|

Vertical Lathe

A vertical lathe is a lathe where the axis of rotation is oriented vertically, unlike most conventional lathes which are oriented horizontally. Many of them are frontal lathes, meaning they do not have the option of mounting a tailstock, but vertical lathes can also be implemented as parallel lathes. Vertical lathes can provide better surface finishes since gravity helps to load the workpiece and tool, and typically takes up less space in a workshop than a horizontal lathe. They can also be suitable for workpieces that are fragile, as gravity helps with holding the workpiece in place. The fact that the headstock rotates in the horizontal plane makes vertical lathes particularly well suited for large and heavy workpieces, as it makes clamping easier and safer. In the industry, vertical lathes can vary considerably in size, with swing diameters from under 1 meter to over 20 meters. Construction * The rotating plate is often a cast iron faceplate with T-slots for clamping w ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Francis Runner InWorkshop 300

Francis may refer to: People and characters *Pope Francis, head of the Catholic Church (2013–2025) *Francis (given name), including a list of people and fictional characters *Francis (surname) * Francis, a character played by YouTuber Boogie2988 Places * Rural Municipality of Francis No. 127, Saskatchewan, Canada *Francis, Saskatchewan, Canada **Francis (electoral district) *Francis, Nebraska, USA *Francis Township, Holt County, Nebraska, USA * Francis, Oklahoma, USA *Francis, Utah, USA Arts, entertainment, media * ''Francis'' (film), the first of a series of comedies featuring Francis the Talking Mule, voiced by Chill Wills *''Francis'', a 1983 play by Julian Mitchell *Francis (band), a Sweden-based folk band *Francis (TV series), a Indian Bengali-language animated television series Other uses *FRANCIS, a bibliographic database * ''Francis'' (1793), a colonial schooner in Australia *Francis turbine, a type of water turbine See also *Saint Francis (other) *Francis ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Way (machine Tool Element)

A way (sometimes known as a slideway, guideway, or bedway) is a type of linear bearing, specifically a linear plain bearing, in a machine tool. It facilitates precise linear motion along a given axis. A way is ground, scraped, or (less often) molded to be very flat, and ways often come in pairs to ensure a flat plane for the carriage or sliding element (slide) to move along smoothly. Ways are usually lubricated with way oil (a kind of machine oil specially made to adhere to the ways while vertical). Ways have been used since the 19th century and are a critical part of manufacturing processes, especially those requiring low tolerances such as machining. They have been made of various materials over the years, ranging from wood to cast iron, and nowadays including plastic alloys and special polymer materials. They are crafted with painstaking precision, usually being scraped into near total flatness with hand tools. This flatness is required to both provide good results in the ma ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Machining

Machining is a manufacturing process where a desired shape or part is created using the controlled removal of material, most often metal, from a larger piece of raw material by cutting. Machining is a form of subtractive manufacturing, which utilizes machine tools, in contrast to ''additive manufacturing'' (e.g. 3D printing processes, 3D printing), which uses controlled addition of material. Machining is a major process of the manufacture of many metal products, but it can also be used on other materials such as wood, plastic, ceramic, and composite material, composites. A person who specializes in machining is called a machinist. As a commercial venture, machining is generally performed in a machine shop, which consists of one or more workrooms containing primary machine tools. Although a machine shop can be a standalone operation, many businesses maintain internal machine shops or tool rooms that support their specialized needs. Much modern-day machining uses Numerical control, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

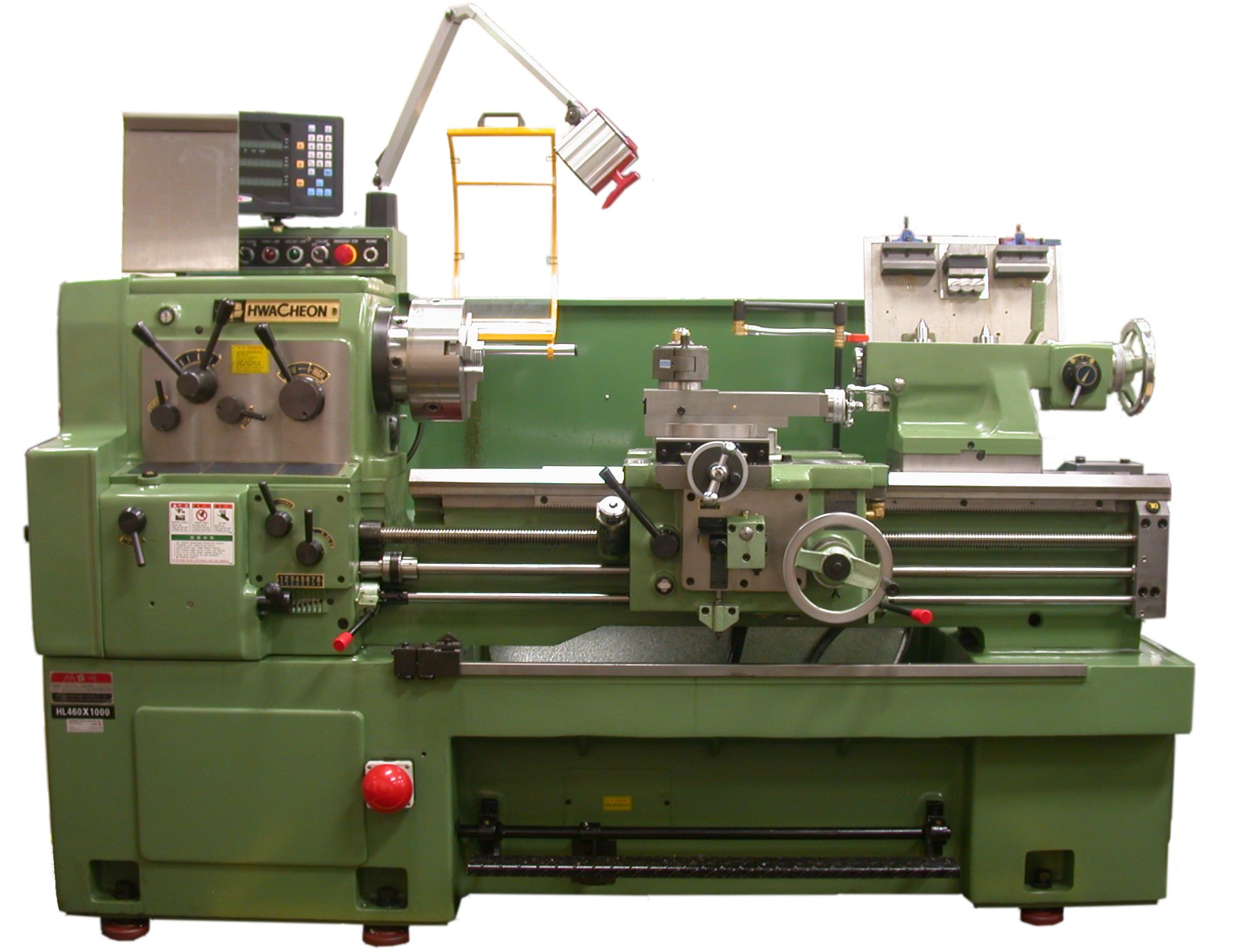

Universal Lathe

A universal lathe or parallel lathe is the most common type of lathe. It differs from other types of lathes in that it has the option of a tailstock, separate mechanisms for longitudinal and transverse feeds (typically via separate handwheels), and an automatic (usually mechanically) driven longitudinal leadscrew for making threads. Description Universal lathes are used for the production of single products or small batches, and are suitable for maintenance and similar minor work in a workshop, as well as anywhere there is a need for tools that should be as versatile as possible. On universal lathes, one can turn longitudinally, transversely, one can turn cylindrical and conical threads, Archimedean spirals, one can also bore, countersink, ream, tap threads with taps and dies, manually polish and file. Extra accessories enables ball turning, copying and grinding. There are even aftermarket accessories for milling; typically by replacing the top slide (compound) with a mi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

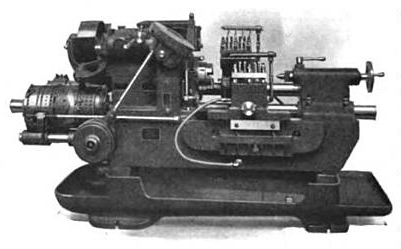

Automatic Lathe

In metalworking and woodworking, an automatic lathe is a lathe with an automation, automatically controlled cutting process. Automatic lathes were first developed in the 1870s and were mechanically controlled. From the advent of NC and CNC in the 1950s, the term automatic lathe has generally been used for only mechanically controlled lathes, although some manufacturers (e.g., DMG Mori and Tsugami) market Swiss-type CNC lathes as 'automatic'. CNC has not yet entirely displaced mechanically automated lathes, as although no longer in production, many mechanically automated lathes remain in service. General nomenclature The term "automatic lathe" is still often used in manufacturing in its earlier sense, referring to automated lathes of non-numerical control, CNC types. The first automatic lathes were mechanically automated and controlled by Cam (mechanism), cams or tracers and pantographs. Thus, before electronic automation via numerical control, the "automatic" in the term "auto ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lathe

A lathe () is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, deformation, facing, threading and turning, with tools that are applied to the workpiece to create an object with symmetry about that axis. Lathes are used in woodturning, metalworking, metal spinning, thermal spraying, reclamation, and glass-working. Lathes can be used to shape pottery, the best-known design being the Potter's wheel. Most suitably equipped metalworking lathes can also be used to produce most solids of revolution, plane surfaces and screw threads or helices. Ornamental lathes can produce three-dimensional solids of incredible complexity. The workpiece is usually held in place by either one or two ''centers'', at least one of which can typically be moved horizontally to accommodate varying workpiece lengths. Other work-holding methods include clamping the work about the axis of rotation using a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Screw Thread

A screw thread is a helical structure used to convert between rotational and linear movement or force. A screw thread is a ridge wrapped around a cylinder or cone in the form of a helix, with the former being called a ''straight'' thread and the latter called a ''tapered'' thread. A screw thread is the essential feature of the screw as a simple machine and also as a threaded fastener. The mechanical advantage of a screw thread depends on its ''lead'', which is the linear distance the screw travels in one revolution. In most applications, the lead of a screw thread is chosen so that friction is sufficient to prevent linear motion being converted to rotary, that is so the screw does not slip even when linear force is applied, as long as no external rotational force is present. This characteristic is essential to the vast majority of its uses. The tightening of a fastener's screw thread is comparable to driving a wedge into a gap until it sticks fast through friction and slight ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Reamer

A reamer is a type of rotary cutting tool used in metalworking. Precision reamers are designed to enlarge the size of a previously formed hole by a small amount but with a high degree of accuracy to leave smooth sides. There are also non-precision reamers which are used for more basic enlargement of holes or for removing Burr (edge), burrs. The process of enlarging the hole is called reaming. There are many different types of reamer and they may be designed for use as a hand tool or in a machine tool, such as a milling machine or drill press. Construction A typical reamer consists of a set of Parallel (geometry), parallel straight or helical cutting edges along the length of a Cylinder (geometry), cylindrical body. Each cutting edge is ground at a slight angle and with a slight undercut below the cutting edge. Reamers must combine both hardness in the cutting edges, for long life, and toughness, so that the tool does not fail under the normal forces of use. They should only be use ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Milling (machining)

Milling is the process of machining using rotary Milling cutter, cutters to remove material by advancing a cutter into a workpiece. This may be done by varying directions on one or several axes, cutter head speed, and pressure. Milling covers a wide variety of different operations and machines, on scales from small individual parts to large, heavy-duty gang milling operations. It is one of the most commonly used processes for machining custom parts to precise tolerances. Milling can be done with a wide range of machine tools. The original class of machine tools for milling was the milling machine (often called a mill). After the advent of computer numerical control (CNC) in the 1960s, milling machines evolved into ''machining centers'': milling machines augmented by automatic tool changers, tool magazines or carousels, CNC capability, coolant systems, and enclosures. Milling centers are generally classified as vertical machining centers (VMCs) or horizontal machining centers (HMCs ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Drilling

Drilling is a cutting process where a drill bit is spun to cut a hole of circular cross section (geometry), cross-section in solid materials. The drill bit is usually a rotary Cutting tool (machining), cutting tool, often multi-point. The bit is Pressure, pressed against the work-piece and rotated at rates from hundreds to thousands of revolutions per minute. This forces the cutting edge against the work-piece, cutting off Swarf, chips (swarf) from the hole as it is drilled. In Rock (geology), rock drilling, the hole is usually not made through a circular cutting motion, though the bit is usually rotated. Instead, the hole is usually made by hammering a drill bit into the hole with quickly repeated short movements. The hammering action can be performed from outside the hole (top-hammer drill) or within the hole (down-the-hole drill, DTH). Drills used for horizontal drilling are called drifter drills. In rare cases, specially-shaped bits are used to cut holes of non-circular cro ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Crown Gear

A crown gear (also known as a face gear or a contrate gear) is a gear which has teeth that project at right angles to the face of the wheel. In particular, a crown gear is a type of bevel gear where the pitch cone angle is 90 degrees. A pitch cone of any other angle is simply called a bevel gear. Crown gears normally mesh with other bevel gears, or sometimes spur gears, a typical use being a crown gear and pinion system which allows a rotary motion to be shifted 90 degrees. See also * Crown circle * Bevel gear Bevel gears are gears where the axes of the two shafts intersect and the tooth-bearing faces of the gears themselves are conically shaped. Bevel gears are most often mounted on shafts that are 90 degrees apart, but can be designed to work at ot ... ** Spiral bevel gear References Gears {{Mech-engineering-stub ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pinion

A pinion is a round gear—usually the smaller of two meshed gears—used in several applications, including drivetrain and rack and pinion systems. Applications Drivetrain Drivetrains usually feature a gear known as the pinion, which may vary in different systems, including * the typically smaller gear in a gear drive train (although in the first commercially successful steam locomotive—the ''Salamanca''—the ''pinion'' was rather large). In many cases, such as remote controlled toys, the pinion is also the drive gear for a reduction in speed, since electric motors operate at higher speed and lower torque than desirable at the wheels. However the reverse is true in watches, where gear trains commence with a high-torque, low-speed spring and terminate in the fast-and-weak escapement. * the smaller gear that drives in a 90-degree angle towards a crown gear in a differential drive. * the small front sprocket on a chain driven motorcycle. *the clutch bell gear when pai ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |