Ericsson Cycle on:

[Wikipedia]

[Google]

[Amazon]

The Ericsson cycle is named after inventor

The following is a list of the four processes that occur between the four stages of the ideal Ericsson cycle:

*Process 1 -> 2:

The following is a list of the four processes that occur between the four stages of the ideal Ericsson cycle:

*Process 1 -> 2:

The Ericsson engine is based on the Ericsson cycle, and is known as an "

The Ericsson engine is based on the Ericsson cycle, and is known as an "

US8481

* The evolution of the heat engine, by: Ivo Kolin Published Moriya Press, 1972 by Longman * Hot Air Caloric and Stirling Engines, by: Robert Sier. Published 1999, by L A Mair.

Inquiry into the Hot Air Engines of the 19th Century

{{Thermodynamic cycles, state=uncollapsed Thermodynamic cycles Piston engines

John Ericsson

John Ericsson (born Johan Ericsson; July 31, 1803 – March 8, 1889) was a Swedish-American engineer and inventor. He was active in England and the United States.

Ericsson collaborated on the design of the railroad steam locomotive Novelty (lo ...

who designed and built many unique heat engine

A heat engine is a system that transfers thermal energy to do mechanical or electrical work. While originally conceived in the context of mechanical energy, the concept of the heat engine has been applied to various other kinds of energy, pa ...

s based on various thermodynamic cycle

A thermodynamic cycle consists of linked sequences of thermodynamic processes that involve heat transfer, transfer of heat and work (physics), work into and out of the system, while varying pressure, temperature, and other state variables within t ...

s. He is credited with inventing two unique heat engine cycles and developing practical engines based on these cycles. His ''first'' cycle is now known as the closed Brayton cycle, while his second cycle is what is now called the Ericsson cycle.

Ericsson is one of the few who built open-cycle engines, but he also built closed-cycle ones.

Ideal Ericsson cycle

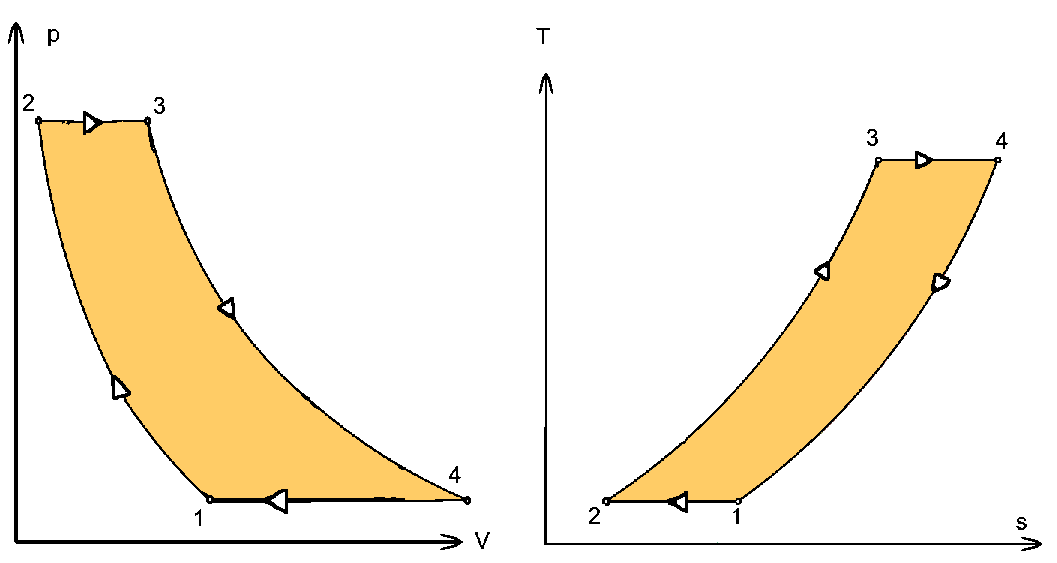

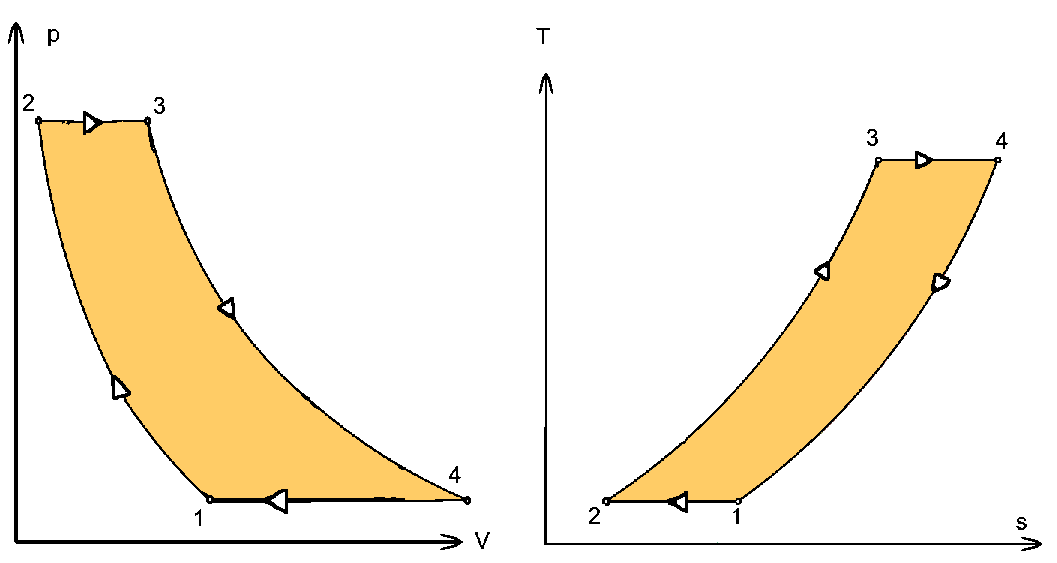

The following is a list of the four processes that occur between the four stages of the ideal Ericsson cycle:

*Process 1 -> 2:

The following is a list of the four processes that occur between the four stages of the ideal Ericsson cycle:

*Process 1 -> 2: Isothermal

An isothermal process is a type of thermodynamic process in which the temperature ''T'' of a system remains constant: Δ''T'' = 0. This typically occurs when a system is in contact with an outside thermal reservoir, and a change in the sys ...

compression. The compression space is assumed to be intercooled, so the gas undergoes isothermal compression. The compressed air flows into a storage tank at constant pressure. In the ideal cycle, there is no heat transfer across the tank walls.

*Process 2 -> 3: Isobaric heat addition. From the tank, the compressed air flows through the regenerator and picks up heat at a high constant-pressure on the way to the heated power-cylinder.

*Process 3 -> 4: Isothermal

An isothermal process is a type of thermodynamic process in which the temperature ''T'' of a system remains constant: Δ''T'' = 0. This typically occurs when a system is in contact with an outside thermal reservoir, and a change in the sys ...

expansion. The power-cylinder expansion-space is heated externally, and the gas undergoes isothermal expansion.

*Process 4 -> 1: Isobaric heat removal. Before the air is released as exhaust, it is passed back through the regenerator, thus cooling the gas at a low constant pressure, and heating the regenerator for the next cycle.

Comparison with Carnot, Diesel, Otto, and Stirling cycles

The ideal Otto and Diesel cycles are not totally reversible because they involve heat transfer through a finite temperature difference during the irreversible isochoric/ isobaric heat-addition and isochoric heat-rejection processes. The aforementioned irreversibility renders thethermal efficiency

In thermodynamics, the thermal efficiency (\eta_) is a dimensionless performance measure of a device that uses thermal energy, such as an internal combustion engine, steam turbine, steam engine, boiler, furnace, refrigerator, ACs etc.

For ...

of these cycles less than that of a Carnot engine operating within the same limits of temperature. Another cycle that features isobaric heat-addition and heat-rejection processes is the Ericsson cycle. The Ericsson cycle is an altered version of the Carnot cycle

A Carnot cycle is an ideal thermodynamic cycle proposed by French physicist Nicolas Léonard Sadi Carnot, Sadi Carnot in 1824 and expanded upon by others in the 1830s and 1840s. By Carnot's theorem (thermodynamics), Carnot's theorem, it provides ...

in which the two isentropic processes featured in the Carnot cycle are replaced by two isothermal

An isothermal process is a type of thermodynamic process in which the temperature ''T'' of a system remains constant: Δ''T'' = 0. This typically occurs when a system is in contact with an outside thermal reservoir, and a change in the sys ...

regeneration processes.

The Ericsson cycle is often compared with the Stirling cycle

The Stirling cycle is a thermodynamic cycle that describes the general class of Stirling devices. This includes the original Stirling engine that was invented, developed and patented in 1816 by Robert Stirling with help from his brother, an en ...

, since the engine designs based on these respective cycles are both external combustion engine

An external combustion engine (EC engine) is a Reciprocating engine, reciprocating heat engine where a working fluid, contained internally, is heated by combustion in an external source, through the engine wall or a heat exchanger. The fluid t ...

s with regenerators. The Ericsson is perhaps most similar to the so-called "double-acting" type of Stirling engine, in which the displacer piston also acts as the power piston. Theoretically, both of these cycles have so called ''ideal'' efficiency, which is the highest allowed by the second law of thermodynamics

The second law of thermodynamics is a physical law based on Universal (metaphysics), universal empirical observation concerning heat and Energy transformation, energy interconversions. A simple statement of the law is that heat always flows spont ...

. The most well-known ideal cycle is the Carnot cycle

A Carnot cycle is an ideal thermodynamic cycle proposed by French physicist Nicolas Léonard Sadi Carnot, Sadi Carnot in 1824 and expanded upon by others in the 1830s and 1840s. By Carnot's theorem (thermodynamics), Carnot's theorem, it provides ...

, although a useful ''Carnot engine'' is not known to have been invented.

The theoretical efficiencies for both, Ericsson and Stirling cycles acting in the same limits are equal to the Carnot Efficiency for same limits.

Comparison with the Brayton cycle

The first cycle Ericsson developed is now called the "Brayton cycle

The Brayton cycle, also known as the Joule cycle, is a thermodynamic cycle that describes the operation of certain heat engines that have air or some other gas as their working fluid.

It is characterized by isentropic process, isentropic compre ...

", commonly applied to gas turbine engine

A gas turbine or gas turbine engine is a type of Internal combustion engine#Continuous combustion, continuous flow internal combustion engine. The main parts common to all gas turbine engines form the power-producing part (known as the gas gene ...

s.

The second Ericsson cycle is the cycle most commonly referred to as simply the "Ericsson cycle". The (second) Ericsson cycle is also the limit of an ideal gas-turbine Brayton cycle, operating with multistage intercooled compression, and multistage expansion with reheat and regeneration. Compared to the Brayton cycle which uses adiabatic compression

An adiabatic process (''adiabatic'' ) is a type of thermodynamic process that occurs without transferring heat between the thermodynamic system and its Environment (systems), environment. Unlike an isothermal process, an adiabatic process transf ...

and expansion, the second Ericsson cycle uses isothermal compression and expansion, thus producing more net work per stroke. Also the use of regeneration in the Ericsson cycle increases efficiency by reducing the required heat input. For further comparisons of thermodynamic cycles, see heat engine

A heat engine is a system that transfers thermal energy to do mechanical or electrical work. While originally conceived in the context of mechanical energy, the concept of the heat engine has been applied to various other kinds of energy, pa ...

.

Ericsson engine

The Ericsson engine is based on the Ericsson cycle, and is known as an "

The Ericsson engine is based on the Ericsson cycle, and is known as an "external combustion engine

An external combustion engine (EC engine) is a Reciprocating engine, reciprocating heat engine where a working fluid, contained internally, is heated by combustion in an external source, through the engine wall or a heat exchanger. The fluid t ...

", because it is externally heated. To improve efficiency, the engine has a regenerator or recuperator

A recuperator (electro- end carbogidro-) - is a special purpose countercurrent exchange, counter-flow energy recovery heat exchanger positioned within the supply and exhaust air streams of an air handling system, or in the exhaust gases of an in ...

between the compressor and the expander. The engine can be run open- or closed-cycle. Expansion occurs simultaneously with compression, on opposite sides of the piston.

Regenerator

Ericsson coined the term "regenerator" for his independent invention of the mixed-flow counter-current heat exchanger. However, Rev. Robert Stirling had invented the same device, prior to Ericsson, so the invention is credited to Stirling. Stirling called it an "economiser" or "economizer", because it increased the fuel economy of various types of heat processes. The invention was found to be useful, in many other devices and systems, where it became more widely used, since other types of engines became favored over the Stirling engine. The term "regenerator" is now the name given to the component in the Stirling engine. The term "recuperator

A recuperator (electro- end carbogidro-) - is a special purpose countercurrent exchange, counter-flow energy recovery heat exchanger positioned within the supply and exhaust air streams of an air handling system, or in the exhaust gases of an in ...

" refers to a separated-flow, counter-current heat exchanger. As if this weren't confusing enough, a mixed-flow regenerator is sometimes used as a quasi-separated-flow recuperator. This can be done through the use of moving valves, or by a rotating regenerates with fixed baffles, or by the use of other moving parts. When heat is recovered from exhaust gases and used to preheat combustion air, typically the term recuperator is used, because the two flows are separate.

History

In 1791, before Ericsson, John Barber proposed a similar engine. The Barber engine used a bellows compressor and a turbine expander, but it lacked a regenerator/recuperator. There are no records of a working Barber engine. Ericsson invented and patented his first engine using an external version of the Brayton cycle in 1833 (number 6409/1833 British). This was 18 years beforeJoule

The joule ( , or ; symbol: J) is the unit of energy in the International System of Units (SI). In terms of SI base units, one joule corresponds to one kilogram- metre squared per second squared One joule is equal to the amount of work d ...

and 43 years before Brayton. Brayton engines were all piston engines and for the most part, internal combustion versions of the un-recuperated Ericsson engine. The "Brayton cycle

The Brayton cycle, also known as the Joule cycle, is a thermodynamic cycle that describes the operation of certain heat engines that have air or some other gas as their working fluid.

It is characterized by isentropic process, isentropic compre ...

" is now known as the gas turbine

A gas turbine or gas turbine engine is a type of Internal combustion engine#Continuous combustion, continuous flow internal combustion engine. The main parts common to all gas turbine engines form the power-producing part (known as the gas gene ...

cycle, which differs from the original "Brayton cycle" in the use of a turbine compressor and expander. The gas turbine cycle is used for all modern gas turbine and turbojet

The turbojet is an airbreathing jet engine which is typically used in aircraft. It consists of a gas turbine with a propelling nozzle. The gas turbine has an air inlet which includes inlet guide vanes, a compressor, a combustion chamber, and ...

engines, however simple cycle turbines are often recuperated to improve efficiency and these recuperated turbines more closely resemble Ericsson's work.

Ericsson eventually abandoned the open cycle in favor of the traditional closed Stirling cycle.

Ericsson's engine can easily be modified to operate in a closed-cycle mode, using a second, lower-pressure, cooled container between the original exhaust and intake. In closed cycle, the lower pressure can be significantly above ambient pressure, and He or H2 working gas can be used. Because of the higher pressure difference between the upward and downward movement of the work-piston, specific output can be greater than of a valveless Stirling engine

A Stirling engine is a heat engine that is operated by the cyclic expansion and contraction of air or other gas (the ''working fluid'') by exposing it to different temperatures, resulting in a net conversion of heat energy to mechanical Work (ph ...

. The added cost is the valve

A valve is a device or natural object that regulates, directs or controls the flow of a fluid (gases, liquids, fluidized solids, or Slurry, slurries) by opening, closing, or partially obstructing various passageways. Valves are technically Pip ...

. Ericsson's engine also minimizes mechanical losses: the power necessary for compression does not go through crank-bearing frictional losses, but is applied directly from the expansion force. The piston-type Ericsson engine can potentially be the highest efficiency heat engine arrangement ever constructed. Admittedly, this has yet to be proven in practical applications.

Ericsson designed and built a very great number of engines running on various cycles including steam, Stirling, Brayton, externally heated diesel air fluid cycle. He ran his engines on a great variety of fuels including coal and solar heat.

Ericsson was also responsible for an early use of the screw propeller

A propeller (often called a screw if on a ship or an airscrew if on an aircraft) is a device with a rotating hub and radiating blades that are set at a pitch to form a helical spiral which, when rotated, exerts linear thrust upon a working flu ...

for ship propulsion, in the USS ''Princeton'', built in 1842–43.

Caloric ship ''Ericsson''

In 1851 the Ericsson-cycle engine (the second of the two discussed here) was used to power a 2,000-ton ship, the caloric ship ''Ericsson'', and ran flawlessly for 73 hours. The combination engine produced about . It had a combination of four dual-piston engines; the larger expansion piston/cylinder, at in diameter, was perhaps the largest piston ever built. Rumor has it that tables were placed on top of those pistons (obviously in the cool compression chamber, not the hot power chamber) and dinner was served and eaten, while the engine was running at full power. At 6.5RPM

Revolutions per minute (abbreviated rpm, RPM, rev/min, r/min, or r⋅min−1) is a unit of rotational speed (or rotational frequency) for rotating machines.

One revolution per minute is equivalent to hertz.

Standards

ISO 80000-3:2019 def ...

the pressure was limited to . According to the official report it only consumed 4200 kg coal per 24 hours (original target was 8000 kg, which is still better than contemporary steam engines). The one sea trial

A sea trial or trial trip is the testing phase of a watercraft (including boats, ships, and submarines). It is also referred to as a "shakedown cruise" by many naval personnel. It is usually the last phase of construction and takes place on op ...

proved that even though the engine ran well, the ship was underpowered. Some time after the trials, the ''Ericsson'' sank. When it was raised, the Ericsson-cycle engine was removed and a steam engine took its place. The ship was wrecked when blown aground in November 1892 at the entrance to Barkley Sound, British Columbia, Canada.

Today's potential

The Ericsson cycle (and the similar Brayton cycle) receives renewed interest today to extract power from the exhaust heat of gas (andproducer gas

Producer gas is a fuel gas manufactured by blowing air and steam simultaneously through a coke or coal fire. It mainly consists of carbon monoxide (CO), hydrogen (H2), as well as substantial amounts of nitrogen (N2). The caloric value of the pro ...

) engines and solar concentrators. An important advantage of the Ericsson cycle over the widely known Stirling engine

A Stirling engine is a heat engine that is operated by the cyclic expansion and contraction of air or other gas (the ''working fluid'') by exposing it to different temperatures, resulting in a net conversion of heat energy to mechanical Work (ph ...

is often not recognized : the volume of the heat exchanger does not adversely affect the efficiency.

(...)''despite having significant advantages over the Stirling. Amongst them, it is worth to note that the Ericsson engine heat exchangers are not dead volumes, whereas the Stirling engine heat exchangers designer has to face a difficult compromise between as large heat transfer areas as possible, but as small heat exchanger volumes as possible.''

For medium and large engines the cost of valves can be small compared to this advantage. Turbocompressor plus turbine implementations seem favorable in the MWe range, positive displacement compressor plus turbine for Nx100 kWe power, and positive displacement compressor+expander below 100 kW. With high temperature hydraulic fluid, both the compressor and the expander can be liquid-ring pumps even up to 400 °C, with rotating casing for best efficiency.

References

US8481

* The evolution of the heat engine, by: Ivo Kolin Published Moriya Press, 1972 by Longman * Hot Air Caloric and Stirling Engines, by: Robert Sier. Published 1999, by L A Mair.

External links

* 1979 RAND report on a new "Ericsson Cycle Gas Turbine Powerplant" desigInquiry into the Hot Air Engines of the 19th Century

{{Thermodynamic cycles, state=uncollapsed Thermodynamic cycles Piston engines