|

Inconel

Inconel is a nickel-chromium-based superalloy often utilized in extreme environments where components are subjected to high temperature, pressure or Mechanical load, mechanical loads. Inconel alloys are oxidation- and corrosion-resistant. When heated, Inconel forms a thick, stable, passivation (chemistry), passivating oxide layer protecting the surface from further attack. Inconel retains strength over a wide temperature range, attractive for high-temperature applications where aluminum and steel would succumb to creep (deformation), creep as a result of thermally-induced crystal vacancies. Inconel's high-temperature strength is developed by solid solution strengthening or precipitation hardening, depending on the alloy.Inconel alloy 718 , Special Metals Corporation Inconel all ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Inconel 718

Inconel is a nickel-chromium-based superalloy often utilized in extreme environments where components are subjected to high temperature, pressure or mechanical loads. Inconel alloys are oxidation- and corrosion-resistant. When heated, Inconel forms a thick, stable, passivating oxide layer protecting the surface from further attack. Inconel retains strength over a wide temperature range, attractive for high-temperature applications where aluminum and steel would succumb to creep as a result of thermally-induced crystal vacancies. Inconel's high-temperature strength is developed by solid solution strengthening or precipitation hardening, depending on the alloy.Inconel alloy 718 , Special Metals Corporation Inconel alloys are typically used in high temperature applications. Com ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Inconel 625

Inconel Alloy 625 (UNS designation N06625) is a nickel-based superalloy that possesses high strength properties and resistance to elevated temperatures. It also demonstrates remarkable protection against corrosion and oxidation. Its ability to withstand high stress and a wide range of temperatures, both in and out of water, as well as being able to resist corrosion while being exposed to highly acidic environments makes it a fitting choice for nuclear and marine applications. Inconel 625 was developed in the 1960s with the purpose of creating a material that could be used for steam-line piping. Some modifications were made to its original composition that have enabled it to be even more creep-resistant and weldable. Because of this, the uses of Inconel 625 have expanded into a wide range of industries such as the chemical processing industry, and for marine and nuclear applications to make pumps and valves and other high pressure equipment. Because of the metal's high Niobium ( ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Precipitation Hardening

Precipitation hardening, also called age hardening or particle hardening, is a heat treatment technique used to increase the yield strength of malleable materials, including most structural alloys of aluminium, magnesium, nickel, titanium, and some steels, stainless steels, and duplex stainless steel. In superalloys, it is known to cause yield strength anomaly providing excellent high-temperature strength. Precipitation hardening relies on changes in solid solubility with temperature to produce fine particles of an impurity phase, which impede the movement of dislocations, or defects in a crystal's lattice. Since dislocations are often the dominant carriers of plasticity, this serves to harden the material. The impurities play the same role as the particle substances in particle-reinforced composite materials. Just as the formation of ice in air can produce clouds, snow, or hail, depending upon the thermal history of a given portion of the atmosphere, precipitation in solids ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Niobium

Niobium is a chemical element; it has chemical symbol, symbol Nb (formerly columbium, Cb) and atomic number 41. It is a light grey, crystalline, and Ductility, ductile transition metal. Pure niobium has a Mohs scale of mineral hardness, Mohs hardness rating similar to pure titanium, and it has similar ductility to iron. Niobium oxidizes in Earth's atmosphere very slowly, hence its application in jewelry as a hypoallergenic alternative to nickel. Niobium is often found in the minerals pyrochlore and columbite. Its name comes from Greek mythology: Niobe, daughter of Tantalus, the namesake of tantalum. The name reflects the great similarity between the two elements in their physical and chemical properties, which makes them difficult to distinguish. English chemist Charles Hatchett reported a new element similar to tantalum in 1801 and named it columbium. In 1809, English chemist William Hyde Wollaston wrongly concluded that tantalum and columbium were identical. German chemist He ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Special Metals Corporation

Special Metals Corporation (SMC) is an American supplier of special refractory alloys and is headquartered in New Hartford, New York, United States. The company has operations in Perth, Western Australia; Albury, New South Wales; Huntington, West Virginia; Dunkirk, New York; Burnaugh, Kentucky; Elkhart, Indiana and Hereford, England. SMC's trademarks include Inconel, Incoloy, Monel, Nimonic, and Udimet. History "In 1952, a predecessor of Special Metals pioneered the melting technology that led to the practical development of the superalloys that are the critical materials used in the 'hot' section of modern jet engines." At year end of 1996, SMC had "45 million pounds of vacuum induction melting capacity", 590 employees, was incorporated in Delaware and was managed by Don Muzyka. SMC acquired Inco Alloys International from Inco in 1998 at the same time as it sold US$125 million of preferred stock to Titanium Metals Corporation. In 2006, Special Metals was acquired by Prec ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mond Nickel Company

The Mond Nickel Company Limited was a United Kingdom-based mining company, formed on September 20, 1900, licensed in Canada to carry on business in the province of Ontario, from October 16, 1900. The firm was founded by Ludwig Mond (1839–1909) to process Canadian ore from mines near Sudbury, which were then shipped to Mond's works in Britain for final purification via his patented carbonyl process. The first of Mond's Canadian mining properties located in Denison Township, was purchased from Rinaldo McConnell and associates in 1899. This site was renamed the Victoria Mine and development began in 1900. About the same time, Mond's refinery at Clydach, near Swansea, Wales, was being erected. Around the same time, Mond purchased a second mining location from Rinaldo McConnell called the Garson Mine which was developed later on in Garson Township. In 1911 the Mond company began construction of a new smelter at Coniston, Ontario. In that year, the company purchased the min ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Superalloy

A superalloy, or high-performance alloy, is an alloy with the ability to operate at a high fraction of its melting point. Key characteristics of a superalloy include mechanical strength, thermal creep deformation resistance, surface stability, and corrosion and oxidation resistance. The crystal structure is typically face-centered cubic (FCC) austenitic. Examples of such alloys are Hastelloy, Inconel, Waspaloy, Rene alloys, Incoloy, MP98T, TMS alloys, and CMSX single crystal alloys. Superalloy development relies on chemical and process innovations. Superalloys develop high temperature strength through solid solution strengthening and precipitation strengthening from secondary phase precipitates such as gamma prime and carbides. Oxidation or corrosion resistance is provided by elements such as aluminium and chromium. Superalloys are often cast as a single crystal in order to eliminate grain boundaries, trading in strength at low temperatures for increased resistance to th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chromium

Chromium is a chemical element; it has Symbol (chemistry), symbol Cr and atomic number 24. It is the first element in Group 6 element, group 6. It is a steely-grey, Luster (mineralogy), lustrous, hard, and brittle transition metal. Chromium is valued for its high corrosion resistance and hardness. A major development in steel production was the discovery that steel could be made highly resistant to corrosion and discoloration by adding metallic chromium to form stainless steel. Stainless steel and chrome plating (electroplating with chromium) together comprise 85% of the commercial use. Chromium is also greatly valued as a metal that is able to be highly polishing, polished while resisting tarnishing. Polished chromium reflects almost 70% of the visible spectrum, and almost 90% of infrared, infrared light. The name of the element is derived from the Ancient Greek, Greek word χρῶμα, ''chrōma'', meaning color, because many chromium compounds are intensely colored. Indust ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Solid Solution Strengthening

In metallurgy, solid solution strengthening is a type of alloying that can be used to improve the strength of a pure metal. The technique works by adding atoms of one element (the alloying element) to the crystalline lattice of another element (the base metal), forming a solid solution. The local nonuniformity in the lattice due to the alloying element makes plastic deformation more difficult by impeding dislocation motion through stress fields. In contrast, alloying beyond the solubility limit can form a second phase, leading to strengthening via other mechanisms (e.g. the precipitation of intermetallic compounds). Types Depending on the size of the alloying element, a substitutional solid solution or an interstitial solid solution can form. In both cases, atoms are visualised as rigid spheres where the overall crystal structure is essentially unchanged. The rationale of crystal geometry to atom solubility prediction is summarized in the Hume-Rothery rules and Pauling's rul ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

International Nickel Company

Vale Canada Limited (formerly Vale Inco, CVRD Inco and Inco Limited; for corporate branding purposes simply known as "Vale" and pronounced in English) is a wholly owned subsidiary of the Brazilian mining company Vale. Vale's nickel mining and metals division is headquartered in Toronto, Ontario, Canada. It produces nickel, copper, cobalt, platinum, rhodium, ruthenium, iridium, gold, and silver. Prior to being purchased by CVRD (now Vale) in 2006, Inco was the world's second largest producer of nickel, and the third largest mining company outside South Africa and Russia of platinum group metals. It was also a charter member of the 30-stock Dow Jones Industrial Average formed on October 1, 1928. History Founding of Inco The company was founded following the discovery by blacksmith Tom Flanagan in Copper Cliff, Ontario of chalcopyrite deposits, while the Canadian Pacific Railway was being built in 1883; the township of Greater Sudbury, Sudbury soon followed in 1884 when JL Mor ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chromium

Chromium is a chemical element; it has Symbol (chemistry), symbol Cr and atomic number 24. It is the first element in Group 6 element, group 6. It is a steely-grey, Luster (mineralogy), lustrous, hard, and brittle transition metal. Chromium is valued for its high corrosion resistance and hardness. A major development in steel production was the discovery that steel could be made highly resistant to corrosion and discoloration by adding metallic chromium to form stainless steel. Stainless steel and chrome plating (electroplating with chromium) together comprise 85% of the commercial use. Chromium is also greatly valued as a metal that is able to be highly polishing, polished while resisting tarnishing. Polished chromium reflects almost 70% of the visible spectrum, and almost 90% of infrared, infrared light. The name of the element is derived from the Ancient Greek, Greek word χρῶμα, ''chrōma'', meaning color, because many chromium compounds are intensely colored. Indust ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nickel

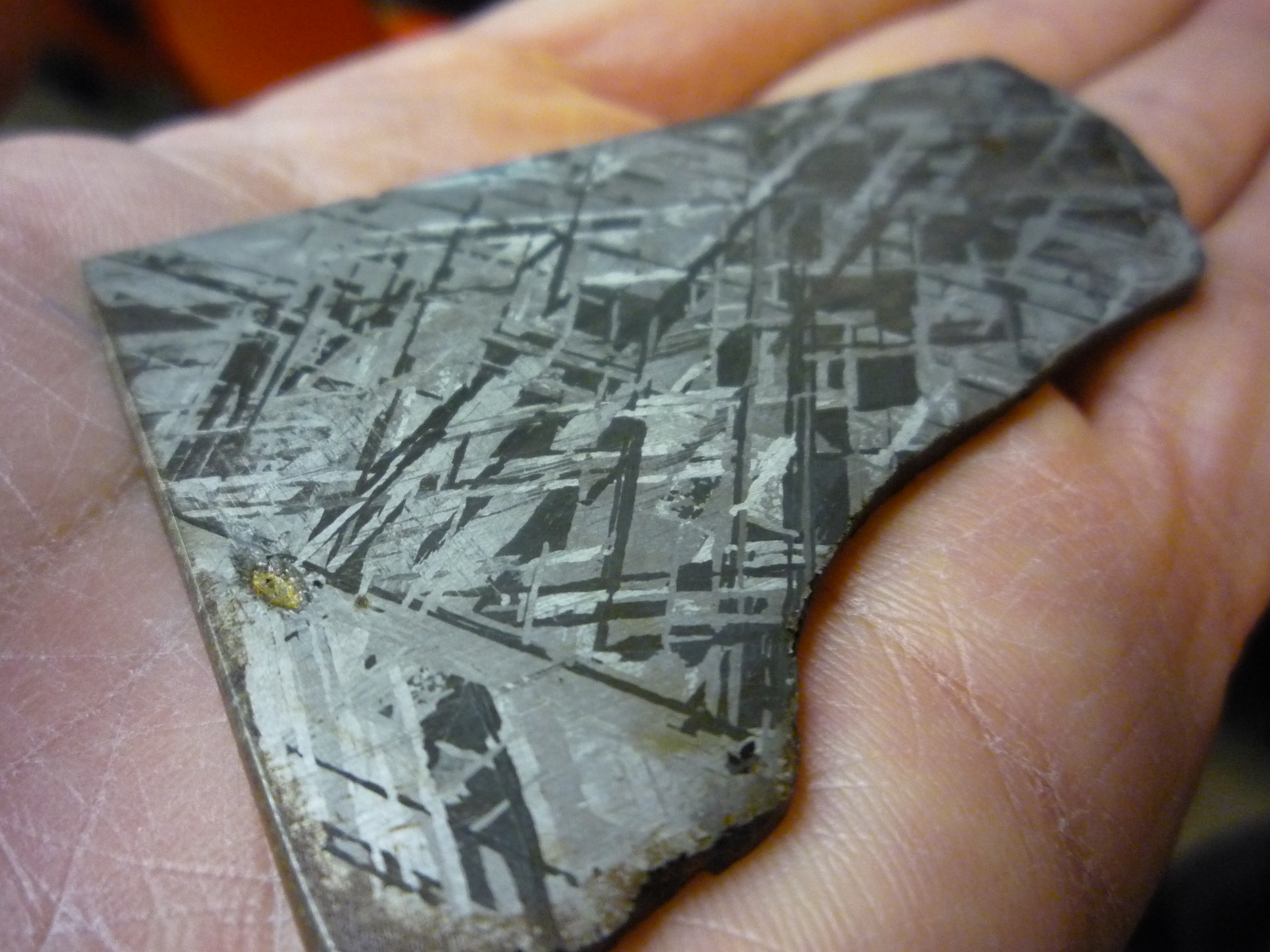

Nickel is a chemical element; it has symbol Ni and atomic number 28. It is a silvery-white lustrous metal with a slight golden tinge. Nickel is a hard and ductile transition metal. Pure nickel is chemically reactive, but large pieces are slow to react with air under standard conditions because a passivation layer of nickel oxide forms on the surface that prevents further corrosion. Even so, pure native nickel is found in Earth's crust only in tiny amounts, usually in ultramafic rocks, and in the interiors of larger nickel–iron meteorites that were not exposed to oxygen when outside Earth's atmosphere. Meteoric nickel is found in combination with iron, a reflection of the origin of those elements as major end products of supernova nucleosynthesis. An iron–nickel mixture is thought to compose Earth's outer and inner cores. Use of nickel (as natural meteoric nickel–iron alloy) has been traced as far back as 3500 BCE. Nickel was first isolated and classifie ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |