Toolmaker on:

[Wikipedia]

[Google]

[Amazon]

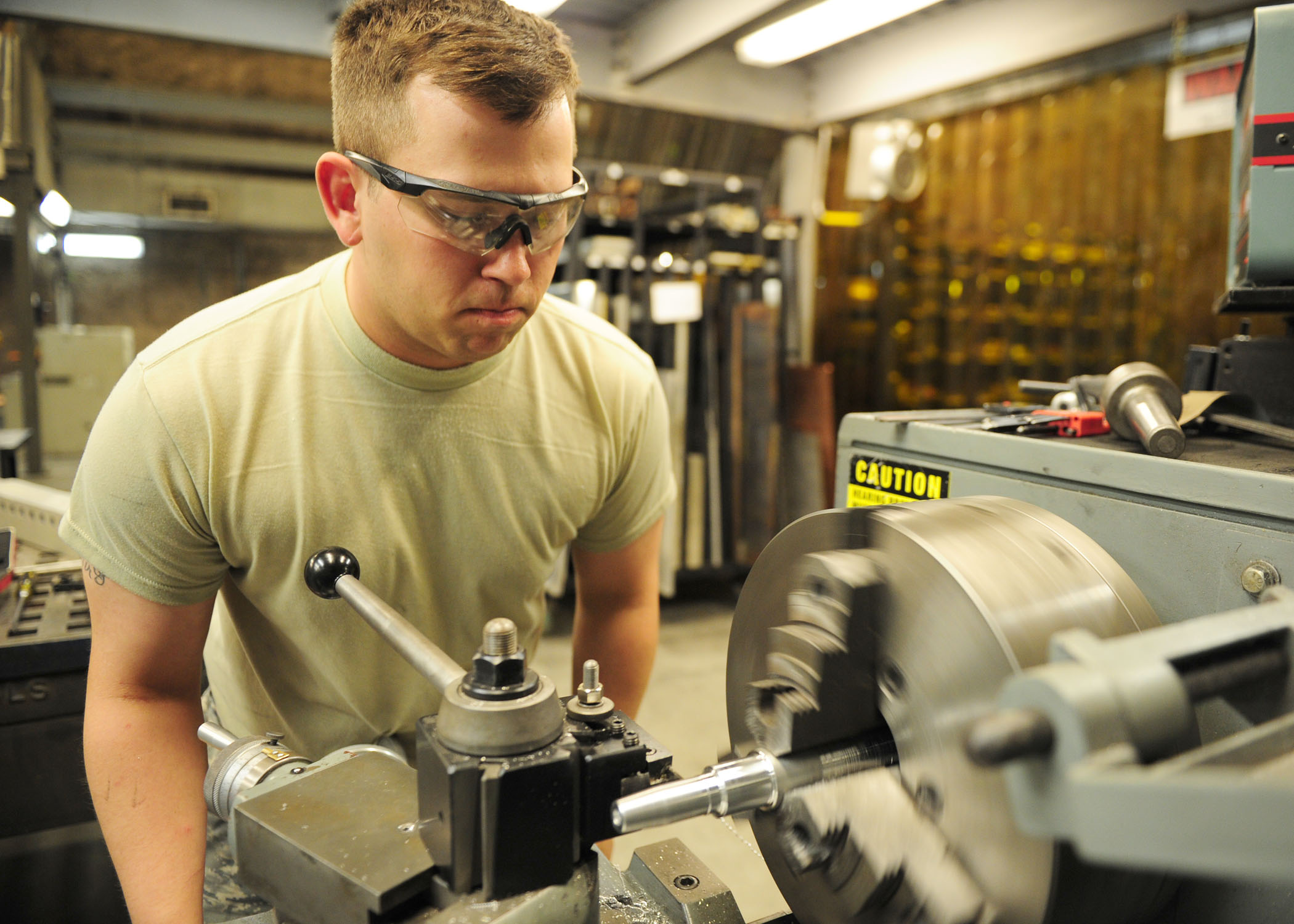

Tool and die makers are highly skilled crafters working in the manufacturing industries.

Tool and die makers work primarily in toolroom environments—sometimes literally in one room but more often in an environment with flexible, semipermeable boundaries from production work. They are skilled

Tool and die makers are highly skilled crafters working in the manufacturing industries.

Tool and die makers work primarily in toolroom environments—sometimes literally in one room but more often in an environment with flexible, semipermeable boundaries from production work. They are skilled

artisan

An artisan (from , ) is a skilled craft worker who makes or creates material objects partly or entirely by hand. These objects may be functional or strictly decorative, for example furniture, decorative art, sculpture, clothing, food ite ...

s ( craftspeople) who typically learn their trade through a combination of academic coursework and with substantial period of on-the-job training that is functionally an apprenticeship

Apprenticeship is a system for training a potential new practitioners of a trade or profession with on-the-job training and often some accompanying study. Apprenticeships may also enable practitioners to gain a license to practice in a regulat ...

. They make jigs, fixtures, dies, molds, machine tool

A machine tool is a machine for handling or machining metal or other rigid materials, usually by cutting, Boring (manufacturing), boring, grinding (abrasive cutting), grinding, shearing, or other forms of deformations. Machine tools employ some s ...

s, cutting tools, gauges, and other tools used in manufacturing processes.

Divisions

The main divisions of the tool & die industry include: *Die casting

Die casting is a casting (metalworking), metal casting process that is characterized by forcing molten metal under high pressure into a mold cavity. The mold cavity is created using two hardened tool steel die (manufacturing), dies which have been ...

* Dies

* Fixtures

*Forging

Forging is a manufacturing process involving the shaping of metal using localized compression (physics), compressive forces. The blows are delivered with a hammer (often a power hammer) or a die (manufacturing), die. Forging is often classif ...

* Gauges

* Jigs

* Metal working

* Moulding

Job description

Working fromengineering drawing

An engineering drawing is a type of technical drawing that is used to convey information about an object. A common use is to specify the geometry necessary for the construction of a component and is called a detail drawing. Usually, a number of ...

s developed by the toolmaker, engineers or technologists, tool makers lay out the design on the raw material (usually metal), then cut it to size and shape using manually controlled machine tool

A machine tool is a machine for handling or machining metal or other rigid materials, usually by cutting, Boring (manufacturing), boring, grinding (abrasive cutting), grinding, shearing, or other forms of deformations. Machine tools employ some s ...

s (such as lathes

A lathe () is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, deformation, facing, threading and turning, with tools that are applied to the ...

, milling machine

Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a workpiece. This may be done by varying directions on one or several axes, cutter head speed, and pressure. Milling covers a wide variety of ...

s, grinding machine

A grinding machine, often shortened to grinder, is any of various power tools or machine tools used for grinding. It is a type of material removal using an abrasive wheel as the cutting tool. Each grain of abrasive on the wheel's surface cuts ...

s, and jig grinders), power tool

A power tool is a tool that is actuator, actuated by an additional engine, power source and mechanism (engineering), mechanism other than the solely manual labour, manual labor used with hand tools. The most common types of power tools use electric ...

s (such as die grinder

Die, as a verb, refers to death, the cessation of life.

Die may also refer to:

Games

* Die, singular of dice, small throwable objects used for producing random numbers

Manufacturing

* Die (integrated circuit), a rectangular piece of a semicon ...

s and rotary tool

A die grinder or rotary tool is a handheld power tool and multitool used for grinding (abrasive cutting), grinding, sanding, honing (metalworking), honing, polishing, or machining material (typically metal, but also plastic or wood). All such t ...

s), and hand tool

A hand tool is any tool that is powered manual labour, by hand rather than a motor. Categories of hand tools include wrenches, pliers, cutter (disambiguation), cutters, File (tool), files, hammer, striking tools, chisel, struck or hammered tools, ...

s (such as files and honing stones).

Art and science (specifically, applied science

Applied science is the application of the scientific method and scientific knowledge to attain practical goals. It includes a broad range of disciplines, such as engineering and medicine. Applied science is often contrasted with basic science, ...

) are thoroughly intermixed in their work, since they're also in engineering

Engineering is the practice of using natural science, mathematics, and the engineering design process to Problem solving#Engineering, solve problems within technology, increase efficiency and productivity, and improve Systems engineering, s ...

.

Manufacturing engineers and tool and die makers often work in close consultation as part of a manufacturing engineering

Manufacturing engineering or production engineering is a branch of professional engineering that shares many common concepts and ideas with other fields of engineering such as mechanical, chemical, electrical, and industrial engineering.

Manufac ...

team. There is often turnover between the careers, as one person may end up working in both at different times of their life, depending on the turns of their particular educational and career path. There was no codified difference between them during the 19th century and earlier parts of the 20th century; it was only after World War II

World War II or the Second World War (1 September 1939 – 2 September 1945) was a World war, global conflict between two coalitions: the Allies of World War II, Allies and the Axis powers. World War II by country, Nearly all of the wo ...

that engineering became a regulated profession exclusively defined by a university or college engineering degree. Both careers require some level of talent in both artistic/artisanal/creative areas and math-and-science areas.

Since the advent of computing in the manufacturing fields (including CNC, CAD, CAM

Cam or CAM may refer to:

Science and technology

* Cam (mechanism), a mechanical linkage which translates motion

* Camshaft, a shaft with a cam

* Camera or webcam, a device that records images or video

In computing

* Computer-aided manufacturin ...

, and other computer-aided technologies), tool and die makers have increasingly added IT skills to their daily work. Today's tool and die makers are generally required to have all of the traditional skills plus substantial digital skills; these formidable requirements make the field challenging to master.

Training

Although the details of training programs vary, many tool and die makers begin anapprenticeship

Apprenticeship is a system for training a potential new practitioners of a trade or profession with on-the-job training and often some accompanying study. Apprenticeships may also enable practitioners to gain a license to practice in a regulat ...

with an employer, possibly including a mix of classroom training and hands-on experience. Some prior qualifications in basic mathematics, science, engineering science or design and technology can be valuable. Many tool and die makers attend a 4- to 5-year apprenticeship program to achieve the status of a journeyman

A journeyman is a worker, skilled in a given building trade or craft, who has successfully completed an official apprenticeship qualification. Journeymen are considered competent and authorized to work in that field as a fully qualified employee ...

tool and die maker. Today's employment relationships often differ in name and detail from the traditional arrangement of an apprenticeship, and the terms "apprentice" and "journeyman" are not always used, but the idea of a period of years of on-the-job training leading to mastery of the field still applies.

In the United States, tool and die makers who graduate from NTMA (National Tooling and Machining Association) have gone through 4 years of college courses as well as 10,000 working hours in order to complete their apprenticeship. They are also accredited through the U.S. Department of Labor.

Jig/fixture maker

A jig and fixture maker is under the faction of a tool and die maker/toolmaker. The standard differentiation of jigs from fixtures is that a jig guides the tool for the operation being carried out while a fixture simply secures the work. The terms are sometimes used interchangeably. A jig and fixture maker needs to know how to use an assortment of machines to build these devices such as having skills in welding and in some cases the knowledge of wood working equipment, of course with the tool room machining skills. They are often advised by an engineer in building the devices. A wide knowledge of various materials is needed beyond wood and metal such as plastics. They also can create, design and build without engineering plans/bluprints. Jig/fixture makers gain hands on practical experience while monitoring and making alterations as the manufacturing process is constantly improved and reviewed with/by engineering. They also can be required to make these adjustments without engineering help, depending on the size of the company. Some Jigs and fixtures require electronic and pneumatic actuation, which will involve knowledge/training in these fields as well. Properly built jigs and fixtures reduce waste by ensuring perfectly fitting parts. Jigs and fixtures can be as big as a car or be held in hand. Production needs dictate form and function. Jigs, fixtures and gages are needed to maintain quality standards for repeated low and high volume production demands. Ongoing evolution of computerized design and control technologies, such as CAD/CAM, CNC, PLC, and others, has limited the use of jigs in manufacturing, however all the computer run machines need some sort of clamping fixture for production runs. A common example is that a drill jig is not needed to guide the drill bits to the hole centers if it is done on a CNC, since it is Computer Numerically Controlled. However, fixtures are still needed to hold the part in place for the operation needed. Jigs are currently needed in many areas of manufacturing but mainly for low-volume production.Terminology

Die making

Die making is a subdiscipline of tool making that focuses on making and maintaining dies. This often includes making punches, dies, steel rule dies, and die sets. Precision is essential in die making; punches and die steels must maintain proper clearance to produce parts accurately, and it is often necessary to have components machined with tolerances of less than one thousandth of an inch.Tool making

Tool making typically means making tooling used to produce products. Common tooling includes metal forming rolls, cutting tools (such as tool bits andmilling cutter

Milling cutters are cutting tools typically used in milling machines or machining centres to perform milling operations (and occasionally in other machine tools). They remove material by their movement within the machine (e.g., a ball nose mill) ...

s), fixtures, or even whole machine tools used to manufacture, hold, or test products during their fabrication. Due to the unique nature of a tool maker's work, it is often necessary to fabricate custom tools or modify standard tools.

Overlap of die making, tool making, and mold making

One person may be called upon for all of the above activities, and the skills and concepts involved overlap, which is why tool and die making is often viewed as one field and is also why mold making is often viewed as a subset thereof (rather than a totally separate field).Toolrooms and toolroom methods

A toolroom in the original sense of the word is a room where tools are stored;The word used in this sense is attested in written English at least as early as 1829. a tool crib. In larger companies, the tools stored there must be checked in and out, and there may be a person assigned to attend the area. In a factory, the toolroom refers to a space where artifacts are made and repaired, particularly tools for use throughout the rest of the factory, jigs for setups, and other parts to assist workers and, as an extension, production. Inengineering

Engineering is the practice of using natural science, mathematics, and the engineering design process to Problem solving#Engineering, solve problems within technology, increase efficiency and productivity, and improve Systems engineering, s ...

and manufacturing

Manufacturing is the creation or production of goods with the help of equipment, labor, machines, tools, and chemical or biological processing or formulation. It is the essence of the

secondary sector of the economy. The term may refer ...

, toolroom activity is everything related to tool-and-die facilities in contrast to production line activity.

Originally a toolroom was literally in one room

In a building or a ship, a room is any enclosed space within a number of walls to which entry is possible only via a door or other dividing structure. The entrance connects it to either a passageway, another room, or the outdoors. The space is ...

, but like ''emergency room

An emergency department (ED), also known as an accident and emergency department (A&E), emergency room (ER), emergency ward (EW) or casualty department, is a medical treatment facility specializing in emergency medicine, the acute care of pat ...

'', the term has been figuratively extended in both substantive

In grammar, a noun is a word that represents a concrete or abstract thing, like living creatures, places, actions, qualities, states of existence, and ideas. A noun may serve as an object or subject within a phrase, clause, or sentence.Example ...

and adjectival senses to all such places and the methods used there, regardless of the physical space. The name was originally styled tool room or tool-room, but toolroom is now the norm in engineering and machining

Machining is a manufacturing process where a desired shape or part is created using the controlled removal of material, most often metal, from a larger piece of raw material by cutting. Machining is a form of subtractive manufacturing, which util ...

.

Making, repairing, and storing tools

The simplestsense

A sense is a biological system used by an organism for sensation, the process of gathering information about the surroundings through the detection of Stimulus (physiology), stimuli. Although, in some cultures, five human senses were traditio ...

of the word ''toolroom'' refers to the storage of tools. A broader use of the term includes reference to a space where tools are made, repaired, inventoried, and/or distributed for use within the factory. This extension of the latter sense reflects the development of greater systemization in manufacturing. During the 19th century, there gradually developed a division of labor

The division of labour is the separation of the tasks in any economic system or organisation so that participants may specialise (Departmentalization, specialisation). Individuals, organisations, and nations are endowed with or acquire specialis ...

whereby the people who made, repaired, kept records of, stored, and retrieved tools were not necessarily the same people who used the tools to do the manufacturing work itself. Examples of such division of labor had existed in prior centuries, but most manufacturing had been done on a craft basis, where there had been no need for the idea of a toolroom separate from the rest of the workshop.

The simplest sense above can also be conveyed by the word toolcrib (sometimes styled tool-crib or tool crib).

Tool-and-die facilities and methods

In engineering and manufacturing, a toolroom is everything related to tool-and-die facilities and methods, in contrast to the factory floor and production line activity. For people not familiar with these fields, in order to understand the specialist usage, some explanation is needed: Within the general field ofmachining

Machining is a manufacturing process where a desired shape or part is created using the controlled removal of material, most often metal, from a larger piece of raw material by cutting. Machining is a form of subtractive manufacturing, which util ...

there is a rough but recurring division between (a) toolroom practice and (b) production practice (the making of large numbers of duplicate parts). It is the difference between manufacturing

Manufacturing is the creation or production of goods with the help of equipment, labor, machines, tools, and chemical or biological processing or formulation. It is the essence of the

secondary sector of the economy. The term may refer ...

itself and the tool-and-die work that is done in support of the manufacturing. Anecdotal examples of similar distinctions can probably be found here and there throughout human history, but as a widespread part of the "fabric" of material culture, this distinction (and the terminology with which to talk about it) has evolved since the Industrial Revolution

The Industrial Revolution, sometimes divided into the First Industrial Revolution and Second Industrial Revolution, was a transitional period of the global economy toward more widespread, efficient and stable manufacturing processes, succee ...

, and most especially since the advent of armory practice and later mass production

Mass production, also known as mass production, series production, series manufacture, or continuous production, is the production of substantial amounts of standardized products in a constant flow, including and especially on assembly lines ...

.

A good, simplistic way to summarize the change in ideas is to compare the making of a certain product in different time periods. In 1750, a rifle

A rifle is a long gun, long-barreled firearm designed for accurate shooting and higher stopping power, with a gun barrel, barrel that has a helical or spiralling pattern of grooves (rifling) cut into the bore wall. In keeping with their focus o ...

was made in a workshop by a craftsman using hand tools, and if he needed a new tool, it is likely that he would make it himself using the same tools and methods that he would use to make his product, the rifle (smithy, files, woodcarving knives, etc.) This type of craftsmanship can still be done today, but it is expensive in terms of skilled labor time per unit of output, and therefore it implies small total output volume and high unit price. However, today the way to make rifles in large quantity with low unit price is to first do the tool-and-die work (toolroom work) (that is, make, or have someone else make, machine tools, jigs, and fixtures), and then use those specialized tools to mass-produce the rifles in an automated way that involves no toolroom methods.

Another example, instead of comparing different centuries, simply compares different methods of toolpath control that could be chosen today: If you need a certain hole location on each part for your drill bit

A drill bit is a cutting tool used in a drill to remove material to create holes, almost always of circular cross-section. Drill bits come in many sizes and shapes and can create different kinds of holes in many different materials. In orde ...

, will you dial it carefully by hand ''many times'' (once for each part produced), or will you dial it carefully by hand ''only once''—while making a drill jig

A drill is a tool used for making round holes or driving fasteners. It is fitted with a drill bit for making holes, or a screwdriver bit for securing fasteners. Historically, they were powered by hand, and later mains power, but cordless ba ...

for subsequent drilling to be quickly and effortlessly guided by?

The manufacturing of small batches has often presented the biggest challenge to this division of methods. When only a small batch of output is demanded, will one (a) produce each piece using "custom" methods (handcrafting or toolroom-style layout and machining), which drives up unit cost; or (b) maintain the capital-cost-intensive toolroom-production division, which also drives up unit costs in its own ways? In other words, is it worth one's time to make a fixture, and is it worth tying up a drill press's availability by setting it up for dedicated use with that fixture? The drill press may be needed tomorrow for a different part, with a different setup. For 100 parts, the costs of making a fixture and tying up a machine's availability are justified. For 5 parts, maybe one should just make each of the 5 using toolroom-style layout and toolpath control.

The evolution of IT and its integration into manufacturing is changing the questions and equations still further. For example, CNC and robotics

Robotics is the interdisciplinary study and practice of the design, construction, operation, and use of robots.

Within mechanical engineering, robotics is the design and construction of the physical structures of robots, while in computer s ...

have led the way to rapid prototyping

Rapid prototyping is a group of techniques used to quickly fabricate a scale model of a physical part or assembly using three-dimensional computer aided design ( CAD) data.

Construction of the part or assembly is usually done using 3D printing ...

and instant manufacturing, which shift the toolroom-production division by giving an up-front toolroom investment the flexibility to be quickly and easily used for any product design, with batch size irrelevant.

In large corporations there may be a very distinct division of labor between toolroom work and production machining, with different employees for each, whereas job-shop work is often a blend of toolroom work and production work, because each project requires some of both, and the same employees may "wear each hat" in sequence.

See also

* * *Notes

References

{{Authority control Machinists