|

Frontal Lathe

A frontal lathe or face lathe is a type of lathe with a horizontal Headstock (lathe), headstock, and without a tailstock. They are suitable for Workpiece, workpieces with a very large diameter (in some cases over 3 meters), but with a relatively short length. Advantages include their simple and inexpensive construction, good access around the workpiece, and a good overview of the work. Disadvantages include that it can be difficult to clamp the workpiece into place safely, and that the front Bearing (mechanical), bearing on the Spindle (tool), spindle is heavily loaded, which is less favourable for accuracy. Description There are several different designs of frontal lathes. In particular, a distinction is made between lathes where the Way (machine tool element), bedway is parallel to the Axle, axis of the main spindle (similar to a universal lathe), and lathes where the bedway is perpendicular to the axis of the main spindle (similar to the letter T in a floor plan). In industr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tour Frontal

Tour or Tours may refer to: Travel * Tourism, travel for pleasure * Tour of duty, a period of time spent in military service * Campus tour, a journey through a college or university's campus * Guided tour, a journey through a location, directed by a guide * Walking tour, a visit of a historical or cultural site undertaken on foot Entertainment * Concert tour, a series of concerts by a musical artist or group of artists in different locations * Comedy tour, an organized trip where comedians travel to various places; see List of stand-up circuits * Touring theatre, independent theatre that travels to different venues Sports * Professional golf tours, otherwise unconnected professional golf tournaments * Tennis tour, tennis played in tournament format at a series of venues * Events in various sports named the Pro Tour (other) * Tour de France ('), the world's biggest bicycle race Places * Tour-de-Faure, Lot, France * Tour-en-Bessin, Calvados, France * Tour-en-Sologne, Lo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Perpendicular

In geometry, two geometric objects are perpendicular if they intersect at right angles, i.e. at an angle of 90 degrees or π/2 radians. The condition of perpendicularity may be represented graphically using the '' perpendicular symbol'', ⟂. Perpendicular intersections can happen between two lines (or two line segments), between a line and a plane, and between two planes. ''Perpendicular'' is also used as a noun: a perpendicular is a line which is perpendicular to a given line or plane. Perpendicularity is one particular instance of the more general mathematical concept of '' orthogonality''; perpendicularity is the orthogonality of classical geometric objects. Thus, in advanced mathematics, the word "perpendicular" is sometimes used to describe much more complicated geometric orthogonality conditions, such as that between a surface and its '' normal vector''. A line is said to be perpendicular to another line if the two lines intersect at a right angle. Explicitly, a fi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Automatic Lathe

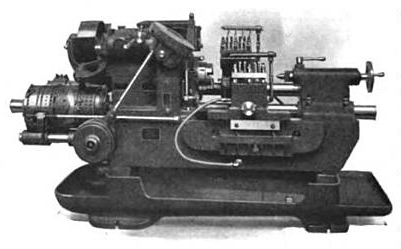

In metalworking and woodworking, an automatic lathe is a lathe with an automation, automatically controlled cutting process. Automatic lathes were first developed in the 1870s and were mechanically controlled. From the advent of NC and CNC in the 1950s, the term automatic lathe has generally been used for only mechanically controlled lathes, although some manufacturers (e.g., DMG Mori and Tsugami) market Swiss-type CNC lathes as 'automatic'. CNC has not yet entirely displaced mechanically automated lathes, as although no longer in production, many mechanically automated lathes remain in service. General nomenclature The term "automatic lathe" is still often used in manufacturing in its earlier sense, referring to automated lathes of non-numerical control, CNC types. The first automatic lathes were mechanically automated and controlled by Cam (mechanism), cams or tracers and pantographs. Thus, before electronic automation via numerical control, the "automatic" in the term "auto ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Vertical Lathe

A vertical lathe is a lathe where the axis of rotation is oriented vertically, unlike most conventional lathes which are oriented horizontally. Many of them are frontal lathes, meaning they do not have the option of mounting a tailstock, but vertical lathes can also be implemented as parallel lathes. Vertical lathes can provide better surface finishes since gravity helps to load the workpiece and tool, and typically takes up less space in a workshop than a horizontal lathe. They can also be suitable for workpieces that are fragile, as gravity helps with holding the workpiece in place. The fact that the headstock rotates in the horizontal plane makes vertical lathes particularly well suited for large and heavy workpieces, as it makes clamping easier and safer. In the industry, vertical lathes can vary considerably in size, with swing diameters from under 1 meter to over 20 meters. Construction * The rotating plate is often a cast iron faceplate with T-slots for clamping w ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Prototyping

A prototype is an early sample, model, or release of a product built to test a concept or process. It is a term used in a variety of contexts, including semantics, design, electronics, and software programming. A prototype is generally used to evaluate a new design to enhance precision by system analysts and users. Prototyping serves to provide specifications for a real, working system rather than a theoretical one. Physical prototyping has a long history, and paper prototyping and virtual prototyping now extensively complement it. In some design workflow models, creating a prototype (a process sometimes called materialization) is the step between the formalization and the evaluation of an idea. A prototype can also mean a typical example of something such as in the use of the derivation prototypical. This is a useful term in identifying objects, behaviours and concepts which are considered the accepted norm and is analogous with terms such as stereotypes and archetypes. T ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Watchmaking

A watchmaker is an artisan who makes and repairs watches. Since a majority of watches are now factory-made, most modern watchmakers only repair watches. However, originally they were master craftsmen who built watches, including all their parts, by hand. Modern watchmakers, when required to repair older watches, for which replacement parts may not be available, must have fabrication skills, and can typically manufacture replacements for many of the parts found in a watch. The term clockmaker refers to an equivalent occupation specializing in clocks. Most practising professional watchmakers service current or recent production watches. They seldom fabricate replacement parts. Instead they obtain and fit factory spare parts applicable to the watch brand being serviced. The majority of modern watchmakers, particularly in Switzerland and other countries in Europe, work directly for the watchmaking industry and may have completed a formal watchmaking degree at a technical school ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Turret Lathe

A turret lathe is a form of lathe (metal), metalworking lathe that is used for repetitive production of duplicate parts, which by the nature of their cutting process are usually interchangeable parts, interchangeable. It evolved from earlier lathes with the addition of the ''turret'', which is an indexing (motion), indexable toolholder that allows multiple cutting operations to be performed, each with a different Cutting tool (machining), cutting tool, in easy, rapid succession, with no need for the operator to perform set-up tasks in between (such as installing or uninstalling tools) or to control the toolpath. The latter is due to the toolpath's being controlled by the machine, either in jig (tool), jig-like fashion, via the mechanical limits placed on it by the turret's slide and stops, or via Digital electronics, digitally-directed servomechanisms for computer numerical control lathes. The name derives from the way early turrets took the general form of a flattened cylindrical ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Numerical Control

Computer numerical control (CNC) or CNC machining is the automated control of machine tools by a computer. It is an evolution of numerical control (NC), where machine tools are directly managed by data storage media such as punched cards or punched tape. Because CNC allows for easier programming, modification, and real-time adjustments, it has gradually replaced NC as computing costs declined. A CNC machine is a motorized maneuverable tool and often a motorized maneuverable platform, which are both controlled by a computer, according to specific input instructions. Instructions are delivered to a CNC machine in the form of a sequential program of machine control instructions such as G-code and M-code, and then executed. The program can be written by a person or, far more often, generated by graphical computer-aided design (CAD) or computer-aided manufacturing (CAM) software. In the case of 3D printers, the part to be printed is "sliced" before the instructions (or the prog ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Universal Lathe

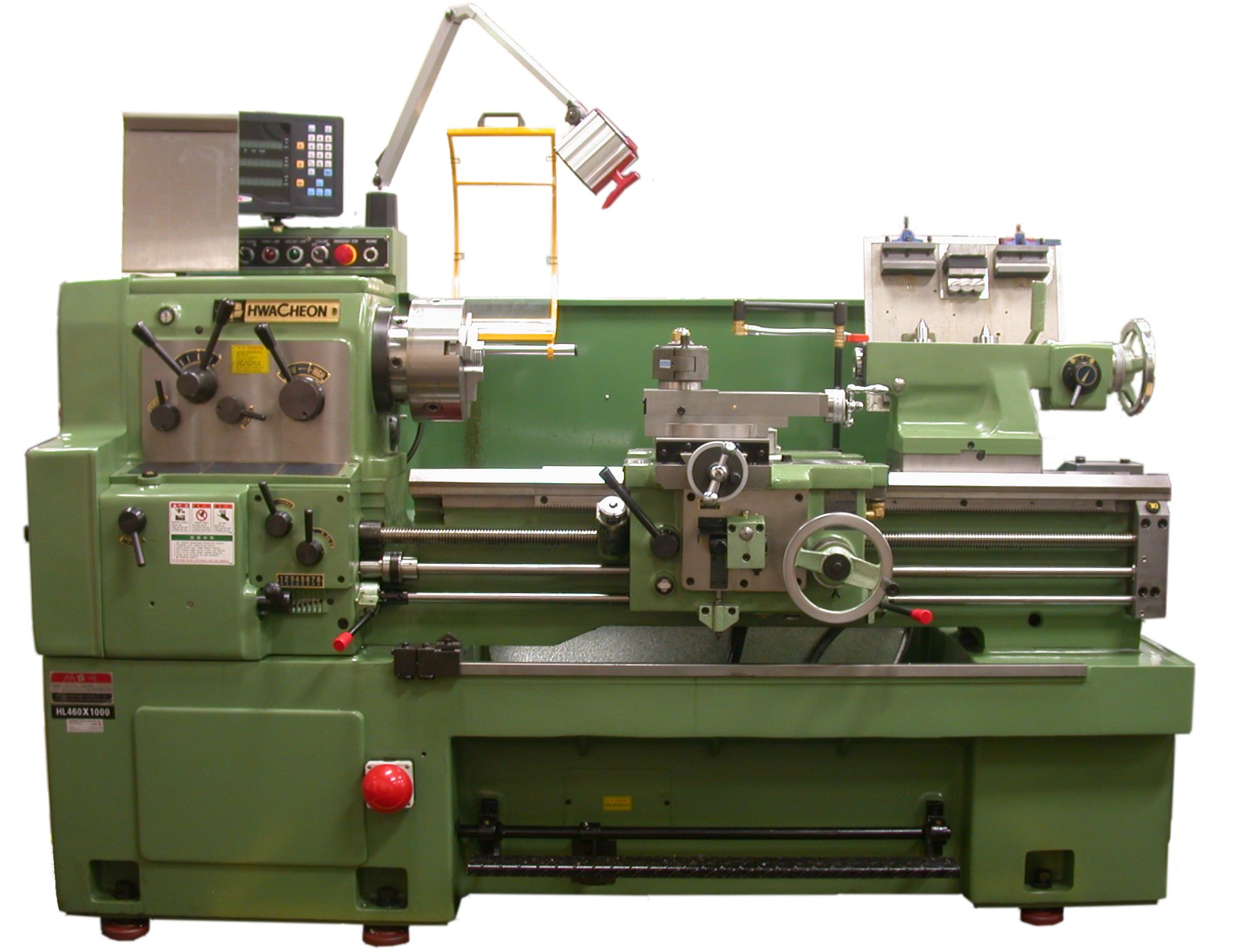

A universal lathe or parallel lathe is the most common type of lathe. It differs from other types of lathes in that it has the option of a tailstock, separate mechanisms for longitudinal and transverse feeds (typically via separate handwheels), and an automatic (usually mechanically) driven longitudinal leadscrew for making threads. Description Universal lathes are used for the production of single products or small batches, and are suitable for maintenance and similar minor work in a workshop, as well as anywhere there is a need for tools that should be as versatile as possible. On universal lathes, one can turn longitudinally, transversely, one can turn cylindrical and conical threads, Archimedean spirals, one can also bore, countersink, ream, tap threads with taps and dies, manually polish and file. Extra accessories enables ball turning, copying and grinding. There are even aftermarket accessories for milling; typically by replacing the top slide (compound) with a mi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Floor Plan

In architecture and building engineering, a floor plan is a technical drawing to scale, showing a view from above, of the relationships between rooms, spaces, traffic patterns, and other physical features at one level of a structure. Dimensions are usually drawn between the walls to specify room sizes and wall lengths. Floor plans may also include details of fixtures like sinks, water heaters, furnaces, etc. Floor plans may include notes for construction to specify finishes, construction methods, or symbols for electrical items. It is also called a ''plan'' which is a measured plane typically projected at the floor height of , as opposed to an ''elevation'' which is a measured plane projected from the side of a building, along its height, or a section or '' cross section'' where a building is cut along an axis to reveal the interior structure. Overview Similar to a map, the orientation of the view is downward from above, but unlike a conventional map, a plan is drawn at a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Axle

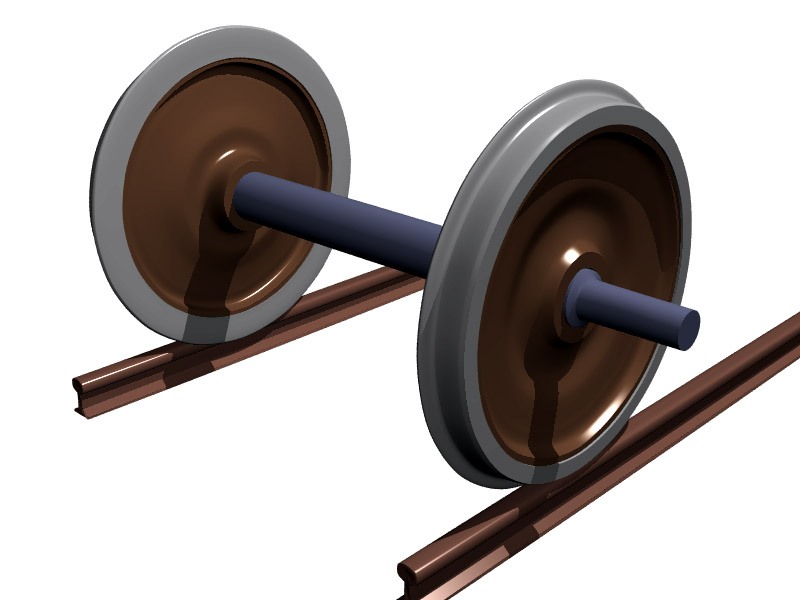

An axle or axletree is a central shaft for a rotation, rotating wheel and axle, wheel or gear. On wheeled vehicles, the axle may be fixed to the wheels, rotating with them, or fixed to the vehicle, with the wheels rotating around the axle. In the former case, bearing (mechanical), bearings or Bushing (bearing), bushings are provided at the mounting points where the axle is supported. In the latter case, a bearing or bushing sits inside a central hole in the wheel to allow the wheel or gear to rotate around the axle. Sometimes, especially on bicycles, the latter type of axle is referred to as a ''spindle (tool), spindle''. Terminology On cars and trucks, several senses of the word ''axle'' occur in casual usage, referring to the shaft itself, its housing, or simply any transverse pair of wheels. Strictly speaking, a shaft that rotates with the wheel, being either Bolt (fastener), bolted or rotating spline, splined in fixed relation to it, is called an ''axle'' or ''axle shaft ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lathe

A lathe () is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, deformation, facing, threading and turning, with tools that are applied to the workpiece to create an object with symmetry about that axis. Lathes are used in woodturning, metalworking, metal spinning, thermal spraying, reclamation, and glass-working. Lathes can be used to shape pottery, the best-known design being the Potter's wheel. Most suitably equipped metalworking lathes can also be used to produce most solids of revolution, plane surfaces and screw threads or helices. Ornamental lathes can produce three-dimensional solids of incredible complexity. The workpiece is usually held in place by either one or two ''centers'', at least one of which can typically be moved horizontally to accommodate varying workpiece lengths. Other work-holding methods include clamping the work about the axis of rotation using a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |