Styrene-butadiene Rubber on:

[Wikipedia]

[Google]

[Amazon]

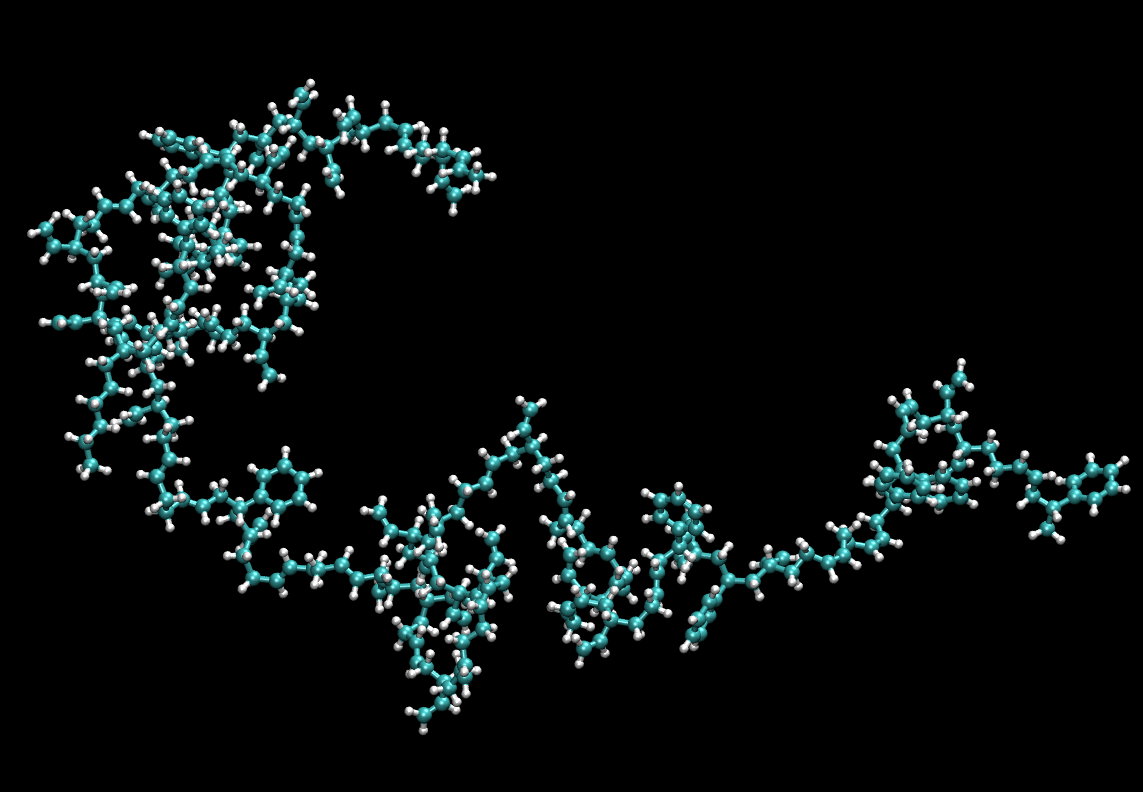

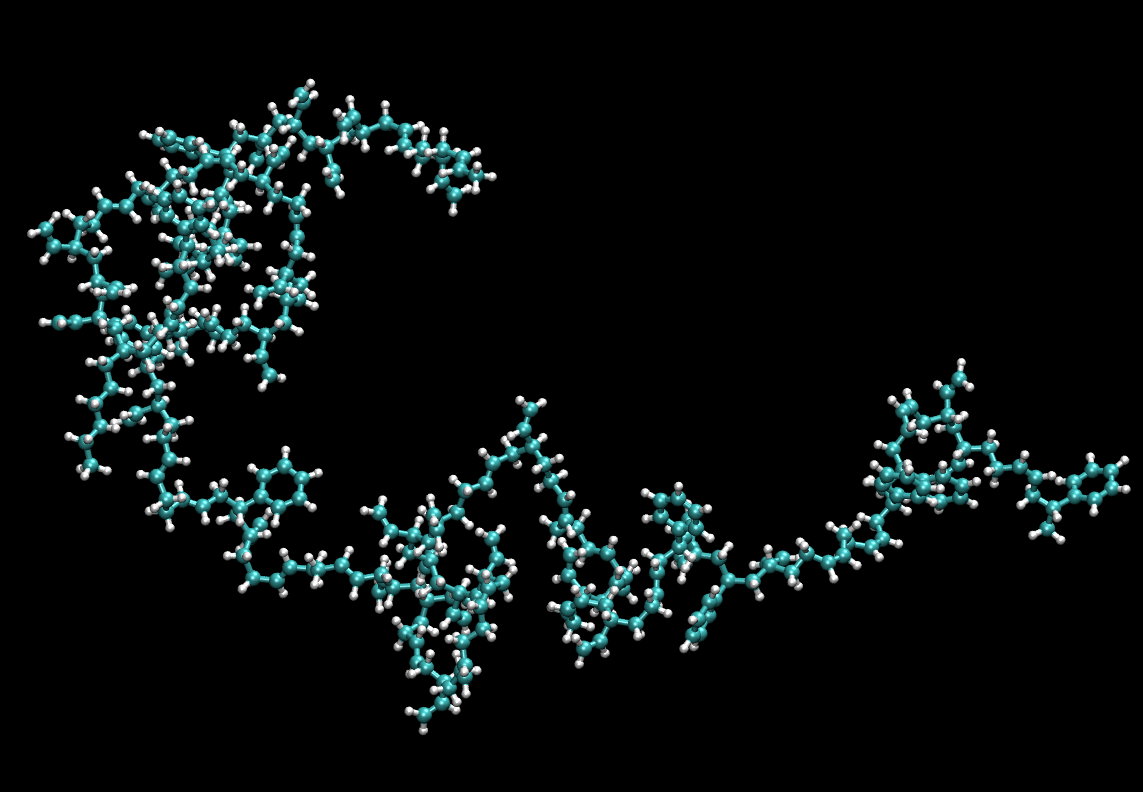

Styrene-butadiene or styrene-butadiene rubber (SBR) describe families of

It is a commodity material which competes with natural rubber. The

It is a commodity material which competes with natural rubber. The

synthetic rubber

A synthetic rubber is an artificial elastomer. They are polymers synthesized from petroleum byproducts. About 32-million metric tons of rubbers are produced annually in the United States, and of that amount two thirds are synthetic. Synthetic rubbe ...

s derived from styrene and butadiene (the version developed by Goodyear is called Neolite). These materials have good abrasion resistance and good aging stability when protected by additives. In 2012, more than 5.4 million tonnes of SBR were processed worldwide. About 50% of car tires are made from various types of SBR. The styrene/butadiene ratio influences the properties of the polymer: with high styrene content, the rubbers are harder and less rubbery. SBR is not to be confused with the thermoplastic elastomer, styrene-butadiene block copolymer, although being derived from the same monomers.

Types of SBR

SBR is derived from two monomers, styrene and butadiene. The mixture of these two monomers is polymerized by two processes: from solution (S-SBR) or as an emulsion (E-SBR). E-SBR is more widely used.Emulsion polymerization

E-SBR produced by emulsion polymerization is initiated by free radicals. Reaction vessels are typically charged with the two monomers, a free radical generator, and a chain transfer agent such as an alkylmercaptan

In organic chemistry, a thiol (; ), or thiol derivative, is any organosulfur compound of the form , where R represents an alkyl or other organic substituent. The functional group itself is referred to as either a thiol group or a sulfhydryl gro ...

. Radical initiators include potassium persulfate and hydroperoxides in combination with ferrous salts. Emulsifying agents include various soaps. By "capping" the growing organic radicals, mercaptans (e.g. dodecylthiol), control the molecular weight, and hence the viscosity, of the product. Typically, polymerizations are allowed to proceed only to ca. 70%, a method called "short stopping". In this way, various additives can be removed from the polymer.

Solution polymerization

Solution-SBR is produced by an anionic polymerization process. Polymerization is initiated byalkyl lithium compound

In organometallic chemistry, organolithium reagents are chemical compounds that contain carbon–lithium (C–Li) bonds. These reagents are important in organic synthesis, and are frequently used to transfer the organic group or the lithium atom ...

s. Water and oxygen are strictly excluded. The process is homogeneous (all components are dissolved), which provides greater control over the process, allowing tailoring of the polymer. The organolithium compound adds to one of the monomers , generating a carbanion

In organic chemistry, a carbanion is an anion in which carbon is trivalent (forms three bonds) and bears a formal negative charge (in at least one significant resonance form).

Formally, a carbanion is the conjugate base of a carbon acid:

:R3C ...

that then adds to another monomer, and so on. For tire manufacture, S-SBR is increasingly favored because it offers improved wet grip and reduced rolling resistance, which translate to greater safety and better fuel economy, respectively.H.-D.Brandt et al. "Rubber, 5. Solution Rubbers" in Ullmann's Encyclopedia of Industrial Chemistry, 2012, Wiley-VCH, Weinheim.

Buna S

The material was initially marketed with the brand name Buna S. Its name derives Bu for butadiene and Na for sodium ( natrium in several languages including Latin, German, and Dutch), and S for styrene. Buna S is an addition copolymer.Properties

Applications

It is a commodity material which competes with natural rubber. The

It is a commodity material which competes with natural rubber. The elastomer

An elastomer is a polymer with viscoelasticity (i.e. both viscosity and elasticity) and with weak intermolecular forces, generally low Young's modulus and high failure strain compared with other materials. The term, a portmanteau of ''elastic p ...

is used widely in pneumatic tires. This application mainly calls for E-SBR, although S-SBR is growing in popularity. Other uses include shoe heels and soles, gaskets, and even chewing gum.

Latex (emulsion) SBR is extensively used in coated paper

Coated paper (also known as enamel paper, gloss paper, and thin paper) is paper that has been coated by a mixture of materials or a polymer to impart certain qualities to the paper, including weight, surface gloss, smoothness, or reduced ink absor ...

s, being one of the cheapest resins to bind pigmented coatings.

It is also used in building applications, as a sealing and binding agent behind renders as an alternative to PVA, but is more expensive. In the latter application, it offers better durability, reduced shrinkage and increased flexibility, as well as being resistant to emulsification in damp conditions.

SBR is often used as part of cement based substructural (basement)waterproofing systems where as a liquid it is mixed with water to form the Gauging solution for mixing the powdered Tanking material to a slurry. SBR aids the bond strength, reduces the potential for shrinkage and adds an element of flexibility.

It is also used by speaker driver manufacturers as the material for Low Damping Rubber Surrounds.

Additionally, it is used in some rubber cutting boards.

SBR is also used as a binder in lithium-ion battery electrodes, in combination with carboxymethyl cellulose as a water-based alternative for, e.g. polyvinylidene fluoride.

Styrene-butane rubber is also used in gasketed-plate heat exchangers. It is used at moderate temperature up to 85 deg C, (358 K) for aqueous systems.

SBS Filaments also exist for FDM 3D printing

3D printing or additive manufacturing is the Manufacturing, construction of a three-dimensional object from a computer-aided design, CAD model or a digital 3D modeling, 3D model. It can be done in a variety of processes in which material is ...

History

SBR is a replacement for natural rubber. It was originally developed prior to World War II in Germany by chemist Walter Bock in 1929. Industrial manufacture began during World War II, and was used extensively by the U.S. Synthetic Rubber Program to produce Government Rubber-Styrene (GR-S); to replace the Southeast Asian supply of natural rubber which, under Japanese occupation, was unavailable to Allied nations.See also

*Synthetic rubber

A synthetic rubber is an artificial elastomer. They are polymers synthesized from petroleum byproducts. About 32-million metric tons of rubbers are produced annually in the United States, and of that amount two thirds are synthetic. Synthetic rubbe ...

* Nitrile rubber

* Elastomer

An elastomer is a polymer with viscoelasticity (i.e. both viscosity and elasticity) and with weak intermolecular forces, generally low Young's modulus and high failure strain compared with other materials. The term, a portmanteau of ''elastic p ...

* Ozone cracking

* Tire

References

{{DEFAULTSORT:Styrene-Butadiene Copolymers Elastomers Polymers U.S. Synthetic Rubber Program German inventions 1929 in science