Fischer–Tropsch process on:

[Wikipedia]

[Google]

[Amazon]

The Fischer–Tropsch process (FT) is a collection of

The Fischer–Tropsch process (FT) is a collection of

8 CO + 17 H2 -> C8H18 + 8 H2O

Fischer–Tropsch plants associated with

Fischer–Tropsch plants associated with

H2O + CO -> H2 + CO2

For FT plants that use CH4 + CO2 -> 2CO + 2H2

: This type of reactor contains several tubes with small diameters. These tubes contain catalysts and are surrounded by cooling water which removes the heat of the reaction. A fixed-bed reactor is suitable for operation at low temperatures and has an upper-temperature limit of 257 °C (530 K). Excess temperature leads to carbon deposition and hence blockage of the reactor. Since large amounts of the products formed are in liquid state, this type of reactor can also be referred to as a trickle flow reactor system.

: This type of reactor contains several tubes with small diameters. These tubes contain catalysts and are surrounded by cooling water which removes the heat of the reaction. A fixed-bed reactor is suitable for operation at low temperatures and has an upper-temperature limit of 257 °C (530 K). Excess temperature leads to carbon deposition and hence blockage of the reactor. Since large amounts of the products formed are in liquid state, this type of reactor can also be referred to as a trickle flow reactor system.

Four metals are active as

Four metals are active as

after the site was sold to another joint venture partner for $4.15 million

The company's Fischer-Tropsch reactors were used by TOYO Engineering Corporation to produce sustainable aviation fuel (SAF) from woodchips at its demonstration plant in Nagoya, Japan in 2020

The produced fuel was used in flight JL 515 from Tokyo to Sapporo on June 17, 2021

marking the first time aviation fuel derived from gasified woodchips and synthesized into SAF was used in a commercial flight.

In 2010, INFRA built a compact Pilo

In 2010, INFRA built a compact Pilo

Plant

for conversion of natural gas into synthetic oil. The plant modeled the full cycle of the GTL chemical process including the intake of pipeline gas, sulfur removal, steam methane reforming, syngas conditioning, and Fischer–Tropsch synthesis. In 2013 the first pilot plant was acquired by VNIIGAZ

another batch of synthetic jet fuel was manufactured for the Air Force by Twelve and Emerging Fuels Technology

- the latter being Syntroleum's successor company which was established by the founders and management team of Syntroleum and having bought its laboratory in Tulsa.

Fischer–Tropsch archives

Fischer–Tropsch fuels from coal and biomass

Abiogenic gas debate (AAPG Explorer Nov. 2002)

Gas origin theories to be studied (AAPG Explorer Nov. 2002)

* '' ttps://web.archive.org/web/20051106005801/http://www.fischer-tropsch.org/primary_documents/patents/GB/gb309002.pdf Process of synthesis of liquid hydrocarbons' – Great Britain patent GB309002 – Hermann Plauson *

Clean diesel from coal

' by Kevin Bullis *

Implementing the "Hydrogen Economy" with Synfuels (pdf)

'

Carbon-to-liquids research

Effect of alkali metals on cobalt catalysts

{{DEFAULTSORT:Fischer-Tropsch Process Biofuels technology Catalysis Coal Organometallic chemistry Petroleum production Synthetic fuel technologies German inventions 1925 in science 1925 in Germany Organic redox reactions Name reactions

The Fischer–Tropsch process (FT) is a collection of

The Fischer–Tropsch process (FT) is a collection of chemical reaction

A chemical reaction is a process that leads to the chemistry, chemical transformation of one set of chemical substances to another. When chemical reactions occur, the atoms are rearranged and the reaction is accompanied by an Gibbs free energy, ...

s that converts a mixture of carbon monoxide

Carbon monoxide (chemical formula CO) is a poisonous, flammable gas that is colorless, odorless, tasteless, and slightly less dense than air. Carbon monoxide consists of one carbon atom and one oxygen atom connected by a triple bond. It is the si ...

and hydrogen

Hydrogen is a chemical element; it has chemical symbol, symbol H and atomic number 1. It is the lightest and abundance of the chemical elements, most abundant chemical element in the universe, constituting about 75% of all baryon, normal matter ...

, known as syngas

Syngas, or synthesis gas, is a mixture of hydrogen and carbon monoxide in various ratios. The gas often contains some carbon dioxide and methane. It is principally used for producing ammonia or methanol. Syngas is combustible and can be used as ...

, into liquid hydrocarbon

In organic chemistry, a hydrocarbon is an organic compound consisting entirely of hydrogen and carbon. Hydrocarbons are examples of group 14 hydrides. Hydrocarbons are generally colourless and Hydrophobe, hydrophobic; their odor is usually fain ...

s. These reactions occur in the presence of metal catalysts

Catalysis () is the increase in reaction rate, rate of a chemical reaction due to an added substance known as a catalyst (). Catalysts are not consumed by the reaction and remain unchanged after it. If the reaction is rapid and the catalyst ...

, typically at temperatures of and pressures of one to several tens of atmospheres. The Fischer–Tropsch process is an important reaction in both coal liquefaction

Coal liquefaction is a process of converting coal into liquid hydrocarbons: liquid fuels and petrochemicals. This process is often known as "coal to X" or "carbon to X", where X can be many different hydrocarbon-based products. However, the most c ...

and gas to liquids

Gas to liquids (GTL) is a oil refinery, refinery process to convert natural gas or other gaseous hydrocarbons into longer-chain hydrocarbons, such as gasoline or diesel fuel. Methane-rich gases are converted into liquid synthetic fuels. Two general ...

technology for producing liquid hydrocarbons.

In the usual implementation, carbon monoxide and hydrogen, the feedstocks for FT, are produced from coal

Coal is a combustible black or brownish-black sedimentary rock, formed as rock strata called coal seams. Coal is mostly carbon with variable amounts of other Chemical element, elements, chiefly hydrogen, sulfur, oxygen, and nitrogen.

Coal i ...

, natural gas

Natural gas (also fossil gas, methane gas, and gas) is a naturally occurring compound of gaseous hydrocarbons, primarily methane (95%), small amounts of higher alkanes, and traces of carbon dioxide and nitrogen, hydrogen sulfide and helium ...

, or biomass

Biomass is a term used in several contexts: in the context of ecology it means living organisms, and in the context of bioenergy it means matter from recently living (but now dead) organisms. In the latter context, there are variations in how ...

in a process known as gasification

Gasification is a process that converts biomass- or fossil fuel-based carbonaceous materials into gases, including as the largest fractions: nitrogen (N2), carbon monoxide (CO), hydrogen (H2), and carbon dioxide (). This is achieved by reacting ...

. The process then converts these gases into synthetic lubrication oil and synthetic fuel

Synthetic fuel or synfuel is a liquid fuel, or sometimes Fuel gas, gaseous fuel, obtained from syngas, a mixture of carbon monoxide and hydrogen, in which the syngas was derived from gasification of solid feedstocks such as coal or biomass or by ...

. This process has received intermittent attention as a source of low-sulfur diesel fuel and to address the supply or cost of petroleum-derived hydrocarbons. Fischer–Tropsch process is discussed as a step of producing carbon-neutral liquid hydrocarbon fuels from CO2 and hydrogen.

The process was first developed by Franz Fischer and Hans Tropsch at the Kaiser Wilhelm Institute for Coal Research in Mülheim an der Ruhr

Mülheim, officially Mülheim an der Ruhr (, ; ; ) and also described as ''"City on the River"'', is a city in North Rhine-Westphalia in western Germany. It is located in the Ruhr Area between Duisburg, Essen, Oberhausen and Ratingen. It is home ...

, Germany, in 1925.

Reaction mechanism

144px, Methylidynetricobaltnonacarbonyl, Methylidynetricobaltnonacarbonyl is a molecule that illustrates the kind of reduced carbon species speculated to occur in the Fischer–Tropsch process. The Fischer–Tropsch process involves a series of chemical reactions that produce a variety of hydrocarbons, ideally having the formula (C''n''H2''n''+2). The more useful reactions producealkane

In organic chemistry, an alkane, or paraffin (a historical trivial name that also has other meanings), is an acyclic saturated hydrocarbon. In other words, an alkane consists of hydrogen and carbon atoms arranged in a tree structure in whi ...

s as follows:

: (2''n'' + 1) H2 + ''n'' CO → C''n''H2''n''+2 + ''n'' H2O

where ''n'' is typically 10–20, resulting mostly in the formation of higher alkanes 320px

Higher alkanes are alkanes with a high number of carbon atoms. It is common jargon. One definition says higher alkanes are alkanes having nine or more carbon atoms. Thus, according to this definition, nonane is the lightest higher alkane ...

. The formation of methane

Methane ( , ) is a chemical compound with the chemical formula (one carbon atom bonded to four hydrogen atoms). It is a group-14 hydride, the simplest alkane, and the main constituent of natural gas. The abundance of methane on Earth makes ...

(''n'' = 1) is unwanted. Most of the alkanes produced tend to be straight-chain, suitable as diesel fuel

Diesel fuel, also called diesel oil, heavy oil (historically) or simply diesel, is any liquid fuel specifically designed for use in a diesel engine, a type of internal combustion engine in which fuel ignition takes place without a spark as a re ...

. In addition to alkane formation, competing reactions give small amounts of alkenes

In organic chemistry, an alkene, or olefin, is a hydrocarbon containing a carbon–carbon double bond. The double bond may be internal or at the terminal position. Terminal alkenes are also known as Alpha-olefin, α-olefins.

The Internationa ...

, as well as alcohols

In chemistry, an alcohol (), is a type of organic compound that carries at least one hydroxyl () functional group bound to a Saturated and unsaturated compounds, saturated carbon atom. Alcohols range from the simple, like methanol and ethanol ...

and other oxygenated hydrocarbons.

The reaction is a highly exothermic reaction

In thermochemistry, an exothermic reaction is a "reaction for which the overall standard enthalpy change Δ''H''⚬ is negative." Exothermic reactions usually release heat. The term is often confused with exergonic reaction, which IUPAC define ...

due to a standard reaction enthalpy (ΔH) of −165 kJ/mol CO combined.

Fischer–Tropsch intermediates and elemental reactions

Converting a mixture of H2 and CO intoaliphatic

In organic chemistry, hydrocarbons ( compounds composed solely of carbon and hydrogen) are divided into two classes: aromatic compounds and aliphatic compounds (; G. ''aleiphar'', fat, oil). Aliphatic compounds can be saturated (in which all ...

products is a multi-step reaction with several intermediate compounds. The growth of the hydrocarbon chain may be visualized as involving a repeated sequence in which hydrogen atoms are added to carbon and oxygen, the C–O bond is split and a new C–C bond is formed.

For one –CH2– group produced by CO + 2 H2 → (CH2) + H2O, several reactions are necessary:

* Associative adsorption of CO

* Splitting of the C–O bond

* Dissociative adsorption of 2 H2

* Transfer of 2 H to the oxygen to yield H2O

* Desorption of H2O

* Transfer of 2 H to the carbon to yield CH2

The conversion of CO to alkanes involves hydrogenation

Hydrogenation is a chemical reaction between molecular hydrogen (H2) and another compound or element, usually in the presence of a catalyst such as nickel, palladium or platinum. The process is commonly employed to redox, reduce or Saturated ...

of CO, the hydrogenolysis

Hydrogenolysis is a chemical reaction whereby a carbon–carbon or carbon–heteroatom single bond is cleaved or undergoes lysis (breakdown) by hydrogen.Ralph Connor, Homer Adkins. Hydrogenolysis Of Oxygenated Organic Compounds. J. Am. Chem. Soc. ...

(cleavage with H2) of C–O bonds, and the formation of C–C bonds. Such reactions are assumed to proceed via initial formation of surface-bound metal carbonyl

A metal () is a material that, when polished or fractured, shows a lustrous appearance, and conducts electricity and heat relatively well. These properties are all associated with having electrons available at the Fermi level, as against n ...

s. The CO ligand

In coordination chemistry, a ligand is an ion or molecule with a functional group that binds to a central metal atom to form a coordination complex. The bonding with the metal generally involves formal donation of one or more of the ligand's el ...

is speculated to undergo dissociation, possibly into oxide and carbide

In chemistry, a carbide usually describes a compound composed of carbon and a metal. In metallurgy, carbiding or carburizing is the process for producing carbide coatings on a metal piece.

Interstitial / Metallic carbides

The carbides of th ...

ligands. Other potential intermediates are various C1 fragments including formyl (CHO), hydroxycarbene (HCOH), hydroxymethyl (CH2OH), methyl

In organic chemistry, a methyl group is an alkyl derived from methane, containing one carbon atom bonded to three hydrogen atoms, having chemical formula (whereas normal methane has the formula ). In formulas, the group is often abbreviated as ...

(CH3), methylene (CH2), methylidyne

Methylidyne, or (unsubstituted) carbyne, is an organic compound whose molecule consists of a single hydrogen atom bonded to a carbon atom. It is the parent compound of the carbynes, which can be seen as obtained from it by substitution of other f ...

(CH), and hydroxymethylidyne (COH). Furthermore, and critical to the production of liquid fuels, are reactions that form C–C bonds, such as migratory insertion. Many related stoichiometric reactions have been simulated on discrete metal clusters, but homogeneous Fischer–Tropsch catalysts are of no commercial importance.

Addition of isotopically labelled alcohol to the feed stream results in incorporation of alcohols into product. This observation establishes the facility of C–O bond scission. Using 14C-labelled ethylene

Ethylene (IUPAC name: ethene) is a hydrocarbon which has the formula or . It is a colourless, flammable gas with a faint "sweet and musky" odour when pure. It is the simplest alkene (a hydrocarbon with carbon–carbon bond, carbon–carbon doub ...

and propene

Propylene, also known as propene, is an unsaturated organic compound with the chemical formula . It has one double bond, and is the second simplest member of the alkene class of hydrocarbons. It is a colorless gas with a faint petroleum-like od ...

over cobalt catalysts results in incorporation of these olefins into the growing chain. Chain growth reaction thus appears to involve both 'olefin insertion' as well as 'CO-insertion'.

:Feedstocks: gasification

Fischer–Tropsch plants associated with

Fischer–Tropsch plants associated with biomass

Biomass is a term used in several contexts: in the context of ecology it means living organisms, and in the context of bioenergy it means matter from recently living (but now dead) organisms. In the latter context, there are variations in how ...

or coal or related solid feedstocks (sources of carbon) must first convert the solid fuel into gases. These gases include CO, H2, and alkanes. This conversion is called gasification

Gasification is a process that converts biomass- or fossil fuel-based carbonaceous materials into gases, including as the largest fractions: nitrogen (N2), carbon monoxide (CO), hydrogen (H2), and carbon dioxide (). This is achieved by reacting ...

. Synthesis gas

Syngas, or synthesis gas, is a mixture of hydrogen and carbon monoxide in various ratios. The gas often contains some carbon dioxide and methane. It is principally used for producing ammonia or methanol. Syngas is combustible and can be used as ...

("syngas") is obtained from biomass/coal gasification is a mixture of hydrogen and carbon monoxide. The H2:CO ratio is adjusted using the water-gas shift reaction. Coal-based FT plants produce varying amounts of CO2, depending upon the energy source of the gasification process. However, most coal-based plants rely on the feed coal to supply all the energy requirements of the process.

Feedstocks: GTL

Carbon monoxide for FT catalysis is derived from hydrocarbons. Ingas to liquids

Gas to liquids (GTL) is a oil refinery, refinery process to convert natural gas or other gaseous hydrocarbons into longer-chain hydrocarbons, such as gasoline or diesel fuel. Methane-rich gases are converted into liquid synthetic fuels. Two general ...

(GTL) technology, the hydrocarbons are low molecular weight materials that often would be discarded or flared. Stranded gas provides relatively cheap gas. For GTL to be commercially viable, gas must remain relatively cheaper than oil.

Several reactions are required to obtain the gaseous reactants required for FT catalysis

Catalysis () is the increase in rate of a chemical reaction due to an added substance known as a catalyst (). Catalysts are not consumed by the reaction and remain unchanged after it. If the reaction is rapid and the catalyst recycles quick ...

. First, reactant gases entering a reactor must be desulfurized. Otherwise, sulfur-containing impurities deactivate ("poison

A poison is any chemical substance that is harmful or lethal to living organisms. The term is used in a wide range of scientific fields and industries, where it is often specifically defined. It may also be applied colloquially or figurati ...

") the catalyst

Catalysis () is the increase in rate of a chemical reaction due to an added substance known as a catalyst (). Catalysts are not consumed by the reaction and remain unchanged after it. If the reaction is rapid and the catalyst recycles quick ...

s required for FT reactions.

Several reactions are employed to adjust the H2:CO ratio. Most important is the water-gas shift reaction, which provides a source of hydrogen

Hydrogen is a chemical element; it has chemical symbol, symbol H and atomic number 1. It is the lightest and abundance of the chemical elements, most abundant chemical element in the universe, constituting about 75% of all baryon, normal matter ...

at the expense of carbon monoxide:

:methane

Methane ( , ) is a chemical compound with the chemical formula (one carbon atom bonded to four hydrogen atoms). It is a group-14 hydride, the simplest alkane, and the main constituent of natural gas. The abundance of methane on Earth makes ...

as the feedstock

A raw material, also known as a feedstock, unprocessed material, or primary commodity, is a basic material that is used to produce goods, finished goods, energy, or intermediate materials/Intermediate goods that are feedstock for future finishe ...

, another important reaction is dry reforming, which converts the methane into CO and H2:

: Process conditions

Generally, the Fischer–Tropsch process is operated in the temperature range of . Higher temperatures lead to faster reactions and higher conversion rates but also tend to favor methane production. For this reason, the temperature is usually maintained at the low to middle part of the range. Increasing the pressure leads to higher conversion rates and also favors the formation of long-chainedalkane

In organic chemistry, an alkane, or paraffin (a historical trivial name that also has other meanings), is an acyclic saturated hydrocarbon. In other words, an alkane consists of hydrogen and carbon atoms arranged in a tree structure in whi ...

s, both of which are desirable. Typical pressures range from one to several tens of atmospheres. Even higher pressures would be favorable, but the benefits may not justify the additional costs of high-pressure equipment, and higher pressures can lead to catalyst deactivation via coke formation.

A variety of synthesis-gas compositions can be used. For cobalt-based catalysts the optimal H2:CO ratio is around 1.8–2.1. Iron

Iron is a chemical element; it has symbol Fe () and atomic number 26. It is a metal that belongs to the first transition series and group 8 of the periodic table. It is, by mass, the most common element on Earth, forming much of Earth's o ...

-based catalysts can tolerate lower ratios, due to their intrinsic water-gas shift reaction activity. This reactivity can be important for synthesis gas derived from coal or biomass, which tend to have relatively low H2:CO ratios (< 1).

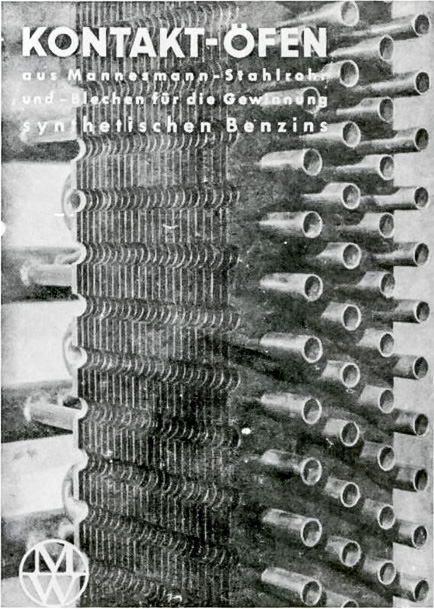

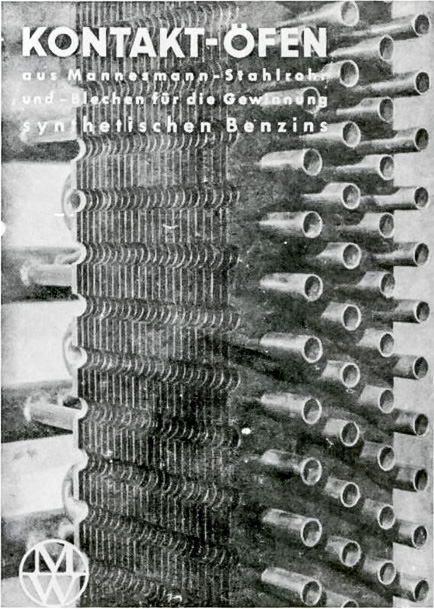

Design of the Fischer–Tropsch process reactor

Efficient removal of heat from the reactor is the basic need of FT reactors since these reactions are characterized by high exothermicity. Four types of reactors are discussed:Multi tubular fixed-bed reactor

: This type of reactor contains several tubes with small diameters. These tubes contain catalysts and are surrounded by cooling water which removes the heat of the reaction. A fixed-bed reactor is suitable for operation at low temperatures and has an upper-temperature limit of 257 °C (530 K). Excess temperature leads to carbon deposition and hence blockage of the reactor. Since large amounts of the products formed are in liquid state, this type of reactor can also be referred to as a trickle flow reactor system.

: This type of reactor contains several tubes with small diameters. These tubes contain catalysts and are surrounded by cooling water which removes the heat of the reaction. A fixed-bed reactor is suitable for operation at low temperatures and has an upper-temperature limit of 257 °C (530 K). Excess temperature leads to carbon deposition and hence blockage of the reactor. Since large amounts of the products formed are in liquid state, this type of reactor can also be referred to as a trickle flow reactor system.

Entrained flow reactor

:This type of reactor contains two banks of heat exchangers which remove heat; the remainder of which is removed by the products and recycled in the system. The formation of heavy waxes should be avoided, since they condense on the catalyst and form agglomerations. This leads to fluidization. Hence, risers are operated over 297 °C (570 K).Slurry reactors

:Heat removal is done by internal cooling coils. The synthesis gas is bubbled through the waxy products and finely-divided catalyst which is suspended in the liquid medium. This also provides agitation of the contents of the reactor. The catalyst particle size reduces diffusional heat and mass transfer limitations. A lower temperature in the reactor leads to a more viscous product and a higher temperature (> 297 °C, 570 K) gives an undesirable product spectrum. Also, separation of the product from the catalyst is a problem.Fluid-bed and circulating catalyst (riser) reactors

:These are used for high-temperature FT synthesis (nearly 340 °C) to produce low-molecular-weight unsaturated hydrocarbons on alkalized fused iron catalysts. The fluid-bed technology (as adapted from the catalytic cracking of heavy petroleum distillates) was introduced by Hydrocarbon Research in 1946–50 and named the 'Hydrocol' process. A large scale Fischer–Tropsch Hydrocol plant (350,000 tons per annum) operated during 1951–57 in Brownsville, Texas. Due to technical problems, and impractical economics due to increasing petroleum availability, this development was discontinued. Fluid-bed FT synthesis has been reinvestigated bySasol

Sasol Limited, commonly referred to as Sasol, is an integrated energy and chemical company based in Sandton, South Africa.

The company was formed in 1950 in Sasolburg, South Africa, and built around coal liquefaction processes that German ...

. One reactor with a capacity of 500,000 tons per annum is in operation. The process has been used for C2 and C7 alkene production. A high-temperature process with a circulating iron catalyst ('circulating fluid bed', 'riser reactor', 'entrained catalyst process') was introduced by the Kellogg Company and a respective plant built at Sasol in 1956. It was improved by Sasol for successful operation. At Secunda, South Africa, Sasol operated 16 advanced reactors of this type with a capacity of approximately 330,000 tons per annum each. The circulating catalyst process can be replaced by fluid-bed technology. Early experiments with cobalt catalyst particles suspended in oil have been performed by Fischer. The bubble column reactor with a powdered iron slurry catalyst and a CO-rich syngas was particularly developed to pilot plant scale by Kölbel at the Rheinpreuben Company in 1953. Since 1990, low-temperature FT slurry processes are under investigation for the use of iron and cobalt catalysts, particularly for the production of a hydrocarbon wax, or to be hydrocracked and isomerized to produce diesel fuel, by Exxon and Sasol. Slurry-phase (bubble column) low-temperature FT synthesis is efficient. This technology is also under development by the Statoil Company (Norway) for use on a vessel to convert associated gas at offshore oil fields into a hydrocarbon liquid.

Product distribution

In general the product distribution of hydrocarbons formed during the Fischer–Tropsch process follows an Anderson–Schulz–Flory distribution, which can be expressed as: : = (1 − ''α'')2''α''''n''−1 where ''W''''n'' is the weight fraction of hydrocarbons containing ''n'' carbon atoms, and ''α'' is the chain growth probability or the probability that a molecule will continue reacting to form a longer chain. In general, α is largely determined by the catalyst and the specific process conditions. Examination of the above equation reveals that methane will always be the largest single product so long as ''α'' is less than 0.5; however, by increasing ''α'' close to one, the total amount of methane formed can be minimized compared to the sum of all of the various long-chained products. Increasing ''α'' increases the formation of long-chained hydrocarbons. The very long-chained hydrocarbons are waxes, which are solid at room temperature. Therefore, for production of liquid transportation fuels it may be necessary to crack some of the FT products. In order to avoid this, some researchers have proposed using zeolites or other catalyst substrates with fixed sized pores that can restrict the formation of hydrocarbons longer than some characteristic size (usually ''n'' < 10). This way they can drive the reaction so as to minimize methane formation without producing many long-chained hydrocarbons. Such efforts have had only limited success.Catalysts

Four metals are active as

Four metals are active as catalyst

Catalysis () is the increase in rate of a chemical reaction due to an added substance known as a catalyst (). Catalysts are not consumed by the reaction and remain unchanged after it. If the reaction is rapid and the catalyst recycles quick ...

s for the Fischer–Tropsch process: iron, cobalt, nickel, and ruthenium. Since FT process typically transforms inexpensive precursors into complex mixtures that require further refining, FT catalysts are based on inexpensive metals, especially iron and cobalt. Nickel generates too much methane, so it is not used.

Typically, such heterogeneous catalysts are obtained through precipitation from iron nitrate solutions. Such solutions can be used to deposit the metal salt onto the catalyst support

In chemistry, a catalyst support or carrier is a material, usually a solid with a high surface area, to which a catalyst is affixed. The activity of heterogeneous catalysts is mainly promoted by atoms present at the accessible surface of the ma ...

(see below). Such treated materials transform into active catalysts by heating under CO, H2 or with the feedstock to be treated, i.e., the catalysts are generated in situ. Owing to the multistep nature of the FT process, analysis of the catalytically active species is challenging. Furthermore, as is known for iron catalysts, a number of phases may coexist and may participate in diverse steps in the reaction. Such phases include various oxides and carbide

In chemistry, a carbide usually describes a compound composed of carbon and a metal. In metallurgy, carbiding or carburizing is the process for producing carbide coatings on a metal piece.

Interstitial / Metallic carbides

The carbides of th ...

s as well as polymorphs of the metals. Control of these constituents may be relevant to product distributions. Aside from iron and cobalt, nickel and ruthenium are active for converting the CO/H2 mixture to hydrocarbons. Although expensive, ruthenium

Ruthenium is a chemical element; it has symbol Ru and atomic number 44. It is a rare transition metal belonging to the platinum group of the periodic table. Like the other metals of the platinum group, ruthenium is unreactive to most chem ...

is the most active of the Fischer–Tropsch catalysts in the sense that It works at the lowest reaction temperatures and produces higher molecular weight hydrocarbons. Ruthenium catalysts consist of the metal, without any promoters, thus providing relatively simple system suitable for mechanistic analysis. Its high price preclude industrial applications. Cobalt catalysts are more active for FT synthesis when the feedstock is natural gas. Natural gas has a high hydrogen to carbon ratio, so the water-gas shift is not needed for cobalt catalysts. Cobalt-based catalysts are more sensitive than their iron counterparts.

Illustrative of real world catalyst selection, high-temperature Fischer–Tropsch (HTFT), which operates at 330–350 °C, uses an iron-based catalyst. This process was used extensively by Sasol

Sasol Limited, commonly referred to as Sasol, is an integrated energy and chemical company based in Sandton, South Africa.

The company was formed in 1950 in Sasolburg, South Africa, and built around coal liquefaction processes that German ...

in their coal-to-liquid plants (CTL). Low-temperature Fischer–Tropsch (LTFT) uses an iron- or cobalt-based catalyst. This process is best known for being used in the first integrated GTL-plant operated and built by Shell

Shell may refer to:

Architecture and design

* Shell (structure), a thin structure

** Concrete shell, a thin shell of concrete, usually with no interior columns or exterior buttresses

Science Biology

* Seashell, a hard outer layer of a marine ani ...

in Bintulu

Bintulu is a coastal town on the island of Borneo in the central region of Sarawak, Malaysia. Bintulu is located northeast of Kuching, northeast of Sibu, and southwest of Miri, Malaysia, Miri. With a population of 114,058 as of 2010, Bintulu ...

, Malaysia.

Promoters and supports

In addition to the active metal (usually Fe or Co), two other components comprise the catalyst: promoters and thecatalyst support

In chemistry, a catalyst support or carrier is a material, usually a solid with a high surface area, to which a catalyst is affixed. The activity of heterogeneous catalysts is mainly promoted by atoms present at the accessible surface of the ma ...

. Promoters are additives that enhance the behavior of the catalyst. For F-T catalysts, typical promoters including potassium and copper, which are usually added as salts. The choice of promoters depends on the primary metal, iron vs cobalt. Iron catalysts need alkali promotion to attain high activity and stability (e.g. 0.5 wt% ). Potassium-doped α-Fe2O3 are synthesized under variable calcination temperatures (400–800 °C). Addition of Cu for reduction promotion, addition of , for structural promotion and maybe some manganese can be applied for selectivity control (e.g. high olefinicity). The choice of promoters depends on the primary metal, i.e., iron vs cobalt. While group 1 alkali metals (e.g., potassium), help iron catalysts, they poison cobalt catalysts.

Catalysts are supported on high-surface-area binders/supports such as silica

Silicon dioxide, also known as silica, is an oxide of silicon with the chemical formula , commonly found in nature as quartz. In many parts of the world, silica is the major constituent of sand. Silica is one of the most complex and abundant f ...

, alumina

Aluminium oxide (or aluminium(III) oxide) is a chemical compound of aluminium and oxygen with the chemical formula . It is the most commonly occurring of several aluminium oxides, and specifically identified as aluminium oxide. It is commonly ...

, or zeolites

Zeolites are a group of several Microporous material, microporous, crystalline aluminosilicate minerals commonly used as commercial adsorption, adsorbents and Catalysis, catalysts. They mainly consist of silicon, aluminium, oxygen, and have the ge ...

.

History

The F-T process attracted attention as a means ofNazi Germany

Nazi Germany, officially known as the German Reich and later the Greater German Reich, was the German Reich, German state between 1933 and 1945, when Adolf Hitler and the Nazi Party controlled the country, transforming it into a Totalit ...

to produce liquid hydrocarbons. The original process was developed by Franz Fischer and Hans Tropsch, working at the Kaiser-Wilhelm-Institut for Chemistry in 1926. They filed a number of patents, ''e.g.'', , applied 1926, published 1930. It was commercialized by Brabag in Germany in 1936. Being petroleum-poor but coal-rich, Germany used the process during World War II

World War II or the Second World War (1 September 1939 – 2 September 1945) was a World war, global conflict between two coalitions: the Allies of World War II, Allies and the Axis powers. World War II by country, Nearly all of the wo ...

to produce ''ersatz

An ersatz good () is a substitute good, especially one that is considered inferior to the good it replaces. It has particular connotations of wartime usage.

Etymology

''Ersatz'' is a German word meaning ''substitute'' or ''replacement''. Altho ...

'' (replacement) fuels. FT production accounted for an estimated 9% of German war production of fuels and 25% of the automobile fuel. Many refinements and adjustments have been made to the process since Fischer and Tropsch's time.

The United States Bureau of Mines

The United States Bureau of Mines (USBM) was the primary Federal government of the United States, United States government agency in the 20th century that conducted scientific research and disseminated information on the extraction, processing ...

, in a program initiated by the Synthetic Liquid Fuels Act, employed seven Operation Paperclip

The Operation Paperclip was a secret United States intelligence program in which more than 1,600 German scientists, engineers, and technicians were taken from former Nazi Germany to the US for government employment after the end of World War I ...

synthetic fuel

Synthetic fuel or synfuel is a liquid fuel, or sometimes Fuel gas, gaseous fuel, obtained from syngas, a mixture of carbon monoxide and hydrogen, in which the syngas was derived from gasification of solid feedstocks such as coal or biomass or by ...

scientists in a Fischer–Tropsch plant in Louisiana, Missouri in 1946.

In Britain, Alfred August Aicher obtained several patent

A patent is a type of intellectual property that gives its owner the legal right to exclude others from making, using, or selling an invention for a limited period of time in exchange for publishing an sufficiency of disclosure, enabling discl ...

s for improvements to the process in the 1930s and 1940s. Aicher's company was named ''Synthetic Oils Ltd'' (not related to a company of the same name in Canada).

Around the 1930s and 1940s, Arthur Imhausen developed and implemented an industrial process for producing edible fats from these synthetic oils through oxidation

Redox ( , , reduction–oxidation or oxidation–reduction) is a type of chemical reaction in which the oxidation states of the reactants change. Oxidation is the loss of electrons or an increase in the oxidation state, while reduction is ...

. The products were fractionally distilled and the edible fats were obtained from the - fraction which were reacted with glycerol

Glycerol () is a simple triol compound. It is a colorless, odorless, sweet-tasting, viscous liquid. The glycerol backbone is found in lipids known as glycerides. It is also widely used as a sweetener in the food industry and as a humectant in pha ...

such as that synthesized from propylene. "Coal butter" margarine made from synthetic oils was found to be nutritious and of agreeable taste, and it was incorporated into diets contributing as much as 700 calories per day. The process required at least 60 kg of coal per kg of synthetic butter.

Commercialization

Uzbekistan GTL

Ras Laffan, Qatar

The LTFT facility Pearl GTL at Ras Laffan, Qatar, is the second largest FT plant in the world afterSasol

Sasol Limited, commonly referred to as Sasol, is an integrated energy and chemical company based in Sandton, South Africa.

The company was formed in 1950 in Sasolburg, South Africa, and built around coal liquefaction processes that German ...

's Secunda plant in South Africa. It uses cobalt

Cobalt is a chemical element; it has Symbol (chemistry), symbol Co and atomic number 27. As with nickel, cobalt is found in the Earth's crust only in a chemically combined form, save for small deposits found in alloys of natural meteoric iron. ...

catalysts at 230 °C, converting natural gas to petroleum liquids at a rate of , with additional production of of oil equivalent in natural gas liquids

Natural-gas condensate, also called natural gas liquids, is a low-density mixture of hydrocarbon liquids that are present as gaseous components in the raw natural gas produced from many natural gas fields. Some gas species within the raw natura ...

and ethane

Ethane ( , ) is a naturally occurring Organic compound, organic chemical compound with chemical formula . At standard temperature and pressure, ethane is a colorless, odorless gas. Like many hydrocarbons, ethane is List of purification methods ...

.

Another plant in Ras Laffan, called Oryx GTL, has been commissioned in 2007 with a capacity of . The plant utilizes the Sasol slurry phase distillate process, which uses a cobalt catalyst. Oryx GTL is a joint venture between QatarEnergy and Sasol

Sasol Limited, commonly referred to as Sasol, is an integrated energy and chemical company based in Sandton, South Africa.

The company was formed in 1950 in Sasolburg, South Africa, and built around coal liquefaction processes that German ...

.

Sasol

The world's largest scale implementation of Fischer–Tropsch technology is a series of plants operated bySasol

Sasol Limited, commonly referred to as Sasol, is an integrated energy and chemical company based in Sandton, South Africa.

The company was formed in 1950 in Sasolburg, South Africa, and built around coal liquefaction processes that German ...

in South Africa

South Africa, officially the Republic of South Africa (RSA), is the Southern Africa, southernmost country in Africa. Its Provinces of South Africa, nine provinces are bounded to the south by of coastline that stretches along the Atlantic O ...

, a country with large coal reserves, but little oil. With a capacity of 165000 Bpd at its Secunda CTL

Secunda CTL is a synthetic fuel plant owned by Sasol at Secunda, Mpumalanga in South Africa. It uses coal liquefaction to produce petroleum-like synthetic crude oil from coal. The process used by Sasol is based on the Fischer–Tropsch proces ...

plant. The first commercial plant opened in 1952. Sasol uses coal and natural gas as feedstocks and produces a variety of synthetic petroleum products, including most of the country's diesel fuel

Diesel fuel, also called diesel oil, heavy oil (historically) or simply diesel, is any liquid fuel specifically designed for use in a diesel engine, a type of internal combustion engine in which fuel ignition takes place without a spark as a re ...

.

PetroSA

PetroSA

PetroSA (The Petroleum, Oil and Gas Corporation of South Africa ( SOC) Ltd.) is the national oil and gas company (NOC) of South Africa.

Its main activities are the extraction of natural gas from offshore fields about 89 km from Mossel B ...

, another South African company, operates a refinery with a 36,000 barrels a day plant that completed semi-commercial demonstration in 2011, paving the way to begin commercial preparation. The technology can be used to convert natural gas, biomass or coal into synthetic fuels.

Shell middle distillate synthesis

One of the largest implementations of Fischer–Tropsch technology is inBintulu

Bintulu is a coastal town on the island of Borneo in the central region of Sarawak, Malaysia. Bintulu is located northeast of Kuching, northeast of Sibu, and southwest of Miri, Malaysia, Miri. With a population of 114,058 as of 2010, Bintulu ...

, Malaysia. This Shell

Shell may refer to:

Architecture and design

* Shell (structure), a thin structure

** Concrete shell, a thin shell of concrete, usually with no interior columns or exterior buttresses

Science Biology

* Seashell, a hard outer layer of a marine ani ...

facility converts natural gas

Natural gas (also fossil gas, methane gas, and gas) is a naturally occurring compound of gaseous hydrocarbons, primarily methane (95%), small amounts of higher alkanes, and traces of carbon dioxide and nitrogen, hydrogen sulfide and helium ...

into low-sulfur

Sulfur ( American spelling and the preferred IUPAC name) or sulphur ( Commonwealth spelling) is a chemical element; it has symbol S and atomic number 16. It is abundant, multivalent and nonmetallic. Under normal conditions, sulfur atoms ...

Diesel fuel

Diesel fuel, also called diesel oil, heavy oil (historically) or simply diesel, is any liquid fuel specifically designed for use in a diesel engine, a type of internal combustion engine in which fuel ignition takes place without a spark as a re ...

s and food-grade wax. The scale is .

Velocys

Velocys operated a demonstration plant with Envia in Oklahoma City during 2017 and 2018. The Joint Venture was closed down and reactors returned to Velocyafter the site was sold to another joint venture partner for $4.15 million

The company's Fischer-Tropsch reactors were used by TOYO Engineering Corporation to produce sustainable aviation fuel (SAF) from woodchips at its demonstration plant in Nagoya, Japan in 2020

The produced fuel was used in flight JL 515 from Tokyo to Sapporo on June 17, 2021

marking the first time aviation fuel derived from gasified woodchips and synthesized into SAF was used in a commercial flight.

SGCE

Starting as a biomass technology licensor In Summer of 2012 SGC Energia (SGCE) successfully commissioned a pilot multi tubular Fischer–Tropsch process unit and associated product upgrading units at the Pasadena, Tx Technology Center. The technology center focused on the development and operations of their XTLH solution which optimized processing of low value carbon waste streams into advanced fuels and wax products. This unit also serves as an operations training environment for the 1100 BPD Juniper GTL facility constructed in Westlake LA.UPM (Finland)

In October 2006, Finnish paper and pulp manufacturer UPM announced its plans to produce biodiesel by the Fischer–Tropsch process alongside the manufacturing processes at its European paper and pulp plants, using wastebiomass

Biomass is a term used in several contexts: in the context of ecology it means living organisms, and in the context of bioenergy it means matter from recently living (but now dead) organisms. In the latter context, there are variations in how ...

resulting from paper and pulp manufacturing processes as source material.

Arcadia eFuels

Texas based Arcadia eFuels in conjunction with Sasol and Topsoe is constructing a sustainable aviation fuel plant in Vordingborg, Denmark that will use Fischer-Tropsch process to convertsyngas

Syngas, or synthesis gas, is a mixture of hydrogen and carbon monoxide in various ratios. The gas often contains some carbon dioxide and methane. It is principally used for producing ammonia or methanol. Syngas is combustible and can be used as ...

derived from water electrolysis and carbon capture into an e-diesel fuel for aviation

Aviation includes the activities surrounding mechanical flight and the aircraft industry. ''Aircraft'' include fixed-wing and rotary-wing types, morphable wings, wing-less lifting bodies, as well as lighter-than-air aircraft such as h ...

. The plant will begin production in 2028 with additional plants in development in Teesside, United Kingdom and the United States.

Rentech

A demonstration-scale Fischer–Tropsch plant was built and operated by Rentech, Inc., in partnership with ClearFuels, a company specializing in biomass gasification. Located in Commerce City CO, the facility produces about of fuels from natural gas. Commercial-scale facilities were planned for Rialto, California;Natchez, Mississippi

Natchez ( ) is the only city in and the county seat of Adams County, Mississippi, United States. The population was 14,520 at the 2020 United States census, 2020 census. Located on the Mississippi River across from Vidalia, Louisiana, Natchez was ...

; Port St. Joe, Florida; and White River, Ontario.http://www.rentechinc.com/ (official site) Rentech closed down their pilot plant in 2013, and abandoned work on their FT process as well as the proposed commercial facilities.

INFRA GTL Technology

In 2010, INFRA built a compact Pilo

In 2010, INFRA built a compact PiloPlant

for conversion of natural gas into synthetic oil. The plant modeled the full cycle of the GTL chemical process including the intake of pipeline gas, sulfur removal, steam methane reforming, syngas conditioning, and Fischer–Tropsch synthesis. In 2013 the first pilot plant was acquired by VNIIGAZ

Gazprom

PJSC Gazprom ( rus, Газпром, , ɡɐsˈprom) is a Russian State-owned enterprise, majority state-owned multinational Energy industry, energy corporation headquartered in the Lakhta Center in Saint Petersburg. The Gazprom name is a contract ...

LLC. In 2014 INFRA commissioned and operated on a continuous basis a new, larger scale full cycle Pilot Plant. It represents the second generation of INFRA's testing facility and is differentiated by a high degree of automation and extensive data gathering system. In 2015, INFRA built its own catalyst factory in Troitsk Troitsk (, ''Tróick'') is the name of several types of inhabited localities in Russia, inhabited localities in Russia.

Modern localities

;Urban localities

*Troitsk, Chelyabinsk Oblast, a town in Chelyabinsk Oblast;

*Troitsk, Moscow, a town in Tro ...

(Moscow, Russia). The catalyst factory has a capacity of over 15 tons per year, and produces the unique proprietary Fischer–Tropsch catalysts developed by the company's R&D division. In 2016, INFRA designed and built a modular, transportable GTL (gas-to-liquid) M100 plant for processing natural and associated gas into synthetic crude oil

Synthetic crude is the output from a bitumen/extra heavy oil upgrader facility used in connection with oil sand production. It may also refer to shale oil, an output from an oil shale pyrolysis. The properties of the synthetic crude depend on t ...

in Wharton TX. The M100 plant is operating as a technology demonstration unit, R&D platform for catalyst refinement, and economic model to scale the Infra GTL process into larger and more efficient plants.

Other

In the United States and India, some coal-producing states have invested in Fischer–Tropsch plants. In Pennsylvania, Waste Management and Processors, Inc. was funded by the state to implement FT technology licensed from Shell and Sasol to convert so-called waste coal (leftovers from the mining process) into low-sulfur diesel fuel.Research developments

Choren Industries has built a plant inGermany

Germany, officially the Federal Republic of Germany, is a country in Central Europe. It lies between the Baltic Sea and the North Sea to the north and the Alps to the south. Its sixteen States of Germany, constituent states have a total popu ...

that converts biomass to syngas and fuels using the Shell FT process structure. The company went bankrupt in 2011 due to impracticalities in the process.

Biomass gasification (BG) and Fischer–Tropsch (FT) synthesis can in principle be combined to produce renewable transportation fuels (biofuel

Biofuel is a fuel that is produced over a short time span from Biomass (energy), biomass, rather than by the very slow natural processes involved in the formation of fossil fuels such as oil. Biofuel can be produced from plants or from agricu ...

s).

In partnership with Sunfire, Audi

Audi AG () is a German automotive manufacturer of luxury vehicles headquartered in Ingolstadt, Bavaria, Germany. A subsidiary of the Volkswagen Group, Audi produces vehicles in nine production facilities worldwide.

The origins of the compa ...

produces E-diesel E-diesel is a synthetic fuel, synthetic diesel fuel for use in automobiles. Currently, e-diesel is created at two sites: by an Audi research facility Germany in partnership with a company named Sunfire, and in Texas. The fuel is created from carbon ...

in small scale with two steps, the second one being FT.

U.S. Air Force testing

Syntroleum, formerly a publicly traded United States company, has produced over of diesel and jet fuel from the Fischer–Tropsch process using natural gas at its demonstration plant nearTulsa, Oklahoma

Tulsa ( ) is the List of municipalities in Oklahoma, second-most-populous city in the U.S. state, state of Oklahoma, after Oklahoma City, and the List of United States cities by population, 48th-most-populous city in the United States. The po ...

. Using natural gas as a feedstock, the ultra-clean, low sulfur fuel has been tested extensively by the United States Department of Energy

The United States Department of Energy (DOE) is an executive department of the U.S. federal government that oversees U.S. national energy policy and energy production, the research and development of nuclear power, the military's nuclear w ...

and the United States Department of Transportation

The United States Department of Transportation (USDOT or DOT) is one of the executive departments of the U.S. federal government. It is headed by the secretary of transportation, who reports directly to the president of the United States a ...

. Syntroleum worked to develop a synthetic jet fuel blend that will help the Air Force to reduce its dependence on imported petroleum. The Air Force, which is the United States military's largest user of fuel, began exploring alternative fuel sources in 1999. On December 15, 2006, a B-52 took off from Edwards Air Force Base

Edwards Air Force Base (AFB) is a United States Air Force installation in California. Most of the base sits in Kern County, California, Kern County, but its eastern end is in San Bernardino County, California, San Bernardino County and a souther ...

, California

California () is a U.S. state, state in the Western United States that lies on the West Coast of the United States, Pacific Coast. It borders Oregon to the north, Nevada and Arizona to the east, and shares Mexico–United States border, an ...

for the first time powered solely by a 50–50 blend of JP-8

JP-8, or JP8 (for "Jet Propellant 8"), is a jet fuel, specified and used widely by the US military. It is specified by MIL-DTL-83133 and British Defence Standard 91-87, and similar to commercial aviation's Jet A-1, but with the addition of corros ...

and Syntroleum's FT fuel. The seven-hour flight test was considered a success. The goal of the flight test program is to qualify the fuel blend for fleet use on the service's B-52s, and then flight test and qualification on other aircraft. The test program concluded in 2007. This program was part of the Department of Defense

The United States Department of Defense (DoD, USDOD, or DOD) is an executive department of the U.S. federal government charged with coordinating and supervising the six U.S. armed services: the Army, Navy, Marines, Air Force, Space Force, ...

Assured Fuel Initiative, an effort to develop secure domestic sources for the military energy needs. The Pentagon had hoped to reduce its use of crude oil from foreign producers and obtain about half of its aviation fuel from alternative sources by 2016. More recently in 2021another batch of synthetic jet fuel was manufactured for the Air Force by Twelve and Emerging Fuels Technology

- the latter being Syntroleum's successor company which was established by the founders and management team of Syntroleum and having bought its laboratory in Tulsa.

Carbon dioxide reuse

Carbon dioxide is not a typical feedstock for FT catalysis. Hydrogen and carbon dioxide react over a cobalt-based catalyst, producing methane. With iron-based catalysts unsaturated short-chain hydrocarbons are also produced. Upon introduction to the catalyst's support, ceria functions as a reverse water-gas shift catalyst, further increasing the yield of the reaction. The short-chain hydrocarbons were upgraded to liquid fuels over solid acid catalysts, such aszeolite

Zeolites are a group of several microporous, crystalline aluminosilicate minerals commonly used as commercial adsorbents and catalysts. They mainly consist of silicon, aluminium, oxygen, and have the general formula ・y where is either a meta ...

s.

Process efficiency

Using conventional FT technology the process ranges in carbon efficiency from 25 to 50 percent and a thermal efficiency of about 50% for CTL facilities idealised at 60% with GTL facilities at about 60% efficiency idealised to 80% efficiency.Fischer–Tropsch in nature

A Fischer–Tropsch-type process has also been suggested to have produced a few of the building blocks ofDNA

Deoxyribonucleic acid (; DNA) is a polymer composed of two polynucleotide chains that coil around each other to form a double helix. The polymer carries genetic instructions for the development, functioning, growth and reproduction of al ...

and RNA

Ribonucleic acid (RNA) is a polymeric molecule that is essential for most biological functions, either by performing the function itself (non-coding RNA) or by forming a template for the production of proteins (messenger RNA). RNA and deoxyrib ...

within asteroids

An asteroid is a minor planet—an object larger than a meteoroid that is neither a planet nor an identified comet—that orbits within the Solar System#Inner Solar System, inner Solar System or is co-orbital with Jupiter (Trojan asteroids). As ...

. Similarly, the hypothetical abiogenic petroleum formation requires some naturally occurring FT-like processes.

Biological Fischer-Tropsch-type chemistry can be carried out by the enzyme nitrogenase at ambient conditions.

See also

* * * * , a generic term for this type of process * * * * * *References

Further reading

* * * *External links

* Modeling and Integration of Green-Hydrogen-Assisted Carbon Dioxide Utilization for Hydrocarbon ManufacturinFischer–Tropsch archives

Fischer–Tropsch fuels from coal and biomass

Abiogenic gas debate (AAPG Explorer Nov. 2002)

Gas origin theories to be studied (AAPG Explorer Nov. 2002)

* '' ttps://web.archive.org/web/20051106005801/http://www.fischer-tropsch.org/primary_documents/patents/GB/gb309002.pdf Process of synthesis of liquid hydrocarbons' – Great Britain patent GB309002 – Hermann Plauson *

Clean diesel from coal

' by Kevin Bullis *

Implementing the "Hydrogen Economy" with Synfuels (pdf)

'

Carbon-to-liquids research

Effect of alkali metals on cobalt catalysts

{{DEFAULTSORT:Fischer-Tropsch Process Biofuels technology Catalysis Coal Organometallic chemistry Petroleum production Synthetic fuel technologies German inventions 1925 in science 1925 in Germany Organic redox reactions Name reactions