|

Fuchs Petrolub

Fuchs Petrolub SE is a German multinational manufacturer of lubricants, and related speciality products. The company's headquarters are at Mannheim, Baden-Württemberg, Germany, where the company was founded in 1931. Fuchs is a public company listed on the Frankfurt Stock Exchange. As of 2008, it is a constituent of the MDAX trading index of German mid-cap companies. Fuchs products Fuchs produces a wide range of products, which include automotive lubricants (engine motor oils and transmission, for motor cars, motorcycles, agricultural, plant and stationary engines), metalworking lubricants, industrial, civil engineering, and hydraulic products. Fuchs also produces the Planto range of biodegradable products. Automotive products * Fuchs Titan is a range of products aimed at motor cars, trucks, buses, agricultural and plant equipment. * Fuchs Silkolene is a product range specifically for motorcycles. * Fuchs Maintain Fricofin is a range of automotive coolants. Industrial produc ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Societas Europaea

A ''societas Europaea'' (, ; "European society" or "company"; plural: ; abbr. SE) is a public company registered in accordance with the corporate law of the European Union (EU), introduced in 2004 with the Council Regulation on the Statute for a European Company. Such a company may more easily transfer to or merge with companies in other member states. As of April 2018, more than 3,000 registrations have been reported, including the following nine components (18%) of the Euro Stoxx 50 stock market index of leading eurozone companies (excluding the SE designation): Airbus, Allianz, BASF, E.ON, Fresenius, LVMH Moët Hennessy Louis Vuitton (and its parent company Dior), SAP, Schneider Electric and Unibail-Rodamco-Westfield. National law continues to supplement the basic rules in the Regulation on formation and mergers. The European Company Regulation is complemented by an Employee Involvement Directive which manages the rules for participation by employees on the company ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Biodegradable

Biodegradation is the breakdown of organic matter by microorganisms, such as bacteria and fungi. It is generally assumed to be a natural process, which differentiates it from composting. Composting is a human-driven process in which biodegradation occurs under a specific set of circumstances. The process of biodegradation is threefold: first an object undergoes biodeterioration, which is the mechanical weakening of its structure; then follows biofragmentation, which is the breakdown of materials by microorganisms; and finally assimilation, which is the incorporation of the old material into new cells. In practice, almost all chemical compounds and materials are subject to biodegradation, the key element being time. Things like vegetables may degrade within days, while glass and some plastics take many millennia to decompose. A standard for biodegradability used by the European Union is that greater than 90% of the original material must be converted into , water and minerals by ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hawker Hurricane

The Hawker Hurricane is a British single-seat fighter aircraft of the 1930s–40s which was designed and predominantly built by Hawker Aircraft Ltd. for service with the Royal Air Force (RAF). It was overshadowed in the public consciousness by the Supermarine Spitfire during the Battle of Britain in 1940, but the Hurricane inflicted 60 percent of the losses sustained by the Luftwaffe in the campaign, and fought in all the major theatres of the Second World War. The Hurricane originated from discussions between RAF officials and aircraft designer Sir Sydney Camm about a proposed monoplane derivative of the Hawker Fury biplane in the early 1930s. Despite an institutional preference for biplanes and lack of interest by the Air Ministry, Hawker refined their monoplane proposal, incorporating several innovations which became critical to wartime fighter aircraft, including retractable landing gear and the more powerful Rolls-Royce Merlin engine. The Air Ministry ordered Hawk ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Supermarine Spitfire

The Supermarine Spitfire is a British single-seat fighter aircraft used by the Royal Air Force and other Allies of World War II, Allied countries before, during, and after World War II. Many variants of the Spitfire were built, from the Mk 1 to the Rolls-Royce Griffon engined Mk 24 using several wing configurations and guns. It was the only British fighter produced continuously throughout the war. The Spitfire remains popular among enthusiasts; around List of surviving Supermarine Spitfires, 70 remain airworthy, and many more are static exhibits in aviation museums throughout the world. The Spitfire was designed as a short-range, high-performance interceptor aircraft by R. J. Mitchell, chief designer at Supermarine Aviation Works, which operated as a subsidiary of Vickers-Armstrong from 1928. Mitchell developed the Spitfire's distinctive elliptical wing with innovative sunken rivets (designed by Beverley Shenstone) to have the thinnest possible cross-section, achieving a poten ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rolls-Royce Merlin

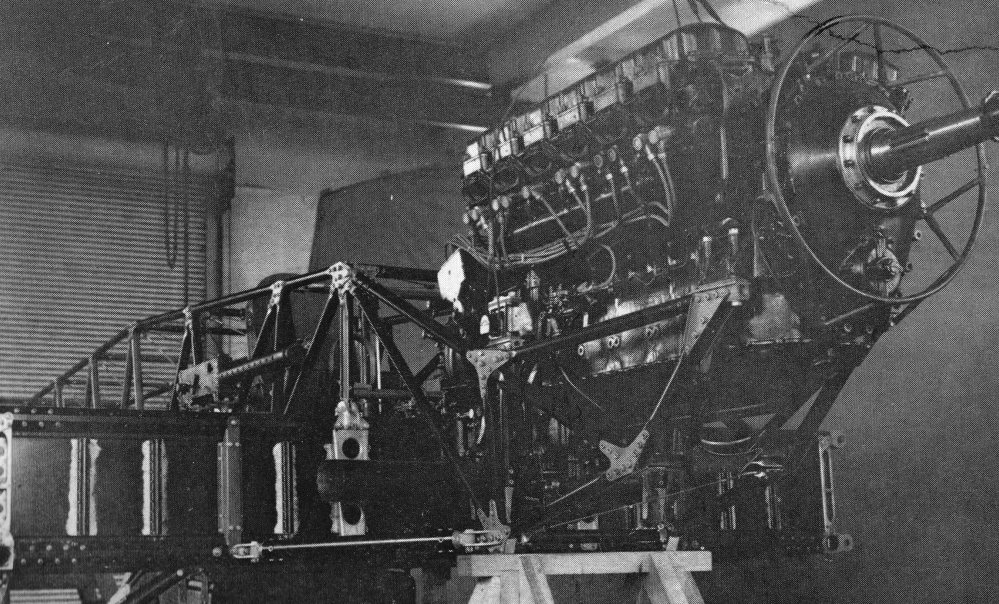

The Rolls-Royce Merlin is a British liquid-cooled V-12 piston aero engine of 27- litres (1,650 cu in) capacity. Rolls-Royce designed the engine and first ran it in 1933 as a private venture. Initially known as the PV-12, it was later called ''Merlin'' following the company convention of naming its four-stroke piston aero engines after birds of prey. After several modifications, the first production variants of the PV-12 were completed in 1936. The first operational aircraft to enter service using the Merlin were the Fairey Battle, Hawker Hurricane and Supermarine Spitfire. The Merlin remains most closely associated with the Spitfire and Hurricane, although the majority of the production run was for the four-engined Avro Lancaster heavy bomber. A series of rapidly-applied developments, brought about by wartime needs, markedly improved the engine's performance and durability. Starting at 1,000 hp for the first production models, most late war versions produced ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Corrosion

Corrosion is a natural process that converts a refined metal into a more chemically stable oxide. It is the gradual deterioration of materials (usually a metal) by chemical or electrochemical reaction with their environment. Corrosion engineering is the field dedicated to controlling and preventing corrosion. In the most common use of the word, this means electrochemical oxidation of metal in reaction with an oxidant such as oxygen, hydrogen or hydroxide. Rusting, the formation of iron oxides, is a well-known example of electrochemical corrosion. This type of damage typically produces oxide(s) or salt(s) of the original metal and results in a distinctive orange colouration. Corrosion can also occur in materials other than metals, such as ceramics or polymers, although in this context, the term "degradation" is more common. Corrosion degrades the useful properties of materials and structures including strength, appearance and permeability to liquids and gases. Many ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Grease (lubricant)

Grease is a solid or semisolid lubricant formed as a dispersion of thickening agents in a liquid lubricant. Grease generally consists of a soap emulsified with mineral or vegetable oil. A common feature of greases is that they possess a high initial viscosity, which upon the application of shear, drops to give the effect of an oil-lubricated bearing of approximately the same viscosity as the base oil used in the grease. This change in viscosity is called shear thinning. Grease is sometimes used to describe lubricating materials that are simply soft solids or high viscosity liquids, but these materials do not exhibit the shear-thinning properties characteristic of the classical grease. For example, petroleum jellies such as Vaseline are not generally classified as greases. Greases are applied to mechanisms that can be lubricated only infrequently and where a lubricating oil would not stay in position. They also act as sealants to prevent ingress of water and incompressible mater ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Heat Treatment

Heat treating (or heat treatment) is a group of industrial, thermal and metalworking processes used to alter the physical, and sometimes chemical, properties of a material. The most common application is metallurgical. Heat treatments are also used in the manufacture of many other materials, such as glass. Heat treatment involves the use of heating or chilling, normally to extreme temperatures, to achieve the desired result such as hardening or softening of a material. Heat treatment techniques include annealing, case hardening, precipitation strengthening, tempering, carburizing, normalizing and quenching. Although the term ''heat treatment'' applies only to processes where the heating and cooling are done for the specific purpose of altering properties intentionally, heating and cooling often occur incidentally during other manufacturing processes such as hot forming or welding. Physical processes Metallic materials consist of a microstructure of small crystals called ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Quenching

In materials science, quenching is the rapid cooling of a workpiece in water, oil, polymer, air, or other fluids to obtain certain material properties. A type of heat treating, quenching prevents undesired low-temperature processes, such as phase transformations, from occurring. It does this by reducing the window of time during which these undesired reactions are both thermodynamically favorable, and kinetically accessible; for instance, quenching can reduce the crystal grain size of both metallic and plastic materials, increasing their hardness. In metallurgy, quenching is most commonly used to harden steel by inducing a martensite transformation, where the steel must be rapidly cooled through its eutectoid point, the temperature at which austenite becomes unstable. In steel alloyed with metals such as nickel and manganese, the eutectoid temperature becomes much lower, but the kinetic barriers to phase transformation remain the same. This allows quenching to start at ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metalworking

Metalworking is the process of shaping and reshaping metals to create useful objects, parts, assemblies, and large scale structures. As a term it covers a wide and diverse range of processes, skills, and tools for producing objects on every scale: from huge ships, buildings, and bridges down to precise engine parts and delicate jewelry. The historical roots of metalworking predate recorded history; its use spans cultures, civilizations and millennia. It has evolved from shaping soft, native metals like gold with simple hand tools, through the smelting of ores and hot forging of harder metals like iron, up to highly technical modern processes such as machining and welding. It has been used as an industry, a driver of trade, individual hobbies, and in the creation of art; it can be regarded as both a science and a craft. Modern metalworking processes, though diverse and specialized, can be categorized into one of three broad areas known as forming, cutting, or joining processes ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Antifreeze

An antifreeze is an additive which lowers the freezing point of a water-based liquid. An antifreeze mixture is used to achieve freezing-point depression for cold environments. Common antifreezes also increase the boiling point of the liquid, allowing higher coolant temperature. However, all common antifreeze additives also have lower heat capacities than water, and do reduce water's ability to act as a coolant when added to it. Because water has good properties as a coolant, water plus antifreeze is used in internal combustion engines and other heat transfer applications, such as HVAC chillers and solar water heaters. The purpose of antifreeze is to prevent a rigid enclosure from bursting due to expansion when water freezes. Commercially, both the ''additive'' (pure concentrate) and the ''mixture'' (diluted solution) are called antifreeze, depending on the context. Careful selection of an antifreeze can enable a wide temperature range in which the mixture remains in the liq ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |