Turbomachinery on:

[Wikipedia]

[Google]

[Amazon]

Turbomachinery, in

Turbomachinery, in

In general, the two kinds of turbomachines encountered in practice are open and closed turbomachines. Open machines such as

In general, the two kinds of turbomachines encountered in practice are open and closed turbomachines. Open machines such as

''Impulse Turbomachines'' operate by accelerating and changing the flow direction of fluid through a stationary nozzle (the stator blade) onto the rotor blade. The nozzle serves to change the incoming pressure into velocity, the

''Impulse Turbomachines'' operate by accelerating and changing the flow direction of fluid through a stationary nozzle (the stator blade) onto the rotor blade. The nozzle serves to change the incoming pressure into velocity, the  ''Reaction Turbomachines'' operate by reacting to the flow of fluid through aerofoil shaped rotor and stator blades. The velocity of the fluid through the sets of blades increases slightly (as with a nozzle) as it passes from rotor to stator and vice versa. The velocity of the fluid then decreases again once it has passed between the gap. Pressure and enthalpy consistently decrease through the sets of blades.

Newton's third law describes the transfer of energy for reaction turbines. A pressure casement is needed to contain the working fluid. For compressible working fluids, multiple turbine stages are usually used to harness the expanding gas efficiently.

Most turbomachines use a combination of impulse and reaction in their design, often with impulse and reaction parts on the same blade.

''Reaction Turbomachines'' operate by reacting to the flow of fluid through aerofoil shaped rotor and stator blades. The velocity of the fluid through the sets of blades increases slightly (as with a nozzle) as it passes from rotor to stator and vice versa. The velocity of the fluid then decreases again once it has passed between the gap. Pressure and enthalpy consistently decrease through the sets of blades.

Newton's third law describes the transfer of energy for reaction turbines. A pressure casement is needed to contain the working fluid. For compressible working fluids, multiple turbine stages are usually used to harness the expanding gas efficiently.

Most turbomachines use a combination of impulse and reaction in their design, often with impulse and reaction parts on the same blade.

The following dimensionless ratios are often used for the characterisation of fluid machines. They allow a comparison of flow machines with different dimensions and boundary conditions.

#Pressure range ψ

#Flow coefficient φ (including delivery or volume number called)

#Performance numbers λ

#Run number σ

#Diameter number δ

The following dimensionless ratios are often used for the characterisation of fluid machines. They allow a comparison of flow machines with different dimensions and boundary conditions.

#Pressure range ψ

#Flow coefficient φ (including delivery or volume number called)

#Performance numbers λ

#Run number σ

#Diameter number δ

Turbochargers - Turbochargers are one of the most popular turbomachines. They are used mainly for adding power to engines by adding more air. It combines both forms of turbomachines. Exhaust gases from the engine spin a bladed wheel, much like a turbine. That wheel then spins another bladed wheel, sucking and compressing outside air into the engine.

Superchargers -

Turbochargers - Turbochargers are one of the most popular turbomachines. They are used mainly for adding power to engines by adding more air. It combines both forms of turbomachines. Exhaust gases from the engine spin a bladed wheel, much like a turbine. That wheel then spins another bladed wheel, sucking and compressing outside air into the engine.

Superchargers -

http://164.100.133.129:81/eCONTENT/Uploads/13-Steam%20Turbines%20%5BCompatibility%20Mode%5D.pdf

* Soares, C. M. (n.d.). GAS TURBINES IN SIMPLE CYCLE & COMBINED CYCLE APPLICATIONS. 1-72. Retrieved April 10, 2017, from https://www.netl.doe.gov/File%20Library/Research/Coal/energy%20systems/turbines/handbook/1-1.pdf

* Perlman, U. H. (2016, December 2). Hydroelectric power: How it works. Retrieved April 10, 2017, from https://water.usgs.gov/edu/hyhowworks.html

* Škorpík, J. (2017, January 1). Lopatkový stroj-English version. Retrieved April 9, 2017, from http://www.transformacni-technologie.cz/en_11.html

* Kayadelen, H. (2013)

Marine Gas Turbines

''7th International Advanced Technologies Symposium''. Retrieved April 15, 2017.

Hydrodynamics of PumpsCtrend website to calculate the head of centrifugal compressor online

{{Authority control Mechanical engineering Gas technologies

Turbomachinery, in

Turbomachinery, in mechanical engineering

Mechanical engineering is the study of physical machines and mechanism (engineering), mechanisms that may involve force and movement. It is an engineering branch that combines engineering physics and engineering mathematics, mathematics principl ...

, describes machine

A machine is a physical system that uses power to apply forces and control movement to perform an action. The term is commonly applied to artificial devices, such as those employing engines or motors, but also to natural biological macromol ...

s that transfer energy

Energy () is the physical quantity, quantitative physical property, property that is transferred to a physical body, body or to a physical system, recognizable in the performance of Work (thermodynamics), work and in the form of heat and l ...

between a rotor and a fluid

In physics, a fluid is a liquid, gas, or other material that may continuously motion, move and Deformation (physics), deform (''flow'') under an applied shear stress, or external force. They have zero shear modulus, or, in simpler terms, are M ...

, including both turbines and compressors. While a turbine transfers energy from a fluid to a rotor, a compressor transfers energy from a rotor to a fluid.Logan, Earl. "Handbook of turbomachinery". 1995. Marcel Deckker.Vandad Talimi (Original author unknown). "Mechanical Equipment and Systems". 2013. Memorial University of Newfoundland. http://www.engr.mun.ca/~yuri/Courses/MechanicalSystems/Turbomachinery.pdf It is an important application of fluid mechanics

Fluid mechanics is the branch of physics concerned with the mechanics of fluids (liquids, gases, and plasma (physics), plasmas) and the forces on them.

Originally applied to water (hydromechanics), it found applications in a wide range of discipl ...

.

These two types of machines are governed by the same basic relationships including Newton's second law of motion

Newton's laws of motion are three physical laws that describe the relationship between the motion of an object and the forces acting on it. These laws, which provide the basis for Newtonian mechanics, can be paraphrased as follows:

# A body re ...

and Euler's pump and turbine equation

The Euler pump and turbine equations are the most fundamental equations in the field of turbo-machinery, turbomachinery. These equations govern the power, efficiencies and other factors that contribute to the design of turbomachines. With the help ...

for compressible fluids. Centrifugal pump

Centrifugal pumps are used to transport fluids by the Energy transformation, conversion of rotational kinetic energy to the hydrodynamic energy of the fluid flow. The rotational energy typically comes from an engine or electric motor. They are ...

s are also turbomachines that transfer energy from a rotor to a fluid, usually a liquid, while turbines and compressors usually work with a gas.

History

The first turbomachines could be identified aswater wheel

A water wheel is a machine for converting the kinetic energy of flowing or falling water into useful forms of power, often in a watermill. A water wheel consists of a large wheel (usually constructed from wood or metal), with numerous b ...

s, which appeared between the 3rd and 1st centuries BCE in the Mediterranean region. These were used throughout the medieval period and began the first Industrial Revolution

The Industrial Revolution, sometimes divided into the First Industrial Revolution and Second Industrial Revolution, was a transitional period of the global economy toward more widespread, efficient and stable manufacturing processes, succee ...

. When steam power started to be used, as the first power source driven by the combustion of a fuel rather than renewable natural power sources, this was as reciprocating engine

A reciprocating engine, more often known as a piston engine, is a heat engine that uses one or more reciprocating pistons to convert high temperature and high pressure into a rotating motion. This article describes the common features of al ...

s. Primitive turbines and conceptual designs for them, such as the smoke jack, appeared intermittently but the temperatures and pressures required for a practically efficient turbine exceeded the manufacturing technology of the time. The first patent for gas turbines were filed in 1791 by John Barber. Practical hydroelectric water turbines and steam turbines did not appear until the 1880s. Gas turbines appeared in the 1930s.

The first impulse type turbine was created by Carl Gustaf de Laval in 1883. This was closely followed by the first practical reaction type turbine in 1884, built by Charles Parsons. Parsons’ first design was a multi-stage axial-flow unit, which George Westinghouse

George Westinghouse Jr. (October 6, 1846 – March 12, 1914) was a prolific American inventor, engineer, and entrepreneurial industrialist based in Pittsburgh, Pennsylvania. He is best known for his creation of the railway air brake and for bei ...

acquired and began manufacturing in 1895, while General Electric

General Electric Company (GE) was an American Multinational corporation, multinational Conglomerate (company), conglomerate founded in 1892, incorporated in the New York (state), state of New York and headquartered in Boston.

Over the year ...

acquired de Laval's designs in 1897. Since then, development has skyrocketed from Parsons’ early design, producing 0.746 kW, to modern nuclear steam turbines producing upwards of 1500 MW. Furthermore, steam turbines accounted for roughly 45% of electrical power generated in the United States in 2021. Then the first functioning industrial gas turbines were used in the late 1890s to power street lights (Meher-Homji, 2000).

Classification

In general, the two kinds of turbomachines encountered in practice are open and closed turbomachines. Open machines such as

In general, the two kinds of turbomachines encountered in practice are open and closed turbomachines. Open machines such as propeller

A propeller (often called a screw if on a ship or an airscrew if on an aircraft) is a device with a rotating hub and radiating blades that are set at a pitch to form a helical spiral which, when rotated, exerts linear thrust upon a working flu ...

s, windmills, and unshrouded fans act on an infinite extent of fluid, whereas closed machines operate on a finite quantity of fluid as it passes through a housing or casing.

Turbomachines are also categorized according to the type of flow. When the flow is parallel to the axis of rotation

Rotation or rotational/rotary motion is the circular movement of an object around a central line, known as an ''axis of rotation''. A plane figure can rotate in either a clockwise or counterclockwise sense around a perpendicular axis intersect ...

, they are called axial flow machines, and when flow is perpendicular to the axis of rotation, they are referred to as radial (or centrifugal) flow machines. There is also a third category, called mixed flow machines, where both radial and axial flow velocity components are present.

Turbomachines may be further classified into two additional categories: those that absorb energy to increase the fluid pressure

In physics, a fluid is a liquid, gas, or other material that may continuously move and deform (''flow'') under an applied shear stress, or external force. They have zero shear modulus, or, in simpler terms, are substances which cannot r ...

, i.e. pump

A pump is a device that moves fluids (liquids or gases), or sometimes Slurry, slurries, by mechanical action, typically converted from electrical energy into hydraulic or pneumatic energy.

Mechanical pumps serve in a wide range of application ...

s, fans, and compressors, and those that produce energy such as turbine

A turbine ( or ) (from the Greek , ''tyrbē'', or Latin ''turbo'', meaning vortex) is a rotary mechanical device that extracts energy from a fluid flow and converts it into useful work. The work produced can be used for generating electrical ...

s by expanding flow to lower pressures. Of particular interest are applications which contain pumps, fans, compressors and turbines. These components are essential in almost all mechanical equipment systems, such as power and refrigeration cycles.Baskharone, E. A. "Principles of Turbomachinery in Air-Breathing Engines". 2006. Cambridge University Press. 580 pages.

Turbomachines

Definition

Any device that extracts energy from or imparts energy to a continuously moving stream of fluid can be called a turbomachine. Elaborating, a turbomachine is a power or heat generating machine which employs the dynamic action of a rotating element, the rotor; the action of the rotor changes the energy level of the continuously flowing fluid through the machine. Turbines, compressors and fans are all members of this family of machines.Rajadurai, J. S. "Thermodynamics and thermal engineering". 2003. New Age International. In contrast to positive displacement machines (particularly of the reciprocating type which are low speed machines based on the mechanical and volumetric efficiency considerations), the majority of turbomachines run at comparatively higher speeds without any mechanical problems and volumetric efficiency close to one hundred percent."Combining Support Vector Machines and Segmentation Algorithms for Efficient Anomaly Detection: A Petroleum Industry Application". International Joint Conference SOCO’14-CISIS’14-ICEUTE’14. 2014. pp.269-278.Categorization

Energy conversion

Turbomachines can be categorized on the basis of the direction of energy conversion: * Absorb power to increase the fluid pressure or head (ducted fans, compressors and pumps). * Produce power by expanding fluid to a lower pressure or head (hydraulic, steam and gas turbines).Fluid flow

Turbomachines can be categorized on the basis of the nature of the flow path through the passage of the rotor:Wills, J. George. "Lubrication fundamentals". 1980. Mobil oil corporation. Marcel Dekker. 460 pages. '' Axial flow turbomachines'' - When the path of the through-flow is wholly or mainly parallel to the axis of rotation, the device is termed an axial flow turbomachine.Dixon, S. L. "Fluid mechanics and thermodynamics of turbomachinery". 1998. Elsevier. 460 pages. The radial component of the fluid velocity is negligible. Since there is no change in the direction of the fluid, several axial stages can be used to increase power output. A Kaplan turbine is an example of an axial flow turbine. In the figure: *U = Blade velocity, *Vf = Flow velocity, *V = Absolute velocity, *Vr = Relative velocity, *Vw = Tangential or Whirl component of velocity. '' Radial flow turbomachines'' - When the path of the throughflow is wholly or mainly in a plane perpendicular to the rotation axis, the device is termed a radial flow turbomachine. Therefore, the change of radius between the entry and the exit is finite. A radial turbomachine can be inward or outward flow type depending on the purpose that needs to be served. The outward flow type increases the energy level of the fluid and vice versa. Due to continuous change in direction, several radial stages are generally not used. Acentrifugal pump

Centrifugal pumps are used to transport fluids by the Energy transformation, conversion of rotational kinetic energy to the hydrodynamic energy of the fluid flow. The rotational energy typically comes from an engine or electric motor. They are ...

is an example of a radial flow turbomachine.

'' Mixed flow turbomachines'' – When axial and radial flow are both present and neither is negligible, the device is termed a mixed flow turbomachine. It combines flow and force components of both radial and axial types.

A Francis turbine is an example of a mixed-flow turbine.

Physical action

Turbomachines can finally be classified on the relative magnitude of thepressure

Pressure (symbol: ''p'' or ''P'') is the force applied perpendicular to the surface of an object per unit area over which that force is distributed. Gauge pressure (also spelled ''gage'' pressure)The preferred spelling varies by country and eve ...

changes that take place across a stage:

enthalpy

Enthalpy () is the sum of a thermodynamic system's internal energy and the product of its pressure and volume. It is a state function in thermodynamics used in many measurements in chemical, biological, and physical systems at a constant extern ...

of the fluid decreases as the velocity increases. Pressure and enthalpy drop over the rotor blades is minimal. Velocity will decrease over the rotor.

Newton's second law describes the transfer of energy. Impulse turbomachines do not require a pressure casement around the rotor since the fluid jet is created by the nozzle prior to reaching the blading on the rotor.

A Pelton wheel

The Pelton wheel or Pelton Turbine is an Impulse (physics), impulse-type water turbine invented by American inventor Lester Allan Pelton in the 1870s. The Pelton wheel extracts energy from the impulse of moving water, as opposed to water's dead w ...

is an impulse design.

Dimensionless ratios to describe turbomachinery

The following dimensionless ratios are often used for the characterisation of fluid machines. They allow a comparison of flow machines with different dimensions and boundary conditions.

#Pressure range ψ

#Flow coefficient φ (including delivery or volume number called)

#Performance numbers λ

#Run number σ

#Diameter number δ

The following dimensionless ratios are often used for the characterisation of fluid machines. They allow a comparison of flow machines with different dimensions and boundary conditions.

#Pressure range ψ

#Flow coefficient φ (including delivery or volume number called)

#Performance numbers λ

#Run number σ

#Diameter number δ

Applications

Power Generation

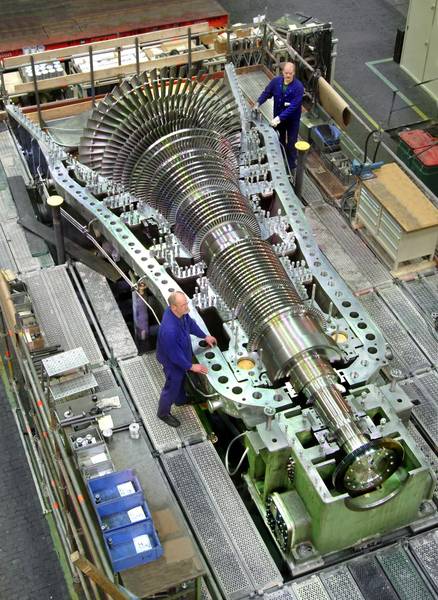

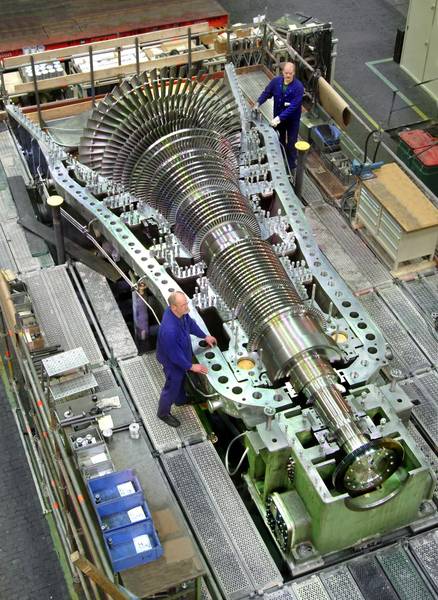

Hydro electric - Hydro-electric turbomachinery uses potential energy stored in water to flow over an open impeller to turn a generator which creates electricity Steam turbines -Steam turbine

A steam turbine or steam turbine engine is a machine or heat engine that extracts thermal energy from pressurized steam and uses it to do mechanical work utilising a rotating output shaft. Its modern manifestation was invented by Sir Charles Par ...

s used in power generation come in many different variations. The overall principle is high pressure steam is forced over blades attached to a shaft, which turns a generator. As the steam travels through the turbine, it passes through smaller blades causing the shaft to spin faster, creating more electricity.

Gas turbines - Gas turbine

A gas turbine or gas turbine engine is a type of Internal combustion engine#Continuous combustion, continuous flow internal combustion engine. The main parts common to all gas turbine engines form the power-producing part (known as the gas gene ...

s work much like steam turbines. Air is forced in through a series of blades that turn a shaft. Then fuel is mixed with the air and causes a combustion reaction, increasing the power. This then causes the shaft to spin faster, creating more electricity.

Windmills - Also known as a wind turbine

A wind turbine is a device that wind power, converts the kinetic energy of wind into electrical energy. , hundreds of thousands of list of most powerful wind turbines, large turbines, in installations known as wind farms, were generating over ...

, windmills are increasing in popularity for their ability to efficiently use the wind to generate electricity. Although they come in many shapes and sizes, the most common one is the large three-blade. The blades work on the same principle as an airplane wing. As wind passes over the blades, it creates an area of low and high pressure, causing the blade to move, spinning a shaft and creating electricity. It is most like a steam turbine, but works with an infinite supply of wind.

Marine

Steam turbine - Steam turbines in marine applications are very similar to those in power generation. The few differences between them are size and power output. Steam turbines on ships are much smaller because they don't need to power a whole town. They aren't very common because of their high initial cost, high specific fuel consumption, and expensive machinery that goes with it. Gas turbines - Gas turbines in marine applications are becoming more popular due to their smaller size, increased efficiency, and ability to burn cleaner fuels. They run just like gas turbines for power generation, but are also much smaller and do require more machinery for propulsion. They are most popular in naval ships as they can be at a dead stop to full power in minutes (Kayadelen, 2013), and are much smaller for a given amount of power. Water jet - Essentially a water jet drive is like an aircraft turbojet with the difference that the operating fluid is water instead of air. Water jets are best suited to fast vessels and are thus used often by the military. Water jet propulsion has many advantages over other forms of marine propulsion, such as stern drives, outboard motors, shafted propellers and surface drives.Auto

Turbochargers - Turbochargers are one of the most popular turbomachines. They are used mainly for adding power to engines by adding more air. It combines both forms of turbomachines. Exhaust gases from the engine spin a bladed wheel, much like a turbine. That wheel then spins another bladed wheel, sucking and compressing outside air into the engine.

Superchargers -

Turbochargers - Turbochargers are one of the most popular turbomachines. They are used mainly for adding power to engines by adding more air. It combines both forms of turbomachines. Exhaust gases from the engine spin a bladed wheel, much like a turbine. That wheel then spins another bladed wheel, sucking and compressing outside air into the engine.

Superchargers - Supercharger

In an internal combustion engine, a supercharger compresses the intake gas, forcing more air into the engine in order to produce more power for a given displacement (engine), displacement. It is a form of forced induction that is mechanically ...

s are used for engine-power enhancement as well, but only work off the principle of compression. They use the mechanical power from the engine to spin a screw or vane, some way to suck in and compress the air into the engine.

General

Pumps -Pump

A pump is a device that moves fluids (liquids or gases), or sometimes Slurry, slurries, by mechanical action, typically converted from electrical energy into hydraulic or pneumatic energy.

Mechanical pumps serve in a wide range of application ...

s are another very popular turbomachine. Although there are very many different types of pumps, they all do the same thing. Pumps are used to move fluids around using some sort of mechanical power, from electric motors to full size diesel engines. Pumps have thousands of uses, and are the true basis to turbomachinery (Škorpík, 2017).

Air compressors - Air compressors are another very popular turbomachine. They work on the principle of compression by sucking in and compressing air into a holding tank. Air compressors are one of the most basic turbomachines.

Fans - Fans are the most general type of turbomachines.

Aerospace

Gas turbines - Aerospace gas turbines, more commonly known as jet engines, are the most common gas turbines. Turbopumps - Rocket engines require very high propellant pressures and mass flow rates, meaning their pumps require a lot of power. One of the most common solutions to this issue is to use a turbopump that extracts energy from an energetic fluid flow. The source of this energetic fluid flow could be one or a combination of many things, including the decomposition of hydrogen peroxide, the combustion of a portion of the propellants, or even the heating of cryogenic propellants run through coolant jackets in the combustion chamber's walls.Partial list of turbomachine topics

Many types of dynamic continuous flow turbomachinery exist. Below is a partial list of these types. What is notable about these turbomachines is that the same fundamentals apply to all. Certainly there are significant differences between these machines and between the types of analysis that are typically applied to specific cases. This does not negate the fact that they are unified by the same underlying physics of fluid dynamics, gas dynamics, aerodynamics, hydrodynamics, and thermodynamics. *Axial compressor

An axial compressor is a gas compressor that can continuously pressurize gases. It is a rotating, airfoil-based compressor in which the gas or working fluid principally flows parallel to the axis of rotation, or axially. This differs from other ...

* Axial fan

* Centrifugal compressor

* Centrifugal fan

*Centrifugal pump

Centrifugal pumps are used to transport fluids by the Energy transformation, conversion of rotational kinetic energy to the hydrodynamic energy of the fluid flow. The rotational energy typically comes from an engine or electric motor. They are ...

* Centrifugal type supercharger

* Exoskeletal engine

* Francis turbine

*Gas turbine

A gas turbine or gas turbine engine is a type of Internal combustion engine#Continuous combustion, continuous flow internal combustion engine. The main parts common to all gas turbine engines form the power-producing part (known as the gas gene ...

* Industrial fans

*Jet engine

A jet engine is a type of reaction engine, discharging a fast-moving jet (fluid), jet of heated gas (usually air) that generates thrust by jet propulsion. While this broad definition may include Rocket engine, rocket, Pump-jet, water jet, and ...

* Mechanical fan

* Mixed flow compressor

* Radial turbine

*Steam turbine

A steam turbine or steam turbine engine is a machine or heat engine that extracts thermal energy from pressurized steam and uses it to do mechanical work utilising a rotating output shaft. Its modern manifestation was invented by Sir Charles Par ...

* Turbocharger

* Turboexpander

* Turbofans

*Turbojet

The turbojet is an airbreathing jet engine which is typically used in aircraft. It consists of a gas turbine with a propelling nozzle. The gas turbine has an air inlet which includes inlet guide vanes, a compressor, a combustion chamber, and ...

*Turboprop

A turboprop is a Gas turbine, gas turbine engine that drives an aircraft Propeller (aeronautics), propeller.

A turboprop consists of an intake, reduction drive, reduction gearbox, gas compressor, compressor, combustor, turbine, and a propellin ...

* Turbopump

*Turboshaft

A turboshaft engine is a form of gas turbine that is optimized to produce shaft horsepower rather than jet thrust. In concept, turboshaft engines are very similar to turbojets, with additional turbine expansion to extract heat energy from the ex ...

* Turbines

* Water turbine

See also

* Blade solidity * Secondary flow in turbomachinery * Slip factor * Three-dimensional losses and correlation in turbomachineryReferences

Sources

* S. M. Yahya. "Turbines Compressors and Fans". 1987. McGraw Hill. * * Nagpurwala, Q. (n.d.). Steam Turbines. Retrieved April 10, 2017, fromMarine Gas Turbines

''7th International Advanced Technologies Symposium''. Retrieved April 15, 2017.

External links

Hydrodynamics of Pumps

{{Authority control Mechanical engineering Gas technologies