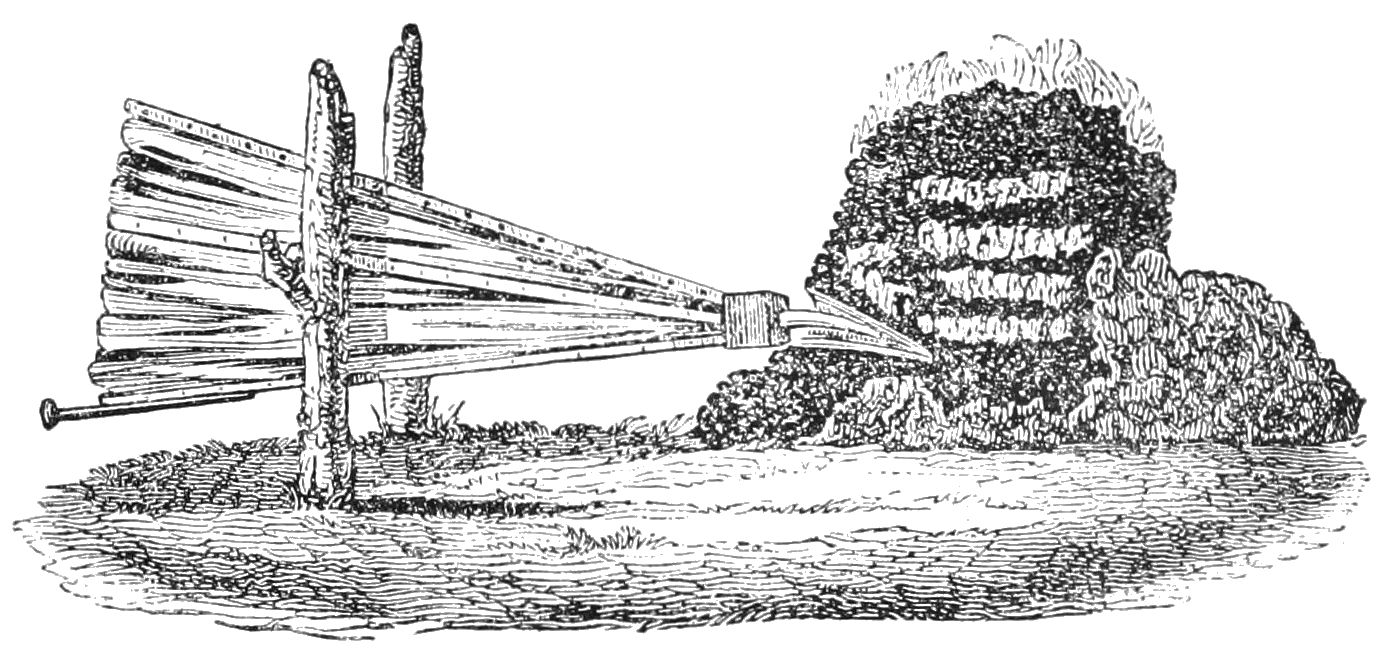

A bloomery consists of a pit or chimney

A chimney is an architectural ventilation structure made of masonry, clay or metal that isolates hot toxic exhaust gases or smoke produced by a boiler, stove, furnace, incinerator, or fireplace from human living areas. Chimneys are typical ...

with heat-resistant walls made of earth, clay

Clay is a type of fine-grained natural soil material containing clay minerals (hydrous aluminium phyllosilicates, e.g. kaolinite, ). Most pure clay minerals are white or light-coloured, but natural clays show a variety of colours from impuriti ...

, or stone

In geology, rock (or stone) is any naturally occurring solid mass or aggregate of minerals or mineraloid matter. It is categorized by the minerals included, its Chemical compound, chemical composition, and the way in which it is formed. Rocks ...

. Near the bottom, one or more pipes (made of clay or metal) enter through the side walls. These pipes, called tuyeres, allow air to enter the furnace, either by natural draught or forced with bellows

A bellows or pair of bellows is a device constructed to furnish a strong blast of air. The simplest type consists of a flexible bag comprising a pair of rigid boards with handles joined by flexible leather sides enclosing an approximately airtig ...

or a trompe

A trompe is a water-powered air compressor, commonly used before the advent of the electric-powered compressor. A trompe is somewhat like an airlift pump working in reverse.

Trompes were used to provide compressed air for bloomery furnaces ...

. An opening at the bottom of the bloomery may be used to remove the bloom, or the bloomery can be tipped over and the bloom removed from the top.

The first step taken before the bloomery can be used is the preparation of the charcoal

Charcoal is a lightweight black carbon residue produced by strongly heating wood (or other animal and plant materials) in minimal oxygen to remove all water and volatile constituents. In the traditional version of this pyrolysis process, ca ...

and the iron ore. Charcoal is nearly pure carbon

Carbon () is a chemical element; it has chemical symbol, symbol C and atomic number 6. It is nonmetallic and tetravalence, tetravalent—meaning that its atoms are able to form up to four covalent bonds due to its valence shell exhibiting 4 ...

, which, when burned, both produces the high temperature needed for the smelting process and provides the carbon monoxide

Carbon monoxide (chemical formula CO) is a poisonous, flammable gas that is colorless, odorless, tasteless, and slightly less dense than air. Carbon monoxide consists of one carbon atom and one oxygen atom connected by a triple bond. It is the si ...

needed for reduction of the metal.

The ore

Ore is natural rock or sediment that contains one or more valuable minerals, typically including metals, concentrated above background levels, and that is economically viable to mine and process. The grade of ore refers to the concentration ...

is broken into small pieces and usually roasted in a fire, to make rock-based ores easier to break up, bake out some impurities, and (to a lesser extent) to remove any moisture in the ore. Any large impurities (as silica) in the ore can be removed as it is crushed. The desired particle size depends primarily on which of several ore types may be available, which will also have a relationship to the layout and operation of the furnace, of which a number of regional, historic/traditional forms exist. Natural iron ores can vary considerably in oxide form ( / / ), and importantly in relative iron content. Since slag

The general term slag may be a by-product or co-product of smelting (pyrometallurgical) ores and recycled metals depending on the type of material being produced. Slag is mainly a mixture of metal oxides and silicon dioxide. Broadly, it can be c ...

from previous blooms may have a high iron content, it can also be broken up and may be recycled

Recycling is the process of converting waste materials into new materials and objects. This concept often includes the recovery of energy from waste materials. The recyclability of a material depends on its ability to reacquire the propert ...

into the bloomery with the new ore.

In operation, after the bloomery is heated typically with a wood fire, shifting to burning sized charcoal, iron ore and additional charcoal are introduced through the top. Again, traditional methods vary, but normally smaller charges of ore are added at the start of the main smelting sequence, increasing to larger amounts as the smelt progresses. Overall, a typical ratio of total charcoal to ore added is in a roughly one-to-one ratio. Inside the furnace, carbon monoxide

Carbon monoxide (chemical formula CO) is a poisonous, flammable gas that is colorless, odorless, tasteless, and slightly less dense than air. Carbon monoxide consists of one carbon atom and one oxygen atom connected by a triple bond. It is the si ...

from the incomplete combustion

Combustion, or burning, is a high-temperature exothermic redox chemical reaction between a fuel (the reductant) and an oxidant, usually atmospheric oxygen, that produces oxidized, often gaseous products, in a mixture termed as smoke. Combustion ...

of the charcoal reduces the iron oxides in the ore to metallic iron without melting the ore; this allows the bloomery to operate at lower temperatures than the melting temperature of the ore. As the desired product of a bloomery is iron that is easily forgeable, it requires a low carbon content. The temperature and ratio of charcoal to iron ore must be carefully controlled to keep the iron from absorbing too much carbon and thus becoming unforgeable. Cast iron occurs when the iron absorbs 2% to 4% carbon. Because the bloomery is self- fluxing, the addition of limestone

Limestone is a type of carbonate rock, carbonate sedimentary rock which is the main source of the material Lime (material), lime. It is composed mostly of the minerals calcite and aragonite, which are different Polymorphism (materials science) ...

is not required to form a slag.

The small particles of iron produced in this way fall to the bottom of the furnace, where they combine with molten slag, often consisting of fayalite

Fayalite (, commonly abbreviated to Fa) is the iron-rich endmember, end-member of the olivine solid solution, solid-solution series. In common with all minerals in the olivine, olivine group, fayalite crystallizes in the orthorhombic system (spac ...

, a compound of silicon

Silicon is a chemical element; it has symbol Si and atomic number 14. It is a hard, brittle crystalline solid with a blue-grey metallic lustre, and is a tetravalent metalloid (sometimes considered a non-metal) and semiconductor. It is a membe ...

, oxygen

Oxygen is a chemical element; it has chemical symbol, symbol O and atomic number 8. It is a member of the chalcogen group (periodic table), group in the periodic table, a highly reactivity (chemistry), reactive nonmetal (chemistry), non ...

, and iron mixed with other impurities from the ore. The hot liquid slag, running to the bottom of the furnace, cools against the base and lower side walls of the furnace, effectively forming a bowl still containing fluid slag. As the individual iron particles form, they fall into this bowl and sinter together under their own weight, forming a spongy mass referred to as the bloom. Because the bloom is typically porous

Porosity or void fraction is a measure of the void (i.e. "empty") spaces in a material, and is a fraction of the volume of voids over the total volume, between 0 and 1, or as a percentage between 0% and 100%. Strictly speaking, some tests measure ...

, and its open spaces can be full of slag, the extracted mass must be beaten with heavy hammers to both compress voids and drive out any molten slag remaining. This process may require several additional heating and compaction cycles, working at high 'welding' temperatures. Iron treated this way is said to be wrought (worked), and the resulting iron, with reduced amounts of slag, is called wrought iron or bar iron. Because of the creation process, individual blooms can often have differing carbon contents between the original top and bottom surfaces, differences that will also be somewhat blended together through the flattening, folding, and hammer-welding sequences. Intentionally producing blooms that are coated in steel

Steel is an alloy of iron and carbon that demonstrates improved mechanical properties compared to the pure form of iron. Due to steel's high Young's modulus, elastic modulus, Yield (engineering), yield strength, Fracture, fracture strength a ...

(i.e. iron with a higher carbon content) by manipulating the charge of and air flow to the bloomery is also possible.

As the era of modern commercial steelmaking

Steelmaking is the process of producing steel from iron ore and/or scrap. Steel has been made for millennia, and was commercialized on a massive scale in the 1850s and 1860s, using the Bessemer process, Bessemer and open hearth furnace, Siemens-M ...

began, the word "bloom" was extended to another sense

A sense is a biological system used by an organism for sensation, the process of gathering information about the surroundings through the detection of Stimulus (physiology), stimuli. Although, in some cultures, five human senses were traditio ...

referring to an intermediate-stage piece of steel, of a size comparable to many traditional iron blooms, that was ready to be further worked into billet

In European militaries, a billet is a living-quarters to which a soldier is assigned to sleep. In American usage, it refers to a specific personnel position, assignment, or duty station to which a soldier can be assigned. Historically, a billet w ...

.

History

The onset of the

The onset of the Iron Age

The Iron Age () is the final epoch of the three historical Metal Ages, after the Chalcolithic and Bronze Age. It has also been considered as the final age of the three-age division starting with prehistory (before recorded history) and progre ...

in most parts of the world coincides with the first widespread use of the bloomery. While earlier examples of iron are found, their high nickel content indicates that this is meteoric iron

Meteoric iron, sometimes meteoritic iron, is a native metal and early-universe protoplanetary-disk remnant found in meteorites and made from the elements iron and nickel, mainly in the form of the mineral phases kamacite and taenite. Meteoric ...

. Other early samples of iron may have been produced by accidental introduction of iron ore in copper-smelting operations. Iron appears to have been smelted in the Middle East as early as 3000 BC, but coppersmiths, not being familiar with iron, did not put it to use until much later. In the West, iron began to be used around 1200 BC.

East Asia

China has long been considered the exception to the general use of bloomeries. The Chinese are thought to have skipped the bloomery process completely, starting with theblast furnace

A blast furnace is a type of metallurgical furnace used for smelting to produce industrial metals, generally pig iron, but also others such as lead or copper. ''Blast'' refers to the combustion air being supplied above atmospheric pressure.

In a ...

and the finery forge

A finery forge is a forge used to produce wrought iron from pig iron by decarburization in a process called "fining" which involved liquifying cast iron in a fining hearth and decarburization, removing carbon from the molten cast iron through Redo ...

to produce wrought iron; by the fifth century BC, metalworkers in the southern state of Wu had invented the blast furnace and the means to both cast iron and to decarburize the carbon-rich pig iron produced in a blast furnace to a low-carbon, wrought iron-like material. Recent evidence, however, shows that bloomeries were used earlier in ancient China

The history of China spans several millennia across a wide geographical area. Each region now considered part of the Chinese world has experienced periods of unity, fracture, prosperity, and strife. Chinese civilization first emerged in the Y ...

, migrating in from the west as early as 800 BC, before being supplanted by the locally developed blast furnace. Supporting this theory was the discovery of "more than ten" iron-digging implements found in the tomb of Duke Jing of Qin (d. 537 BC), whose tomb is located in Fengxiang County

Fengxiang District (), formerly, Fengxiang County and its ancient name is Yong county (雍县), is a district administered by Baoji City in the west of Shaanxi province, China. The county covers an area of and as of 2004 had a population of 510, ...

, Shaanxi

Shaanxi is a Provinces of China, province in north Northwestern China. It borders the province-level divisions of Inner Mongolia to the north; Shanxi and Henan to the east; Hubei, Chongqing, and Sichuan to the south; and Gansu and Ningxia to t ...

(a museum exists on the site today).

Sub-Saharan Africa

The earliest records of bloomery-type furnaces in East Africa are discoveries of smelted iron and carbon in Nubia in ancient Sudan dated at least to the seventh to the sixth century BC. The ancient bloomeries that produced metal tools for the Nubians and Kushites produced a surplus for sale. All traditional sub-Saharan African iron-smelting processes are variants of the bloomery process. There is considerable discussion about the origins ofiron metallurgy in Africa

Iron metallurgy in Africa concerns the origin and development of ferrous metallurgy on the Africa, African continent. Whereas the development of iron metallurgy in North Africa and the Horn of Africa, Horn closely mirrors that of the Ancient Nea ...

. Smelting in bloomery type furnaces in West Africa and forging of tools appeared in the Nok culture

The Nok culture is a population whose material remains are named after the Ham people, Ham village of Nok in Southern Kaduna, southern Kaduna State of Nigeria, where their terracotta sculptures were first discovered in 1928. The Nok people and ...

of central Nigeria by at least 550 BC and possibly several centuries earlier. Also, evidence indicates iron smelting with bloomery-style furnaces dated to 750 BC in Opi (Augustin Holl 2009) and Lejja dated to 2,000 BC (Pamela Eze-Uzomaka 2009), both sites in the Nsukka region of southeast Nigeria in what is now Igboland

Igbo land ( Standard ) is a cultural and common linguistic region in southeastern Nigeria which is the indigenous homeland of the Igbo people. Geographically, it is divided into two sections, eastern (the larger of the two) and western. Its popu ...

. The site of Gbabiri, in the Central African Republic

The Central African Republic (CAR) is a landlocked country in Central Africa. It is bordered by Chad to Central African Republic–Chad border, the north, Sudan to Central African Republic–Sudan border, the northeast, South Sudan to Central ...

, has also yielded evidence of iron metallurgy, from a reduction furnace and blacksmith workshop, with earliest dates of 896–773 and 907–796 BC, respectively.

South Asia

During a hydroelectric plant project, in the southern foothills of the Central Highlands, Samanalawewa, inSri Lanka

Sri Lanka, officially the Democratic Socialist Republic of Sri Lanka, also known historically as Ceylon, is an island country in South Asia. It lies in the Indian Ocean, southwest of the Bay of Bengal, separated from the Indian subcontinent, ...

, a wind-driven furnace was found in an excavation site. Such furnaces were powered by the monsoon winds and have been dated to 300 BC using radiocarbon-dating techniques. These ancient Lankan furnaces might have produced the best-quality steel for legendary Damascus swords as referred in earlier Syrian records. Field trials using replica furnaces confirmed that this furnace type uses a wind-based air-supply principle that is distinct from either forced or natural draught, and show also that they are capable of producing high-carbon steel.

Wrought iron was used in the construction of monuments such as the iron pillar of Delhi, built in the third century AD during the Gupta Empire

The Gupta Empire was an Indian empire during the classical period of the Indian subcontinent which existed from the mid 3rd century to mid 6th century CE. At its zenith, the dynasty ruled over an empire that spanned much of the northern Indian ...

. The latter was built using a towering series of disc-shaped iron blooms. Similar to China, high-carbon steel was eventually used in India, although cast iron was not used for architecture until modern times.

Early to medieval Europe

Early European bloomeries were relatively small, primarily due to the mechanical limits of human-powered bellows and the amount of force possible to apply with hand-driven sledge hammers. Those known archaeologically from the pre-Roman Iron Age tend to be in the 2 kg range, produced in low shaft furnaces. Roman-era production often used furnaces tall enough to create a natural draft effect (into the range of 200 cm tall), and increasing bloom sizes into the range of 10–15 kg. Contemporary experimenters had routinely made blooms using Northern European-derived "short-shaft" furnaces with blown air supplies in the 5–10 kg range The use of

Early European bloomeries were relatively small, primarily due to the mechanical limits of human-powered bellows and the amount of force possible to apply with hand-driven sledge hammers. Those known archaeologically from the pre-Roman Iron Age tend to be in the 2 kg range, produced in low shaft furnaces. Roman-era production often used furnaces tall enough to create a natural draft effect (into the range of 200 cm tall), and increasing bloom sizes into the range of 10–15 kg. Contemporary experimenters had routinely made blooms using Northern European-derived "short-shaft" furnaces with blown air supplies in the 5–10 kg range The use of waterwheel

A water wheel is a machine for converting the kinetic energy of flowing or falling water into useful forms of power, often in a watermill. A water wheel consists of a large wheel (usually constructed from wood or metal), with numerous blade ...

s, spreading around the turn of the first millennium and used to power more massive bellows, allowed the bloomery to become larger and hotter, with associated trip hammers allowing the consolidation forging of the larger blooms created. Progressively larger bloomeries were constructed in the late 14th century, with a capacity of about 15 kg on average, though exceptions did exist. European average bloom sizes quickly rose to 300 kg, where they levelled off until the demise of the bloomery.

As a bloomery's size is increased, the iron ore is exposed to burning charcoal for a longer time. When combined with the strong air blast required to penetrate the large ore and charcoal stack, this may cause part of the iron to melt and become saturated with carbon in the process, producing unforgeable pig iron, which requires oxidation

Redox ( , , reduction–oxidation or oxidation–reduction) is a type of chemical reaction in which the oxidation states of the reactants change. Oxidation is the loss of electrons or an increase in the oxidation state, while reduction is ...

to be reduced into cast iron, steel, and iron. This pig iron was considered a waste product detracting from the largest bloomeries' yield, and early blast furnace

A blast furnace is a type of metallurgical furnace used for smelting to produce industrial metals, generally pig iron, but also others such as lead or copper. ''Blast'' refers to the combustion air being supplied above atmospheric pressure.

In a ...

s, identical in construction, but dedicated to the production of molten iron, were not built until the 14th century.

Bloomery type furnaces typically produced a range of iron products from very low-carbon iron to steel containing around 0.2–1.5% carbon. The master smith had to select pieces of low-carbon iron, carburize them, and pattern-weld them together to make steel sheets. Even when applied to a noncarburized bloom, this pound, fold, and weld process resulted in a more homogeneous product and removed much of the slag. The process had to be repeated up to 15 times when high-quality steel was needed, as for a sword. The alternative was to carburize the surface of a finished product. Each welding's heat oxidises some carbon, so the master smith had to make sure enough carbon was in the starting mixture.

In England and Wales, despite the arrival of the blast furnace in the Weald

The Weald () is an area of South East England between the parallel chalk escarpments of the North and the South Downs. It crosses the counties of Hampshire, Surrey, West Sussex, East Sussex, and Kent. It has three parts, the sandstone "High W ...

in about 1491, bloomery forges, probably using waterpower for the hammer and the bellows, were operating in the West Midlands region beyond 1580. In Furness

Furness ( ) is a peninsula and region of Cumbria, England. Together with the Cartmel Peninsula it forms North Lonsdale, Historic counties of England, historically an exclave of Lancashire. On 1 April 2023 it became part of the new unitary author ...

and Cumberland

Cumberland ( ) is an area of North West England which was historically a county. The county was bordered by Northumberland to the north-east, County Durham to the east, Westmorland to the south-east, Lancashire to the south, and the Scottish ...

, they operated into the early 17th century and the last one in England (near Garstang) did not close until about 1770.H. R. Schubert, ''History of the British Iron and Steel Industry'' (1957).

One of the oldest-known blast furnaces in Europe has been found in Lapphyttan in Sweden

Sweden, formally the Kingdom of Sweden, is a Nordic countries, Nordic country located on the Scandinavian Peninsula in Northern Europe. It borders Norway to the west and north, and Finland to the east. At , Sweden is the largest Nordic count ...

, carbon-14 dated to be from the 12th century. The oldest bloomery in Sweden, also found in the same area, has been carbon-14 dated to 700 BC.

Bloomeries survived in Spain and southern France as Catalan forges into the mid-19th century, and in Austria

Austria, formally the Republic of Austria, is a landlocked country in Central Europe, lying in the Eastern Alps. It is a federation of nine Federal states of Austria, states, of which the capital Vienna is the List of largest cities in Aust ...

as the to 1775.

The Americas

Iron smelting was rare in pre-Columbian America. Excavations atL'Anse aux Meadows

L'Anse aux Meadows () is an archaeological site, first excavated in the 1960s, of a Norse colonization of North America, Norse settlement dating to approximately 1,000 years ago. The site is located on the northernmost tip of the island of Newf ...

, Newfoundland, have found considerable evidence for the processing of bog iron and the production of iron in a bloomery by the Norse. The cluster of Viking Age (–1022 AD) at L'Anse aux Meadows are situated on a raised marine terrace, between a sedge peat bog and the ocean. Estimates from the smaller amount of slag recovered archaeologically suggest 15 kg of slag was produced during what appears to have been a single smelting attempt. By comparing the iron content of the primary bog iron ore found in the purpose built 'furnace hut' with the iron remaining in that slag, an estimated 3 kg iron bloom was produced. At a yield of at best 20% from what is a good iron rich ore, this suggests the workers processing the ore had not been particularly skilled. This supports the idea that iron processing knowledge was widespread and not restricted to major centers of trade and commerce. Archaeologists also found 98 nail, and importantly, ship rivet fragments, at the site as well as considerable evidence for woodworking – which points to boat or possibly ship repairs being undertaken at the site. (An important consideration remains that a potential 3 kg raw bloom most certainly does not make enough refined bar to manufacture the 3 kg of recovered nails and rivets.)

In the Spanish colonization of the Americas

The Spanish colonization of the Americas began in 1493 on the Caribbean island of Hispaniola (now Haiti and the Dominican Republic) after the initial 1492 voyage of Genoa, Genoese mariner Christopher Columbus under license from Queen Isabella ...

, bloomeries or "Catalan forges" were part of "self-sufficiency" at some of the missions, , and . As part of the Franciscan Spanish missions in Alta California

Alta California (, ), also known as Nueva California () among other names, was a province of New Spain formally established in 1804. Along with the Baja California peninsula, it had previously comprised the province of , but was made a separat ...

, the "Catalan forges" at Mission San Juan Capistrano

Mission San Juan Capistrano () is a Spanish missions in California, Spanish mission in San Juan Capistrano, California, San Juan Capistrano, Orange County, California, Orange County, California. Founded November 1, 1776 in colonial ''The Califo ...

from the 1790s are the oldest existing facilities of their kind in the present day state of California

California () is a U.S. state, state in the Western United States that lies on the West Coast of the United States, Pacific Coast. It borders Oregon to the north, Nevada and Arizona to the east, and shares Mexico–United States border, an ...

. The bloomeries' sign proclaims the site as being "part of Orange County's first industrial complex".

The archaeology at Jamestown Virginia (''circa'' 1610–1615) had recovered the remains of a simple short-shaft bloomery furnace, likely intended as yet another "resource test" like the one in Vinland much earlier. The English settlers of the Thirteen Colonies

The Thirteen Colonies were the British colonies on the Atlantic coast of North America which broke away from the British Crown in the American Revolutionary War (1775–1783), and joined to form the United States of America.

The Thirteen C ...

were prevented by law from manufacture; for a time, the British sought to situate most of the skilled artisanry at domestic locations. In fact, this was one of the problems that led to the revolution. The Falling Creek Ironworks

Falling Creek Ironworks was the first iron production facility in North America. It was established by the Virginia Company of London in Henrico City (Virginia Company), Henrico Cittie (sic) on Falling Creek (James River tributary), Falling Cre ...

was the first in the United States. The Neabsco Iron Works is an example of the early Virginia

Virginia, officially the Commonwealth of Virginia, is a U.S. state, state in the Southeastern United States, Southeastern and Mid-Atlantic (United States), Mid-Atlantic regions of the United States between the East Coast of the United States ...

n effort to form a workable American industry.

The earliest iron forge in colonial Pennsylvania was Thomas Rutter's bloomery near Pottstown, founded in 1716. In the Adirondacks

The Adirondack Mountains ( ) are a massif of mountains in Northeastern New York (state), New York which form a circular dome approximately wide and covering about . The region contains more than 100 peaks, including Mount Marcy, which is the hi ...

, New York, new bloomeries using the hot blast technique were built in the 19th century.Gordon C. Pollard, "Experimentation in 19th century bloomery production: evidence from the Adirondacks of New York", ''Historical Metallurgy'' 32(1) (1998), 33–40.

Oceania

The first commercially smelted iron in Australia, was made at the Fitzroy Iron Works, using a Catalan forge, in 1848. In New Zealand, a sophisticated direct-reduction furnace was used to smelt iron sand, at the Onehunga Ironworks, in 1883.See also

* Double hammer * Tatara (furnace) * Direct reduction * Direct reduction (blast furnace)References

External links

Experimental Iron Smelting (at the Wareham Forge)

Viking-Era Norse techniques by DARC

The Catalan process for the direct production of malleable iron and its spread to Europe and the Americas PDF

by Estanislau Tomàs (retrieved 23 March 2010) * A Practical Treatise on the Smelting and Smithing of Bloomery ''Iron'' https://hmsjournal.org/index.php/home/article/view/268/257 * An Update on "A Practical Treatise" https://www.researchgate.net/publication/285737243_An_American_bloomery_in_Sussex#fullTextFileContent {{Authority control Industrial furnaces Steelmaking Iron Archaeometallurgy Smelting Iron Age Europe