|

Poppet Valve

A poppet valve (also sometimes called mushroom valve) is a valve typically used to control the timing and quantity of petrol (gas) or vapour flow into or out of an engine, but with many other applications. It consists of a hole or open-ended chamber, usually round or oval in cross-section, and a plug, usually a disk shape on the end of a shaft known as a valve stem. The working end of this plug, the valve face, is typically ground at a 45° bevel to seal against a corresponding valve seat ground into the rim of the chamber being sealed. The shaft travels through a valve guide to maintain its alignment. A pressure differential on either side of the valve can assist or impair its performance. In exhaust applications higher pressure against the valve helps to seal it, and in intake applications lower pressure helps open it. Etymology The word poppet shares etymology with "puppet": it is from the Middle English ''popet'' ("youth" or "doll"), from Middle French ''poupette'', whic ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Valve

A valve is a device or natural object that regulates, directs or controls the flow of a fluid (gases, liquids, fluidized solids, or Slurry, slurries) by opening, closing, or partially obstructing various passageways. Valves are technically Piping and plumbing fitting, fittings, but are usually discussed as a separate category. In an open valve, fluid flows in a direction from higher pressure to lower pressure. The word is derived from the Latin ''valva'', the moving part of a door, in turn from ''volvere'', to turn, roll. The simplest, and very ancient, valve is simply a freely hinged flap which swings down to obstruct fluid (gas or liquid) flow in one direction, but is pushed up by the flow itself when the flow is moving in the opposite direction. This is called a check valve, as it prevents or "checks" the flow in one direction. Modern control valves may regulate pressure or Fluid dynamics, flow downstream and operate on sophisticated Automation#Industrial automation, automat ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Torpedo Tube

A torpedo tube is a cylindrical device for launching torpedoes. There are two main types of torpedo tube: underwater tubes fitted to submarines and some surface ships, and deck-mounted units (also referred to as torpedo launchers) installed aboard surface vessels. Deck-mounted torpedo launchers are usually designed for a specific type of torpedo, while submarine torpedo tubes are general-purpose launchers, and are often also capable of deploying naval mine, mines and cruise missiles. Most modern launchers are standardized on a diameter for light torpedoes (deck mounted aboard ship) or a diameter for heavy torpedoes (underwater tubes), although Torpedo#Classes and diameters, torpedoes of other classes and diameters have been used. Submarine torpedo tube A submarine torpedo tube is a more complex mechanism than a torpedo tube on a surface ship, because the tube has to accomplish the function of moving the torpedo from the normal atmospheric pressure within the submarine into the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Tetraethyllead

Tetraethyllead (commonly styled tetraethyl lead), abbreviated TEL, is an organolead compound with the formula lead, Pb(ethyl group, C2H5)4. It was widely used as a fuel additive for much of the 20th century, first being mixed with gasoline beginning in the 1920s. This "leaded gasoline" had an increased octane rating that allowed Compression ratio, engine compression to be raised substantially and in turn increased vehicle performance and fuel economy. TEL was first chemical synthesis, synthesized by German chemist Carl Jacob Löwig in 1853. American chemical engineer Thomas Midgley Jr., who was working for the U.S. corporation General Motors, was the first to discover its effectiveness as an Antiknock agent, knock inhibitor on December 9th, 1921, after spending six years attempting to find an antiknock agent, additive that was both highly effective and inexpensive. Of the some 33,000 substances in total screened, lead was found to be the most effective antiknock agent, in that i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Valve Job

A valve job is the colloquial term for resurfacing the mating surfaces of the poppet valves and their respective valve seats that control the intake and exhaust of the air/fuel mixture in four stroke internal combustion engine, replacing valve oil seals, replacing any deficient valve springs, and otherwise bringing the components of a cylinder head up to manufacturer’s spec. A resurfacing of the head’s meeting surface with the engine block to true it is often done at the same time if a head has been removed from the engine. Some reasons that may induce the need for a valve job in a modern passenger car include: excessive RPM, high mileage, overheating, material failure, corrosion, and foreign object damage (FOD). History In the earliest automotive engines, the valves needed to be removed and the sealing surfaces sanded, ground or lapped multiple times during the life of a typical engine. As the decades passed, however, engines ran cleaner and the addition of tetraethyllead in g ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Metallurgy

Metallurgy is a domain of materials science and engineering that studies the physical and chemical behavior of metallic elements, their inter-metallic compounds, and their mixtures, which are known as alloys. Metallurgy encompasses both the science and the technology of metals, including the production of metals and the engineering of metal components used in products for both consumers and manufacturers. Metallurgy is distinct from the craft of metalworking. Metalworking relies on metallurgy in a similar manner to how medicine relies on medical science for technical advancement. A specialist practitioner of metallurgy is known as a metallurgist. The science of metallurgy is further subdivided into two broad categories: chemical metallurgy and physical metallurgy. Chemical metallurgy is chiefly concerned with the reduction and oxidation of metals, and the chemical performance of metals. Subjects of study in chemical metallurgy include mineral processing, the extraction ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Manifold Vacuum

Manifold vacuum, or engine vacuum in a petrol engine is the difference in air pressure between the engine's intake manifold and Earth's atmosphere. Manifold vacuum is an effect of a piston's movement on the induction stroke and the airflow through a throttle in the intervening carburetor or throttle body leading to the intake manifold. It is a result of the amount of restriction of airflow through the engine. In some engines, the manifold vacuum is also used as an auxiliary power source to drive engine accessories and for the crankcase ventilation system. Manifold vacuums should not be confused with venturi vacuums, which are an effect exploited in some carburetors to establish a pressure difference roughly proportional to mass airflow and to maintain a somewhat constant air/fuel ratio. It is also used in light airplanes to provide airflow for pneumatic gyroscopic instruments. Overview The rate of airflow through an internal combustion engine is an important factor deter ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Oil Seal

Valve guides are cylindrical metal bushes, pressed or integrally cast into the cylinder head of most types of reciprocating engines, to support the inlet valve and exhaust valve stems. So that they may make proper contact with its valve seat. Along with a corresponding valve spring, they are one component of an engine’s valve train. Guides also serve to conduct heat from the combustion process out from the exhaust valve and into the cylinder head where it may be taken up by the cooling system. Bronze is commonly used, as are various iron alloys; a balance between stiffness and wear on the valve is essential to achieve a useful service life. Powder metallurgy materials are also commonly used in the manufacture of valve guides, which have the advantages of flexible material composition and the self-lubricating properties. The clearance between the inner diameter of the valve guide and the outer diameter of the poppet valve stem is critical for the proper performance of an e ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Cast Iron

Cast iron is a class of iron–carbon alloys with a carbon content of more than 2% and silicon content around 1–3%. Its usefulness derives from its relatively low melting temperature. The alloying elements determine the form in which its carbon appears: Cast iron#White cast iron, white cast iron has its carbon combined into an iron carbide named cementite, which is very hard, but brittle, as it allows cracks to pass straight through; Grey iron, grey cast iron has graphite flakes which deflect a passing crack and initiate countless new cracks as the material breaks, and Ductile iron, ductile cast iron has spherical graphite "nodules" which stop the crack from further progressing. Carbon (C), ranging from 1.8 to 4 wt%, and silicon (Si), 1–3 wt%, are the main alloying elements of cast iron. Iron alloys with lower carbon content are known as steel. Cast iron tends to be brittle, except for malleable iron, malleable cast irons. With its relatively low melting point, g ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Heat Transfer

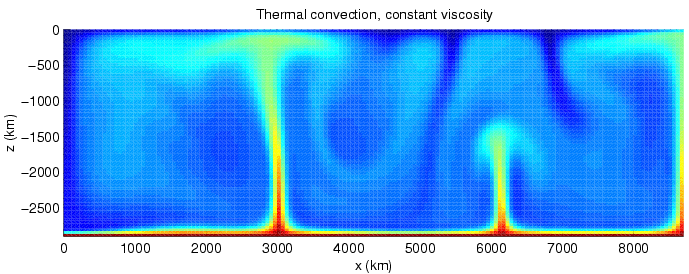

Heat transfer is a discipline of thermal engineering that concerns the generation, use, conversion, and exchange of thermal energy (heat) between physical systems. Heat transfer is classified into various mechanisms, such as thermal conduction, Convection (heat transfer), thermal convection, thermal radiation, and transfer of energy by phase changes. Engineers also consider the transfer of mass of differing chemical species (mass transfer in the form of advection), either cold or hot, to achieve heat transfer. While these mechanisms have distinct characteristics, they often occur simultaneously in the same system. Heat conduction, also called diffusion, is the direct microscopic exchanges of kinetic energy of particles (such as molecules) or quasiparticles (such as lattice waves) through the boundary between two systems. When an object is at a different temperature from another body or its surroundings, heat flows so that the body and the surroundings reach the same temperature, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Sodium

Sodium is a chemical element; it has Symbol (chemistry), symbol Na (from Neo-Latin ) and atomic number 11. It is a soft, silvery-white, highly reactive metal. Sodium is an alkali metal, being in group 1 element, group 1 of the periodic table. Its only stable isotope is 23Na. The free metal does not occur in nature and must be prepared from compounds. Sodium is the Abundance of elements in Earth's crust, sixth most abundant element in the Earth's crust and exists in numerous minerals such as feldspars, sodalite, and halite (NaCl). Many salts of sodium are highly water-soluble: sodium ions have been Leaching (chemistry), leached by the action of water from the Earth, Earth's minerals over eons, and thus sodium and chlorine are the most common dissolved elements by weight in the oceans. Sodium was first isolated by Humphry Davy in 1807 by the electrolysis of sodium hydroxide. Among many other useful sodium compounds, sodium hydroxide (lye) is used in Soap, soap manufac ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Alloy

An alloy is a mixture of chemical elements of which in most cases at least one is a metal, metallic element, although it is also sometimes used for mixtures of elements; herein only metallic alloys are described. Metallic alloys often have properties that differ from those of the pure elements from which they are made. The vast majority of metals used for commercial purposes are alloyed to improve their properties or behavior, such as increased strength, hardness or corrosion resistance. Metals may also be alloyed to reduce their overall cost, for instance alloys of gold and Copper(II) sulfate, copper. A typical example of an alloy is SAE 304 stainless steel, 304 grade stainless steel which is commonly used for kitchen utensils, pans, knives and forks. Sometime also known as 18/8, it as an alloy consisting broadly of 74% iron, 18% chromium and 8% nickel. The chromium and nickel alloying elements add strength and hardness to the majority iron element, but their main function is ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Combustion Chamber

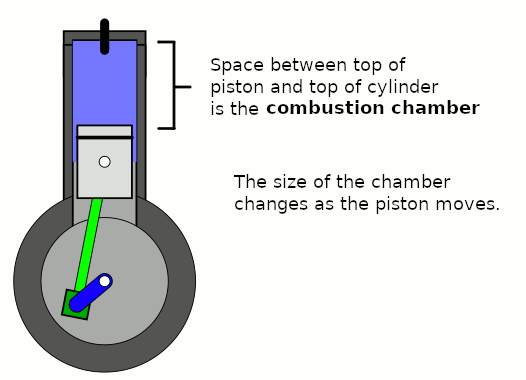

A combustion chamber is part of an internal combustion engine in which the air–fuel ratio, fuel/air mix is burned. For steam engines, the term has also been used for an extension of the Firebox (steam engine), firebox which is used to allow a more complete combustion process. Internal combustion engines In an internal combustion engine, the pressure caused by the burning air/fuel mixture applies direct force to part of the engine (e.g. for a piston engine, the force is applied to the top of the piston), which converts the gas pressure into mechanical energy (often in the form of a rotating output shaft). This contrasts an external combustion engine, where the combustion takes place in a separate part of the engine to where the gas pressure is converted into mechanical energy. Spark-ignition engines In spark ignition engines, such as petrol engine, petrol (gasoline) engines, the combustion chamber is usually located in the cylinder head. The engines are often designed such ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |