Printed Circuit Board Fabrication on:

[Wikipedia]

[Google]

[Amazon]

Printed circuit board manufacturing is the process of manufacturing bare printed circuit boards (PCBs) and populating them with

Printed circuit board manufacturing is the process of manufacturing bare printed circuit boards (PCBs) and populating them with

Manufacturing starts from the fabrication data generated by

Manufacturing starts from the fabrication data generated by  Modern PCBs are designed with dedicated layout software, generally in the following steps:

#

Modern PCBs are designed with dedicated layout software, generally in the following steps:

#

The process by which copper traces are applied to the surface is known as ''

The process by which copper traces are applied to the surface is known as ''

Multi-layer printed circuit boards have trace layers inside the board. This is achieved by laminating a stack of materials in a press by applying pressure and heat for a period of time. This results in an inseparable one piece product. For example, a four-layer PCB can be fabricated by starting from a two-sided copper-clad laminate, etch the circuitry on both sides, then laminate to the top and bottom pre-preg and copper foil. It is then drilled, plated, and etched again to get traces on top and bottom layers.

The inner layers are given a complete machine inspection before lamination because mistakes cannot be corrected afterwards. Automatic optical inspection (AOI) machines compare an image of the board with the digital image generated from the original design data. Automated Optical Shaping (AOS) machines can then add missing copper or remove excess copper using a laser, reducing the number of PCBs that have to be discarded. PCB tracks can have a width of just 10 micrometers.

Multi-layer printed circuit boards have trace layers inside the board. This is achieved by laminating a stack of materials in a press by applying pressure and heat for a period of time. This results in an inseparable one piece product. For example, a four-layer PCB can be fabricated by starting from a two-sided copper-clad laminate, etch the circuitry on both sides, then laminate to the top and bottom pre-preg and copper foil. It is then drilled, plated, and etched again to get traces on top and bottom layers.

The inner layers are given a complete machine inspection before lamination because mistakes cannot be corrected afterwards. Automatic optical inspection (AOI) machines compare an image of the board with the digital image generated from the original design data. Automated Optical Shaping (AOS) machines can then add missing copper or remove excess copper using a laser, reducing the number of PCBs that have to be discarded. PCB tracks can have a width of just 10 micrometers.

Holes through a PCB are typically drilled with

Holes through a PCB are typically drilled with

Proper plating or surface finish selection can be critical to process yield, the amount of rework, field failure rate, and reliability.

PCBs may be plated with solder, tin, or gold over nickel.

After PCBs are etched and then rinsed with water, the solder mask is applied, and then any exposed copper is coated with solder, nickel/gold, or some other anti-corrosion coating.

It is important to use solder compatible with both the PCB and the parts used. An example is

Proper plating or surface finish selection can be critical to process yield, the amount of rework, field failure rate, and reliability.

PCBs may be plated with solder, tin, or gold over nickel.

After PCBs are etched and then rinsed with water, the solder mask is applied, and then any exposed copper is coated with solder, nickel/gold, or some other anti-corrosion coating.

It is important to use solder compatible with both the PCB and the parts used. An example is

Areas that should not be soldered may be covered with solder resist ( solder mask). The solder mask is what gives PCBs their characteristic green color, although it is also available in several other colors, such as red, blue, purple, yellow, black and white. One of the most common solder resists used today is called "LPI" (

Areas that should not be soldered may be covered with solder resist ( solder mask). The solder mask is what gives PCBs their characteristic green color, although it is also available in several other colors, such as red, blue, purple, yellow, black and white. One of the most common solder resists used today is called "LPI" (

In assembly the bare board is populated (or "stuffed") with electronic components to form a functional ''printed circuit assembly'' (PCA), sometimes called a "printed circuit board assembly" (PCBA). In

In assembly the bare board is populated (or "stuffed") with electronic components to form a functional ''printed circuit assembly'' (PCA), sometimes called a "printed circuit board assembly" (PCBA). In

Printed circuit board manufacturing is the process of manufacturing bare printed circuit boards (PCBs) and populating them with

Printed circuit board manufacturing is the process of manufacturing bare printed circuit boards (PCBs) and populating them with electronic component

An electronic component is any basic discrete electronic device or physical entity part of an electronic system used to affect electrons or their associated fields. Electronic components are mostly industrial products, available in a singula ...

s. It includes all the processes to produce the full assembly of a board into a functional circuit board.

In board manufacturing, multiple PCBs are grouped on a single panel for efficient processing. After assembly, they are separated (depaneled

Depaneling or depanelization is a process step in high-volume electronics assembly production. In order to increase the throughput of printed circuit board (PCB) manufacturing and surface-mount technology, surface mount (SMT) lines, PCBs are ofte ...

). Various techniques, such as silk screening and photoengraving, replicate the desired copper patterns on the PCB layers. Multi-layer boards are created by laminating different layers under heat and pressure. Holes for via

Via or VIA may refer to the following:

Arts and entertainment

* ''Via'' (Volumes album), 2011

* Via (Thalia Zedek album), 2013

* VIA (music), Soviet and Russian term for a music collective

Businesses and organisations

* Via Foundation, a Cz ...

s (vertical connections between layers) are also drilled.

The final assembly involves placing components onto the PCB and soldering them in place. This process can include through-hole technology

In electronics, through-hole technology (also spelled "thru-hole") is a manufacturing scheme in which leads on the components are inserted through holes drilled in printed circuit boards (PCB) and soldered to pads on the opposite side, eithe ...

(in which the component goes through the board) or surface-mount technology

Surface-mount technology (SMT), originally called planar mounting, is a method in which the electrical components are mounted directly onto the surface of a printed circuit board (PCB). An electrical component mounted in this manner is referred ...

(SMT) (in which the component lays on top of the board).

Design

Manufacturing starts from the fabrication data generated by

Manufacturing starts from the fabrication data generated by computer aided design

Computer-aided design (CAD) is the use of computers (or ) to aid in the creation, modification, analysis, or optimization of a design. This software is used to increase the productivity of the designer, improve the quality of design, improve c ...

, and component information. The fabrication data is read into the CAM (Computer Aided Manufacturing) software. CAM performs the following functions:

# Input of the fabrication data.

# Verification of the data

# Compensation for deviations in the manufacturing processes (e.g. scaling to compensate for distortions during lamination)

# Panelization

# Output of the digital tools (copper patterns, drill files, inspection, and others)

Initially PCBs were designed manually by creating a photomask

A photomask (also simply called a mask) is an opaque plate with transparent areas that allow light to shine through in a defined pattern. Photomasks are commonly used in photolithography for the production of integrated circuits (ICs or "chips") ...

on a clear mylar

BoPET (biaxially oriented polyethylene terephthalate) is a polyester film made from stretched polyethylene terephthalate (PET) and is used for its high tensile strength, chemical stability, dimensional stability, transparency reflectivity, an ...

sheet, usually at two or four times the true size. Starting from the schematic diagram the component pin pads were laid out on the mylar and then traces were routed to connect the pads. Rub-on dry transfer

Dry transfers (also called rub-ons or rubdowns) are decals that can be applied without the use of water or other solvent. The decal itself is on a backing material such as paper or plastic sheeting much like a transparency. The dry transfer is ...

s of common component footprints increased efficiency. Traces were made with self-adhesive tape. Pre-printed non-reproducing grids on the mylar assisted in layout. The finished photomask was photolithographically reproduced onto a photoresist coating on the blank copper-clad boards.

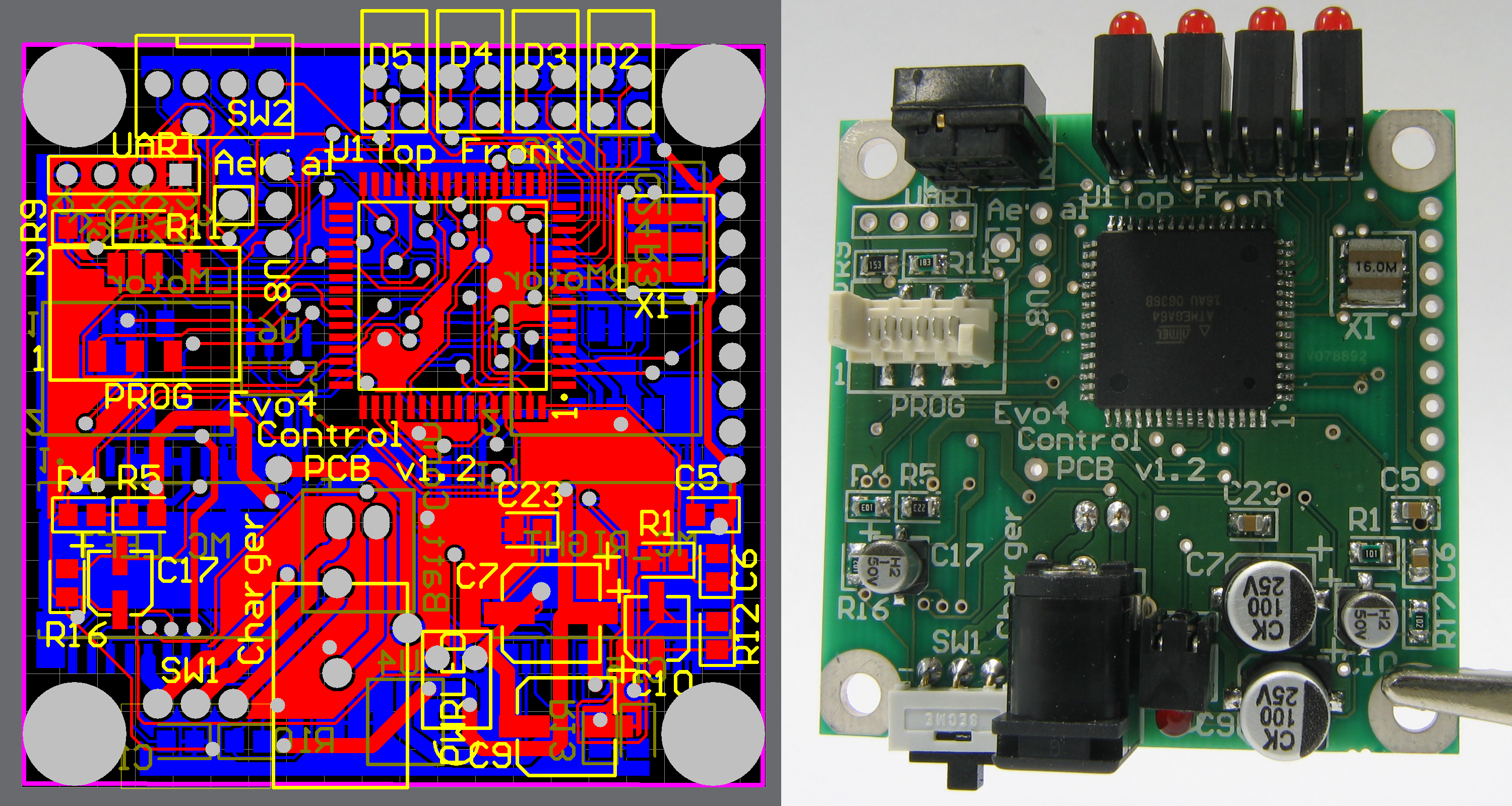

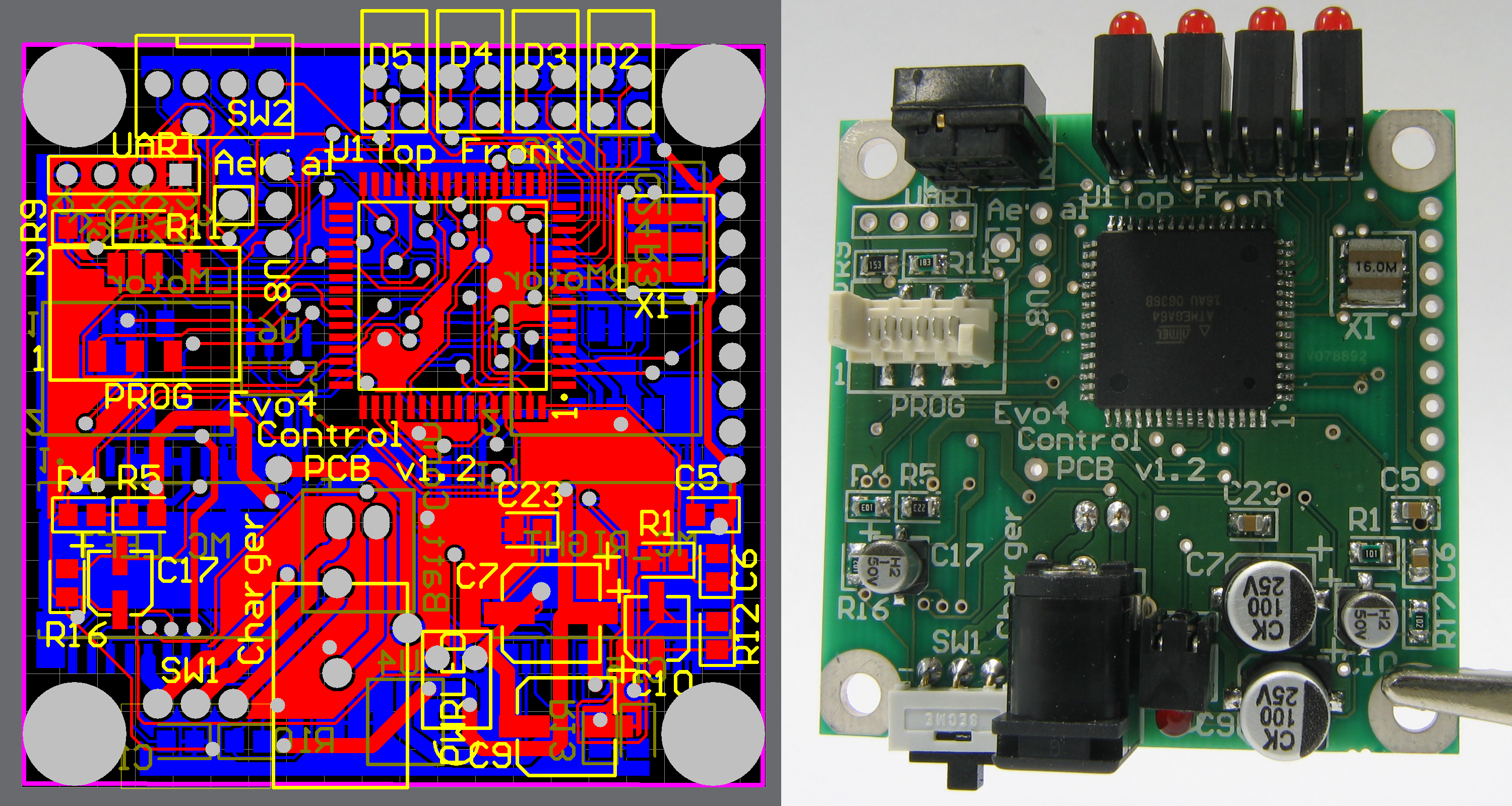

Modern PCBs are designed with dedicated layout software, generally in the following steps:

#

Modern PCBs are designed with dedicated layout software, generally in the following steps:

# Schematic capture

Schematic capture or schematic entry is a step in the design cycle of electronic design automation (EDA) at which the electronic diagram, or electronic schematic of the designed electronic circuit, is created by a designer. This is done interac ...

through an electronic design automation

Electronic design automation (EDA), also referred to as electronic computer-aided design (ECAD), is a category of software tools for designing Electronics, electronic systems such as integrated circuits and printed circuit boards. The tools wo ...

(''EDA'') tool.

# Card dimensions and template are decided based on required circuitry and enclosure of the PCB.

# The positions of the components and heat sink

A heat sink (also commonly spelled heatsink) is a passive heat exchanger that transfers the heat generated by an electronic or a mechanical device to a fluid medium, often air or a liquid coolant, where it is thermal management (electronics), ...

s are determined.

# Layer stack of the PCB is decided, with one to tens of layers depending on complexity. Ground and power plane

A printed circuit board (PCB), also called printed wiring board (PWB), is a Lamination, laminated sandwich structure of electrical conduction, conductive and Insulator (electricity), insulating layers, each with a pattern of traces, planes ...

s are decided. A power plane is the counterpart to a ground plane and behaves as an AC signal ground while providing DC power to the circuits mounted on the PCB. Signal interconnections are traced on signal planes. Signal planes can be on the outer as well as inner layers. For optimal EMI

EMI Group Limited (formerly EMI Group plc until 2007; originally an initialism for Electric and Musical Industries, also referred to as EMI Records or simply EMI) was a British transnational conglomerate founded in March 1931 in London. At t ...

performance high frequency signals are routed in internal layers between power or ground planes.

# Line impedance

In electrical engineering, impedance matching is the practice of designing or adjusting the input impedance or output impedance of an electrical device for a desired value. Often, the desired value is selected to maximize power transfer or ...

is determined using dielectric layer thickness, routing copper thickness and trace-width. Trace separation is also taken into account in case of differential signals. Microstrip

Microstrip is a type of electrical transmission line which can be fabricated with any technology where a conductor is separated from a ground plane by a dielectric layer known as ''substrate''. Microstrip lines are used to convey microwave-freq ...

, stripline

In electronics, stripline is a transverse electromagnetic (TEM) transmission line medium invented by Robert M. Barrett of the Air Force Cambridge Research Centre in the 1950s. Stripline is the earliest form of planar transmission line.

De ...

or dual stripline can be used to route signals.

# Components are placed. Thermal considerations and geometry are taken into account. Via

Via or VIA may refer to the following:

Arts and entertainment

* ''Via'' (Volumes album), 2011

* Via (Thalia Zedek album), 2013

* VIA (music), Soviet and Russian term for a music collective

Businesses and organisations

* Via Foundation, a Cz ...

s and lands are marked.

# Signal trace In electronics, a signal trace or circuit trace on a printed circuit board (PCB) or integrated circuit (IC) is the equivalent of a wire for conducting signals. Each trace consists of a flat, narrow part of the copper

Copper is a chemical elem ...

s are routed. Electronic design automation tools usually create clearances and connections in power and ground planes automatically.

# Fabrication data consists of a set of Gerber format

The Gerber format is an open, ASCII, vector format for printed circuit board (PCB) designs. It is the ''de facto'' standard used by PCB industry software to describe the printed circuit board images: copper layers, solder mask, legend, drill d ...

files, a drill file, and a pick-and-place file.

Panelization

Several small printed circuit boards can be grouped together for processing as a panel. A panel consisting of a design duplicated ''n''-times is also called an ''n''-panel, whereas a ''multi-panel'' combines several different designs onto a single panel. The outer tooling strip often includestooling hole

Tooling may refer to:

* Machine tools and the tooling, such as cutting tools, fixtures, and accessories, that is used on them

** Cutting tool (machining), any of hundreds of kinds of cutters

** Fixture (tool), a fixed workholding or support device ...

s, a set of panel fiducial

A fiducial marker or fiducial is an object placed in the field of view of an image for use as a point of reference or a measure. It may be either something placed into or on the imaging subject, or a mark or set of marks in the reticle of an opt ...

s, a test coupon, and may include hatched copper pour

In electronics, the term copper pour refers to an area on a printed circuit board filled with copper (the metal used to make connections in printed circuit boards). Copper pour is commonly used to create a ground plane. Another reason for using c ...

or similar patterns for even copper distribution over the whole panel in order to avoid bending. The assemblers often mount components on panels rather than single PCBs because this is efficient. Panelization may also be necessary for boards with components placed near an edge of the board because otherwise the board could not be mounted during assembly. Most assembly shops require a free area of at least 10 mm around the board.

Depaneling

The panel is eventually broken into individual PCBs along perforations or grooves in the panel through milling or cutting. For milled panels a common distance between the individual boards is 2–3 mm. Today depaneling is often done by lasers which cut the board with no contact. Laser depaneling reduces stress on the fragile circuits, improving the yield of defect-free units.Copper patterning

The first step is to replicate the pattern in the fabricator's CAM system on a protective mask on the copper foil PCB layers. Subsequent etching removes the unwanted copper unprotected by the mask. (Alternatively, a conductive ink can be ink-jetted on a blank (non-conductive) board. This technique is also used in the manufacture ofhybrid circuit

A hybrid integrated circuit (HIC), hybrid microcircuit, hybrid circuit or simply hybrid is a miniaturized electronic circuit constructed of individual devices, such as semiconductor devices (e.g. transistors, diodes or monolithic ICs) and pa ...

s.)

# '' Silk screen printing'' uses etch-resistant inks to create the protective mask.

# ''Photoengraving

Photoengraving is a process that uses a light-sensitive photoresist applied to the surface to be engraved to create a mask that protects some areas during a subsequent operation which etches, dissolves, or otherwise removes some or all of the ma ...

'' uses a photomask and developer to selectively remove a UV-sensitive photoresist coating and thus create a photoresist mask that will protect the copper below it. Direct imaging techniques are sometimes used for high-resolution requirements. Experiments have been made with thermal resist. A laser may be used instead of a photomask. This is known as maskless lithography

Maskless lithography (MPL) is a photomask-less photolithography-like technology used to project or focal-spot write the image pattern onto a chemical resist-coated substrate (e.g. wafer) by means of UV radiation or electron beam.

In microlithog ...

or direct imaging.

# '' PCB milling'' uses a two or three-axis mechanical milling system to mill away the copper foil from the substrate. A PCB milling machine (referred to as a 'PCB Prototyper') operates in a similar way to a plotter

A plotter is a machine that produces vector graphics drawings. Plotters draw lines on paper using a pen, or in some applications, use a knife to cut a material like Polyvinyl chloride, vinyl or leather. In the latter case, they are sometimes k ...

, receiving commands from the host software that control the position of the milling head in the x, y, and (if relevant) z axis.

# ''Laser resist ablation'' involves spraying black paint onto copper clad laminate, then placing the board into CNC laser plotter. The laser raster-scans the PCB and ablates (vaporizes) the paint where no resist is wanted. (Note: laser copper ablation is rarely used and is considered experimental.)

# ''Laser etching'', in which the copper may be removed directly by a CNC laser. Like PCB milling above, this is used mainly for prototyping.

# '' EDM etching'' uses an electrical discharge

In electromagnetism, an electric discharge is the release and transmission of electricity in an applied electric field through a medium such as a gas (i.e., an outgoing flow of electric current through a non-metal medium).American Geophysical U ...

to remove a metal from a substrate submerged into a dielectric fluid.

The method chosen depends on the number of boards to be produced and the required resolution.

; Large volume:

* Silk screen printing – Used for PCBs with bigger features

* Photoengraving – Used when finer features are required

; Small volume:

* Print onto transparent film and use as photo mask along with photo-sensitized boards, then etch. (Alternatively, use a film photoplotter.)

* Laser resist ablation

* PCB milling

* Laser etching

; Hobbyist:

* Laser-printed resist: Laser-print onto toner transfer paper, heat-transfer with an iron or modified laminator onto bare laminate, soak in water bath, touch up with a marker, then etch.

* Vinyl film and resist, non-washable marker, some other methods. Labor-intensive, only suitable for single boards.

Etching

etching

Etching is traditionally the process of using strong acid or mordant to cut into the unprotected parts of a metal surface to create a design in intaglio (incised) in the metal. In modern manufacturing, other chemicals may be used on other type ...

'' after the subtractive method of the process, though there are also additive and semi-additive methods.

Subtractive methods remove copper from an entirely copper-coated board to leave only the desired copper pattern. The simplest method, used for small-scale production and often by hobbyists, is immersion etching, in which the board is submerged in etching solution such as ferric chloride

Iron(III) chloride describes the inorganic compounds with the formula (H2O)x. Also called ferric chloride, these compounds are some of the most important and commonplace compounds of iron. They are available both in anhydrous and in hydrated f ...

. Compared with methods used for mass production, the etching time is long. Heat and agitation can be applied to the bath to speed the etching rate. In bubble etching, air is passed through the etchant bath to agitate the solution and speed up etching. Splash etching uses a motor-driven paddle to splash boards with etchant; the process has become commercially obsolete since it is not as fast as spray etching. In spray etching, the etchant solution is distributed over the boards by nozzles, and recirculated by pumps. Adjustment of the nozzle pattern, flow rate, temperature, and etchant composition gives predictable control of etching rates and high production rates. As more copper is consumed from the boards, the etchant becomes saturated and less effective; different etchants have different capacities for copper, with some as high as 150 grams of copper per liter of solution. In commercial use, etchants can be regenerated to restore their activity, and the dissolved copper recovered and sold. Small-scale etching requires attention to disposal of used etchant, which is corrosive and toxic due to its metal content. The etchant removes copper on all surfaces not protected by the resist. "Undercut" occurs when etchant attacks the thin edge of copper under the resist; this can reduce conductor widths and cause open-circuits. Careful control of etch time is required to prevent undercut. Where metallic plating is used as a resist, it can "overhang" which can cause short circuits between adjacent traces when closely spaced. Overhang can be removed by wire-brushing the board after etching.

In additive methods the pattern is electroplated

Electroplating, also known as electrochemical deposition or electrodeposition, is a process for producing a metal coating on a solid substrate through the reduction of cations of that metal by means of a direct electric current. The part to be ...

onto a bare substrate using a complex process. The advantage of the additive method is that less material is needed and less waste is produced. In the full additive process the bare laminate is covered with a photosensitive film which is imaged (exposed to light through a mask and then developed which removes the unexposed film). The exposed areas are sensitized in a chemical bath, usually containing palladium and similar to that used for through hole plating which makes the exposed area capable of bonding metal ions. The laminate is then plated with copper in the sensitized areas. When the mask is stripped, the PCB is finished.

Semi-additive is the most common process: The unpatterned board has a thin layer of copper already on it. A reverse mask is then applied (Unlike a subtractive process mask, this mask exposes those parts of the substrate that will eventually become the traces). Additional copper is then plated onto the board in the unmasked areas; copper may be plated to any desired weight. Tin-lead or other surface platings are then applied. The mask is stripped away and a brief etching step removes the now-exposed bare original copper laminate from the board, isolating the individual traces. Some single-sided boards which have plated-through holes are made in this way. General Electric

General Electric Company (GE) was an American Multinational corporation, multinational Conglomerate (company), conglomerate founded in 1892, incorporated in the New York (state), state of New York and headquartered in Boston.

Over the year ...

made consumer radio sets in the late 1960s using additive boards. The (semi-)additive process is commonly used for multi-layer boards as it facilitates the plating

Plating is a finishing process in which a metal is deposited on a surface. Plating has been done for hundreds of years; it is also critical for modern technology. Plating is used to decorate objects, for corrosion inhibition, to improve solderab ...

-through of the holes to produce conductive vias in the circuit board.

Industrial etching

Chemical milling or industrial etching is the subtractive manufacturing process of using baths of temperature-regulated etching chemicals to remove material to create an object with the desired shape. Other names for chemical etching incl ...

is usually done with ammonium persulfate

Ammonium persulfate (APS) is the inorganic compound with the formula (NH4)2S2O8. It is a colourless (white) salt that is highly soluble in water, much more so than the related potassium salt. It is a strong oxidizing agent that is used as a cataly ...

or ferric chloride

Iron(III) chloride describes the inorganic compounds with the formula (H2O)x. Also called ferric chloride, these compounds are some of the most important and commonplace compounds of iron. They are available both in anhydrous and in hydrated f ...

. For PTH (plated-through holes), additional steps of electroless deposition are done after the holes are drilled, then copper is electroplated to build up the thickness, the boards are screened, and plated with tin/lead. The tin/lead becomes the resist leaving the bare copper to be etched away.

Lamination

Multi-layer printed circuit boards have trace layers inside the board. This is achieved by laminating a stack of materials in a press by applying pressure and heat for a period of time. This results in an inseparable one piece product. For example, a four-layer PCB can be fabricated by starting from a two-sided copper-clad laminate, etch the circuitry on both sides, then laminate to the top and bottom pre-preg and copper foil. It is then drilled, plated, and etched again to get traces on top and bottom layers.

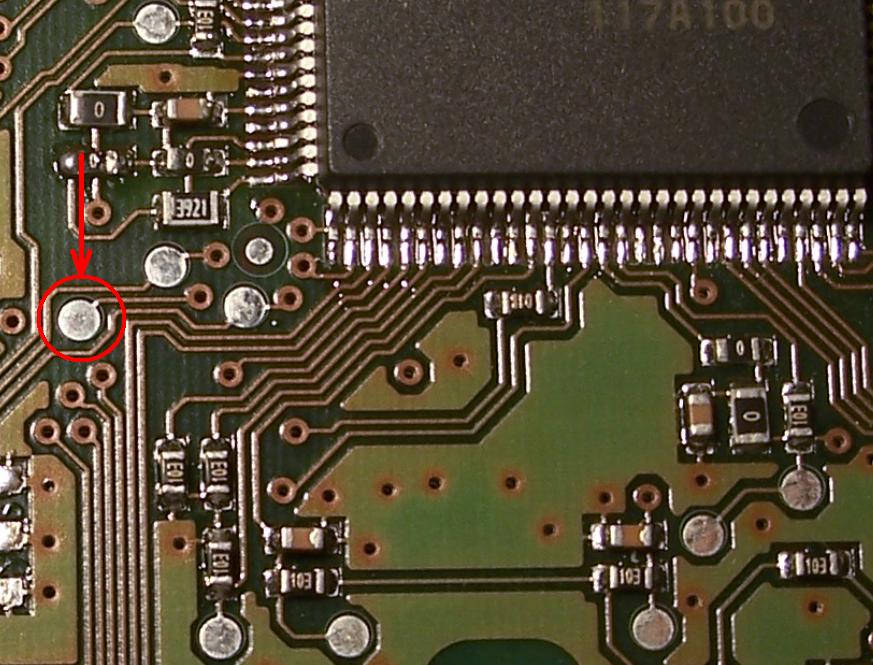

The inner layers are given a complete machine inspection before lamination because mistakes cannot be corrected afterwards. Automatic optical inspection (AOI) machines compare an image of the board with the digital image generated from the original design data. Automated Optical Shaping (AOS) machines can then add missing copper or remove excess copper using a laser, reducing the number of PCBs that have to be discarded. PCB tracks can have a width of just 10 micrometers.

Multi-layer printed circuit boards have trace layers inside the board. This is achieved by laminating a stack of materials in a press by applying pressure and heat for a period of time. This results in an inseparable one piece product. For example, a four-layer PCB can be fabricated by starting from a two-sided copper-clad laminate, etch the circuitry on both sides, then laminate to the top and bottom pre-preg and copper foil. It is then drilled, plated, and etched again to get traces on top and bottom layers.

The inner layers are given a complete machine inspection before lamination because mistakes cannot be corrected afterwards. Automatic optical inspection (AOI) machines compare an image of the board with the digital image generated from the original design data. Automated Optical Shaping (AOS) machines can then add missing copper or remove excess copper using a laser, reducing the number of PCBs that have to be discarded. PCB tracks can have a width of just 10 micrometers.

Drilling

Holes through a PCB are typically drilled with

Holes through a PCB are typically drilled with drill bit

A drill bit is a cutting tool used in a drill to remove material to create holes, almost always of circular cross-section. Drill bits come in many sizes and shapes and can create different kinds of holes in many different materials. In orde ...

s coated with tungsten carbide

Tungsten carbide (chemical formula: ) is a carbide containing equal parts of tungsten and carbon atoms. In its most basic form, tungsten carbide is a fine gray powder, but it can be pressed and formed into shapes through sintering for use in in ...

. Coated tungsten carbide is used because board materials are abrasive. High-speed-steel bits would dull quickly, tearing the copper and ruining the board. Drilling is done by computer-controlled drilling machines, using a ''drill file'' or Excellon file PCB NC drill files convey PCB drilling and routing information. The NC formats were originally designed by CNC drill and route machine vendors as proprietary input formats for their equipment, and are known under their company name: Excellon, Hitach ...

that describes the location and size of each drilled hole.

Vias

Holes may be made conductive, by electroplating or inserting hollow metal eyelets, to connect board layers. Some conductive holes are intended for the insertion of through-hole-component leads. Others used to connect board layers, are called vias.Micro vias

When vias with a diameter smaller than 76.2 micrometers are required, drilling with mechanical bits is impossible because of high rates of wear and breakage. In this case, the vias may be laser drilled—evaporated bylaser

A laser is a device that emits light through a process of optical amplification based on the stimulated emission of electromagnetic radiation. The word ''laser'' originated as an acronym for light amplification by stimulated emission of radi ...

s. Laser-drilled vias typically have an inferior surface finish inside the hole. These holes are called ''micro vias'' and can have diameters as small as 10 micrometers.

Blind and buried vias

It is also possible with ''controlled-depth'' drilling, laser drilling, or by pre-drilling the individual sheets of the PCB before lamination, to produce holes that connect only some of the copper layers, rather than passing through the entire board. These holes are called ''blind vias'' when they connect an internal copper layer to an outer layer, or ''buried vias'' when they connect two or more internal copper layers and no outer layers. Laser drilling machines can drill thousands of holes per second and can use either UV or lasers. The hole walls for boards with two or more layers can be made conductive and then electroplated with copper to form ''plated-through holes''. These holes electrically connect the conducting layers of the PCB.Smear

For multi-layer boards, those with three layers or more, drilling typically produces a ''smear'' of the high temperature decomposition products of bonding agent in the laminate system. Before the holes can be plated through, this smear must be removed by a chemical ''de-smear'' process, or by ''Plasma etching

Plasma etching is a form of plasma processing used to fabricate integrated circuits. It involves a high-speed stream of glow discharge (Plasma (physics), plasma) of an appropriate gas mixture being shot (in pulses) at a sample. The plasma source, ...

''. The de-smear process ensures that a good connection is made to the copper layers when the hole is plated through. On high reliability boards a process called etch-back is performed chemically with a potassium permanganate based etchant or plasma etching. The etch-back removes resin and the glass fibers so that the copper layers extend into the hole and as the hole is plated become integral with the deposited copper.

Plating and coating

Proper plating or surface finish selection can be critical to process yield, the amount of rework, field failure rate, and reliability.

PCBs may be plated with solder, tin, or gold over nickel.

After PCBs are etched and then rinsed with water, the solder mask is applied, and then any exposed copper is coated with solder, nickel/gold, or some other anti-corrosion coating.

It is important to use solder compatible with both the PCB and the parts used. An example is

Proper plating or surface finish selection can be critical to process yield, the amount of rework, field failure rate, and reliability.

PCBs may be plated with solder, tin, or gold over nickel.

After PCBs are etched and then rinsed with water, the solder mask is applied, and then any exposed copper is coated with solder, nickel/gold, or some other anti-corrosion coating.

It is important to use solder compatible with both the PCB and the parts used. An example is ball grid array

A ball grid array (BGA) is a type of surface-mount packaging (a chip carrier) used for integrated circuits. BGA packages are used to permanently mount devices such as microprocessors. A BGA can provide more interconnection pins than can be pu ...

(BGA) using tin-lead solder balls for connections losing their balls on bare copper traces or using lead-free solder paste.

Other platings used are organic solderability preservative

Organic solderability preservative or OSP is a method for coating of printed circuit boards. It uses a water-based organic compound that selectively bonds to copper and protects the copper until soldering. Compared to the traditional HASL process, ...

(OSP), immersion silver (IAg), immersion tin (ISn), electroless nickel immersion gold

Electroless nickel immersion gold (ENIG or ENi/IAu), also known as immersion gold (Au), chemical Ni/Au or soft gold, is a metal plating process used in the manufacture of printed circuit boards (PCBs), to avoid oxidation and improve the solderabili ...

(ENIG) coating, electroless nickel electroless palladium immersion gold (ENEPIG), hot air solder leveling

HASL or HAL (for hot air (solder) leveling) is a type of finish used on printed circuit boards (PCBs).

The PCB is typically dipped into a bath of molten solder so that all exposed copper surfaces are covered by solder. Excess solder is removed by ...

(HASL) and direct gold plating

Gold plating is a method of depositing a thin layer of gold onto the surface of another metal, most often copper or silver (to make silver-gilt), by a chemical or electrochemical (electroplating) process. Plating refers to modern coating met ...

(over nickel). Edge connector

An edge connector is the portion of a printed circuit board (PCB) consisting of signal trace, traces leading to the edge of the board that are intended to plug into a matching jack (connector), socket. The edge connector is a money-saving devic ...

s, placed along one edge of some boards, are often nickel-plated then gold-plated

Gold plating is a method of depositing a thin layer of gold onto the surface of another metal, most often copper or silver (to make silver-gilt), by a chemical or electrochemical (electroplating) process. Plating refers to modern coating met ...

using ENIG. Another coating consideration is rapid diffusion of coating metal into tin solder. Tin forms intermetallics such as Cu6Sn5 and Ag3Cu that dissolve into the Tin liquidus or solidus (at 50 °C), stripping surface coating or leaving voids.

''Electrochemical migration'' (ECM) is the growth of conductive metal filaments on or in a printed circuit board (PCB) under the influence of a DC voltage bias. Silver, zinc, and aluminum are known to grow whiskers

Whiskers, also known as vibrissae (; vibrissa; ) are a type of stiff, functional hair used by most therian mammals to sense their environment. These hairs are finely specialised for this purpose, whereas other types of hair are coarser as ta ...

under the influence of an electric field. Silver also grows conducting surface paths in the presence of halide and other ions, making it a poor choice for electronics use. Tin will grow "whiskers" due to tension in the plated surface. Tin-lead or solder plating also grows whiskers, only reduced by reducing the percentage of tin. Reflow to melt solder or tin plate to relieve surface stress lowers whisker incidence. Another coating issue is tin pest

Tin pest is an autocatalytic, allotropic transformation of the element tin, which causes deterioration of tin objects at low temperatures. Tin pest has also been called ''tin disease'', ''tin blight'', ''tin plague'', or ''tin leprosy''. It is ...

, the transformation of tin to a powdery allotrope at low temperature.

Solder resist application

Areas that should not be soldered may be covered with solder resist ( solder mask). The solder mask is what gives PCBs their characteristic green color, although it is also available in several other colors, such as red, blue, purple, yellow, black and white. One of the most common solder resists used today is called "LPI" (

Areas that should not be soldered may be covered with solder resist ( solder mask). The solder mask is what gives PCBs their characteristic green color, although it is also available in several other colors, such as red, blue, purple, yellow, black and white. One of the most common solder resists used today is called "LPI" (liquid photoimageable solder mask

Solder mask, solder stop mask or solder resist is a thin lacquer-like layer of polymer that is usually applied to the copper traces of a printed circuit board (PCB) for protection against oxidation and to prevent solder bridges from forming b ...

). A photo-sensitive coating is applied to the surface of the PWB, then exposed to light through the solder mask image film, and finally developed where the unexposed areas are washed away. Dry film solder mask is similar to the dry film used to image the PWB for plating or etching. After being laminated to the PWB surface it is imaged and developed as LPI. Once but no longer commonly used, because of its low accuracy and resolution, is to screen print epoxy ink. In addition to repelling solder, solder resist also provides protection from the environment to the copper that would otherwise be exposed.

Legend / silkscreen

A legend (also known as ''silk'' or ''silkscreen'') is often printed on one or both sides of the PCB. It contains the component designators, switch settings, test points and other indications helpful in assembling, testing, servicing, and sometimes using the circuit board. There are three methods to print the legend: # Silkscreen printing epoxy ink was the established method, resulting in the alternative name. # Liquid photo imaging is a more accurate method than screen printing. #Inkjet printing

Inkjet printing is a type of computer printing that recreates a digital image by propelling droplets of ink onto paper or plastic substrates. Inkjet printers were the most commonly used type of printer in 2008, and range from small inexpensi ...

is increasingly used. Inkjet printers can print variable data, unique to each PCB unit, such as text, a serial number

A serial number (SN) is a unique identifier used to ''uniquely'' identify an item, and is usually assigned incrementally or sequentially.

Despite being called serial "numbers", they do not need to be strictly numerical and may contain letters ...

, or a bar code

A barcode or bar code is a method of representing data in a visual, Machine-readable data, machine-readable form. Initially, barcodes represented data by varying the widths, spacings and sizes of parallel lines. These barcodes, now commonly ref ...

.

Bare-board test

Boards with no components installed are usually ''bare-board tested'' for "shorts" and "opens". This is called ''electrical test'' or ''PCB e-test''. A short is a connection between two points that should not be connected. An open is a missing connection between points that should be connected. For high-volume testing, a rigid needle adapter makes contact with copper lands on the board. The fixture or adapter is a significant fixed cost and this method is only economical for high-volume or high-value production. For small or medium volume production ''flying probe

Flying probes are test probes used for testing both bare circuit boards and boards loaded with components. Flying probes were introduced in the late 1980s and can be found in many manufacturing and assembly operations, most often in manufacturin ...

'' testers are used where test probes are moved over the board by an XY drive to make contact with the copper lands. There is no need for a fixture and hence the fixed costs are much lower. The CAM system ''instructs'' the electrical tester to apply a voltage to each contact point as required and to check that this voltage appears on the appropriate contact points and only on these.

Assembly

through-hole technology

In electronics, through-hole technology (also spelled "thru-hole") is a manufacturing scheme in which leads on the components are inserted through holes drilled in printed circuit boards (PCB) and soldered to pads on the opposite side, eithe ...

, the component leads are inserted in holes surrounded by conductive ''pads''; the holes keep the components in place. In surface-mount technology

Surface-mount technology (SMT), originally called planar mounting, is a method in which the electrical components are mounted directly onto the surface of a printed circuit board (PCB). An electrical component mounted in this manner is referred ...

(SMT), the component is placed on the PCB so that the pins line up with the conductive ''pads'' or ''lands'' on the surfaces of the PCB; solder paste, which was previously applied to the pads, holds the components in place temporarily; if surface-mount components are applied to both sides of the board, the bottom-side components are glued to the board. In both through hole and surface mount, the components are then soldered; once cooled and solidified, the solder holds the components in place permanently and electrically connects them to the board.

There are a variety of soldering

Soldering (; ) is a process of joining two metal surfaces together using a filler metal called solder. The soldering process involves heating the surfaces to be joined and melting the solder, which is then allowed to cool and solidify, creatin ...

techniques used to attach components to a PCB. High volume production is usually done with a pick-and-place machine

Surface-mount technology (SMT) component placement systems, commonly called pick-and-place machines or P&Ps, are robotic machines which are used to place surface-mount devices (SMDs) onto a printed circuit board (PCB). They are used for high ...

and bulk wave soldering

Wave soldering is a bulk soldering process used in printed circuit board manufacturing. The circuit board is passed over a pan of molten solder in which a pump produces an upwelling of solder that looks like a standing wave. As the circuit bo ...

for through-hole parts or reflow oven

A reflow oven is a machine used primarily for reflow soldering of surface mount electronic components to printed circuit boards (PCBs).

In commercial high-volume use, reflow ovens take the form of a long tunnel containing a conveyor belt along w ...

s for SMT components or through-hole parts, but skilled technicians are able to hand-solder very tiny parts (for instance 0201 packages which are 0.02 in. by 0.01 in.) under a microscope

A microscope () is a laboratory equipment, laboratory instrument used to examine objects that are too small to be seen by the naked eye. Microscopy is the science of investigating small objects and structures using a microscope. Microscopic ...

, using tweezers and a fine-tip soldering iron

A soldering iron is a hand tool used in soldering. It supplies heat to melt solder so that it can flow into the joint between two workpieces.

A soldering iron is composed of a heated metal tip (the ''bit'') and an insulated handle. Heating is o ...

, for small volume prototypes. Selective soldering

Selective soldering is the process of selectively soldering components to printed circuit boards and molded modules that could be damaged by the heat of a reflow oven or wave soldering in a traditional surface-mount technology (SMT) or through-hol ...

may be used for delicate parts. Some SMT parts cannot be soldered by hand, such as ball grid array

A ball grid array (BGA) is a type of surface-mount packaging (a chip carrier) used for integrated circuits. BGA packages are used to permanently mount devices such as microprocessors. A BGA can provide more interconnection pins than can be pu ...

(BGA) packages. All through-hole components can be hand soldered, making them favored for prototyping where size, weight, and the use of the exact components that would be used in high volume production are not concerns.

Often, through-hole and surface-mount construction must be combined in a single assembly because some required components are available only in surface-mount packages, while others are available only in through-hole packages. Or, even if all components are available in through-hole packages, it might be desired to take advantage of the size, weight, and cost reductions obtainable by using some available surface-mount devices. Another reason to use both methods is that through-hole mounting can provide needed strength for components likely to endure physical stress (such as connectors that are frequently mated and demated or that connect to cables expected to impart substantial stress to the PCB-and-connector interface), while components that are expected to go untouched will take up less space using surface-mount techniques. ''For further comparison, see the SMT page.''

After the board has been populated it may be tested in a variety of ways:

* While the power is off, visual inspection

Visual inspection is a common method of quality control, data acquisition, and data analysis.

Visual Inspection, used in maintenance of facilities, mean inspection of equipment and structures using either or all of raw human senses such as vision, ...

, automated optical inspection

Automated optical inspection (AOI) is an automated visual inspection of printed circuit board (PCB) (or LCD, transistor) manufacture where a camera machine vision, autonomously scans the device under test for both catastrophic failure (e.g. missin ...

. JEDEC

The Joint Electron Device Engineering Council (JEDEC) Solid State Technology Association is a consortium of the semiconductor industry headquartered in Arlington County, Virginia, Arlington, United States. It has over 300 members and is focused ...

guidelines for PCB component placement, soldering, and inspection are commonly used to maintain quality control

Quality control (QC) is a process by which entities review the quality of all factors involved in production. ISO 9000 defines quality control as "a part of quality management focused on fulfilling quality requirements".

This approach plac ...

in this stage of PCB manufacturing.

* While the power is off, analog signature analysis

Analog signature analysis is an electronic component and circuit board

A printed circuit board (PCB), also called printed wiring board (PWB), is a laminated sandwich structure of conductive and insulating layers, each with a pattern o ...

, power-off testing

Power-off testing is often necessary to test the printed circuit assembly (PCA) board due to uncertainty as to the nature of the failure. When the PCA can be further damaged by applying power it is necessary to use power off test techniques to saf ...

.

* While the power is on, in-circuit test

In-circuit testing (ICT) is an example of white box testing where an electrical probe tests a populated printed circuit board (PCB), checking for shorts, opens, resistance, capacitance, and other basic quantities which will show whether the asse ...

, where physical measurements (for example, voltage) can be done.

* While the power is on, functional test

In software development, functional testing is a form of software testing that verifies whether a system meets its functional requirements.ISO/IEC/IEEE 24765:2017, "Systems and software engineering — Vocabulary", International Organization fo ...

, just checking if the PCB does what it had been designed to do.

To facilitate these tests, PCBs may be designed with extra pads to make temporary connections. Sometimes these pads must be isolated with resistors. The in-circuit test may also exercise boundary scan

Boundary scan is a method for testing interconnects (wire lines) on printed circuit boards or sub-blocks inside an integrated circuit (IC). Boundary scan is also widely used as a debugging method to watch integrated circuit pin states, measure ...

test features of some components. In-circuit test systems may also be used to program nonvolatile memory

Non-volatile memory (NVM) or non-volatile storage is a type of computer memory that can retain stored information even after power is removed. In contrast, volatile memory needs constant power in order to retain data.

Non-volatile memory typi ...

components on the board.

In boundary scan testing, test circuits integrated into various ICs on the board form temporary connections between the PCB traces to test that the ICs are mounted correctly. Boundary scan testing requires that all the ICs to be tested use a standard test configuration procedure, the most common one being the Joint Test Action Group (JTAG

JTAG (named after the Joint Test Action Group which codified it) is an industry standard for verifying designs of and testing printed circuit boards after manufacture.

JTAG implements standards for on-chip instrumentation in electronic design ...

) standard. The JTAG

JTAG (named after the Joint Test Action Group which codified it) is an industry standard for verifying designs of and testing printed circuit boards after manufacture.

JTAG implements standards for on-chip instrumentation in electronic design ...

test architecture provides a means to test interconnects between integrated circuits on a board without using physical test probes, by using circuitry in the ICs to employ the IC pins themselves as test probes. JTAG

JTAG (named after the Joint Test Action Group which codified it) is an industry standard for verifying designs of and testing printed circuit boards after manufacture.

JTAG implements standards for on-chip instrumentation in electronic design ...

tool vendors provide various types of stimuli and sophisticated algorithms, not only to detect the failing nets, but also to isolate the faults to specific nets, devices, and pins.

When boards fail the test, technicians may desolder and replace failed components, a task known as '' rework''.

Protection and packaging

PCBs intended for extreme environments often have aconformal coating

Conformal coating is a protective, breathable coating of thin polymeric film applied to printed circuit boards (PCBs). Conformal coatings are typically applied with 25–250 μm thickness on electronic circuitry to protect against moisture and ...

, which is applied by dipping or spraying after the components have been soldered. The coat prevents corrosion and leakage currents or shorting due to condensation. The earliest conformal coats were wax

Waxes are a diverse class of organic compounds that are lipophilic, malleable solids near ambient temperatures. They include higher alkanes and lipids, typically with melting points above about 40 °C (104 °F), melting to give lo ...

; modern conformal coats are usually dips of dilute solutions of silicone rubber, polyurethane, acrylic, or epoxy. Another technique for applying a conformal coating is for plastic to be sputtered onto the PCB in a vacuum chamber. The chief disadvantage of conformal coatings is that servicing of the board is rendered extremely difficult.

Many assembled PCBs are static sensitive, and therefore they must be placed in antistatic bag

An antistatic bag is a bag used for storing electronic components, which are prone to damage caused by electrostatic discharge (ESD).

These bags are usually plastic polyethylene terephthalate (PET) and have a distinctive color (silvery for me ...

s during transport. When handling these boards, the user must be grounded (earthed). Improper handling techniques might transmit an accumulated static charge through the board, damaging or destroying components. The damage might not immediately affect function but might lead to early failure later on, cause intermittent operating faults, or cause a narrowing of the range of environmental and electrical conditions under which the board functions properly.

See also

Reference list

{{Reflist Electronics manufacturing Printed circuit board manufacturing