|

Solid Solution Strengthening

In metallurgy, solid solution strengthening is a type of alloying that can be used to improve the strength of a pure metal. The technique works by adding atoms of one element (the alloying element) to the crystalline lattice of another element (the base metal), forming a solid solution. The local nonuniformity in the lattice due to the alloying element makes plastic deformation more difficult by impeding dislocation motion through stress fields. In contrast, alloying beyond the solubility limit can form a second phase, leading to strengthening via other mechanisms (e.g. the precipitation of intermetallic compounds). Types Depending on the size of the alloying element, a substitutional solid solution or an interstitial solid solution can form. In both cases, atoms are visualised as rigid spheres where the overall crystal structure is essentially unchanged. The rationale of crystal geometry to atom solubility prediction is summarized in the Hume-Rothery rules and Pauling's rul ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metallurgy

Metallurgy is a domain of materials science and engineering that studies the physical and chemical behavior of metallic elements, their inter-metallic compounds, and their mixtures, which are known as alloys. Metallurgy encompasses both the science and the technology of metals, including the production of metals and the engineering of metal components used in products for both consumers and manufacturers. Metallurgy is distinct from the craft of metalworking. Metalworking relies on metallurgy in a similar manner to how medicine relies on medical science for technical advancement. A specialist practitioner of metallurgy is known as a metallurgist. The science of metallurgy is further subdivided into two broad categories: chemical metallurgy and physical metallurgy. Chemical metallurgy is chiefly concerned with the reduction and oxidation of metals, and the chemical performance of metals. Subjects of study in chemical metallurgy include mineral processing, the extraction ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

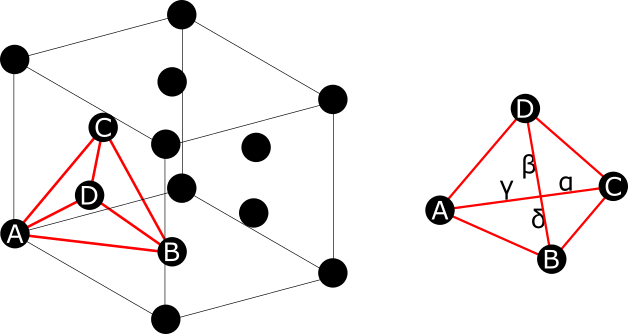

Crystal Structure

In crystallography, crystal structure is a description of ordered arrangement of atoms, ions, or molecules in a crystalline material. Ordered structures occur from intrinsic nature of constituent particles to form symmetric patterns that repeat along the principal directions of three-dimensional space in matter. The smallest group of particles in a material that constitutes this repeating pattern is the unit cell of the structure. The unit cell completely reflects the symmetry and structure of the entire crystal, which is built up by repetitive translation of the unit cell along its principal axes. The translation vectors define the nodes of the Bravais lattice. The lengths of principal axes/edges, of the unit cell and angles between them are lattice constants, also called ''lattice parameters'' or ''cell parameters''. The symmetry properties of a crystal are described by the concept of space groups. All possible symmetric arrangements of particles in three-dimensional space ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Aluminum Alloys

An aluminium alloy ( UK/IUPAC) or aluminum alloy ( NA; see spelling differences) is an alloy in which aluminium (Al) is the predominant metal. The typical alloying elements are copper, magnesium, manganese, silicon, tin, nickel and zinc. There are two principal classifications, namely casting alloys and wrought alloys, both of which are further subdivided into the categories heat-treatable and non-heat-treatable. About 85% of aluminium is used for wrought products, for example rolled plate, foils and extrusions. Cast aluminium alloys yield cost-effective products due to their low melting points, although they generally have lower tensile strengths than wrought alloys. The most important cast aluminium alloy system is Al–Si, where the high levels of silicon (4–13%) contribute to give good casting characteristics. Aluminium alloys are widely used in engineering structures and components where light weight or corrosion resistance is required.I. J. Polmear, ''Light Alloys'', Ar ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Burger's Vector

In materials science, the Burgers vector, named after Dutch physicist Jan Burgers, is a vector, often denoted as , that represents the magnitude and direction of the lattice distortion resulting from a dislocation in a crystal lattice. Concepts The vector's magnitude and direction is best understood when the dislocation-bearing crystal structure is first visualized ''without'' the dislocation, that is, the ''perfect'' crystal structure. In this perfect crystal structure, a rectangle whose lengths and widths are integer multiples of (the unit cell edge length) is drawn ''encompassing'' the site of the dislocation's origin. Once this encompassing rectangle is drawn, the dislocation can be introduced. This dislocation will have the effect of deforming, not only the perfect crystal structure, but the rectangle as well. The rectangle could have one of its sides disjointed from the perpendicular side, severing the connection of the length and width line segments of the rectangle at o ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Shear Modulus

In materials science, shear modulus or modulus of rigidity, denoted by ''G'', or sometimes ''S'' or ''μ'', is a measure of the Elasticity (physics), elastic shear stiffness of a material and is defined as the ratio of shear stress to the shear strain: :G \ \stackrel\ \frac = \frac = \frac where :\tau_ = F/A \, = shear stress :F is the force which acts :A is the area on which the force acts :\gamma_ = shear strain. In engineering :=\Delta x/l = \tan \theta , elsewhere := \theta :\Delta x is the transverse displacement :l is the initial length of the area. The derived SI unit of shear modulus is the Pascal (unit), pascal (Pa), although it is usually expressed in Pascal (unit), gigapascals (GPa) or in thousand pounds per square inch (ksi). Its dimensional analysis, dimensional form is M1L−1T−2, replacing ''force'' by ''mass'' times ''acceleration''. Explanation The shear modulus is one of several quantities for measuring the stiffness of materials. All of them arise in ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Case Hardening

Case-hardening or carburization is the process of introducing carbon to the surface of a low-carbon iron, or more commonly a low-carbon steel object, in order to harden the surface. Iron which has a carbon content greater than ~0.02% is known as steel. Steel which has a carbon content greater than ~0.25% can be direct-hardened by heating to around 600°C, and then quickly cooling, often by immersing in water or oil, known as quenching. Hardening is desirable for metal components because it gives increased strength and wear resistance, the tradeoff being that hardened steel is generally more brittle and less malleable than when it is in a softer state. In order to produce a hard skin on steels which have less than ~0.2% carbon, carbon can be introduced into the surface by heating steel in the presence of some carbon-rich substance such as powdered charcoal or hydrocarbon gas. This causes carbon to diffuse into the surface of the steel. The depth of this high carbon layer depend ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Partial Dislocation

In materials science, a partial dislocation is a decomposed form of dislocation that occurs within a crystalline material. An ''extended dislocation'' is a dislocation that has dissociated into a pair of partial dislocations. The vector sum of the Burgers vectors of the partial dislocations is the Burgers vector of the extended dislocation. Reaction favorability A dislocation will decompose into partial dislocations if the energy state of the sum of the partials is less than the energy state of the original dislocation. This is summarized by ''Frank's Energy Criterion'': : \begin , \boldsymbol, ^2>&, \boldsymbol, ^2+, \boldsymbol, ^2 \text\\ , \boldsymbol, ^2& , \frac \sqrt, ^2+, \frac \sqrt, ^2\\ \frac >& \frac+\frac \end The components of the ''Shockley Partials'' must add up to the original vector that is being decomposed: : \begin \frac (1) =& \frac(2)+\frac(1)\\ \frac (0) =& \frac(-1)+\frac(1)\\ \frac (-1) =& \frac(-1)+\frac(-2) \end Frank partial dislocations ''Frank p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stacking Fault

In crystallography, a stacking fault is a planar defect that can occur in crystalline materials.Fine, Morris E. (1921). "Introduction to Chemical and Structural Defects in Crystalline Solids", in ''Treatise on Solid State Chemistry Volume 1'', Springer. Crystalline materials form repeating patterns of layers of atoms. Errors can occur in the sequence of these layers and are known as stacking faults. Stacking faults are in a higher energy state which is quantified by the formation enthalpy per unit area called the stacking-fault energy. Stacking faults can arise during crystal growth or from plastic deformation. In addition, dislocations in low stacking-fault energy materials typically dissociate into an ''extended dislocation'', which is a stacking fault bounded by partial dislocations. The most common example of stacking faults is found in close-packed crystal structures. Face-centered cubic (fcc) structures differ from hexagonal close packed (hcp) structures only in stacking ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Elastic Modulus

An elastic modulus (also known as modulus of elasticity (MOE)) is a quantity that describes an object's or substance's resistance to being deformed elastically (i.e., non-permanently) when a stress is applied to it. Definition The elastic modulus of an object is defined as the slope of its stress–strain curve in the elastic deformation region: A stiffer material will have a higher elastic modulus. An elastic modulus has the form: :\delta \ \stackrel\ \frac where stress is the force causing the deformation divided by the area to which the force is applied and strain is the ratio of the change in some parameter caused by the deformation to the original value of the parameter. Since strain is a dimensionless quantity, the units of \delta will be the same as the units of stress. Elastic constants and moduli Elastic constants are specific parameters that quantify the stiffness of a material in response to applied stresses and are fundamental in defining the elastic pr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Edge Dislocation

In materials science, a dislocation or Taylor's dislocation is a linear crystallographic defect or irregularity within a crystal structure that contains an abrupt change in the arrangement of atoms. The movement of dislocations allow atoms to slide over each other at low stress levels and is known as ''glide'' or slip. The crystalline order is restored on either side of a ''glide dislocation'' but the atoms on one side have moved by one position. The crystalline order is not fully restored with a ''partial dislocation''. A dislocation defines the boundary between ''slipped'' and ''unslipped'' regions of material and as a result, must either form a complete loop, intersect other dislocations or defects, or extend to the edges of the crystal. A dislocation can be characterised by the distance and direction of movement it causes to atoms which is defined by the Burgers vector. Plastic deformation of a material occurs by the creation and movement of many dislocations. The number and ar ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Modulus Effect

Modulus is the diminutive from the Latin word ''modus'' meaning measure or manner. It, or its plural moduli, may refer to the following: Physics, engineering and computing * Moduli (physics), scalar fields for which the potential energy function has continuous families of global minima * The measurement of standard pitch in the teeth of a rotating gear * Bulk modulus, a measure of compression resistance * Elastic modulus, a measure of stiffness *Shear modulus, a measure of elastic stiffness * Young's modulus, a specific elastic modulus * Modulo operation (a % b, mod(a, b), etc.), in both math and programming languages; results in remainder of a division * Casting modulus used in Chvorinov's rule. Mathematics * Modulus (modular arithmetic), base of modular arithmetic * Modulus, the absolute value of a real or complex number ( ) * Moduli space, in mathematics a geometric space whose points represent algebro-geometric objects * Conformal modulus, a measure of the size of a curv ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Yield Stress

In materials science and engineering, the yield point is the point on a stress–strain curve that indicates the limit of elasticity (physics), elastic behavior and the beginning of plasticity (physics), plastic behavior. Below the yield point, a material will deformation (engineering)#elastic deformation, deform elastically and will return to its original shape when the applied stress (mechanics), stress is removed. Once the yield point is passed, some fraction of the deformation will be permanent and non-reversible and is known as Deformation (engineering)#plastic deformation, plastic deformation. The yield strength or yield stress is a List of materials properties, material property and is the stress corresponding to the yield point at which the material begins to deform plastically. The yield strength is often used to determine the maximum allowable Structural load, load in a mechanical component, since it represents the upper limit to forces that can be applied without pro ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |