Lathe (tool) on:

[Wikipedia]

[Google]

[Amazon]

A lathe () is a

A lathe () is a

The lathe is an ancient tool. The earliest evidence of a lathe dates back to 4th century BC

The lathe is an ancient tool. The earliest evidence of a lathe dates back to 4th century BC  Precision metal-cutting lathes were developed organically during the lead up to the

Precision metal-cutting lathes were developed organically during the lead up to the  By the 1770s, precision lathes became practical and well-known. A slide-rest is clearly shown in a 1772 edition of the Encyclopédie and during that same year a horse-powered cannon boring lathe was installed in the

By the 1770s, precision lathes became practical and well-known. A slide-rest is clearly shown in a 1772 edition of the Encyclopédie and during that same year a horse-powered cannon boring lathe was installed in the

A lathe may or may not have legs, which sit on the floor and elevate the lathe bed to a working height. A lathe may be small and sit on a workbench or table, not requiring a stand.

Almost all lathes have a bed, which is almost always a horizontal beam, although CNC lathes commonly have an inclined or vertical beam for a bed to ensure that

A lathe may or may not have legs, which sit on the floor and elevate the lathe bed to a working height. A lathe may be small and sit on a workbench or table, not requiring a stand.

Almost all lathes have a bed, which is almost always a horizontal beam, although CNC lathes commonly have an inclined or vertical beam for a bed to ensure that

Unless a workpiece has a taper machined onto it which perfectly matches the internal taper in the spindle, or has threads which perfectly match the external threads on the spindle (two conditions which rarely exist), an accessory must be used to mount a workpiece to the spindle.

A workpiece may be bolted or screwed to a faceplate, a large, flat disk that mounts to the spindle. In the alternative, faceplate dogs may be used to secure the work to the faceplate.

A workpiece may be mounted on a

Unless a workpiece has a taper machined onto it which perfectly matches the internal taper in the spindle, or has threads which perfectly match the external threads on the spindle (two conditions which rarely exist), an accessory must be used to mount a workpiece to the spindle.

A workpiece may be bolted or screwed to a faceplate, a large, flat disk that mounts to the spindle. In the alternative, faceplate dogs may be used to secure the work to the faceplate.

A workpiece may be mounted on a  A soft dead center is used in the headstock spindle as the work rotates with the centre. Because the centre is soft it can be trued in place before use. The included angle is 60°. Traditionally, a hard dead center is used together with suitable lubricant in the tailstock to support the workpiece. In modern practice the dead center is frequently replaced by a running or live center, as it turns freely with the workpiece—usually on ball bearings—reducing the frictional heat, especially important at high speeds. When clear facing a long length of material it must be supported at both ends. This can be achieved by the use of a traveling or fixed steady. If a steady is not available, the end face being worked on may be supported by a dead (stationary) half center. A half center has a flat surface machined across a broad section of half of its diameter at the pointed end. A small section of the tip of the dead center is retained to ensure concentricity. Lubrication must be applied at this point of contact and tail stock pressure reduced. A lathe carrier or

A soft dead center is used in the headstock spindle as the work rotates with the centre. Because the centre is soft it can be trued in place before use. The included angle is 60°. Traditionally, a hard dead center is used together with suitable lubricant in the tailstock to support the workpiece. In modern practice the dead center is frequently replaced by a running or live center, as it turns freely with the workpiece—usually on ball bearings—reducing the frictional heat, especially important at high speeds. When clear facing a long length of material it must be supported at both ends. This can be achieved by the use of a traveling or fixed steady. If a steady is not available, the end face being worked on may be supported by a dead (stationary) half center. A half center has a flat surface machined across a broad section of half of its diameter at the pointed end. A small section of the tip of the dead center is retained to ensure concentricity. Lubrication must be applied at this point of contact and tail stock pressure reduced. A lathe carrier or

Woodworking lathes are the oldest variety, apart from pottery wheels. All other varieties are descended from these simple lathes. An adjustable horizontal metal rail, the tool-rest, between the material and the operator accommodates the positioning of shaping tools, which are usually hand-held. After shaping, it is common practice to press and slide sandpaper against the still-spinning object to smooth the surface made with the metal shaping tools. The tool-rest is usually removed during sanding, as it may be unsafe to have the operators hands between it and the spinning wood.

Many woodworking lathes can also be used for making bowls and plates. The bowl or plate needs only to be held at the bottom by one side of the lathe. It is usually attached to a metal face plate attached to the spindle. With many lathes, this operation happens on the left side of the headstock, where are no rails and therefore more clearance. In this configuration, the piece can be shaped inside and out. A specific curved tool-rest may be used to support tools while shaping the inside. Further detail can be found on the

Woodworking lathes are the oldest variety, apart from pottery wheels. All other varieties are descended from these simple lathes. An adjustable horizontal metal rail, the tool-rest, between the material and the operator accommodates the positioning of shaping tools, which are usually hand-held. After shaping, it is common practice to press and slide sandpaper against the still-spinning object to smooth the surface made with the metal shaping tools. The tool-rest is usually removed during sanding, as it may be unsafe to have the operators hands between it and the spinning wood.

Many woodworking lathes can also be used for making bowls and plates. The bowl or plate needs only to be held at the bottom by one side of the lathe. It is usually attached to a metal face plate attached to the spindle. With many lathes, this operation happens on the left side of the headstock, where are no rails and therefore more clearance. In this configuration, the piece can be shaped inside and out. A specific curved tool-rest may be used to support tools while shaping the inside. Further detail can be found on the

One type of specialized lathe is duplicating or copying lathe. Some types of them are known as Blanchard lathe, after Thomas Blanchard. This type of lathe was able to create shapes identical to a standard pattern and it revolutionized the process of gun

One type of specialized lathe is duplicating or copying lathe. Some types of them are known as Blanchard lathe, after Thomas Blanchard. This type of lathe was able to create shapes identical to a standard pattern and it revolutionized the process of gun

Modern American Lathe Practice. A New, Complete and Practical Work on the "king of Machine Shop Tools."

'' 1907. * * Joshua Rose.

The Complete Practical Machinist: Embracing Lathe Work, Vise Work, Drills, etc.

'' Philadelphia: H.C. Baird & Co., 1876

2nd ed. 1885

* * *

Lathe Machine Operations

Modern Machine Shop Practice

a historic Victorian text describing lathe design, construction and use in the 1880s.

"The Forgotten Power Tool."

''Popular Science'', December 1959, pp. 149–152.

History of the Lathe

{{Authority control Egyptian inventions

A lathe () is a

A lathe () is a machine tool

A machine tool is a machine for handling or machining metal or other rigid materials, usually by cutting, Boring (manufacturing), boring, grinding (abrasive cutting), grinding, shearing, or other forms of deformations. Machine tools employ some s ...

that rotates a workpiece

A workpiece is a piece, often made of a single material, that is being processed into another desired shape (such as building blocks).

The workpiece is usually a piece of relatively rigid material such as wood, metal, plastic, or stone. After a ...

about an axis of rotation

Rotation or rotational/rotary motion is the circular movement of an object around a central line, known as an ''axis of rotation''. A plane figure can rotate in either a clockwise or counterclockwise sense around a perpendicular axis intersect ...

to perform various operations such as cutting

Cutting is the separation or opening of a physical object, into two or more portions, through the application of an acutely directed force.

Implements commonly used for wikt:cut, cutting are the knife and saw, or in medicine and science the sca ...

, sanding

file:Schleifpapier verschiedene Sorten.jpg, upright=1.35, Sheets of sandpaper with different grit sizes (40 (coarse), 80, 150, 240, 600 (fine))

Sandpaper, also known as coated abrasive or emery paper, is a type of material that consists of sheet ...

, knurling, drilling

Drilling is a cutting process where a drill bit is spun to cut a hole of circular cross section (geometry), cross-section in solid materials. The drill bit is usually a rotary Cutting tool (machining), cutting tool, often multi-point. The bit i ...

, deformation, facing, threading and turning

Turning is a machining process in which a cutting tool, typically a non-rotary tool bit, describes a helix toolpath by moving more or less linearly while the workpiece rotates.

Usually the term "turning" is reserved for the generation of ...

, with tools that are applied to the workpiece to create an object with symmetry

Symmetry () in everyday life refers to a sense of harmonious and beautiful proportion and balance. In mathematics, the term has a more precise definition and is usually used to refer to an object that is Invariant (mathematics), invariant und ...

about that axis.

Lathes are used in woodturning

Woodturning is the craft of using a wood lathe with hand-held tools to cut a shape that is symmetrical around the axis of rotation. Like the potter's wheel, the wood lathe is a mechanism that can generate a variety of forms. The operator is kno ...

, metalworking

Metalworking is the process of shaping and reshaping metals in order to create useful objects, parts, assemblies, and large scale structures. As a term, it covers a wide and diverse range of processes, skills, and tools for producing objects on e ...

, metal spinning

Metal spinning, also known as spin forming or spinning or metal turning most commonly, is a metalworking process by which a disc or tube of metal is rotated at high speed and formed into an axially symmetric part. Spinning can be performed by ha ...

, thermal spraying

Thermal spraying techniques are coating processes in which melted (or heated) materials are sprayed onto a surface. The "feedstock" (coating precursor) is heated by electrical (plasma or arc) or chemical means (combustion flame).

Thermal sprayi ...

, reclamation, and glass-working. Lathes can be used to shape pottery

Pottery is the process and the products of forming vessels and other objects with clay and other raw materials, which are fired at high temperatures to give them a hard and durable form. The place where such wares are made by a ''potter'' is al ...

, the best-known design being the Potter's wheel

In pottery, a potter's wheel is a machine used in the shaping (known as throwing) of clay into round ceramic ware. The wheel may also be used during the process of trimming excess clay from leather-hard dried ware that is stiff but malleable, ...

. Most suitably equipped metalworking lathes can also be used to produce most solids of revolution, plane surfaces and screw threads or helices

A helix (; ) is a shape like a cylindrical coil spring or the thread of a machine screw. It is a type of smoothness (mathematics), smooth space curve with tangent lines at a constant angle to a fixed axis. Helices are important in biology, as ...

. Ornamental lathes can produce three-dimensional solids of incredible complexity. The workpiece is usually held in place by either one or two ''centers'', at least one of which can typically be moved horizontally to accommodate varying workpiece lengths. Other work-holding methods include clamping the work about the axis of rotation using a chuck or collet

A collet is a segmented sleeve, band or ''collar''. One of the two radial surfaces of a collet is usually tapered (i.e a truncated cone) and the other is cylindrical. The term ''collet'' commonly refers to a type of chuck that uses collets ...

, or to a faceplate, using clamps or dog clutch. Of course, lathes can also complete milling operations by installing special lathe milling fixtures.

Examples of objects that can be produced on a lathe include screw

A screw is an externally helical threaded fastener capable of being tightened or released by a twisting force (torque) to the screw head, head. The most common uses of screws are to hold objects together and there are many forms for a variety ...

s, candlesticks, gun barrel

A gun barrel is a crucial part of gun-type weapons such as small arms, small firearms, artillery pieces, and air guns. It is the straight shooting tube, usually made of rigid high-strength metal, through which a contained rapid expansion of high ...

s, cue stick

A cue stick (or simply cue, more specifically billiards cue, pool cue, or snooker cue) is an item of sporting equipment essential to the games of pool, snooker and carom billiards. It is used to strike a ball, usually the . Cues are tapered stic ...

s, table

Table may refer to:

* Table (database), how the table data arrangement is used within the databases

* Table (furniture), a piece of furniture with a flat surface and one or more legs

* Table (information), a data arrangement with rows and column ...

legs, bowl

A bowl is a typically round dish or container generally used for preparing, serving, storing, or consuming food. The interior of a bowl is characteristically shaped like a spherical cap, with the edges and the bottom, forming a seamless curve ...

s, baseball bat

A baseball bat is a smooth wooden or metal Club (weapon), club used in the sport of baseball to hit the Baseball (ball), ball after it is thrown by the pitcher. By regulation it may be no more than in diameter at the thickest part and no more t ...

s, pen

PEN may refer to:

* (National Ecological Party), former name of the Brazilian political party Patriota (PATRI)

* PEN International, a worldwide association of writers

** English PEN, the founding centre of PEN International

** PEN America, located ...

s, musical instruments (especially woodwind instruments

Woodwind instruments are a family of musical instruments within the greater category of wind instruments.

Common examples include flute, clarinet, oboe, bassoon, and saxophone. There are two main types of woodwind instruments: flutes and Ree ...

), and crankshaft

A crankshaft is a mechanical component used in a reciprocating engine, piston engine to convert the reciprocating motion into rotational motion. The crankshaft is a rotating Shaft (mechanical engineering), shaft containing one or more crankpins, ...

s.

History

The lathe is an ancient tool. The earliest evidence of a lathe dates back to 4th century BC

The lathe is an ancient tool. The earliest evidence of a lathe dates back to 4th century BC Egypt

Egypt ( , ), officially the Arab Republic of Egypt, is a country spanning the Northeast Africa, northeast corner of Africa and Western Asia, southwest corner of Asia via the Sinai Peninsula. It is bordered by the Mediterranean Sea to northe ...

an is a depiction in the tomb of Petosiris. There is also tenuous evidence for a turned artifact at a Mycenaean Greek site, dating back as far as the 13th or 14th century BC.

Clear evidence of turned artifacts have been found from the 6th century BC: fragments of a wooden bowl in an Etruscan tomb in Northern Italy as well as two flat wooden dishes with decorative turned rims from modern Turkey.

During the Warring States period

The Warring States period in history of China, Chinese history (221 BC) comprises the final two and a half centuries of the Zhou dynasty (256 BC), which were characterized by frequent warfare, bureaucratic and military reforms, and ...

in China

China, officially the People's Republic of China (PRC), is a country in East Asia. With population of China, a population exceeding 1.4 billion, it is the list of countries by population (United Nations), second-most populous country after ...

, , the ancient Chinese used rotary lathes to sharpen tools and weapons on an industrial scale.

The first known painting showing a lathe dates to the 4th century BC in ancient Egypt

Ancient Egypt () was a cradle of civilization concentrated along the lower reaches of the Nile River in Northeast Africa. It emerged from prehistoric Egypt around 3150BC (according to conventional Egyptian chronology), when Upper and Lower E ...

. Pliny later describes the use of a lathe for turning soft stone in his Natural History

Natural history is a domain of inquiry involving organisms, including animals, fungi, and plants, in their natural environment, leaning more towards observational than experimental methods of study. A person who studies natural history is cal ...

(Book XXX, Chapter 44).

Precision metal-cutting lathes were developed organically during the lead up to the

Precision metal-cutting lathes were developed organically during the lead up to the Industrial Revolution

The Industrial Revolution, sometimes divided into the First Industrial Revolution and Second Industrial Revolution, was a transitional period of the global economy toward more widespread, efficient and stable manufacturing processes, succee ...

, with many inventors contributing. They were critical to the manufacture of mechanical inventions of that period. There are many claims in the literature for the person who invented the precision lathe.

Some of the earliest examples include a version with a mechanical cutting tool-supporting carriage and a set of gears by Russian engineer Andrey Nartov in 1718 and another with a slide-rest shown in a 1717 edition of the French ''Encyclopédie

, better known as ''Encyclopédie'' (), was a general encyclopedia published in France between 1751 and 1772, with later supplements, revised editions, and translations. It had many writers, known as the Encyclopédistes. It was edited by Denis ...

''. The slide-rest was a particularly important development because it constrains the motion of the cutting tool to generate accurate cylindrical or conical surfaces, unlike earlier lathes that involved freehand manipulation of the tool.. Reprinted by McGraw-Hill, New York and London, 1926 (); and by Lindsay Publications, Inc., Bradley, Illinois, ().

By the 1770s, precision lathes became practical and well-known. A slide-rest is clearly shown in a 1772 edition of the Encyclopédie and during that same year a horse-powered cannon boring lathe was installed in the

By the 1770s, precision lathes became practical and well-known. A slide-rest is clearly shown in a 1772 edition of the Encyclopédie and during that same year a horse-powered cannon boring lathe was installed in the Royal Arsenal

The Royal Arsenal, Woolwich is an establishment on the south bank of the River Thames in Woolwich in south-east London, England, that was used for the manufacture of armaments and ammunition, proof test, proofing, and explosives research for ...

in Woolwich

Woolwich () is a town in South London, southeast London, England, within the Royal Borough of Greenwich.

The district's location on the River Thames led to its status as an important naval, military and industrial area; a role that was mainta ...

, England by Jan Verbruggen. Cannon bored by Verbruggen's lathe were stronger and more accurate than their predecessors and saw service in American Revolutionary War

The American Revolutionary War (April 19, 1775 – September 3, 1783), also known as the Revolutionary War or American War of Independence, was the armed conflict that comprised the final eight years of the broader American Revolution, in which Am ...

. Henry Maudslay

Henry Maudslay ( pronunciation and spelling) (22 August 1771 – 14 February 1831) was an English machine tool innovator, tool and die maker, and inventor. He is considered a founding father of machine tool technology. His inventions were a ...

, the inventor of many subsequent improvements to the lathe worked as an apprentice in Verbruggen's workshop in Woolwich.

During the Industrial Revolution

The Industrial Revolution, sometimes divided into the First Industrial Revolution and Second Industrial Revolution, was a transitional period of the global economy toward more widespread, efficient and stable manufacturing processes, succee ...

, mechanized power generated by water wheels or steam engines

A steam engine is a heat engine that performs Work (physics), mechanical work using steam as its working fluid. The steam engine uses the force produced by steam pressure to push a piston back and forth inside a Cylinder (locomotive), cyl ...

was transmitted to the lathe via line shafting, allowing faster and easier work. Metalworking lathes evolved into heavier machines with thicker, more rigid parts. Between the late 19th and mid-20th centuries, individual electric motors at each lathe replaced line shafting as the power source. Beginning in the 1950s, servomechanism

In mechanical and control engineering, a servomechanism (also called servo system, or simply servo) is a control system for the position and its time derivatives, such as velocity, of a mechanical system. It often includes a servomotor, and ...

s were applied to the control of lathes and other machine tools via numerical control, which often was coupled with computers to yield computerized numerical control (CNC). Today manually controlled and CNC lathes coexist in the manufacturing industries.

Design

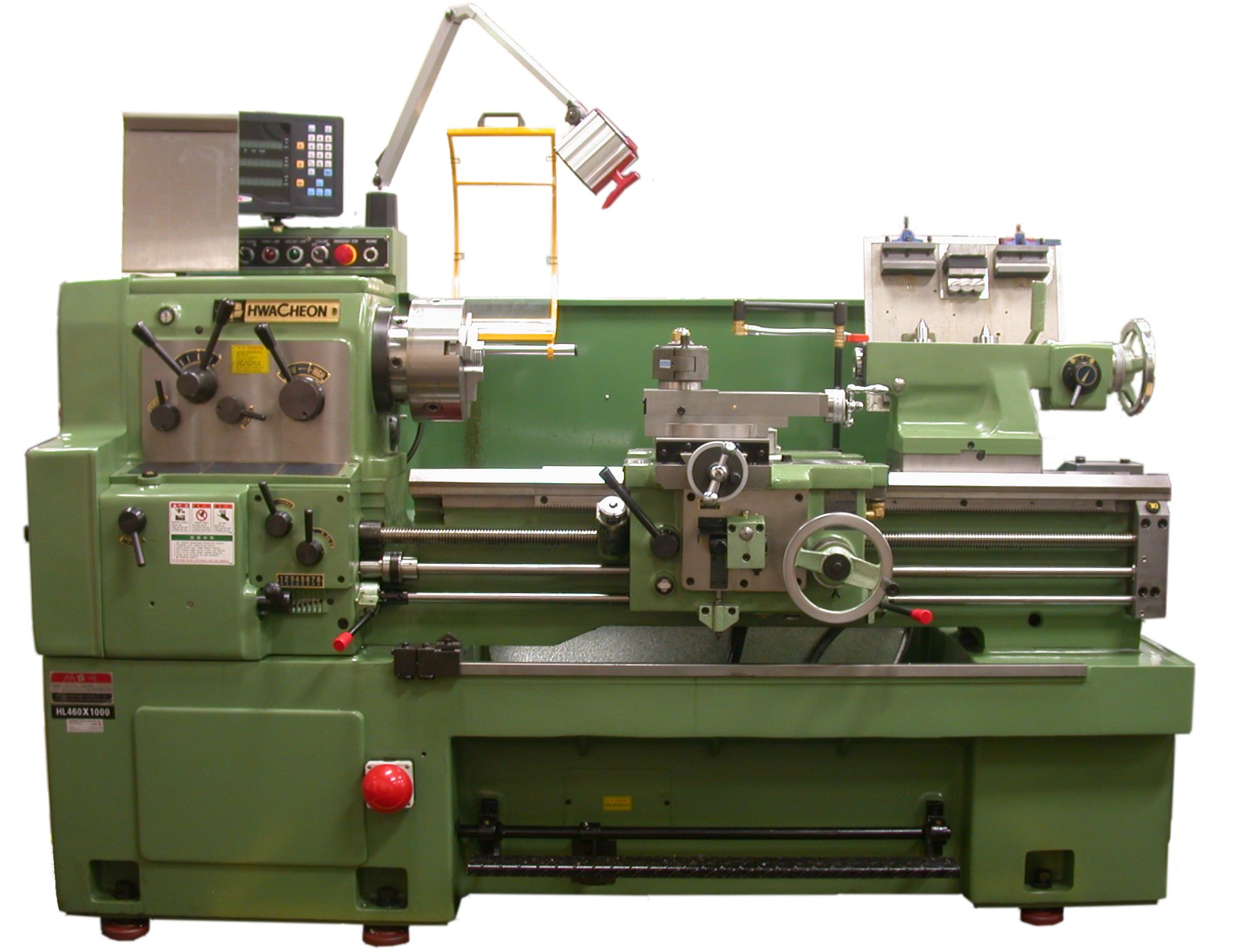

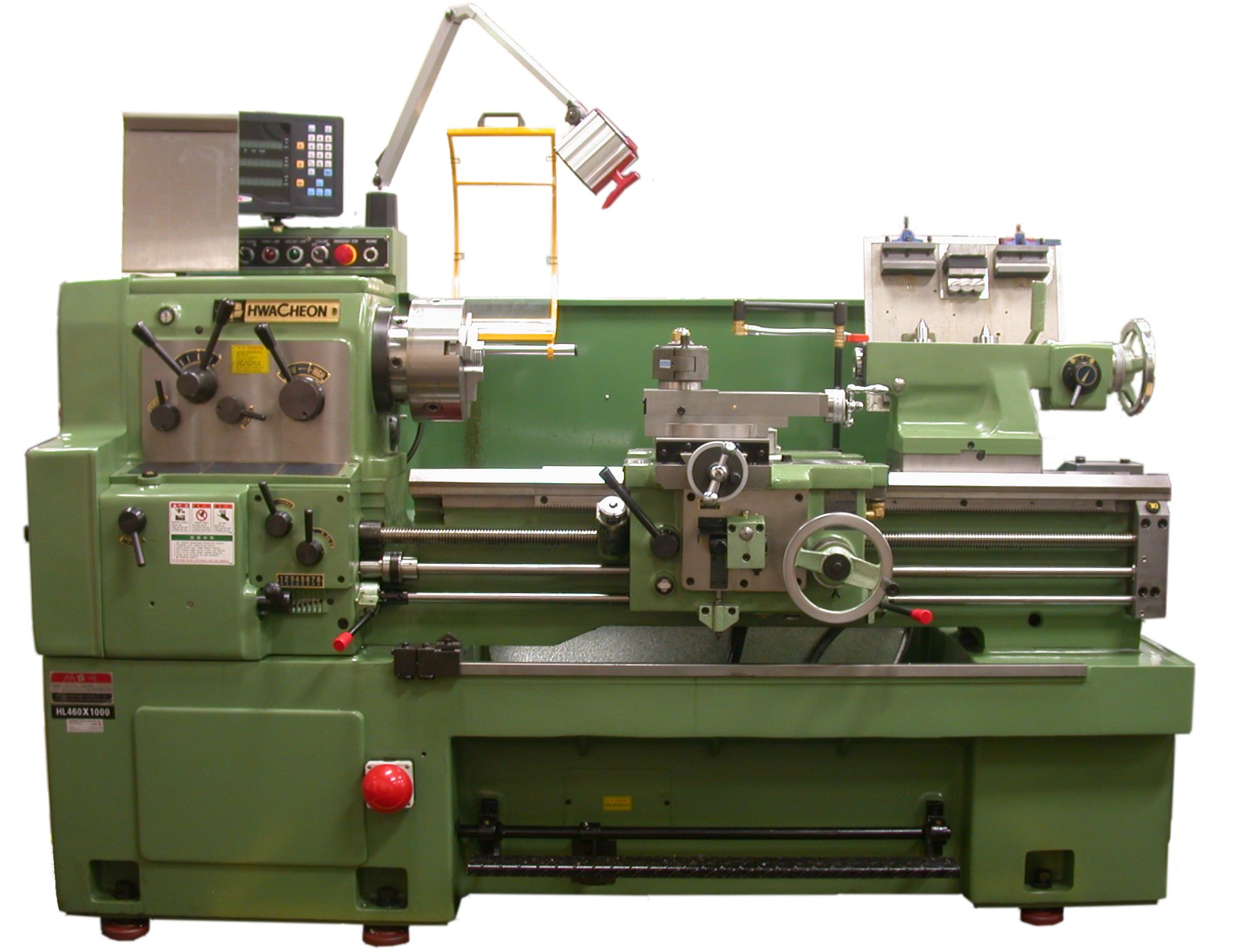

The most common design is known as the universal lathe or parallel lathe. Other general designs include the frontal and vertical lathe, and others.Components

swarf

Swarf, also known as chips or by other process-specific names (such as turnings, filings, or shavings), are pieces of metal, wood, or plastic that are the debris or waste resulting from machining, woodworking, or similar subtractive (material-r ...

, or chips, falls free of the bed. Woodturning lathes specialized for turning large bowls often have no bed or tail stock, merely a free-standing headstock and a cantilevered tool-rest.

At one end of the bed (almost always the left, as the operator faces the lathe) is a headstock. The headstock contains high-precision spinning bearings. Rotating within the bearings is a horizontal axle, with an axis parallel to the bed, called the spindle. Spindles are often hollow and have an interior Morse taper

A machine taper is a system for securing cutting tools or toolholders in the spindle of a machine tool or power tool. A male member of conical form (that is, with a taper) fits into the female socket, which has a matching taper of equal ang ...

on the spindle nose (i.e., facing to the right / towards the bed) by which work-holding accessories may be mounted to the spindle. Spindles may also have arrangements for work-holding on the left-hand end of the spindle with other tooling arrangements for particular tasks. (i.e., facing away from the main bed) end, or may have a hand-wheel or other accessory mechanism on their outboard end. Spindles are powered and impart motion to the workpiece.

The spindle is driven either by foot power from a treadle and flywheel or by a belt or gear drive from a power source such as electric motor or overhead line shafts. In most modern lathes this power source is an integral electric motor, often either in the headstock, to the left of the headstock, or beneath the headstock, concealed in the stand.

In addition to the spindle and its bearings, the headstock often contains parts to convert the motor speed into various spindle speeds. Various types of speed-changing mechanism achieve this, from a cone pulley or step pulley, to a cone pulley with back gear (which is essentially a low range, similar in net effect to the two-speed rear of a truck), to an entire gear train similar to that of a manual-shift automotive transmission. Some motors have electronic rheostat-type speed controls, which obviates cone pulleys or gears.

The counterpoint to the headstock is the tailstock, sometimes referred to as the loose head, as it can be positioned at any convenient point on the bed by sliding it to the required area. The tail-stock contains a barrel, which does not rotate, but can slide in and out parallel to the axis of the bed and directly in line with the headstock spindle. The barrel is hollow and usually contains a taper to facilitate the gripping of various types of tooling. Its most common uses are to hold a hardened steel center, which is used to support long thin shafts while turning, or to hold drill bits for drilling axial holes in the work piece. Many other uses are possible.

Metalworking lathes have a carriage (comprising a saddle and apron) topped with a cross-slide, which is a flat piece that sits crosswise on the bed and can be cranked at right angles to the bed. Sitting atop the cross slide is usually another slide called a compound rest, which provides two additional axes of motion, rotary and linear. Atop that sits a toolpost, which holds a cutting tool

Cutting is the separation or opening of a physical object, into two or more portions, through the application of an acutely directed force.

Implements commonly used for cutting are the knife and saw, or in medicine and science the scalpel an ...

, which removes material from the workpiece. There may or may not be a leadscrew

A leadscrew (or lead screw), also known as a power screw or translation screw,Bhandari, p. 202. is a screw used as a linkage in a machine, to translate turning motion into linear motion. Because of the large area of sliding contact between ...

, which moves the cross-slide along the bed.

Woodturning and metal spinning lathes do not have cross-slides, but rather have banjos, which are flat pieces that sit crosswise on the bed. The position of a banjo can be adjusted by hand; no gearing is involved. Ascending vertically from the banjo is a tool-post, at the top of which is a horizontal tool-rest. In woodturning, hand tools are braced against the tool-rest and levered into the workpiece. In metal spinning, the further pin ascends vertically from the tool-rest and serves as a fulcrum against which tools may be levered into the workpiece.

Accessories

Unless a workpiece has a taper machined onto it which perfectly matches the internal taper in the spindle, or has threads which perfectly match the external threads on the spindle (two conditions which rarely exist), an accessory must be used to mount a workpiece to the spindle.

A workpiece may be bolted or screwed to a faceplate, a large, flat disk that mounts to the spindle. In the alternative, faceplate dogs may be used to secure the work to the faceplate.

A workpiece may be mounted on a

Unless a workpiece has a taper machined onto it which perfectly matches the internal taper in the spindle, or has threads which perfectly match the external threads on the spindle (two conditions which rarely exist), an accessory must be used to mount a workpiece to the spindle.

A workpiece may be bolted or screwed to a faceplate, a large, flat disk that mounts to the spindle. In the alternative, faceplate dogs may be used to secure the work to the faceplate.

A workpiece may be mounted on a mandrel

A mandrel, mandril, or arbor is a tapered tool against which material can be forged, pressed, stretched or shaped (e.g., a ring mandrel - also called a triblet - used by jewellers to increase the diameter of a wedding ring), or a flanged or t ...

, or circular work clamped in a three- or four-jaw chuck. For irregular shaped workpieces it is usual to use a four jaw (independent moving jaws) chuck. These holding devices mount directly to the lathe headstock spindle.

In precision work, and in some classes of repetition work, cylindrical workpieces are usually held in a collet

A collet is a segmented sleeve, band or ''collar''. One of the two radial surfaces of a collet is usually tapered (i.e a truncated cone) and the other is cylindrical. The term ''collet'' commonly refers to a type of chuck that uses collets ...

inserted into the spindle and secured either by a draw-bar, or by a collet closing cap on the spindle. Suitable collets may also be used to mount square or hexagonal workpieces. In precision toolmaking work such collets are usually of the draw-in variety, where, as the collet is tightened, the workpiece moves slightly back into the headstock, whereas for most repetition work the dead length variety is preferred, as this ensures that the position of the workpiece does not move as the collet is tightened.

A soft workpiece (e.g., wood) may be pinched between centers by using a spur drive at the headstock, which bites into the wood and imparts torque to it.

A soft dead center is used in the headstock spindle as the work rotates with the centre. Because the centre is soft it can be trued in place before use. The included angle is 60°. Traditionally, a hard dead center is used together with suitable lubricant in the tailstock to support the workpiece. In modern practice the dead center is frequently replaced by a running or live center, as it turns freely with the workpiece—usually on ball bearings—reducing the frictional heat, especially important at high speeds. When clear facing a long length of material it must be supported at both ends. This can be achieved by the use of a traveling or fixed steady. If a steady is not available, the end face being worked on may be supported by a dead (stationary) half center. A half center has a flat surface machined across a broad section of half of its diameter at the pointed end. A small section of the tip of the dead center is retained to ensure concentricity. Lubrication must be applied at this point of contact and tail stock pressure reduced. A lathe carrier or

A soft dead center is used in the headstock spindle as the work rotates with the centre. Because the centre is soft it can be trued in place before use. The included angle is 60°. Traditionally, a hard dead center is used together with suitable lubricant in the tailstock to support the workpiece. In modern practice the dead center is frequently replaced by a running or live center, as it turns freely with the workpiece—usually on ball bearings—reducing the frictional heat, especially important at high speeds. When clear facing a long length of material it must be supported at both ends. This can be achieved by the use of a traveling or fixed steady. If a steady is not available, the end face being worked on may be supported by a dead (stationary) half center. A half center has a flat surface machined across a broad section of half of its diameter at the pointed end. A small section of the tip of the dead center is retained to ensure concentricity. Lubrication must be applied at this point of contact and tail stock pressure reduced. A lathe carrier or lathe dog

A lathe () is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, Deformation (engineering), deformation, facing (machining), facing, Threading (manufac ...

may also be employed when turning between two centers.

In woodturning, one variation of a running center is a cup center, which is a cone of metal surrounded by an annular ring of metal that decreases the chances of the workpiece splitting.

A circular metal plate with even spaced holes around the periphery, mounted to the spindle, is called an "index plate". It can be used to rotate the spindle to a precise angle, then lock it in place, facilitating repeated auxiliary operations done to the workpiece.

Other accessories, including items such as taper turning attachments, knurling tools, vertical slides, fixed and traveling steadies, etc., increase the versatility of a lathe and the range of work it may perform.

Modes of use

When a workpiece is fixed between the headstock and the tail-stock, it is said to be "between centers". When a workpiece is supported at both ends, it is more stable, and more force may be applied to the workpiece, via tools, at a right angle to the axis of rotation, without fear that the workpiece may break loose. When a workpiece is fixed only to the spindle at the headstock end, the work is said to be "face work". When a workpiece is supported in this manner, less force may be applied to the workpiece, via tools, at a right angle to the axis of rotation, lest the workpiece rip free. Thus, most work must be done axially, towards the headstock, or at right angles, but gently. When a workpiece is mounted with a certain axis of rotation, worked, then remounted with a new axis of rotation, this is referred to as "eccentric turning" or "multi-axis turning". The result is that various cross sections of the workpiece are rotationally symmetric, but the workpiece as a whole is not rotationally symmetric. This technique is used for camshafts, various types of chair legs.Sizes

Lathes are usually 'sized' by the capacity of the work that they may hold. Usually large work is held at both ends either using a chuck or other drive in the headstock and a centre in the tailstock. To maximise size, turning between centres allows the work to be as close to the headstock as possible and is used to determine the longest piece the lathe will turn: when the base of the tailstock is aligned with the end of the bed. The distance between centres gives the maximum length of work the lathe will officially hold. It is possible to get slightly longer items in if the tailstock overhangs the end of the bed but this is an ill-advised practice. Purchasing an extension or larger bed would be a wise alternative. The other dimension of the workpiece is how far off-centre it can be. This is known as the 'swing' ("The distance from the head center of a lathe to the bed or ways, or to the rest. The swing determines the diametric size of the object which is capable of being turned in the lathe; anything larger would interfere with the bed. This limit is called the swing of the bed. The swing of the rest is the size which will rotate above the rest, which lies upon the bed.") from the notion that the work 'swings' from the centre upon which it is mounted. This makes more sense with odd-shaped work but as the lathe is most often used with cylindrical work, it is useful to know the maximum diameter of work the lathe will hold. This is simply the value of the swing (or centre height above the bed) multiplied by two. For some reason, in the U.S. swing is assumed to be diameter but this is incorrect. To be clear on size, it is better, therefore, to describe the dimension as 'centre height above the bed'. As parts of the lathe reduce capacity, measurements such as 'swing over cross slide' or other named parts can be found.Varieties

The smallest lathes are "jewelers lathes" or "watchmaker lathes", which, though often small enough to be held in one hand are normally fastened to a bench. There are rare and even smaller mini lathes made for precision cutting. The workpieces machined on a jeweler's lathe are often metal, but other softer materials can also be machined. Jeweler's lathes can be used with hand-held "graver" tools or with a "compound rest" that attach to the lathe bed and allows the tool to be clamped in place and moved by a screw or lever feed. Graver tools are generally supported by a T-rest, not fixed to a cross slide or compound rest. The work is usually held in a collet, but high-precision 3 and 6-jaw chucks are also commonly employed. Common spindle bore sizes are 6 mm, 8 mm and 10 mm. The term WW refers to the Webster/Whitcomb collet and lathe, invented by the American Watch Tool Company of Waltham, Massachusetts. Most lathes commonly referred to as watchmakers lathes are of this design. In 1909, the American Watch Tool company introduced the Magnus type collet (a 10-mm body size collet) using a lathe of the same basic design, the Webster/Whitcomb Magnus. (F.W.Derbyshire, Inc. retains the trade names Webster/Whitcomb and Magnus and still produces these collets.) Two bed patterns are common: the WW (Webster Whitcomb) bed, a truncated triangular prism (found only on 8 and 10 mm watchmakers' lathes); and the continental D-style bar bed (used on both 6 mm and 8 mm lathes by firms such as Lorch and Star). Other bed designs have been used, such as a triangular prism on some Boley 6.5 mm lathes, and a V-edged bed on IME's 8 mm lathes. Smaller metalworking lathes that are larger than jewelers' lathes and can sit on a bench or table, but offer such features as tool holders and a screw-cutting gear train are called hobby lathes, and larger versions, "bench lathes" - this term also commonly applied to a special type of high-precision lathe used by toolmakers for one-off jobs. Even larger lathes offering similar features for producing or modifying individual parts are called "engine lathes". Lathes of these types do not have additional integral features for repetitive production, but rather are used for individual part production or modification as the primary role. Lathes of this size that are designed for mass manufacture, but not offering the versatile screw-cutting capabilities of the engine or bench lathe, are referred to as "second operation" lathes. Lathes with a very large spindle bore and a chuck on both ends of the spindle are called "oil field lathes". Fully automatic mechanical lathes, employing cams and gear trains for controlled movement, are called screw machines. Lathes that are controlled by a computer are CNC lathes. Lathes with the spindle mounted in a vertical configuration, instead of horizontal configuration, are called vertical lathes or vertical boring machines. They are used where very large diameters must be turned, and the workpiece (comparatively) is not very long. A lathe with a tool post that can rotate around a vertical axis, so as to present different tools towards the headstock (and the workpiece) are turret lathes. A lathe equipped with indexing plates, profile cutters, spiral or helical guides, etc., so as to enableornamental turning Ornamental turning is a type of turning, a craft that involves cutting of a work mounted in a lathe. The work can be made of any material that is suitable for being cut in this way, such as wood, bone, ivory or metal. Plain turning is work executed ...

is an ornamental lathe.

Various combinations are possible: for example, a vertical lathe can have CNC capabilities as well (such as a CNC VTL).

Lathes can be combined with other machine tools, such as a drill press

A drill press is a Drill, drilling machine suitable for quick and easy drilling of straight holes, Countersink, countersinking or Counterbore, counterboring that are perpendicular to both directions of a table surface. In comparison, it is more di ...

or vertical milling machine. These are usually referred to as combination lathes.

Uses

Woodworking

Woodworking lathes are the oldest variety, apart from pottery wheels. All other varieties are descended from these simple lathes. An adjustable horizontal metal rail, the tool-rest, between the material and the operator accommodates the positioning of shaping tools, which are usually hand-held. After shaping, it is common practice to press and slide sandpaper against the still-spinning object to smooth the surface made with the metal shaping tools. The tool-rest is usually removed during sanding, as it may be unsafe to have the operators hands between it and the spinning wood.

Many woodworking lathes can also be used for making bowls and plates. The bowl or plate needs only to be held at the bottom by one side of the lathe. It is usually attached to a metal face plate attached to the spindle. With many lathes, this operation happens on the left side of the headstock, where are no rails and therefore more clearance. In this configuration, the piece can be shaped inside and out. A specific curved tool-rest may be used to support tools while shaping the inside. Further detail can be found on the

Woodworking lathes are the oldest variety, apart from pottery wheels. All other varieties are descended from these simple lathes. An adjustable horizontal metal rail, the tool-rest, between the material and the operator accommodates the positioning of shaping tools, which are usually hand-held. After shaping, it is common practice to press and slide sandpaper against the still-spinning object to smooth the surface made with the metal shaping tools. The tool-rest is usually removed during sanding, as it may be unsafe to have the operators hands between it and the spinning wood.

Many woodworking lathes can also be used for making bowls and plates. The bowl or plate needs only to be held at the bottom by one side of the lathe. It is usually attached to a metal face plate attached to the spindle. With many lathes, this operation happens on the left side of the headstock, where are no rails and therefore more clearance. In this configuration, the piece can be shaped inside and out. A specific curved tool-rest may be used to support tools while shaping the inside. Further detail can be found on the woodturning

Woodturning is the craft of using a wood lathe with hand-held tools to cut a shape that is symmetrical around the axis of rotation. Like the potter's wheel, the wood lathe is a mechanism that can generate a variety of forms. The operator is kno ...

page.

Most woodworking lathes are designed to be operated at a speed of between 200 and 1,400 revolutions per minute, with slightly over 1,000 rpm considered optimal for most such work, and with larger workpieces requiring lower speeds.

Duplicating

One type of specialized lathe is duplicating or copying lathe. Some types of them are known as Blanchard lathe, after Thomas Blanchard. This type of lathe was able to create shapes identical to a standard pattern and it revolutionized the process of gun

One type of specialized lathe is duplicating or copying lathe. Some types of them are known as Blanchard lathe, after Thomas Blanchard. This type of lathe was able to create shapes identical to a standard pattern and it revolutionized the process of gun stock

Stocks (also capital stock, or sometimes interchangeably, shares) consist of all the Share (finance), shares by which ownership of a corporation or company is divided. A single share of the stock means fractional ownership of the corporatio ...

making in the 1820s when it was invented.

The Hermitage Museum

The State Hermitage Museum ( rus, Государственный Эрмитаж, r=Gosudarstvennyj Ermitaž, p=ɡəsʊˈdarstvʲɪn(ː)ɨj ɪrmʲɪˈtaʂ, links=no) is a museum of art and culture in Saint Petersburg, Russia, and holds the large ...

, Russia displays the copying lathe for ornamental turning Ornamental turning is a type of turning, a craft that involves cutting of a work mounted in a lathe. The work can be made of any material that is suitable for being cut in this way, such as wood, bone, ivory or metal. Plain turning is work executed ...

: making medals and guilloche patterns, designed by Andrey Nartov, 1721.

Patternmaking

Used to make apattern

A pattern is a regularity in the world, in human-made design, or in abstract ideas. As such, the elements of a pattern repeat in a predictable manner. A geometric pattern is a kind of pattern formed of geometric shapes and typically repeated l ...

for foundries, often from wood, but also plastics. A patternmaker's lathe looks like a heavy wood lathe, often with a turret and either a leadscrew

A leadscrew (or lead screw), also known as a power screw or translation screw,Bhandari, p. 202. is a screw used as a linkage in a machine, to translate turning motion into linear motion. Because of the large area of sliding contact between ...

or a rack and pinion to manually position the turret

Turret may refer to:

* Turret (architecture), a small tower that projects above the wall of a building

* Gun turret, a mechanism of a projectile-firing weapon

* Optical microscope#Objective turret (revolver or revolving nose piece), Objective turre ...

. The turret is used to accurately cut straight lines. They often have a provision to turn very large parts on the other end of the headstock, using a free-standing toolrest. Another way of turning large parts is a sliding bed, which can slide away from the headstock and thus open up a gap in front of the headstock for large parts.

Metalworking

In a metalworking lathe, metal is removed from the workpiece using a hardenedcutting tool

Cutting is the separation or opening of a physical object, into two or more portions, through the application of an acutely directed force.

Implements commonly used for cutting are the knife and saw, or in medicine and science the scalpel an ...

, which is usually fixed to a solid moveable mounting, either a tool-post or a turret, which is then moved against the workpiece using handwheels or computer-controlled motors. These cutting tools come in a wide range of sizes and shapes, depending upon their application. Some common styles are diamond, round, square and triangular.

The tool-post is operated by lead-screws that can accurately position the tool in a variety of planes. The tool-post may be driven manually or automatically to produce the roughing and finishing cuts required to ''turn'' the workpiece to the desired shape and dimensions, or for cutting threads, worm gear

A worm drive is a gear train, gear arrangement in which a worm (which is a gear in the form of a Screw thread, screw) meshes with a worm wheel (which is similar in appearance to a spur gear). Its main purpose is to translate the motion of two p ...

s, etc. Cutting fluid

Cutting fluid is a type of coolant and lubricant designed specifically for metalworking processes, such as machining and stamping. There are various kinds of cutting fluids, which include oils, oil-water emulsions, pastes, gels, aerosols (mists ...

may also be pumped to the cutting site to provide cooling, lubrication and clearing of swarf

Swarf, also known as chips or by other process-specific names (such as turnings, filings, or shavings), are pieces of metal, wood, or plastic that are the debris or waste resulting from machining, woodworking, or similar subtractive (material-r ...

from the workpiece. Some lathes

A lathe () is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, deformation, facing, threading and turning, with tools that are applied to the ...

may be operated under control of a computer

A computer is a machine that can be Computer programming, programmed to automatically Execution (computing), carry out sequences of arithmetic or logical operations (''computation''). Modern digital electronic computers can perform generic set ...

for mass production

Mass production, also known as mass production, series production, series manufacture, or continuous production, is the production of substantial amounts of standardized products in a constant flow, including and especially on assembly lines ...

of parts (see "Computer numerical control

Computer numerical control (CNC) or CNC machining is the Automation, automated control of machine tools by a computer. It is an evolution of numerical control (NC), where machine tools are directly managed by data storage media such as punched ...

").

Manually controlled metalworking lathes are commonly provided with a variable-ratio gear-train to drive the main lead-screw. This enables different thread pitches to be cut. On some older lathes or more affordable new lathes, the gear trains are changed by swapping gears with various numbers of teeth onto or off of the shafts, while more modern or expensive manually controlled lathes have a quick-change box to provide commonly used ratios by the operation of a lever. CNC lathes use computers and servomechanisms to regulate the rates of movement.

On manually controlled lathes, the thread pitches that can be cut are, in some ways, determined by the pitch of the lead-screw: A lathe with a metric

Metric or metrical may refer to:

Measuring

* Metric system, an internationally adopted decimal system of measurement

* An adjective indicating relation to measurement in general, or a noun describing a specific type of measurement

Mathematics

...

lead-screw will readily cut metric threads (including BA), while one with an imperial lead-screw will readily cut imperial-unit-based threads such as BSW or UTS (UNF, UNC). This limitation is not insurmountable, because a 127-tooth gear, called a transposing gear, is used to translate between metric and inch thread pitches. However, this is optional equipment that many lathe owners do not own. It is also a larger change-wheel than the others, and on some lathes may be larger than the change-wheel mounting banjo is capable of mounting.

The workpiece may be supported between a pair of points called centres, or it may be bolted to a faceplate or held in a chuck

Chuck () is a masculine given name or a nickname for Charles or Charlie. It may refer to:

People

Arts and entertainment

* Chuck Alaimo, American saxophonist, leader of the Chuck Alaimo Quartet

* Chuck Barris (1929–2017), American TV produce ...

. A chuck has movable jaws that can grip the workpiece securely.

There are some effects on material properties when using a metalworking lathe. There are few chemical or physical effects, but there are many mechanical effects, which include residual stress, micro-cracks, work-hardening, and tempering in hardened materials.

Cue lathes

Cue lathes function similarly to turning and spinning lathes, allowing a perfectly radially-symmetrical cut for billiard cues. They can also be used to refinish cues that have been worn over the years.Glass-working

Glass-working lathes are similar in design to other lathes, but differ markedly in how the workpiece is modified. Glass-working lathes slowly rotate a hollow glass vessel over a fixed- or variable-temperature flame. The source of the flame may be either hand-held or mounted to a banjo/cross-slide that can be moved along the lathe bed. The flame serves to soften the glass being worked, so that the glass in a specific area of the workpiece becomes ductile and subject to forming either by inflation ("glassblowing

Glassblowing is a glassforming technique that involves inflating molten glass into a bubble (or parison) with the aid of a blowpipe (or blow tube). A person who blows glass is called a ''glassblower'', ''glassmith'', or ''gaffer''. A '' lampworke ...

") or by deformation with a heat-resistant tool. Such lathes usually have two head-stocks with chucks holding the work, arranged so that they both rotate together in unison. Air can be introduced through the headstock chuck spindle for glassblowing. The tools to deform the glass and tubes to blow (inflate) the glass are usually handheld.

In diamond turning, a computer-controlled lathe with a diamond-tipped tool is used to make precision optical surfaces in glass or other optical materials. Unlike conventional optical grinding, complex aspheric surfaces can be machined easily. Instead of the dovetailed ways used on the tool slide of a metal-turning lathe, the ways typically float on air bearings, and the position of the tool is measured by optical interferometry to achieve the necessary standard of precision for optical work. The finished work piece usually requires a small amount of subsequent polishing by conventional techniques to achieve a finished surface suitably smooth for use in a lens, but the rough grinding time is significantly reduced for complex lenses.

Metal-spinning

Inmetal spinning

Metal spinning, also known as spin forming or spinning or metal turning most commonly, is a metalworking process by which a disc or tube of metal is rotated at high speed and formed into an axially symmetric part. Spinning can be performed by ha ...

, a disk of sheet metal is held perpendicularly to the main axis of the lathe, and tools with polished tips (''spoons'') or roller tips are hand-held, but levered by hand against fixed posts, to develop pressure that deforms the spinning sheet of metal.

Metal-spinning lathes are almost as simple as wood-turning lathes. Typically, metal spinning requires a mandrel, usually made from wood, which serves as the template onto which the workpiece is formed (asymmetric shapes can be made, but it is a very advanced technique). For example, to make a sheet metal

Sheet metal is metal formed into thin, flat pieces, usually by an industrial process.

Thicknesses can vary significantly; extremely thin sheets are considered foil (metal), foil or Metal leaf, leaf, and pieces thicker than 6 mm (0.25 ...

bowl, a solid block of wood in the shape of the bowl is required; similarly, to make a vase

A vase ( or ) is an open container. It can be made from a number of materials, such as ceramics, glass, non- rusting metals, such as aluminium, brass, bronze, or stainless steel. Even wood has been used to make vases, either by using tree specie ...

, a solid template of the vase is required.

Given the advent of high-speed, high-pressure, industrial die forming, metal spinning is less common now than it once was, but still a valuable technique for producing one-off prototypes or small batches, where die forming would be uneconomical.

Ornamental turning

The ornamental turning lathe was developed around the same time as the industrial screw-cutting lathe in the nineteenth century. It was used not for making practical objects, but fordecorative

Beauty is commonly described as a feature of objects that makes them pleasure, pleasurable to perceive. Such objects include landscapes, sunsets, humans and works of art. Beauty, art and taste are the main subjects of aesthetics, one of the fie ...

work: ''ornamental turning''. By using accessories such as the horizontal and vertical cutting frames, eccentric chuck

Chuck () is a masculine given name or a nickname for Charles or Charlie. It may refer to:

People

Arts and entertainment

* Chuck Alaimo, American saxophonist, leader of the Chuck Alaimo Quartet

* Chuck Barris (1929–2017), American TV produce ...

and elliptical chuck, solids of extraordinary complexity may be produced by various generative procedures.

A special-purpose lathe, the Rose engine lathe, is also used for ornamental turning, in particular for engine turning, typically in precious metals, for example to decorate pocket-watch cases. As well as a wide range of accessories, these lathes usually have complex dividing arrangements to allow the exact rotation of the mandrel. Cutting is usually carried out by rotating cutters, rather than directly by the rotation of the work itself. Because of the difficulty of polishing such work, the materials turned, such as wood or ivory, are usually quite soft, and the cutter has to be exceptionally sharp. The finest ornamental lathes are generally considered to be those made by Holtzapffel around the turn of the 19th century.

Reducing

Many types of lathes can be equipped with accessory components to allow them to reproduce an item: the original item is mounted on one spindle, the blank is mounted on another, and as both turn in synchronized manner, one end of an arm "reads" the original and the other end of the arm "carves" the duplicate. A reduction lathe is a specialized lathe that is designed with this feature and incorporates a mechanism similar to apantograph

A pantograph (, from their original use for copying writing) is a Linkage (mechanical), mechanical linkage connected in a manner based on parallelograms so that the movement of one pen, in tracing an image, produces identical movements in a se ...

, so that when the "reading" end of the arm reads a detail that measures one inch (for example), the cutting end of the arm creates an analogous detail that is (for example) one quarter of an inch (a 4:1 reduction, although given appropriate machinery and appropriate settings, any reduction ratio is possible).

Reducing lathes are used in coin-making, where a plaster original (or an epoxy master made from the plaster original, or a copper-shelled master made from the plaster original, etc.) is duplicated and reduced on the reducing lathe, generating a master die.

Rotary lathes

A lathe in which wood logs are turned against a very sharp blade and peeled off in one continuous or semi-continuous roll. Invented byImmanuel Nobel

Immanuel Nobel the Younger ( , ; 24 March 1801 – 3 September 1872) was a Swedish people, Swedish engineer, architect, inventor and industrialist. He was the inventor of the Lathe (tool), rotary lathe used in plywood manufacturing. He was a mem ...

(father of the more famous Alfred Nobel

Alfred Bernhard Nobel ( ; ; 21 October 1833 – 10 December 1896) was a Swedish chemist, inventor, engineer, and businessman. He is known for inventing dynamite, as well as having bequeathed his fortune to establish the Nobel Prizes. He also m ...

). The first such lathes in the United States were set up in the mid-19th century. The product is called wood veneer

Veneer refers to thin slices of wood and sometimes bark that typically are glued onto core panels (typically, wood, particle board or medium-density fiberboard) to produce flat panels such as doors, tops and panels for cabinets, parquet fl ...

and it is used for making plywood

Plywood is a composite material manufactured from thin layers, or "plies", of wood veneer that have been stacked and glued together. It is an engineered wood from the family of manufactured boards, which include plywood, medium-density fibreboa ...

and as a cosmetic surface veneer on some grades of chipboard.

Watchmaking

Watchmakers lathes are delicate but precise metalworking lathes, usually without provision for screwcutting, and are still used by horologists for work such as the turning of balance staffs. A handheld tool called a graver, supported by a tool-rest, is often used in preference to a slide-mounted tool. The original watchmaker's turns was a simple dead-center lathe with a moveable rest and two loose head-stocks. The workpiece would be rotated by a bow, typically ofhorsehair

Horsehair is the long hair growing on the Mane (horse), manes and Tail (horse), tails of horses. It is used for various purposes, including upholstery, brushes, the Bow (music), bows of musical instruments, a hard-wearing Textile, fabric called ...

, wrapped around it.

Transcription or recording

Transcription or recordinglathes

A lathe () is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, deformation, facing, threading and turning, with tools that are applied to the ...

are used to make grooves on a surface for recording sounds. These were used in creating sound grooves on wax cylinders and then on flat recording discs originally also made of wax, but later as lacquers on a substratum. Originally the cutting lathes were driven by sound vibrations through a horn in a process known as acoustic recording

A phonograph record (also known as a gramophone record, especially in British English) or a vinyl record (for later varieties only) is an analog sound storage medium in the form of a flat disc with an inscribed, modulated spiral groove. The g ...

and later driven by an electric current when microphone

A microphone, colloquially called a mic (), or mike, is a transducer that converts sound into an electrical signal. Microphones are used in many applications such as telephones, hearing aids, public address systems for concert halls and publi ...

s were first used in sound recording. Many such lathes were professional models, but others were developed for home recording and were common before the advent of home tape recording.

Performance

National and international standards are used to standardize the definitions, environmental requirements, and test methods used for the performance evaluation of lathes. Election of the standard to be used is an agreement between the supplier and the user and has some significance in the design of the lathe. In the United States, ASME has developed the B5.57 Standard entitled "Methods for Performance Evaluation of Computer Numerically Controlled Lathes and Turning Centers", which establishes requirements and methods for specifying and testing the performance of CNC lathes and turning centers.See also

* Diamond turning *Gun drill

Gun drills (through coolant drill) are straight fluted drills which allow cutting fluid (either compressed air or a suitable liquid) to be injected through the drill's hollow body to the cutting face. They are used for deep hole drilling—a ...

* Mandrel

A mandrel, mandril, or arbor is a tapered tool against which material can be forged, pressed, stretched or shaped (e.g., a ring mandrel - also called a triblet - used by jewellers to increase the diameter of a wedding ring), or a flanged or t ...

* Segmented turning

* Solid of revolution

In geometry, a solid of revolution is a Solid geometry, solid figure obtained by rotating a plane figure around some straight line (the ''axis of revolution''), which may not Intersection (geometry), intersect the generatrix (except at its bound ...

* Unimat

* Automatic lathe

In metalworking and woodworking, an automatic lathe is a lathe with an automation, automatically controlled cutting process. Automatic lathes were first developed in the 1870s and were mechanically controlled. From the advent of NC and CNC in t ...

, a lathe with mechanically controlled feeding

* Vertical lathe, lathe where the axis of rotation is oriented vertically, unlike most conventional lathes which are oriented horizontally

* Frontal lathe, a lathe without the option of mounting a tailstock

References

Further reading

* * * Oscar E. Perrigo.Modern American Lathe Practice. A New, Complete and Practical Work on the "king of Machine Shop Tools."

'' 1907. * * Joshua Rose.

The Complete Practical Machinist: Embracing Lathe Work, Vise Work, Drills, etc.

'' Philadelphia: H.C. Baird & Co., 1876

2nd ed. 1885

* * *

External links

Lathe Machine Operations

Modern Machine Shop Practice

a historic Victorian text describing lathe design, construction and use in the 1880s.

"The Forgotten Power Tool."

''Popular Science'', December 1959, pp. 149–152.

History of the Lathe

{{Authority control Egyptian inventions