An internal combustion engine (ICE or IC engine) is a

heat engine in which the

combustion of a

fuel

A fuel is any material that can be made to react with other substances so that it releases energy as thermal energy or to be used for work. The concept was originally applied solely to those materials capable of releasing chemical energy but ...

occurs with an

oxidizer (usually air) in a

combustion chamber that is an integral part of the

working fluid flow circuit. In an internal combustion engine, the expansion of the high-

temperature and high-

pressure gases produced by combustion applies direct

force

In physics, a force is an influence that can change the motion of an object. A force can cause an object with mass to change its velocity (e.g. moving from a state of rest), i.e., to accelerate. Force can also be described intuitively as a p ...

to some component of the engine. The force is typically applied to

piston

A piston is a component of reciprocating engines, reciprocating pumps, gas compressors, hydraulic cylinders and pneumatic cylinders, among other similar mechanisms. It is the moving component that is contained by a cylinder and is made gas-tig ...

s (

piston engine

A reciprocating engine, also often known as a piston engine, is typically a heat engine that uses one or more reciprocating pistons to convert high temperature and high pressure into a rotating motion. This article describes the common featu ...

),

turbine blades (

gas turbine), a

rotor (Wankel engine), or a

nozzle

A nozzle is a device designed to control the direction or characteristics of a fluid flow (specially to increase velocity) as it exits (or enters) an enclosed chamber or pipe.

A nozzle is often a pipe or tube of varying cross sectional area, a ...

(

jet engine

A jet engine is a type of reaction engine discharging a fast-moving jet of heated gas (usually air) that generates thrust by jet propulsion. While this broad definition can include rocket, Pump-jet, water jet, and hybrid propulsion, the term ...

). This force moves the component over a distance, transforming

chemical energy

Chemical energy is the energy of chemical substances that is released when they undergo a chemical reaction and transform into other substances. Some examples of storage media of chemical energy include batteries, Schmidt-Rohr, K. (2018). "How ...

into

kinetic energy which is used to propel, move or power whatever the engine is attached to. This replaced the

external combustion engine for applications where the weight or size of an engine was more important.

The first commercially successful internal combustion engine was created by

Ătienne Lenoir around 1860,

and the first modern internal combustion engine, known as the

Otto engine, was created in 1876 by

Nicolaus Otto. The term ''

internal combustion engine'' usually refers to an engine in which combustion is

intermittent

Intermittency is a behavior of dynamical systems: regular alternation of phases of apparently periodic and chaotic dynamics.

Intermittent or intermittency may also refer to:

*Intermittent river or stream, the one that ceases to flow every year or ...

, such as the more familiar

two-stroke and

four-stroke

A four-stroke (also four-cycle) engine is an internal combustion (IC) engine in which the piston completes four separate strokes while turning the crankshaft. A stroke refers to the full travel of the piston along the cylinder, in either directio ...

piston engines, along with variants, such as the

six-stroke piston engine and the

Wankel rotary engine. A second class of internal combustion engines use continuous combustion:

gas turbines,

jet engine

A jet engine is a type of reaction engine discharging a fast-moving jet of heated gas (usually air) that generates thrust by jet propulsion. While this broad definition can include rocket, Pump-jet, water jet, and hybrid propulsion, the term ...

s and most

rocket engines, each of which are internal combustion engines on the same principle as previously described.

Firearm

A firearm is any type of gun designed to be readily carried and used by an individual. The term is legally defined further in different countries (see Legal definitions).

The first firearms originated in 10th-century China, when bamboo tubes ...

s are also a form of internal combustion engine,

though of a type so specialized that they are commonly treated as a separate category, along with weaponry such as mortars and anti-aircraft cannons. In contrast, in

external combustion engines, such as

steam

Steam is a substance containing water in the gas phase, and sometimes also an aerosol of liquid water droplets, or air. This may occur due to evaporation or due to boiling, where heat is applied until water reaches the enthalpy of vaporization ...

or

Stirling engines, energy is delivered to a working fluid not consisting of, mixed with, or contaminated by combustion products. Working fluids for external combustion engines include air, hot water,

pressurized water or even

boiler-heated

liquid sodium

Sodium is a chemical element with the symbol Na (from Latin ''natrium'') and atomic number 11. It is a soft, silvery-white, highly reactive metal. Sodium is an alkali metal, being in group 1 of the periodic table. Its only stable isot ...

.

While there are many stationary applications, most ICEs are used in mobile applications and are the primary power supply for

vehicles such as

cars,

aircraft

An aircraft is a vehicle that is able to fly by gaining support from the air. It counters the force of gravity by using either static lift or by using the dynamic lift of an airfoil, or in a few cases the downward thrust from jet engines. ...

and

boats. ICEs are typically powered by

hydrocarbon-based fuels like

natural gas,

gasoline,

diesel fuel, or

ethanol.

Renewable fuels like

biodiesel are used in compression ignition (CI) engines and

bioethanol or

ETBE

Ethyl ''tertiary''-butyl ether (ETBE), also known as ethyl ''tert''-butyl ether, is commonly used as an oxygenate gasoline additive in the production of gasoline from crude oil. ETBE offers equal or greater air quality benefits than ethanol ...

(ethyl tert-butyl ether) produced from bioethanol in spark ignition (SI) engines. As early as 1900 the inventor of the diesel engine,

Rudolf Diesel, was using peanut oil to run his engines. Renewable fuels are commonly blended with fossil fuels.

Hydrogen, which is rarely used, can be obtained from either fossil fuels or renewable energy.

History

Various

scientists and

engineer

Engineers, as practitioners of engineering, are professionals who invent, design, analyze, build and test machines, complex systems, structures, gadgets and materials to fulfill functional objectives and requirements while considering the l ...

s contributed to the development of internal combustion engines. In 1791,

John Barber John Barber may refer to:

Politics

*John Barber (Lord Mayor of London) (died 1741), Jacobite printer, Lord Mayor of London in 1732

*John Barber, represented Tryon County in the North Carolina General Assembly of 1777

* John Roaf Barber (1841â1917 ...

developed the

gas turbine. In 1794 Thomas Mead patented a

gas engine

A gas engine is an internal combustion engine that runs on a gaseous fuel, such as coal gas, producer gas, biogas, landfill gas or natural gas. In the United Kingdom, the term is unambiguous. In the United States, due to the widespread use of ...

. Also in 1794, Robert Street patented an internal combustion engine, which was also the first to use

liquid fuel, and built an engine around that time. In 1798,

John Stevens built the first American internal combustion engine. In 1807,

French

French (french: français(e), link=no) may refer to:

* Something of, from, or related to France

** French language, which originated in France, and its various dialects and accents

** French people, a nation and ethnic group identified with Franc ...

engineers

Nicéphore Niépce (who went on to invent

photography) and

Claude Niépce ran a prototype internal combustion engine, using controlled dust explosions, the

Pyréolophore, which was granted a patent by

Napoleon Bonaparte

Napoleon Bonaparte ; it, Napoleone Bonaparte, ; co, Napulione Buonaparte. (born Napoleone Buonaparte; 15 August 1769 â 5 May 1821), later known by his regnal name Napoleon I, was a French military commander and political leader who ...

. This engine powered a boat on the

SaĂŽne river in France.

In the same year,

Swiss

Swiss may refer to:

* the adjectival form of Switzerland

* Swiss people

Places

* Swiss, Missouri

* Swiss, North Carolina

*Swiss, West Virginia

* Swiss, Wisconsin

Other uses

*Swiss-system tournament, in various games and sports

*Swiss Internation ...

engineer

François Isaac de Rivaz invented a hydrogen-based internal combustion engine and powered the engine by electric spark. In 1808, De Rivaz fitted his invention to a primitive working vehicle â "the world's first internal combustion powered automobile". In 1823,

Samuel Brown Samuel Brown may refer to:

* Samuel Brown (Royal Navy officer) (1776â1852), English pioneer suspension bridge engineer and inventor

* Samuel Brown (engineer) (died 1849), English inventor of early internal combustion engine

* Samuel Brown (Wisco ...

patented the first internal combustion engine to be applied industrially.

In 1854 in the

UK, the Italian inventors

Eugenio Barsanti and

Felice Matteucci obtained the certification: "Obtaining Motive Power by the Explosion of Gases". In 1857 the Great Seal Patent Office conceded them patent No.1655 for the invention of an "Improved Apparatus for Obtaining Motive Power from Gases". Barsanti and Matteucci obtained other patents for the same invention in France, Belgium and Piedmont between 1857 and 1859. In 1860,

Belgian engineer

Jean Joseph Etienne Lenoir produced a gas-fired internal combustion engine.

In 1864,

Nicolaus Otto patented the first atmospheric gas engine. In 1872, American

George Brayton invented the first commercial liquid-fueled internal combustion engine. In 1876,

Nicolaus Otto began working with

Gottlieb Daimler and

Wilhelm Maybach, patented the compressed charge, four-cycle engine. In 1879,

Karl Benz patented a reliable

two-stroke gasoline engine. Later, in 1886, Benz began the first commercial production of motor vehicles with an internal combustion engine, in which a three-wheeled, four-cycle engine and chassis formed a single unit.

In 1892,

Rudolf Diesel developed the first compressed charge, compression ignition engine. In 1926,

Robert Goddard launched the first liquid-fueled rocket. In 1939, the

Heinkel He 178 became the world's first

jet aircraft

A jet aircraft (or simply jet) is an aircraft (nearly always a fixed-wing aircraft) propelled by jet engines.

Whereas the engines in propeller-powered aircraft generally achieve their maximum efficiency at much lower speeds and altitudes, je ...

.

Etymology

At one time, the word ''engine'' (via

Old French, from

Latin ''ingenium'', "ability") meant any piece of

machinery

A machine is a physical system using power to apply forces and control movement to perform an action. The term is commonly applied to artificial devices, such as those employing engines or motors, but also to natural biological macromolecule ...

âa sense that persists in expressions such as ''

siege engine''. A "motor" (from Latin ''motor'', "mover") is any machine that produces mechanical

power. Traditionally,

electric motors are not referred to as "engines"; however, combustion engines are often referred to as "motors". (An ''

electric engine'' refers to a

locomotive

A locomotive or engine is a rail transport vehicle that provides the Power (physics), motive power for a train. If a locomotive is capable of carrying a payload, it is usually rather referred to as a multiple unit, Motor coach (rail), motor ...

operated by electricity.)

In boating, an internal combustion engine that is installed in the hull is referred to as an engine, but the engines that sit on the transom are referred to as motors.

Applications

Reciprocating piston engines are by far the most common power source for land and water

vehicles, including

automobiles,

motorcycles,

ships and to a lesser extent,

locomotive

A locomotive or engine is a rail transport vehicle that provides the Power (physics), motive power for a train. If a locomotive is capable of carrying a payload, it is usually rather referred to as a multiple unit, Motor coach (rail), motor ...

s (some are electrical but most use Diesel engines). Rotary engines of the Wankel design are used in some automobiles, aircraft and motorcycles. These are collectively known as internal-combustion-engine vehicles (ICEV).

Where high power-to-weight ratios are required, internal combustion engines appear in the form of

combustion turbines, or sometimes Wankel engines.

Powered aircraft typically use an ICE which may be a reciprocating engine. Airplanes can instead use

jet engine

A jet engine is a type of reaction engine discharging a fast-moving jet of heated gas (usually air) that generates thrust by jet propulsion. While this broad definition can include rocket, Pump-jet, water jet, and hybrid propulsion, the term ...

s and

helicopters can instead employ

turboshafts; both of which are types of turbines. In addition to providing propulsion,

airliner

An airliner is a type of aircraft for transporting passengers and air cargo. Such aircraft are most often operated by airlines. Although the definition of an airliner can vary from country to country, an airliner is typically defined as an ...

s may employ a separate ICE as an

auxiliary power unit. Wankel engines are fitted to many

unmanned aerial vehicles.

ICEs drive large electric generators that power electrical grids. They are found in the form of

combustion turbines with a typical electrical output in the range of some 100 MW.

Combined cycle power plants use the high temperature exhaust to boil and superheat water steam to run a

steam turbine

A steam turbine is a machine that extracts thermal energy from pressurized steam and uses it to do mechanical work on a rotating output shaft. Its modern manifestation was invented by Charles Parsons in 1884. Fabrication of a modern steam turbin ...

. Thus, the efficiency is higher because more energy is extracted from the fuel than what could be extracted by the combustion engine alone.

Combined cycle power plants achieve efficiencies in the range of 50% to 60%. In a smaller scale,

stationary engine

A stationary engine is an engine whose framework does not move. They are used to drive immobile equipment, such as pumps, generators, mills or factory machinery, or cable cars. The term usually refers to large immobile reciprocating engines, pr ...

s like

gas engine

A gas engine is an internal combustion engine that runs on a gaseous fuel, such as coal gas, producer gas, biogas, landfill gas or natural gas. In the United Kingdom, the term is unambiguous. In the United States, due to the widespread use of ...

s or

diesel generators are used for backup or for providing electrical power to areas not connected to an

electric grid.

Small engines (usually 2âstroke gasoline/petrol engines) are a common power source for

lawnmowers,

string trimmers,

chain saws,

leafblowers,

pressure washers,

snowmobiles,

jet skis,

outboard motors,

mopeds, and

motorcycles.

Classification

There are several possible ways to classify internal combustion engines.

Reciprocating

By number of strokes:

*

Two-stroke engine

** Clerk cycle

** Day cycle

*

Four-stroke engine (

Otto cycle)

*

Six-stroke engine

By type of ignition:

*

Compression-ignition engine

*

Spark-ignition engine (commonly found as

gasoline engines)

By mechanical/thermodynamic cycle (these cycles are infrequently used but are commonly found in

hybrid vehicles, along with other vehicles manufactured for

fuel efficiency

Fuel efficiency is a form of thermal efficiency, meaning the ratio of effort to result of a process that converts chemical potential energy contained in a carrier (fuel) into kinetic energy or work. Overall fuel efficiency may vary per device, wh ...

):

*

Atkinson cycle

*

Miller cycle

Rotary

*

Wankel engine

Continuous combustion

*

Gas turbine engine

**

Turbojet, through a propelling nozzle

**

Turbofan, through a duct-fan

**

Turboprop, through an unducted propeller, usually with variable pitch

**

Turboshaft, a gas turbine optimized for producing mechanical torque instead of thrust

*

Ramjet, similar to a turbojet but uses vehicle speed to compress (ram) the air instead of a compressor.

*

Scramjet, a variant of the ramjet that uses supersonic combustion.

*

Rocket engine

Reciprocating engines

Structure

The base of a reciprocating internal combustion engine is the

engine block, which is typically made of

cast iron

Cast iron is a class of ironâ carbon alloys with a carbon content more than 2%. Its usefulness derives from its relatively low melting temperature. The alloy constituents affect its color when fractured: white cast iron has carbide impu ...

(due to its good wear resistance and low cost)

or

aluminum. In the latter case, the cylinder liners are made of cast iron or steel,

or a coating such as

nikasil or

alusil. The engine block contains the

cylinders

A cylinder (from ) has traditionally been a three-dimensional solid, one of the most basic of curvilinear geometric shapes. In elementary geometry, it is considered a prism with a circle as its base.

A cylinder may also be defined as an infini ...

. In engines with more than one cylinder they are usually arranged either in 1 row (

straight engine

The straight or inline engine is an internal combustion engine with all cylinders aligned in one row and having no offset. Usually found in four, six and eight cylinder configurations, they have been used in automobiles, locomotives and aircraft ...

) or 2 rows (

boxer engine or

V engine); 3 rows are occasionally used (

W engine) in contemporary engines, and other

engine configurations are possible and have been used.

Single cylinder engines (or ''thumpers'') are common for motorcycles and other small engines found in light machinery. On the outer side of the cylinder, passages that contain cooling fluid are cast into the engine block whereas, in some heavy duty engines, the passages are the types of removable cylinder sleeves which can be replaceable.

Water-cooled engines contain passages in the engine block where cooling fluid circulates (the

water jacket). Some small engines are air-cooled, and instead of having a water jacket the cylinder block has fins protruding away from it to cool the engine by directly transferring heat to the air. The cylinder walls are usually finished by

honing to obtain a cross hatch, which is able to retain more oil. A too rough surface would quickly harm the engine by excessive wear on the piston.

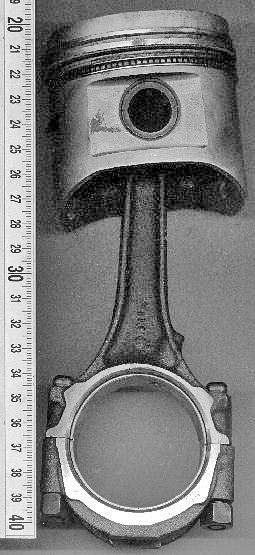

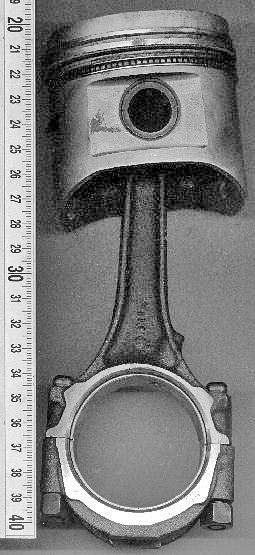

The

piston

A piston is a component of reciprocating engines, reciprocating pumps, gas compressors, hydraulic cylinders and pneumatic cylinders, among other similar mechanisms. It is the moving component that is contained by a cylinder and is made gas-tig ...

s are short cylindrical parts which seal one end of the cylinder from the high pressure of the compressed air and combustion products and slide continuously within it while the engine is in operation. In smaller engines, the pistons are made of aluminum; while in larger applications, they are typically made of cast iron.

The top wall of the piston is termed its ''crown'' and is typically flat or concave. Some two-stroke engines use pistons with a

deflector head. Pistons are open at the bottom and hollow except for an integral reinforcement structure (the piston web). When an engine is working, the gas pressure in the combustion chamber exerts a force on the piston crown which is transferred through its web to a

gudgeon pin. Each piston has

rings fitted around its circumference that mostly prevent the gases from leaking into the crankcase or the oil into the combustion chamber.

A

ventilation system drives the small amount of gas that escapes past the pistons during normal operation (the blow-by gases) out of the crankcase so that it does not accumulate contaminating the oil and creating corrosion.

In two-stroke gasoline engines the crankcase is part of the airâfuel path and due to the continuous flow of it, two-stroke engines do not need a separate crankcase ventilation system.

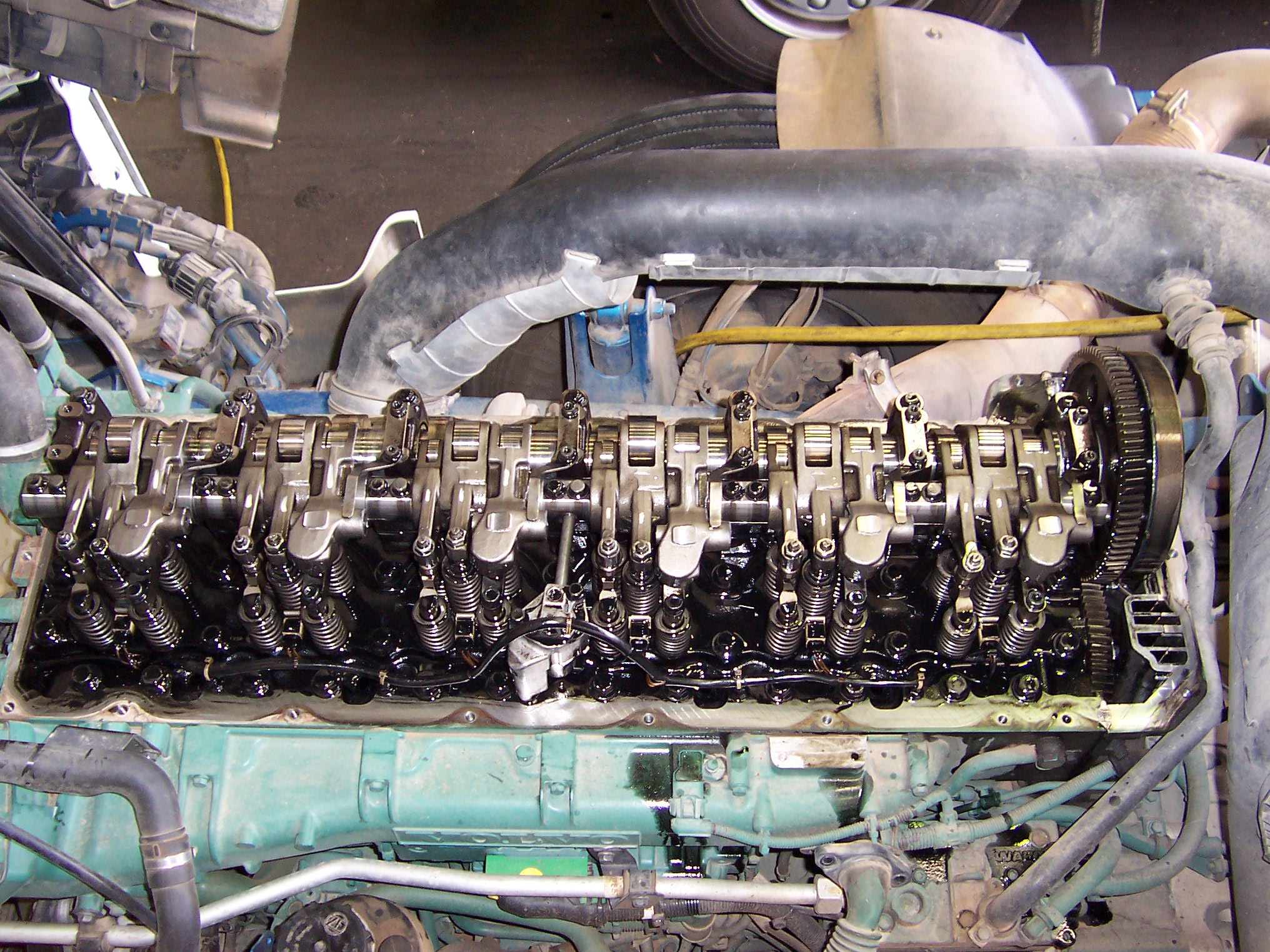

The

cylinder head is attached to the engine block by numerous

bolts or

studs. It has several functions. The cylinder head seals the cylinders on the side opposite to the pistons; it contains short ducts (the ''ports'') for intake and exhaust and the associated intake

valves that open to let the cylinder be filled with fresh air and exhaust valves that open to allow the combustion gases to escape. However, 2-stroke crankcase scavenged engines connect the gas ports directly to the cylinder wall without poppet valves; the piston controls their opening and occlusion instead. The cylinder head also holds the

spark plug

A spark plug (sometimes, in British English, a sparking plug, and, colloquially, a plug) is a device for delivering electric current from an ignition system to the combustion chamber of a spark-ignition engine to ignite the compressed fuel/air ...

in the case of spark ignition engines and the

injector for engines that use direct injection. All CI (compression ignition) engines use fuel injection, usually direct injection but some engines instead use

indirect injection. SI (spark ignition) engines can use a

carburetor

A carburetor (also spelled carburettor) is a device used by an internal combustion engine to control and mix air and fuel entering the engine. The primary method of adding fuel to the intake air is through the venturi tube in the main meteri ...

or fuel injection as port injection or

direct injection. Most SI engines have a single spark plug per cylinder but

some have 2. A

head gasket prevents the gas from leaking between the cylinder head and the engine block. The opening and closing of the valves is controlled by one or several

camshaft

A camshaft is a shaft that contains a row of pointed cams, in order to convert rotational motion to reciprocating motion. Camshafts are used in piston engines (to operate the intake and exhaust valves), mechanically controlled ignition systems ...

s and springsâor in some enginesâa

desmodromic mechanism that uses no springs. The camshaft may press directly the stem of the valve or may act upon a

rocker arm, again, either directly or through a

pushrod.

The crankcase is sealed at the bottom with a

sump that collects the falling oil during normal operation to be cycled again. The cavity created between the cylinder block and the sump houses a

crankshaft

A crankshaft is a mechanical component used in a piston engine to convert the reciprocating motion into rotational motion. The crankshaft is a rotating shaft containing one or more crankpins, that are driven by the pistons via the connecting ...

that converts the reciprocating motion of the pistons to rotational motion. The crankshaft is held in place relative to the engine block by

main bearings, which allow it to rotate. Bulkheads in the crankcase form a half of every main bearing; the other half is a detachable cap. In some cases a single ''main bearing deck'' is used rather than several smaller caps. A

connecting rod

A connecting rod, also called a 'con rod', is the part of a piston engine which connects the piston to the crankshaft. Together with the crank, the connecting rod converts the reciprocating motion of the piston into the rotation of the cranksh ...

is connected to offset sections of the crankshaft (the

crankpins) in one end and to the piston in the other end through the gudgeon pin and thus transfers the force and translates the reciprocating motion of the pistons to the circular motion of the crankshaft. The end of the connecting rod attached to the gudgeon pin is called its small end, and the other end, where it is connected to the crankshaft, the big end. The big end has a detachable half to allow assembly around the crankshaft. It is kept together to the connecting rod by removable bolts.

The cylinder head has an

intake manifold and an

exhaust manifold

In automotive engineering, an exhaust manifold collects the exhaust gases from multiple cylinders into one pipe. The word ''manifold'' comes from the Old English word ''manigfeald'' (from the Anglo-Saxon ''manig'' anyand ''feald'' old and refe ...

attached to the corresponding ports. The intake manifold connects to the

air filter directly, or to a carburetor when one is present, which is then connected to the

air filter. It distributes the air incoming from these devices to the individual cylinders. The exhaust manifold is the first component in the

exhaust system. It collects the exhaust gases from the cylinders and drives it to the following component in the path. The

exhaust system of an ICE may also include a

catalytic converter and

muffler. The final section in the path of the exhaust gases is the

tailpipe.

4-stroke engines

The ''top dead center'' (TDC) of a piston is the position where it is nearest to the valves; ''bottom dead center'' (BDC) is the opposite position where it is furthest from them. A ''stroke'' is the movement of a piston from TDC to BDC or vice versa, together with the associated process. While an engine is in operation, the crankshaft rotates continuously at a nearly constant

speed. In a 4-stroke ICE, each piston experiences 2 strokes per crankshaft revolution in the following order. Starting the description at TDC, these are:

# Intake, induction or suction: The intake valves are open as a result of the cam lobe pressing down on the valve stem. The piston moves downward increasing the volume of the combustion chamber and allowing air to enter in the case of a CI engine or an air-fuel mix in the case of SI engines that do not use

direct injection. The air or air-fuel mixture is called the ''charge'' in any case.

# Compression: In this stroke, both valves are closed and the piston moves upward reducing the combustion chamber volume which reaches its minimum when the piston is at TDC. The piston performs

work on the charge as it is being compressed; as a result, its pressure, temperature and density increase; an approximation to this behavior is provided by the

ideal gas law. Just before the piston reaches TDC, ignition begins. In the case of a SI engine, the spark plug receives a high voltage pulse that generates the spark which gives it its name and ignites the charge. In the case of a CI engine, the fuel injector quickly injects fuel into the combustion chamber as a spray; the fuel ignites due to the high temperature.

# Power or working stroke: The pressure of the combustion gases pushes the piston downward, generating more

kinetic energy than is required to compress the charge. Complementary to the compression stroke, the combustion gases expand and as a result their temperature, pressure and density decreases. When the piston is near to BDC the exhaust valve opens. The combustion gases expand

irreversibly due to the leftover pressureâin excess of

back pressure, the gauge pressure on the exhaust portâ; this is called the ''blowdown''.

# Exhaust: The exhaust valve remains open while the piston moves upward expelling the combustion gases. For naturally aspirated engines a small part of the combustion gases may remain in the cylinder during normal operation because the piston does not close the combustion chamber completely; these gases dissolve in the next charge. At the end of this stroke, the exhaust valve closes, the intake valve opens, and the sequence repeats in the next cycle. The intake valve may open before the exhaust valve closes to allow better scavenging.

2-stroke engines

The defining characteristic of this kind of engine is that each piston completes a cycle every crankshaft revolution. The 4 processes of intake, compression, power and exhaust take place in only 2 strokes so that it is not possible to dedicate a stroke exclusively for each of them. Starting at TDC the cycle consists of:

# Power: While the piston is descending the combustion gases perform work on it, as in a 4-stroke engine. The same

thermodynamic considerations about the expansion apply.

# Scavenging: Around 75° of crankshaft rotation before BDC the exhaust valve or port opens, and blowdown occurs. Shortly thereafter the intake valve or transfer port opens. The incoming charge displaces the remaining combustion gases to the exhaust system and a part of the charge may enter the exhaust system as well. The piston reaches BDC and reverses direction. After the piston has traveled a short distance upwards into the cylinder the exhaust valve or port closes; shortly the intake valve or transfer port closes as well.

# Compression: With both intake and exhaust closed the piston continues moving upwards compressing the charge and performing work on it. As in the case of a 4-stroke engine, ignition starts just before the piston reaches TDC and the same consideration on the thermodynamics of the compression on the charge apply.

While a 4-stroke engine uses the piston as a

positive displacement pump to accomplish scavenging taking 2 of the 4 strokes, a 2-stroke engine uses the last part of the power stroke and the first part of the compression stroke for combined intake and exhaust. The work required to displace the charge and exhaust gases comes from either the crankcase or a separate blower. For scavenging, expulsion of burned gas and entry of fresh mix, two main approaches are described: Loop scavenging, and Uniflow scavenging. SAE news published in the 2010s that 'Loop Scavenging' is better under any circumstance than Uniflow Scavenging.

Crankcase scavenged

Some SI engines are crankcase scavenged and do not use poppet valves. Instead, the crankcase and the part of the cylinder below the piston is used as a pump. The intake port is connected to the crankcase through a

reed valve or a rotary disk valve driven by the engine. For each cylinder, a transfer port connects in one end to the crankcase and in the other end to the cylinder wall. The exhaust port is connected directly to the cylinder wall. The transfer and exhaust port are opened and closed by the piston. The reed valve opens when the crankcase pressure is slightly below intake pressure, to let it be filled with a new charge; this happens when the piston is moving upwards. When the piston is moving downwards the pressure in the crankcase increases and the reed valve closes promptly, then the charge in the crankcase is compressed. When the piston is moving downwards, it also uncovers the exhaust port and the transfer port and the higher pressure of the charge in the crankcase makes it enter the cylinder through the transfer port, blowing the exhaust gases. Lubrication is accomplished by adding ''

2-stroke oil'' to the fuel in small ratios. ''

Petroil'' refers to the mix of gasoline with the aforesaid oil. This kind of 2-stroke engine has a lower efficiency than comparable 4-strokes engines and releases more polluting

exhaust gases

Exhaust gas or flue gas is emitted as a result of the combustion of fuels such as natural gas, gasoline, gasoline (petrol), diesel fuel, fuel oil, biodiesel blends, or coal. According to the type of engine, it is discharged into the atmosphere th ...

for the following conditions:

* They use a ''

total-loss lubrication system'': all the lubricating oil is eventually burned along with the fuel.

* There are conflicting requirements for scavenging: On one side, enough fresh charge needs to be introduced in each cycle to displace almost all the combustion gases but introducing too much of it means that a part of it gets in the exhaust.

* They must use the transfer port(s) as a carefully designed and placed nozzle so that a gas current is created in a way that it sweeps the whole cylinder before reaching the exhaust port so as to expel the combustion gases, but minimize the amount of charge exhausted. 4-stroke engines have the benefit of forcibly expelling almost all of the combustion gases because during exhaust the combustion chamber is reduced to its minimum volume. In crankcase scavenged 2-stroke engines, exhaust and intake are performed mostly simultaneously and with the combustion chamber at its maximum volume.

The main advantage of 2-stroke engines of this type is mechanical simplicity and a higher

power-to-weight ratio

Power-to-weight ratio (PWR, also called specific power, or power-to-mass ratio) is a calculation commonly applied to engines and mobile power sources to enable the comparison of one unit or design to another. Power-to-weight ratio is a measuremen ...

than their 4-stroke counterparts. Despite having twice as many power strokes per cycle, less than twice the power of a comparable 4-stroke engine is attainable in practice.

In the US, 2-stroke engines were banned for road vehicles due to the pollution. Off-road only motorcycles are still often 2-stroke but are rarely road legal. However, many thousands of 2-stroke lawn maintenance engines are in use.

Blower scavenged

Using a separate blower avoids many of the shortcomings of crankcase scavenging, at the expense of increased complexity which means a higher cost and an increase in maintenance requirement. An engine of this type uses ports or valves for intake and valves for exhaust, except

opposed piston engines, which may also use ports for exhaust. The blower is usually of the

Roots-type but other types have been used too. This design is commonplace in CI engines, and has been occasionally used in SI engines.

CI engines that use a blower typically use ''

uniflow scavenging''. In this design the cylinder wall contains several intake ports placed uniformly spaced along the circumference just above the position that the piston crown reaches when at BDC. An exhaust valve or several like that of 4-stroke engines is used. The final part of the intake manifold is an air sleeve that feeds the intake ports. The intake ports are placed at a horizontal angle to the cylinder wall (I.e: they are in plane of the piston crown) to give a swirl to the incoming charge to improve combustion. The largest reciprocating IC are low speed CI engines of this type; they are used for marine propulsion (see

marine diesel engine) or

electric power generation and achieve the highest thermal efficiencies among internal combustion engines of any kind. Some Diesel-electric

locomotive engines operate on the 2-stroke cycle. The most powerful of them have a brake power of around 4.5

MW or 6,000

HP. The

EMD SD90MAC class of locomotives are an example of such. The comparable class

GE AC6000CW whose prime mover has almost the same brake power uses a 4-stroke engine.

An example of this type of engine is the

WÀrtsilÀ-Sulzer RT-flex96-C turbocharged 2-stroke Diesel, used in large container ships. It is the most efficient and powerful reciprocating internal combustion engine in the world with a

thermal efficiency over 50%. For comparison, the most efficient small four-stroke engines are around 43% thermally-efficient (SAE 900648); size is an advantage for efficiency due to the increase in the ratio of volume to surface area.

See the

external links for an in-cylinder combustion video in a 2-stroke, optically accessible motorcycle engine.

Historical design

Dugald Clerk developed the first two-cycle engine in 1879. It used a separate cylinder which functioned as a pump in order to transfer the fuel mixture to the cylinder.

In 1899

John Day simplified Clerk's design into the type of 2 cycle engine that is very widely used today.

Day cycle engines are crankcase scavenged and port timed. The crankcase and the part of the cylinder below the exhaust port is used as a pump. The operation of the Day cycle engine begins when the crankshaft is turned so that the piston moves from BDC upward (toward the head) creating a vacuum in the crankcase/cylinder area. The carburetor then feeds the fuel mixture into the crankcase through a

reed valve or a rotary disk valve (driven by the engine). There are cast in ducts from the crankcase to the port in the cylinder to provide for intake and another from the exhaust port to the exhaust pipe. The height of the port in relationship to the length of the cylinder is called the "port timing".

On the first upstroke of the engine there would be no fuel inducted into the cylinder as the crankcase was empty. On the downstroke, the piston now compresses the fuel mix, which has lubricated the piston in the cylinder and the bearings due to the fuel mix having oil added to it. As the piston moves downward it first uncovers the exhaust, but on the first stroke there is no burnt fuel to exhaust. As the piston moves downward further, it uncovers the intake port which has a duct that runs to the crankcase. Since the fuel mix in the crankcase is under pressure, the mix moves through the duct and into the cylinder.

Because there is no obstruction in the cylinder of the fuel to move directly out of the exhaust port prior to the piston rising far enough to close the port, early engines used a high domed piston to slow down the flow of fuel. Later the fuel was "resonated" back into the cylinder using an expansion chamber design. When the piston rose close to TDC, a spark ignited the fuel. As the piston is driven downward with power, it first uncovers the exhaust port where the burned fuel is expelled under high pressure and then the intake port where the process has been completed and will keep repeating.

Later engines used a type of porting devised by the Deutz company to improve performance. It was called the

Schnurle Reverse Flow system. DKW licensed this design for all their motorcycles. Their

DKW RT 125 was one of the first motor vehicles to achieve over 100 mpg as a result.

Ignition

Internal combustion engines require ignition of the mixture, either by

spark ignition (SI) or

compression ignition (CI). Before the invention of reliable electrical methods, hot tube and flame methods were used. Experimental engines with

laser ignition Laser ignition is an alternative method for igniting mixtures of fuel and oxidiser. The phase of the mixture can be gaseous or liquid. The method is based on laser ignition devices that produce short but powerful flashes regardless of the pressure i ...

have been built.

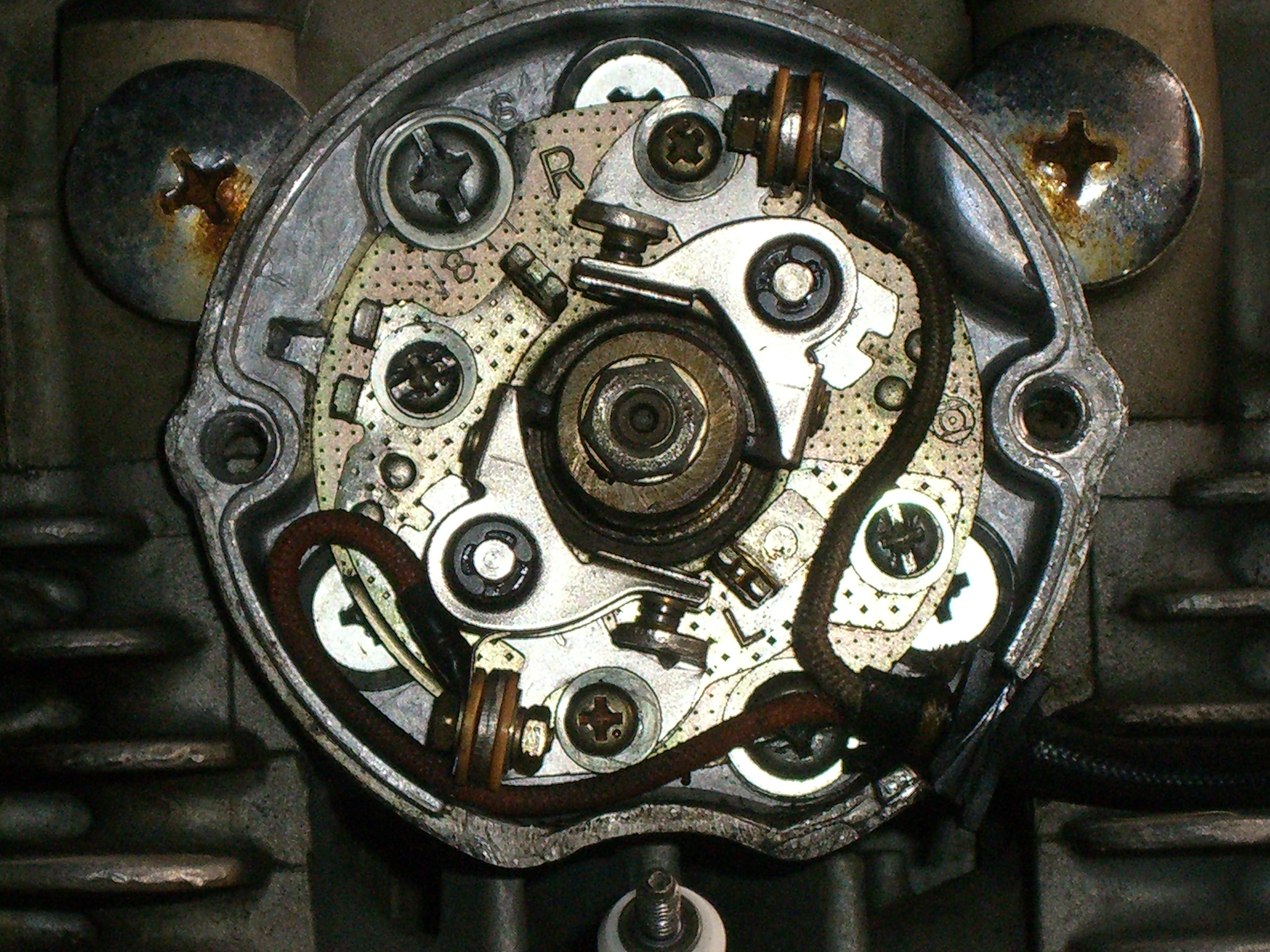

Spark ignition process

The spark-ignition engine was a refinement of the early engines which used Hot Tube ignition. When Bosch developed the

magneto it became the primary system for producing electricity to energize a spark plug. Many small engines still use magneto ignition. Small engines are started by hand cranking using a

recoil starter or hand crank. Prior to

Charles F. Kettering of Delco's development of the automotive starter all gasoline engined automobiles used a hand crank.

Larger engines typically power their

starting motors and

ignition systems using the electrical energy stored in a

leadâacid battery. The battery's charged state is maintained by an

automotive alternator or (previously) a generator which uses engine power to create electrical energy storage.

The battery supplies electrical power for starting when the engine has a

starting motor system, and supplies electrical power when the engine is off. The battery also supplies electrical power during rare run conditions where the alternator cannot maintain more than 13.8 volts (for a common 12V automotive electrical system). As alternator voltage falls below 13.8 volts, the lead-acid storage battery increasingly picks up electrical load. During virtually all running conditions, including normal idle conditions, the alternator supplies primary electrical power.

Some systems disable alternator field (rotor) power during wide-open throttle conditions. Disabling the field reduces alternator pulley mechanical loading to nearly zero, maximizing crankshaft power. In this case, the battery supplies all primary electrical power.

Gasoline engines take in a mixture of air and gasoline and compress it by the movement of the piston from bottom dead center to top dead center when the fuel is at maximum compression. The reduction in the size of the swept area of the cylinder and taking into account the volume of the combustion chamber is described by a ratio. Early engines had

compression ratio

The compression ratio is the ratio between the volume of the cylinder and combustion chamber in an internal combustion engine at their maximum and minimum values.

A fundamental specification for such engines, it is measured two ways: the stati ...

s of 6 to 1. As compression ratios were increased, the efficiency of the engine increased as well.

With early induction and ignition systems the compression ratios had to be kept low. With advances in fuel technology and combustion management, high-performance engines can run reliably at 12:1 ratio. With low octane fuel, a problem would occur as the compression ratio increased as the fuel was igniting due to the rise in temperature that resulted.

Charles Kettering developed a

lead additive which allowed higher compression ratios, which was progressively

abandoned for automotive use from the 1970s onward, partly due to

lead poisoning

Lead poisoning, also known as plumbism and saturnism, is a type of metal poisoning caused by lead in the body. The brain is the most sensitive. Symptoms may include abdominal pain, constipation, headaches, irritability, memory problems, inferti ...

concerns.

The fuel mixture is ignited at different progressions of the piston in the cylinder. At low rpm, the spark is timed to occur close to the piston achieving top dead center. In order to produce more power, as rpm rises the spark is advanced sooner during piston movement. The spark occurs while the fuel is still being compressed progressively more as rpm rises.

The necessary high voltage, typically 10,000 volts, is supplied by an

induction coil

An induction coil or "spark coil" (archaically known as an inductorium or Ruhmkorff coil after Heinrich RĂŒhmkorff) is a type of electrical transformer used to produce high-voltage pulses from a low-voltage direct current (DC) supply. p.98 To ...

or transformer. The induction coil is a fly-back system, using interruption of electrical primary system current through some type of synchronized interrupter. The interrupter can be either contact points or a power transistor. The problem with this type of ignition is that as RPM increases the availability of electrical energy decreases. This is especially a problem, since the amount of energy needed to ignite a more dense fuel mixture is higher. The result was often a high RPM misfire.

Capacitor discharge ignition was developed. It produces a rising voltage that is sent to the spark plug. CD system voltages can reach 60,000 volts. CD ignitions use step-up

transformers. The step-up transformer uses energy stored in a capacitance to generate

electric spark. With either system, a mechanical or electrical control system provides a carefully timed high-voltage to the proper cylinder. This spark, via the spark plug, ignites the air-fuel mixture in the engine's cylinders.

While gasoline internal combustion engines are much easier to start in cold weather than diesel engines, they can still have cold weather starting problems under extreme conditions. For years, the solution was to park the car in heated areas. In some parts of the world, the oil was actually drained and heated overnight and returned to the engine for cold starts. In the early 1950s, the gasoline Gasifier unit was developed, where, on cold weather starts, raw gasoline was diverted to the unit where part of the fuel was burned causing the other part to become a hot vapor sent directly to the intake valve manifold. This unit was quite popular until electric

engine block heater

A block heater is used in cold climates to warm an engine prior to starting. They are mostly used for car engines; however they have also been used in aircraft engines.

The most common design of block heater is an electrical heating element embed ...

s became standard on gasoline engines sold in cold climates.

Compression ignition process

For ignition, diesel,

PPC and

HCCI engines rely solely on the high temperature and pressure created by the engine in its compression process. The compression level that occurs is usually twice or more than a gasoline engine. Diesel engines take in air only, and shortly before peak compression, spray a small quantity of diesel fuel into the cylinder via a fuel injector that allows the fuel to instantly ignite. HCCI type engines take in both air and fuel, but continue to rely on an unaided auto-combustion process, due to higher pressures and temperature. This is also why diesel and HCCI engines are more susceptible to cold-starting issues, although they run just as well in cold weather once started. Light duty diesel engines with

indirect injection in automobiles and light trucks employ

glowplugs (or other pre-heating: see

Cummins ISB#6BT) that pre-heat the

combustion chamber just before starting to reduce no-start conditions in cold weather. Most diesels also have a battery and charging system; nevertheless, this system is secondary and is added by manufacturers as a luxury for the ease of starting, turning fuel on and off (which can also be done via a switch or mechanical apparatus), and for running auxiliary electrical components and accessories. Most new engines rely on electrical and electronic

engine control unit

An engine control unit (ECU), also commonly called an engine control module (ECM), is a type of electronic control unit that controls a series of actuators on an internal combustion engine to ensure optimal engine performance. It does this by re ...

s (ECU) that also adjust the combustion process to increase efficiency and reduce emissions.

Lubrication

Surfaces in contact and relative motion to other surfaces require

lubrication

Lubrication is the process or technique of using a lubricant to reduce friction and wear and tear in a contact between two surfaces. The study of lubrication is a discipline in the field of tribology.

Lubrication mechanisms such as fluid-lubric ...

to reduce wear, noise and increase efficiency by reducing the power wasting in overcoming

friction, or to make the mechanism work at all. Also, the lubricant used can reduce excess heat and provide additional cooling to components. At the very least, an engine requires lubrication in the following parts:

* Between pistons and cylinders

* Small bearings

* Big end bearings

* Main bearings

* Valve gear (The following elements may not be present):

** Tappets

** Rocker arms

** Pushrods

** Timing chain or gears. Toothed belts do not require lubrication.

In 2-stroke crankcase scavenged engines, the interior of the crankcase, and therefore the crankshaft, connecting rod and bottom of the pistons are sprayed by the

2-stroke oil in the air-fuel-oil mixture which is then burned along with the fuel. The valve train may be contained in a compartment flooded with lubricant so that no

oil pump is required.

In a ''splash lubrication system'' no oil pump is used. Instead the crankshaft dips into the oil in the sump and due to its high speed, it splashes the crankshaft, connecting rods and bottom of the pistons. The connecting rod big end caps may have an attached scoop to enhance this effect. The valve train may also be sealed in a flooded compartment, or open to the crankshaft in a way that it receives splashed oil and allows it to drain back to the sump. Splash lubrication is common for small 4-stroke engines.

In a ''forced'' (also called ''pressurized'') ''lubrication system'', lubrication is accomplished in a closed-loop which carries

motor oil

Motor oil, engine oil, or engine lubricant is any one of various substances used for the lubrication of internal combustion engines. They typically consist of base oils enhanced with various additives, particularly antiwear additives, deterg ...

to the surfaces serviced by the system and then returns the oil to a reservoir. The auxiliary equipment of an engine is typically not serviced by this loop; for instance, an

alternator may use

ball bearings sealed with their own lubricant. The reservoir for the oil is usually the sump, and when this is the case, it is called a ''

wet sump'' system. When there is a different oil reservoir the crankcase still catches it, but it is continuously drained by a dedicated pump; this is called a ''

dry sump'' system.

On its bottom, the sump contains an oil intake covered by a mesh filter which is connected to an oil pump then to an

oil filter outside the crankcase. From there it is diverted to the crankshaft main bearings and valve train. The crankcase contains at least one ''oil gallery'' (a conduit inside a crankcase wall) to which oil is introduced from the oil filter. The main bearings contain a groove through all or half its circumference; the oil enters these grooves from channels connected to the oil gallery. The crankshaft has drillings that take oil from these grooves and deliver it to the big end bearings. All big end bearings are lubricated this way. A single main bearing may provide oil for 0, 1 or 2 big end bearings. A similar system may be used to lubricate the piston, its gudgeon pin and the small end of its connecting rod; in this system, the connecting rod big end has a groove around the crankshaft and a drilling connected to the groove which distributes oil from there to the bottom of the piston and from then to the cylinder.

Other systems are also used to lubricate the cylinder and piston. The connecting rod may have a nozzle to throw an oil jet to the cylinder and bottom of the piston. That nozzle is in movement relative to the cylinder it lubricates, but always pointed towards it or the corresponding piston.

Typically forced lubrication systems have a lubricant flow higher than what is required to lubricate satisfactorily, in order to assist with cooling. Specifically, the lubricant system helps to move heat from the hot engine parts to the cooling liquid (in water-cooled engines) or fins (in air-cooled engines) which then transfer it to the environment. The lubricant must be designed to be chemically stable and maintain suitable viscosities within the temperature range it encounters in the engine.

Cylinder configuration

Common cylinder configurations include the

straight or inline configuration, the more compact

V configuration, and the wider but smoother

flat or boxer configuration.

Aircraft engine

An aircraft engine, often referred to as an aero engine, is the power component of an aircraft propulsion system. Most aircraft engines are either piston engines or gas turbines, although a few have been rocket powered and in recent years many ...

s can also adopt a

radial configuration, which allows more effective cooling. More unusual configurations such as the

H,

U,

X, and

W have also been used.

Multiple cylinder engines have their valve train and crankshaft configured so that pistons are at different parts of their cycle. It is desirable to have the pistons' cycles uniformly spaced (this is called ''even firing'') especially in forced induction engines; this reduces torque pulsations and makes

inline engines

In aviation, an inline engine is a reciprocating engine with banks of cylinders, one behind another, rather than rows of cylinders, with each bank having any number of cylinders, although more than six is uncommon. The major reciprocating-engi ...

with more than 3 cylinders statically

balanced in its primary forces. However, some

engine configurations require odd firing to achieve better balance than what is possible with even firing. For instance, a 4-stroke

I2 engine has better balance when the angle between the crankpins is 180° because the pistons move in opposite directions and inertial forces partially cancel, but this gives an odd firing pattern where one cylinder fires 180° of crankshaft rotation after the other, then no cylinder fires for 540°. With an even firing pattern, the pistons would move in unison and the associated forces would add.

Multiple crankshaft configurations do not necessarily need a

cylinder head at all because they can instead have a piston at each end of the cylinder called an

opposed piston design. Because fuel inlets and outlets are positioned at opposed ends of the cylinder, one can achieve uniflow scavenging, which, as in the four-stroke engine is efficient over a wide range of engine speeds. Thermal efficiency is improved because of a lack of cylinder heads. This design was used in the

Junkers Jumo 205 diesel aircraft engine, using two crankshafts at either end of a single bank of cylinders, and most remarkably in the

Napier Deltic diesel engines. These used three crankshafts to serve three banks of

double-ended cylinders arranged in an equilateral triangle with the crankshafts at the corners. It was also used in single-bank

locomotive engines, and is still used in

marine propulsion engines and marine auxiliary generators.

Diesel cycle

Most truck and automotive diesel engines use a cycle reminiscent of a four-stroke cycle, but with temperature increase by compression causing ignition, rather than needing a separate ignition system. This variation is called the diesel cycle. In the diesel cycle, diesel fuel is injected directly into the cylinder so that combustion occurs at constant pressure, as the piston moves.

Otto cycle

The

Otto cycle is the most common cycle for most cars' internal combustion engines that use gasoline as a fuel. It consists of the same major steps as described for the four-stroke engine: Intake, compression, ignition, expansion and exhaust.

Five-stroke engine

In 1879,

Nicolaus Otto manufactured and sold a double expansion engine (the double and triple expansion principles had ample usage in steam engines), with two small cylinders at both sides of a low-pressure larger cylinder, where a second expansion of exhaust stroke gas took place; the owner returned it, alleging poor performance. In 1906, the concept was incorporated in a car built by EHV (

Eisenhuth Horseless Vehicle Company

Eisenhuth Horseless Vehicle Company was a manufacturer of Brass Age automobiles who were originally based in New York City. In 1902 the company purchased the Keating Wheel and Automobile Company and established manufacturing operations in Midd ...

); and in the 21st century

Ilmor designed and successfully tested a 5-stroke double expansion internal combustion engine, with high power output and low SFC (Specific Fuel Consumption).

Six-stroke engine

The

six-stroke engine was invented in 1883. Four kinds of six-stroke engines use a regular piston in a regular cylinder (Griffin six-stroke, Bajulaz six-stroke, Velozeta six-stroke and Crower six-stroke), firing every three crankshaft revolutions. These systems capture the waste heat of the

four-stroke

A four-stroke (also four-cycle) engine is an internal combustion (IC) engine in which the piston completes four separate strokes while turning the crankshaft. A stroke refers to the full travel of the piston along the cylinder, in either directio ...

Otto cycle with an injection of air or water.

The

Beare Head The Beare-head engine internal combustion engine technology combines a four-stroke engine bottom end and piston, with a ported cylinder head closely resembling that of a two-stroke engine. The head piston is smaller and moves at half cycling of the ...

and "piston charger" engines operate as

opposed-piston engine

An opposed-piston engine is a piston engine in which each cylinder has a piston at both ends, and no cylinder head. Petrol and diesel opposed-piston engines have been used mostly in large-scale applications such as ships, military tanks, and ...

s, two pistons in a single cylinder, firing every two revolutions rather than every four like a four-stroke engine.

Other cycles

The very first internal combustion engines did not compress the mixture. The first part of the piston downstroke drew in a fuel-air mixture, then the inlet valve closed and, in the remainder of the down-stroke, the fuel-air mixture fired. The exhaust valve opened for the piston upstroke. These attempts at imitating the principle of a

steam engine

A steam engine is a heat engine that performs mechanical work using steam as its working fluid. The steam engine uses the force produced by steam pressure to push a piston back and forth inside a cylinder. This pushing force can be trans ...

were very inefficient.

There are a number of variations of these cycles, most notably the

Atkinson and

Miller cycles.

Split-cycle engines separate the four strokes of intake, compression, combustion and exhaust into two separate but paired cylinders. The first cylinder is used for intake and compression. The compressed air is then transferred through a crossover passage from the compression cylinder into the second cylinder, where combustion and exhaust occur. A split-cycle engine is really an

air compressor on one side with a combustion chamber on the other.

Previous split-cycle engines have had two major problemsâpoor breathing (volumetric efficiency) and low thermal efficiency. However, new designs are being introduced that seek to address these problems.

The

Scuderi Engine addresses the breathing problem by reducing the clearance between the piston and the cylinder head through various turbocharging techniques. The Scuderi design requires the use of outwardly opening valves that enable the piston to move very close to the cylinder head without the interference of the valves. Scuderi addresses the low thermal efficiency via firing after top dead center (ATDC).

Firing ATDC can be accomplished by using high-pressure air in the transfer passage to create sonic flow and high turbulence in the power cylinder.

The four-stroke crank-rocker engine with a curve cylinder was also invented to study its efficiency.

Combustion turbines

Jet engine

Jet engines use a number of rows of fan blades to compress air which then enters a

combustor where it is mixed with fuel (typically JP fuel) and then ignited. The burning of the fuel raises the temperature of the air which is then exhausted out of the engine creating thrust. A modern

turbofan engine can operate at as high as 48% efficiency.

There are six sections to a turbofan engine:

* Fan

* Compressor

* Combustor

* Turbine

* Mixer

* Nozzle

Gas turbines

A gas turbine compresses air and uses it to turn a

turbine. It is essentially a jet engine which directs its output to a shaft. There are three stages to a turbine: 1) air is drawn through a compressor where the temperature rises due to compression, 2) fuel is added in the

combuster, and 3) hot air is exhausted through turbine blades which rotate a shaft connected to the compressor.

A gas turbine is a rotary machine similar in principle to a

steam turbine

A steam turbine is a machine that extracts thermal energy from pressurized steam and uses it to do mechanical work on a rotating output shaft. Its modern manifestation was invented by Charles Parsons in 1884. Fabrication of a modern steam turbin ...

and it consists of three main components: a compressor, a combustion chamber, and a turbine. The temperature of the air, after being compressed in the compressor, is increased by burning fuel in it. The heated air and the products of combustion expand in a turbine, producing work output. About of the work drives the compressor: the rest (about ) is available as useful work output.

Gas turbines are among the most efficient internal combustion engines. The General Electric 7HA and 9HA turbine

combined cycle

A combined cycle power plant is an assembly of heat engines that work in tandem from the same source of heat, converting it into mechanical energy. On land, when used to make electricity the most common type is called a combined cycle gas turb ...

electrical plants are rated at over 61% efficiency.

Brayton cycle

A gas turbine is a rotary machine somewhat similar in principle to a steam turbine. It consists of three main components: compressor, combustion chamber, and turbine. The air is compressed by the compressor where a temperature rise occurs. The temperature of the compressed air is further increased by combustion of injected fuel in the combustion chamber which expands the air. This energy rotates the turbine which powers the compressor via a mechanical coupling. The hot gases are then exhausted to provide thrust.

Gas turbine cycle engines employ a continuous combustion system where compression, combustion, and expansion occur simultaneously at different places in the engineâgiving continuous power. Notably, the combustion takes place at constant pressure, rather than with the Otto cycle, constant volume.

Wankel engines

The Wankel engine (rotary engine) does not have piston strokes. It operates with the same separation of phases as the four-stroke engine with the phases taking place in separate locations in the engine. In

thermodynamic terms it follows the

Otto engine cycle, so may be thought of as a "four-phase" engine. While it is true that three power strokes typically occur per rotor revolution, due to the 3:1 revolution ratio of the rotor to the eccentric shaft, only one power stroke per shaft revolution actually occurs. The drive (eccentric) shaft rotates once during every power stroke instead of twice (crankshaft), as in the Otto cycle, giving it a greater power-to-weight ratio than piston engines. This type of engine was most notably used in the

Mazda RX-8, the earlier

RX-7, and other vehicle models. The engine is also used in unmanned aerial vehicles, where the small size and weight and the high power-to-weight ratio are advantageous.

Forced induction

Forced induction is the process of delivering compressed air to the intake of an internal combustion engine. A forced induction engine uses a

gas compressor to increase the pressure, temperature and

density of the air. An engine without forced induction is considered a

naturally aspirated engine

Naturally may refer to:

;Albums

* ''Naturally!'', an album by Nat Adderley

* ''Naturally'' (Houston Person album)

* ''Naturally'' (J. J. Cale album)

* ''Naturally'' (John Pizzarelli album)

* ''Naturally'' (Sharon Jones album)

* ''Naturally'' ...

.

Forced induction is used in the automotive and aviation industry to increase engine power and efficiency. It particularly helps aviation engines, as they need to operate at high altitude.

Forced induction is achieved by a

supercharger

In an internal combustion engine, a supercharger compresses the intake gas, forcing more air into the engine in order to produce more power for a given displacement.

The current categorisation is that a supercharger is a form of forced induct ...

, where the compressor is directly powered from the engine shaft or, in the

turbocharger, from a turbine powered by the engine exhaust.

Fuels and oxidizers

All internal combustion engines depend on

combustion of a

chemical fuel

A fuel is any material that can be made to react with other substances so that it releases energy as thermal energy or to be used for work. The concept was originally applied solely to those materials capable of releasing chemical energy but ...

, typically with oxygen from the air (though it is possible to inject

nitrous oxide to do more of the same thing and gain a power boost). The combustion process typically results in the production of a great quantity of thermal energy, as well as the production of steam and carbon dioxide and other chemicals at very high temperature; the

temperature reached is determined by the chemical make up of the fuel and oxidizers (see

stoichiometry

Stoichiometry refers to the relationship between the quantities of reactants and products before, during, and following chemical reactions.

Stoichiometry is founded on the law of conservation of mass where the total mass of the reactants equal ...

), as well as by the compression and other factors.

Fuels

The most common modern fuels are made up of

hydrocarbons and are derived mostly from

fossil fuel

A fossil fuel is a hydrocarbon-containing material formed naturally in the Earth's crust from the remains of dead plants and animals that is extracted and burned as a fuel. The main fossil fuels are coal, oil, and natural gas. Fossil fuels ...

s (

petroleum). Fossil fuels include

diesel fuel,

gasoline and

petroleum gas

Liquefied petroleum gas (LPG or LP gas) is a fuel gas which contains a flammable mixture of hydrocarbon gases, specifically propane, propylene, butylene, isobutane and n-butane.

LPG is used as a fuel gas in HVAC, heating appliances, cookin ...

, and the rarer use of

propane

Propane () is a three-carbon alkane with the molecular formula . It is a gas at standard temperature and pressure, but compressible to a transportable liquid. A by-product of natural gas processing and petroleum refining, it is commonly used a ...

. Except for the fuel delivery components, most internal combustion engines that are designed for gasoline use can run on

natural gas or liquefied petroleum gases without major modifications. Large diesels can run with air mixed with gases and a pilot diesel fuel ignition injection. Liquid and gaseous

biofuel

Biofuel is a fuel that is produced over a short time span from biomass, rather than by the very slow natural processes involved in the formation of fossil fuels, such as oil. According to the United States Energy Information Administration (EIA ...

s, such as

ethanol and

biodiesel (a form of diesel fuel that is produced from crops that yield

triglycerides such as

soybean oil), can also be used. Engines with appropriate modifications can also run on

hydrogen gas,

wood gas, or

charcoal gas, as well as from so-called

producer gas

Producer gas is fuel gas that is manufactured by blowing a coke or coal with air and steam simultaneously. It mainly consists of carbon monoxide (CO), hydrogen (H2), as well as substantial amounts of nitrogen (N2). The caloric value of the produce ...

made from other convenient biomass. Experiments have also been conducted using powdered solid fuels, such as the

magnesium injection cycle.

Presently, fuels used include:

*

Petroleum:

** Petroleum spirit (

North American term:

gasoline,

British term: petrol)

**

Petroleum diesel.

**

Autogas (

liquified petroleum gas).

**

Compressed natural gas

Compressed natural gas (CNG) is a fuel gas mainly composed of methane (CH4), compressed to less than 1% of the volume it occupies at standard atmospheric pressure. It is stored and distributed in hard containers at a pressure of , usually in ...

.

**

Jet fuel

Jet fuel or aviation turbine fuel (ATF, also abbreviated avtur) is a type of aviation fuel designed for use in aircraft powered by gas-turbine engines. It is colorless to straw-colored in appearance. The most commonly used fuels for commercial a ...

(

aviation fuel

Aviation fuels are petroleum-based fuels, or petroleum and synthetic fuel blends, used to power aircraft. They have more stringent requirements than fuels used for ground use, such as heating and road transport, and contain additives to enhanc ...

)

**

Residual fuel

Fuel oil is any of various fractions obtained from the distillation of petroleum (crude oil). Such oils include distillates (the lighter fractions) and residues (the heavier fractions). Fuel oils include heavy fuel oil, marine fuel oil (MFO), bun ...

*

Coal

Coal is a combustible black or brownish-black sedimentary rock, formed as stratum, rock strata called coal seams. Coal is mostly carbon with variable amounts of other Chemical element, elements, chiefly hydrogen, sulfur, oxygen, and nitrogen ...

:

** Gasoline can be made from carbon (coal) using the

FischerâTropsch process

** Diesel fuel can be made from carbon using the

FischerâTropsch process

* Biofuels and vegetable oils:

**

Peanut oil and other

vegetable oils.

**

Woodgas, from an onboard

wood gasifier

A wood gas generator is a gasification unit which converts timber or charcoal into wood gas, a producer gas consisting of atmospheric nitrogen, carbon monoxide, hydrogen, traces of methane, and other gases, which â after cooling and filtering ...

using solid wood as a fuel

** Biofuels:

***

Biobutanol

220px, Butanol, a C-4 hydrocarbon is a promising bio-derived fuel, which shares many properties with gasoline.

Butanol may be used as a fuel in an internal combustion engine. It is more similar to gasoline than it is to ethanol. A C4-hydrocarbon ...

(replaces gasoline).

***

Biodiesel (replaces petrodiesel).

***

Dimethyl Ether

Dimethyl ether (DME; also known as methoxymethane) is the organic compound with the formula CH3OCH3,

(sometimes ambiguously simplified to C2H6O as it is an isomer of ethanol). The simplest ether, it is a colorless gas that is a useful precurs ...

(replaces petrodiesel).

***

Bioethanol and

Biomethanol

Methanol fuel is an alternative biofuel for internal combustion and other engines, either in combination with gasoline or independently. Methanol ( C H3 O H) is less expensive to produce sustainably than ethanol fuel, although it produces more ...

(

wood alcohol) and other

biofuel

Biofuel is a fuel that is produced over a short time span from biomass, rather than by the very slow natural processes involved in the formation of fossil fuels, such as oil. According to the United States Energy Information Administration (EIA ...

s (see

Flexible-fuel vehicle).

***

Biogas

Biogas is a mixture of gases, primarily consisting of methane, carbon dioxide and hydrogen sulphide, produced from raw materials such as agricultural waste, manure, municipal waste, plant material, sewage, green waste and food waste. I ...

*

Hydrogen (mainly

spacecraft rocket engines)

Even fluidized metal powders and explosives have seen some use. Engines that use gases for fuel are called gas engines and those that use liquid hydrocarbons are called oil engines; however, gasoline engines are also often colloquially referred to as "gas engines" ("

petrol engines" outside North America).

The main limitations on fuels are that it must be easily transportable through the

fuel system to the

combustion chamber, and that the fuel releases sufficient

energy in the form of

heat upon

combustion to make practical use of the engine.

Diesel engine

The diesel engine, named after Rudolf Diesel, is an internal combustion engine in which ignition of the fuel is caused by the elevated temperature of the air in the cylinder due to mechanical compression; thus, the diesel engine is a so-ca ...

s are generally heavier, noisier, and more powerful at lower speeds than

gasoline engines. They are also more fuel-efficient in most circumstances and are used in heavy road vehicles, some automobiles (increasingly so for their increased

fuel efficiency

Fuel efficiency is a form of thermal efficiency, meaning the ratio of effort to result of a process that converts chemical potential energy contained in a carrier (fuel) into kinetic energy or work. Overall fuel efficiency may vary per device, wh ...

over gasoline engines), ships,

railway locomotive

A locomotive or engine is a rail transport vehicle that provides the Power (physics), motive power for a train. If a locomotive is capable of carrying a payload, it is usually rather referred to as a multiple unit, Motor coach (rail), motor ...

s, and light

aircraft

An aircraft is a vehicle that is able to fly by gaining support from the air. It counters the force of gravity by using either static lift or by using the dynamic lift of an airfoil, or in a few cases the downward thrust from jet engines. ...

. Gasoline engines are used in most other road vehicles including most cars,

motorcycles, and

mopeds. Note that in

Europe

Europe is a large peninsula conventionally considered a continent in its own right because of its great physical size and the weight of its history and traditions. Europe is also considered a subcontinent of Eurasia and it is located enti ...

, sophisticated diesel-engined cars have taken over about 45% of the market since the 1990s. There are also engines that run on

hydrogen,

methanol

Methanol (also called methyl alcohol and wood spirit, amongst other names) is an organic chemical and the simplest aliphatic alcohol, with the formula C H3 O H (a methyl group linked to a hydroxyl group, often abbreviated as MeOH). It is a ...

,

ethanol,

liquefied petroleum gas

Liquefied petroleum gas (LPG or LP gas) is a fuel gas which contains a flammable mixture of hydrocarbon gases, specifically propane, propylene, butylene, isobutane and n-butane.

LPG is used as a fuel gas in heating appliances, cooking e ...

(LPG),

biodiesel,

paraffin and

tractor vaporizing oil (TVO).

Hydrogen

Hydrogen could eventually

replace conventional fossil fuels in traditional internal combustion engines. Alternatively

fuel cell

A fuel cell is an electrochemical cell that converts the chemical energy of a fuel (often hydrogen) and an oxidizing agent (often oxygen) into electricity through a pair of redox reactions. Fuel cells are different from most batteries in requ ...

technology may come to deliver its promise and the use of the internal combustion engines could even be phased out.

Although there are multiple ways of producing free hydrogen, those methods require converting combustible molecules into hydrogen or consuming electric energy. Unless that electricity is produced from a renewable sourceâand is not required for other purposesâhydrogen does not solve any

energy crisis. In many situations the disadvantage of hydrogen, relative to carbon fuels, is

its storage.

Liquid hydrogen has extremely low density (14 times lower than water) and requires extensive insulationâwhilst gaseous hydrogen requires heavy tankage. Even when liquefied, hydrogen has a higher specific energy but the volumetric energetic storage is still roughly five times lower than gasoline. However, the energy density of hydrogen is considerably higher than that of electric batteries, making it a serious contender as an energy carrier to replace fossil fuels. The 'Hydrogen on Demand' process (see

direct borohydride fuel cell) creates hydrogen as needed, but has other issues, such as the high price of the

sodium borohydride that is the raw material.

Oxidizers

Since air is plentiful at the surface of the earth, the oxidizer is typically atmospheric oxygen, which has the advantage of not being stored within the vehicle. This increases the power-to-weight and power-to-volume ratios. Other materials are used for special purposes, often to increase power output or to allow operation under water or in space.

* Compressed air has been commonly used in

torpedoes.

* Compressed

oxygen, as well as some compressed air, was used in the Japanese

Type 93 torpedo. Some

submarines

A submarine (or sub) is a watercraft capable of independent operation underwater. It differs from a submersible, which has more limited underwater capability. The term is also sometimes used historically or colloquially to refer to remotely o ...

carry pure oxygen. Rockets very often use

liquid oxygen.

*

Nitromethane is added to some racing and

model fuels to increase power and control combustion.