|

Jig (tool)

A jig is a type of custom-made tool used to control the location and/or motion of parts or other tools. Description A jig's primary purpose is to provide repeatability, accuracy, and interchangeability in the manufacturing of products.. An example of a jig is when a key is duplicated; the original is used as a jig so the new key can have the same path as the old one. Since the advent of automation and computer numerical controlled (CNC) machines, jigs are often not required because the tool path is digitally programmed and stored in memory. Jigs may be made for reforming plastics. Jigs or templates have been known long before the industrial age. There are many types of jigs, and each one is custom-tailored to do a specific job. Drill jig A ''drill jig'' is a type of jig that expedites repetitive hole center location on multiple interchangeable parts by acting as a template to guide the twist drill or other boring device into the precise location of each intended hole cen ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Frame Building Jig

A frame is often a structural system that supports other components of a physical construction and/or steel frame that limits the construction's extent. Frame and FRAME may also refer to: Physical objects In building construction *Framing (construction), a building term known as light frame construction *Framer, a carpenter who assembles major structural elements in constructing a building *A-frame, a basic structure designed to bear a load in a lightweight economical manner **A-frame house, a house following the same principle *Door frame or window frame, fixed structures to which the hinges of doors or windows are attached *Frame and panel, a method of woodworking *Space frame, a method of construction using lightweight or light materials *Timber framing, a method of building for creating framed structures of heavy timber or willow wood In vehicles *Frame (aircraft), structural rings in an aircraft fuselage *Frame (nautical), the skeleton of a boat *Bicycle frame, the main c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Machine Tool

A machine tool is a machine for handling or machining metal or other rigid materials, usually by cutting, Boring (manufacturing), boring, grinding (abrasive cutting), grinding, shearing, or other forms of deformations. Machine tools employ some sort of tool that does the cutting or shaping. All machine tools have some means of constraining the workpiece and provide a guided movement of the parts of the machine. Thus, the relative movement between the workpiece and the cutting tool (which is called the toolpath) is controlled or constrained by the machine to at least some extent, rather than being entirely "offhand" or "wikt:freehand#Adjective, freehand". It is a power-driven metal cutting machine which assists in managing the needed relative motion between cutting tool and the job that changes the size and shape of the job material. The precise definition of the term ''machine tool'' varies among users. While all machine tools are "machines that help people to make things", not a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Woodworking Jigs

Woodworking is the skill of making items from wood, and includes cabinetry, furniture making, wood carving, joinery, carpentry, and woodturning. History Along with stone, clay and animal parts, wood was one of the first materials worked by early humans. Microwear analysis of the Mousterian stone tools used by the Neanderthals show that many were used to work wood. The development of civilization was closely tied to the development of increasingly greater degrees of skill in working these materials. Among the earlliest finds of woodworking are shaped sticks displaying notches from Kalambo Falls in southen Africa, dating to around 476,000 years ago. The Clacton spearhead from Clacton-on-Sea, England, dating to around 400,000 years ago,Allington-Jones, L., (2015) ''Archaeological Journal'', 172 (2) 273–296 The Clacton Spear – The Last One Hundred Years the Schöningen spears, from Schöningen (Germany) dating around 300,000 years ago and the Lehringen spear from northern Ge ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Industrial Press

Industrial Press, Inc., is a privately held corporation headquartered in South Norwalk, Connecticut. Its primary areas of business are publishing technical books for engineering, technology, and manufacturing. The company was founded in New York City in 1883, and moved to Connecticut in 2013. Industrial Press's flagship title is the ''Machinery's Handbook ''Machinery's Handbook'' ''for machine shop and drafting-room; a reference book on machine design and shop practice for the mechanical engineer, draftsman, toolmaker, and machinist'' (the full title of the 1st edition) is a classic reference ...''. It is a reference for mechanical and manufacturing engineers, designers, draftsmen, toolmakers, and machinists. External links * Book publishing companies based in Connecticut Companies based in Norwalk, Connecticut Publishing companies based in New York City Publishing companies established in 1880 1880 establishments in New York (state) Privately held companies bas ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tapering Jig

A tapering jig is a woodworking jig used to cut a progressively deeper cut along a workpiece usually parallel to the grain. Tapering jigs are often used to create table legs, with the taper usually cut into the two sides of the leg facing the inside of the table. There are various commercial varieties of tapering jigs, ranging for simple two hinged pieces of aluminum square tubing with a device to maintain angle settings, to more complex varieties that utilize clamps to affix the workpiece to a bed using toggle clamps or other clamping devices. Many woodworkers prefer to make the jig in the shop in order to customize it to the particular project at hand. See also *Jig (tool) * Staircase jig *Sharpening jig A sharpening jig is often used when sharpening woodworking tools. Many of the tools used in woodworking have steel blades which are sharpened to a fine edge. A cutting edge is created on the blade at the point at which two surfaces of the blad ... Woodworking jigs [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sharpening Jig

A sharpening jig is often used when sharpening woodworking tools. Many of the tools used in woodworking have steel blades which are sharpened to a fine edge. A cutting edge is created on the blade at the point at which two surfaces of the blade meet. To create this cutting edge a bevel is formed on the blade, usually by grinding. This bevel is subsequently refined by honing until a satisfactorily sharp edge is created. The purpose of the sharpening jig is to hold the blade or tool at the desired angle while grinding or honing the bevel. In some cases, the angle of the bevel is critical to the performance of the cutting edge—a jig allows for repeatability of this angle over a number of sharpening sessions. There are many styles of jig available commercially. Fundamentally, all jigs are similar in that they allow the user to clamp the blade or tool in some way. The jig then has some means of referencing the clamped blade to the grinding or honing apparatus so that the bevel ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

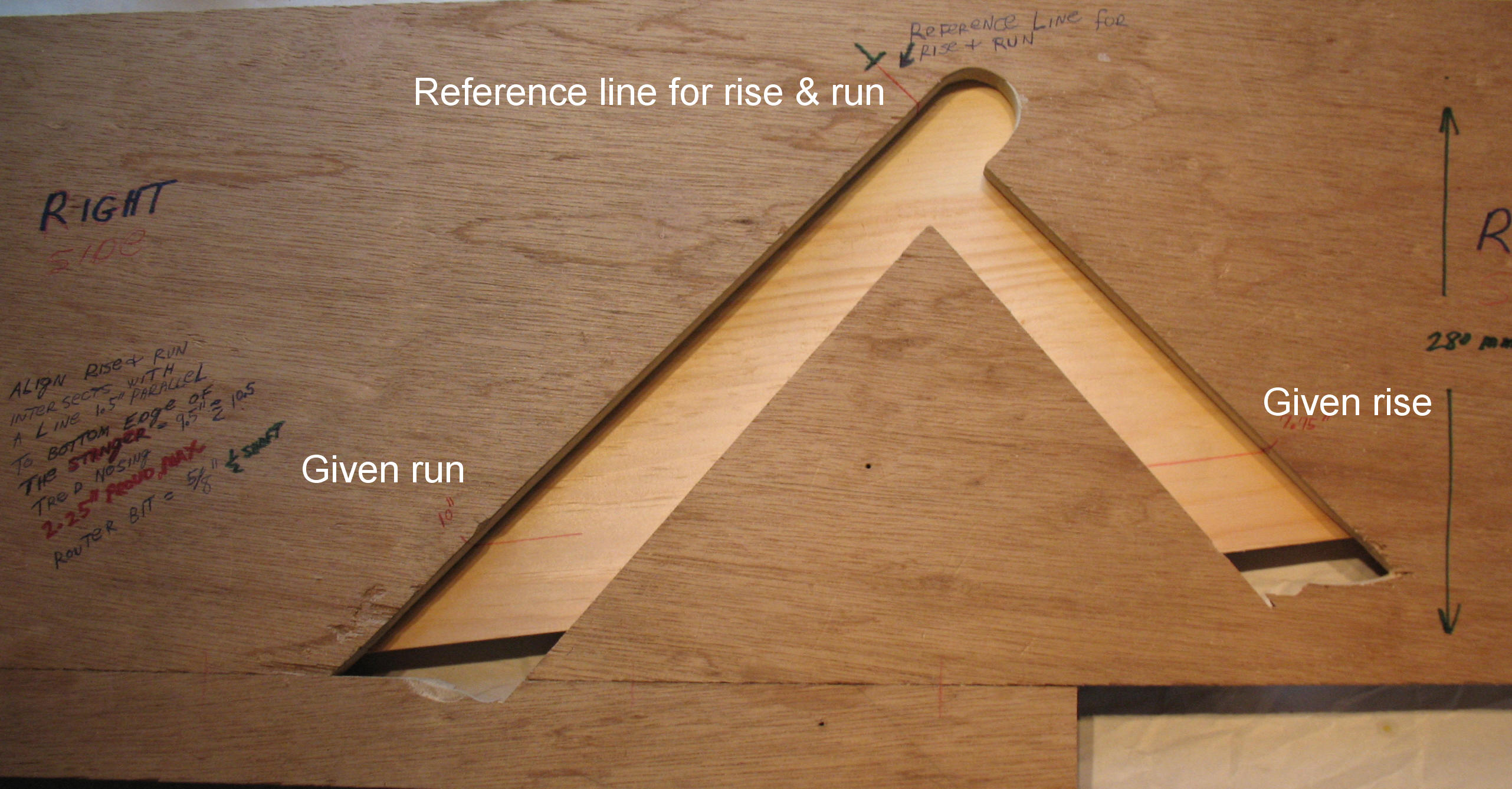

Staircase Jig

A staircase jig is a woodworking tool that incorporates both a right angle and an acute angle in its design. The jig is easily transported due to its small size and light weight. Precise measurements are required to layout the diagonal locations. This jig uses a zero reference line from which the rise and tread are measured. The upper part of the jig is a right triangle with a roundover overhang. The template allows for a tight fit of the tread into the stringer in the overhang section. The bottom of the jig incorporates an acute angle. This tapered angle allows a space for a wedge to fit against the back side of the vertical and the horizontal plane of the stringer. This jig can be used to lay out different rise (vertical) and tread (horizontal) widths. The jig is used with a plunge router and a bushing guide. The router plows out a precise groove into the finished product that allows all the parts to fit together. Uses of jig The jig is used to make finish stringers, in in ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Jig Grinder

A jig grinder is a machine tool used for grinding complex shapes and holes where the highest degrees of accuracy and finish are required. The jig grinder is very similar to a jig borer, in that the table positioning and spindles are very accurate (far more so than a manual milling machine or lathe A lathe () is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, deformation, facing, threading and turning, with tools that are applied to the w ...). It is used almost exclusively by tool and die makers in the creation of jigs or mating holes and pegs on dies. There are usually many peripheral elements to a large jig grinder, including separate hydraulic motors, air compressors, and various cooling systems for both the hydraulic circuit and supplying coolant to the work and machine itself. The machine operates by a high-speed air spindle rotating a grinding bit. The air spindl ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Drill

A drill is a tool used for making round holes or driving fasteners. It is fitted with a drill bit for making holes, or a screwdriver bit for securing fasteners. Historically, they were powered by hand, and later mains power, but cordless battery-powered drills are proliferating due to increased efficiency and ease of use. Drills are commonly used in woodworking, metalworking, construction, machine tool fabrication, and utility projects. Specially designed versions are made for surgery, dentistry, miniatures, and other applications. History Around 35,000 BC, ''Homo sapiens'' discovered the benefits of the application of rotary tools. This would have rudimentarily consisted of a pointed rock being spun between the hands to bore a hole through another material. This led to the hand drill, a smooth stick, that was sometimes attached to flint point, and was rubbed between the palms. This was used by many ancient civilizations around the world including the Mayans. The ear ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Servomechanism

In mechanical and control engineering, a servomechanism (also called servo system, or simply servo) is a control system for the position and its time derivatives, such as velocity, of a mechanical system. It often includes a servomotor, and uses closed-loop control to reduce steady-state error and improve dynamic response. In closed-loop control, error-sensing negative feedback is used to correct the action of the mechanism. In displacement-controlled applications, it usually includes a built-in encoder or other position feedback mechanism to ensure the output is achieving the desired effect. Following a specified motion trajectory is called servoing, where "servo" is used as a verb. The ''servo'' prefix originates from the Latin word ''servus'' meaning slave. The term correctly applies only to systems where the feedback or error-correction signals help control mechanical position, speed, attitude or any other measurable variables. For example, an automotive power win ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Jig Borer

The jig borer is a type of machine tool invented at the end of World War I to enable the quick and precise location of hole centers. It was invented independently in Switzerland and the United States. It resembles a specialized kind of milling machine that provides tool and die makers with a higher degree of positioning precision (repeatability) and accuracy than those provided by general machines. Although capable of light milling, a jig borer is more suited to highly accurate drilling, boring, and reaming, where the quill or headstock does not see the significant side loading that it would with mill work. The result is a machine designed more for location accuracy than heavy material removal. A typical jig borer has a work table of around which can be moved using large handwheels (with micrometer-style readouts and verniers) on particularly carefully made shafts with a strong degree of gearing; this allows positions to be set on the two axes to an accuracy of . It is generally ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tool

A tool is an Physical object, object that can extend an individual's ability to modify features of the surrounding environment or help them accomplish a particular task. Although many Tool use by animals, animals use simple tools, only human beings, whose use of stone tools dates back hundreds of millennia, have been observed using tools to make other tools. Early human tools, made of such materials as Rock (geology), stone, bone, and wood, were used for the preparation of food, hunting, the manufacture of weapons, and the working of materials to produce clothing and useful Cultural artifact, artifacts and crafts such as pottery, along with the construction of housing, businesses, infrastructure, and transportation. The development of metalworking made additional types of tools possible. Harnessing energy sources, such as Working animal, animal power, wind, or steam, allowed increasingly complex tools to produce an even larger range of items, with the Industrial Revolution markin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |