|

Selective Soldering

Selective soldering is the process of selectively soldering components to printed circuit boards and molded modules that could be damaged by the heat of a reflow oven or wave soldering in a traditional surface-mount technology (SMT) or through-hole technology assembly processes. This usually follows an SMT oven reflow process; parts to be selectively soldered are usually surrounded by parts that have been previously soldered in a surface-mount reflow process, and the selective-solder process must be sufficiently precise to avoid damaging them. Processes Assembly processes used in selective soldering include: * ''Selective aperture tooling over wave solder'': These tools mask off areas previously soldered in the SMT reflow soldering process, exposing only those areas to be selectively soldered in the tool's aperture or window. The tool and printed circuit board (PCB) assembly are then passed over wave soldering equipment to complete the process. Each tool is specific to a PCB assemb ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stencil

Stencilling produces an image or pattern on a surface by applying pigment to a surface through an intermediate object, with designed holes in the intermediate object. The holes allow the pigment to reach only some parts of the surface creating the design. The stencil is both the resulting image or pattern and the intermediate object; the context in which ''stencil'' is used makes clear which meaning is intended. In practice, the (object) stencil is usually a thin sheet of material, such as paper, plastic, wood or metal, with lettering, letters or a design cut from it, used to produce the letters or design on an underlying surface by applying pigment through the cut-out holes in the material. The key advantage of a stencil is that it can be reused to repeatedly and rapidly produce the same letters or design. Although aerosol paint, aerosol or painting stencils can be made for one-time use, typically they are made with the intention of being reused. To be reusable, they must rem ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Surface-mount Technology

Surface-mount technology (SMT), originally called planar mounting, is a method in which the electrical components are mounted directly onto the surface of a printed circuit board (PCB). An electrical component mounted in this manner is referred to as a surface-mount device (SMD). In industry, this approach has largely replaced through-hole technology construction method of fitting components, in large part because SMT allows for increased manufacturing automation which reduces cost and improves quality. It also allows for more components to fit on a given area of substrate. Both technologies can be used on the same board, with the through-hole technology often used for components not suitable for surface mounting such as large transformers and heat-sinked power semiconductors. An SMT component is usually smaller than its through-hole counterpart because it has either smaller leads or no leads at all. It may have short pins or leads of various styles, flat contacts, a matrix of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dip Soldering

Dip soldering is a small-scale soldering process by which electronic components are soldered to a printed circuit board (PCB) to form an electronic assembly. The solder wets to the exposed metallic areas of the board (those not protected with solder mask), creating a mechanical and electrical connection. Dip soldering is used for both through-hole printed circuit assemblies, and surface mount. It is one of the cheapest methods to solder and is extensively used in the small scale industries of developing countries . Dip soldering is a manual equivalent of automated wave soldering. The apparatus required is just a small tank containing molten solder. A PCB with mounted components is dipped manually into the tank so that the molten solder sticks to the exposed metallic areas of the board. Dip solder process Dip soldering is accomplished by submerging parts to be joined into a molten solder bath. Thus, all components surfaces are coated with filler metal. Solder Solder (; ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Flux (metallurgy)

In metallurgy, a flux is a chemical reducing agent, flowing agent, or purifying agent. Fluxes may have more than one function at a time. They are used in both extractive metallurgy and metal joining. Some of the earliest known fluxes were sodium carbonate, potash, charcoal, coke, borax, lime, lead sulfide and certain minerals containing phosphorus. Iron ore was also used as a flux in the smelting of copper. These agents served various functions, the simplest being a reducing agent, which prevented oxides from forming on the surface of the molten metal, while others absorbed impurities into slag, which could be scraped off molten metal. Fluxes are also used in foundries for removing impurities from molten nonferrous metals such as aluminium, or for adding desirable trace elements such as titanium. As reducing agents, fluxes facilitate soldering, brazing, and welding by removing oxidation from the metals to be joined. In some applications molten flux also serves as ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Aerosol

An aerosol is a suspension (chemistry), suspension of fine solid particles or liquid Drop (liquid), droplets in air or another gas. Aerosols can be generated from natural or Human impact on the environment, human causes. The term ''aerosol'' commonly refers to the mixture of particulates in air, and not to the particulate matter alone. Examples of natural aerosols are fog, mist or dust. Examples of human caused aerosols include particulate air pollutants, mist from the discharge at hydroelectric dams, irrigation mist, perfume from Spray nozzle, atomizers, smoke, dust, Pesticide, sprayed pesticides, and medical treatments for respiratory illnesses. Several types of atmospheric aerosol have a significant effect on Earth's climate: volcanic, desert dust, sea-salt, that originating from biogenic sources and human-made. Volcanic aerosol forms in the stratosphere after an eruption as droplets of sulfuric acid that can prevail for up to two years, and reflect sunlight, lowering tempera ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wave Soldering

Wave soldering is a bulk soldering process used in printed circuit board manufacturing. The circuit board is passed over a pan of molten solder in which a pump produces an upwelling of solder that looks like a standing wave. As the circuit board makes contact with this wave, the components become soldered to the board. Wave soldering is used for both through-hole printed circuit assemblies, and surface mount. In the latter case, the components are glued onto the surface of a printed circuit board (PCB) by placement equipment, before being run through the molten solder wave. Wave soldering is mainly used in soldering of through hole components. As through-hole components have been largely replaced by surface mount components, wave soldering has been supplanted by reflow soldering methods in many large-scale electronics applications. However, there is still significant wave soldering where surface-mount technology (SMT) is not suitable (e.g., large power devices and high pi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fire Sprinkler

A fire sprinkler or sprinkler head is the component of a fire sprinkler system that discharges water when the effects of a fire have been detected, such as when a predetermined temperature has been exceeded. Fire sprinklers are extensively used worldwide, with over 40 million sprinkler heads fitted each year. In buildings protected by properly designed and maintained fire sprinklers, over 99% of fires were controlled by fire sprinklers alone. History In 1812, British inventor Sir William Congreve, 2nd Baronet, Sir William Congreve patented a manual sprinkler system using perforated pipes along the ceiling. When someone noticed a fire, a valve outside the building could be opened to send water through the pipes. It was not until a short time later that, as a result of a large furniture factory that repeatedly burned down, Hiram Stevens Maxim was consulted on how to prevent a recurrence and invented the first automatic fire sprinkler. It would douse the areas that were on fire an ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

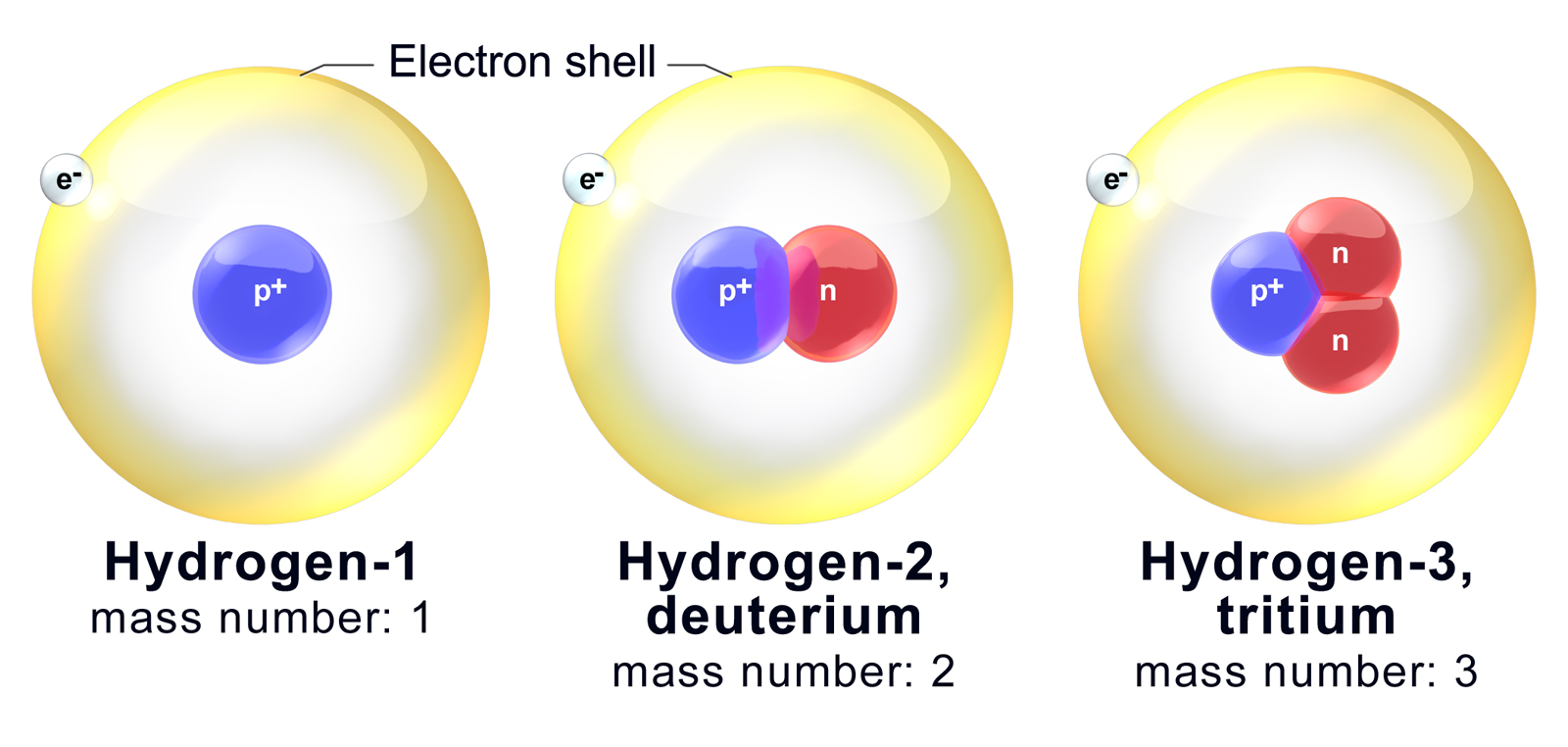

Hydrogen

Hydrogen is a chemical element; it has chemical symbol, symbol H and atomic number 1. It is the lightest and abundance of the chemical elements, most abundant chemical element in the universe, constituting about 75% of all baryon, normal matter. Under standard conditions, hydrogen is a gas of diatomic molecules with the chemical formula, formula , called dihydrogen, or sometimes hydrogen gas, molecular hydrogen, or simply hydrogen. Dihydrogen is colorless, odorless, non-toxic, and highly combustible. Stars, including the Sun, mainly consist of hydrogen in a plasma state, while on Earth, hydrogen is found as the gas (dihydrogen) and in molecular forms, such as in water and organic compounds. The most common isotope of hydrogen (H) consists of one proton, one electron, and no neutrons. Hydrogen gas was first produced artificially in the 17th century by the reaction of acids with metals. Henry Cavendish, in 1766–1781, identified hydrogen gas as a distinct substance and discovere ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thermal Stress

In mechanics and thermodynamics, thermal stress is mechanical stress created by any change in temperature Temperature is a physical quantity that quantitatively expresses the attribute of hotness or coldness. Temperature is measurement, measured with a thermometer. It reflects the average kinetic energy of the vibrating and colliding atoms making ... of a material. These stresses can lead to fracturing or plastic deformation depending on the other variables of heating, which include material types and constraints. Temperature gradients, thermal expansion or contraction and thermal shocks are things that can lead to thermal stress. This type of stress is highly dependent on the thermal expansion coefficient which varies from material to material. In general, the greater the temperature change, the higher the level of stress that can occur. Thermal shock can result from a rapid change in temperature, resulting in cracking or shattering. Temperature gradients When a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Soldering

Soldering (; ) is a process of joining two metal surfaces together using a filler metal called solder. The soldering process involves heating the surfaces to be joined and melting the solder, which is then allowed to cool and solidify, creating a strong and durable joint. Soldering is commonly used in the electronics industry for the manufacture and repair of Printed circuit board, printed circuit boards (PCBs) and other electronic components. It is also used in plumbing and Metalworking, metalwork, as well as in the manufacture of jewelry and other decorative items. The solder used in the process can vary in composition, with different alloys used for different applications. Common solder alloys include tin-lead, tin-silver, and tin-copper, among others. Lead-free solder has also become more widely used in recent years due to health and environmental concerns associated with the use of lead. In addition to the type of solder used, the temperature and method of heating also p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gerber Format

The Gerber format is an open, ASCII, vector format for printed circuit board (PCB) designs. It is the ''de facto'' standard used by PCB industry software to describe the printed circuit board images: copper layers, solder mask, legend, drill data, etc. The standard file extension is .GBR or .gbr though other extensions like .GB, .geb or .gerber are also used. It is documented by The Gerber Layer Format Specification and some related (but less universally supported) extensions such as XNC drill files and GerberJob to convey information about the entire PCB, as opposed to single layers. Gerber is used in PCB fabrication data. PCBs are designed on a specialized electronic design automation (EDA) or a computer-aided design (CAD) system. The CAD systems output PCB fabrication data to allow fabrication of the board. This data typically contains a Gerber file for each image layer (copper layers, solder mask, legend or silk...). Gerber is also the standard image input format for all ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |