|

Maskless Lithography

Maskless lithography (MPL) is a photomask-less photolithography-like technology used to project or focal-spot write the image pattern onto a chemical resist-coated substrate (e.g. wafer) by means of UV radiation or electron beam. In microlithography, typically UV radiation casts an image of a time constant mask onto a photosensitive emulsion (or photoresist). Traditionally, mask aligners, steppers, scanners, and other kinds of non-optical techniques are used for high speed microfabrication of microstructures, but in case of MPL, some of these become redundant. Maskless lithography has two approaches to project a pattern: rasterized and vectorized. In the first one it utilizes generation of a time-variant intermittent image on an electronically modifiable (virtual) mask that is projected with known means (also known as laser direct imaging and other synonyms). In the vectored approach, direct writing is achieved by radiation that is focused to a narrow beam that is scanned ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Photomask

A photomask (also simply called a mask) is an opaque plate with transparent areas that allow light to shine through in a defined pattern. Photomasks are commonly used in photolithography for the production of integrated circuits (ICs or "chips") to produce a pattern on a thin wafer of material (usually silicon). In semiconductor manufacturing, a mask is sometimes called a reticle. In photolithography, several masks are used in turn, each one reproducing a layer of the completed design, and together known as a mask set. A curvilinear photomask has patterns with curves, which is a departure from conventional photomasks which only have patterns that are completely vertical or horizontal, known as manhattan geometry. These photomasks require special equipment to manufacture. History For IC production in the 1960s and early 1970s, an opaque rubylith film laminated onto a transparent mylar sheet was used. The design of one layer was cut into the rubylith, initially by hand on an i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Printed Circuit Board

A printed circuit board (PCB), also called printed wiring board (PWB), is a Lamination, laminated sandwich structure of electrical conduction, conductive and Insulator (electricity), insulating layers, each with a pattern of traces, planes and other features (similar to wires on a flat surface) Chemical milling, etched from one or more sheet layers of copper laminated onto or between sheet layers of a non-conductive substrate. PCBs are used to connect or Electrical wiring, "wire" Electronic component, components to one another in an electronic circuit. Electrical components may be fixed to conductive pads on the outer layers, generally by soldering, which both electrically connects and mechanically fastens the components to the board. Another manufacturing process adds Via (electronics), vias, metal-lined drilled holes that enable electrical interconnections between conductive layers, to boards with more than a single side. Printed circuit boards are used in nearly all e ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lithography

Lithography () is a planographic method of printing originally based on the miscibility, immiscibility of oil and water. The printing is from a stone (lithographic limestone) or a metal plate with a smooth surface. It was invented in 1796 by the German author and actor Alois Senefelder and was initially used mostly for sheet music, musical scores and maps.Meggs, Philip B. ''A History of Graphic Design''. (1998) John Wiley & Sons, Inc. p 146, .Carter, Rob, Ben Day, Philip Meggs. ''Typographic Design: Form and Communication'', Third Edition. (2002) John Wiley & Sons, Inc. p. 11. Lithography can be used to print text or images onto paper or other suitable material. A lithograph is something printed by lithography, but this term is only used for printmaking, fine art prints and some other, mostly older, types of printed matter, not for those made by modern commercial lithography. Traditionally, the image to be printed was drawn with a greasy substance, such as oil, fat, or wax on ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Proton Beam Writing

Proton beam writing (or p-beam writing) is a direct-write lithography process that uses a focused beam of high-energy ( MeV) protons to pattern resist material at nanodimensions. The process, although similar in many ways to direct writing using electrons, nevertheless offers some interesting and unique advantages. Protons, which are approximately 1800 times more massive than electrons, have deeper penetration in materials and travel in an almost straight path. This feature allows the fabrication of three-dimensional, high-aspect-ratio structures with vertical, smooth sidewalls, and low line-edge roughness. Calculations have also indicated that p-beam writing exhibits minimal proximity effects (unwanted exposure due to secondary electrons), since the secondary electrons induced in proton–electron collisions have low energy. A further advantage stems from the ability of protons to displace atoms while traversing material, thereby increasing localized damage especially at the end of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Focused Ion Beam

Focused ion beam, also known as FIB, is a technique used particularly in the semiconductor industry, materials science and increasingly in the biological field for site-specific analysis, deposition, and ablation of materials. A FIB setup is a scientific instrument that resembles a scanning electron microscope (SEM). However, while the SEM uses a focused beam of electrons to image the sample in the chamber, a FIB setup uses a focused beam of ions instead. FIB can also be incorporated in a system with both electron and ion beam columns, allowing the same feature to be investigated using either of the beams. FIB should not be confused with using a beam of focused ions for direct write lithography (such as in proton beam writing). These are generally quite different systems where the material is modified by other mechanisms. Ion beam source Most widespread instruments are using liquid metal ion sources (LMIS), especially gallium ion sources. Ion sources based on elemental gold an ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ultraviolet

Ultraviolet radiation, also known as simply UV, is electromagnetic radiation of wavelengths of 10–400 nanometers, shorter than that of visible light, but longer than X-rays. UV radiation is present in sunlight and constitutes about 10% of the total electromagnetic radiation output from the Sun. It is also produced by electric arcs, Cherenkov radiation, and specialized lights, such as mercury-vapor lamps, tanning lamps, and black lights. The photons of ultraviolet have greater energy than those of visible light, from about 3.1 to 12 electron volts, around the minimum energy required to ionize atoms. Although long-wavelength ultraviolet is not considered an ionizing radiation because its photons lack sufficient energy, it can induce chemical reactions and cause many substances to glow or fluoresce. Many practical applications, including chemical and biological effects, are derived from the way that UV radiation can interact with organic molecules. The ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Localized Surface Plasmon

A localized surface plasmon (LSP) is the result of the confinement of a surface plasmon in a nanoparticle of size comparable to or smaller than the wavelength of light used to excite the plasmon. When a small spherical metallic nanoparticle is irradiated by light, the oscillating electric field causes the conduction electrons to oscillate coherently. When the electron cloud is displaced relative to its original position, a restoring force arises from Coulombic attraction between electrons and nuclei. This force causes the electron cloud to oscillate. The oscillation frequency is determined by the density of electrons, the effective electron mass, and the size and shape of the charge distribution. The LSP has two important effects: electric fields near the particle's surface are greatly enhanced and the particle's optical absorption has a maximum at the plasmon resonant frequency. Surface plasmon resonance can also be tuned based on the shape of the nanoparticle. The plasmon frequenc ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plasmonic Nanolithography

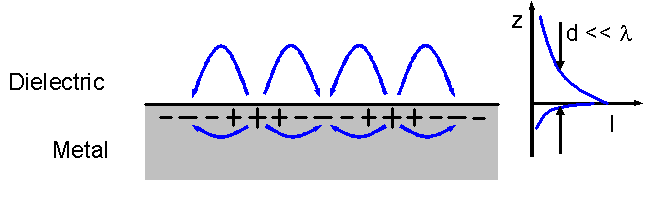

Plasmonic nanolithography (also known as plasmonic lithography or plasmonic photolithography) is a nanolithographic process that utilizes surface plasmon excitations such as surface plasmon polaritons (SPPs) to fabricate nanoscale structures. SPPs, which are surface waves that propagate in between planar dielectric-metal layers in the optical regime, can bypass the diffraction limit on the optical resolution that acts as a bottleneck for conventional photolithography. Theory Surface plasmon polaritons are surface electromagnetic waves that propagate in between two surfaces with sign-changing permittivities. They originate from coupling of photons to plasma oscillations, quantized as plasmons. SPPs result in evanescent fields that decay perpendicularly to the interface where the propagation occurs. The dispersion relation for SPPs permits the excitation of wavelengths shorter than the free-space wavelength of the inbound light, additionally ensuring subwavelength field confinemen ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Interference Lithography

Interference lithography (or holographic lithography) is a technique that uses coherent light (such as light from a laser) for patterning regular arrays of fine features without the use of complex optics, optical systems or photomasks. Basic principle The basic principle is the same as in interferometry or holography. An interference pattern between two or more Coherence (physics), coherent light, light waves is set up and recorded in a recording layer (photoresist). This interference pattern consists of a periodic series of fringes representing intensity minima and maxima. Upon post-exposure photolithography, photolithographic processing, a photoresist pattern corresponding to the periodic intensity pattern emerges. For 2-beam interference, the fringe-to-fringe spacing or period is given by \frac, where is the wavelength and is the angle between the two interfering waves. The minimum period achievable is then half the wavelength. By using 3-beam interference, arrays with hexag ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Spatial Light Modulator

A spatial light modulator (SLM) is a device that can control the intensity, phase, or polarization of light in a spatially varying manner. A simple example is an overhead projector transparency. Usually when the term SLM is used, it means that the transparency can be controlled by a computer. SLMs are primarily marketed for image projection, displays devices, and maskless lithography. SLMs are also used in optical computing and holographic optical tweezers. Usually, an SLM modulates the intensity of the light beam. However, it is also possible to produce devices that modulate the phase of the beam or both the intensity and the phase simultaneously. It is also possible to produce devices that modulate the polarization of the beam, and modulate the polarization, phase, and intensity simultaneously. SLMs are used extensively in holographic data storage setups to encode information into a laser beam similarly to the way a transparency does for an overhead projector. They can ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Direct Laser Writing

Multiphoton lithography (also known as direct laser lithography or direct laser writing) is similar to standard photolithography techniques; structuring is accomplished by illuminating negative-tone or positive-tone photoresists via light of a well-defined wavelength. The main difference is the avoidance of photomasks. Instead, two-photon absorption is utilized to induce a change in the solubility of the resist for appropriate developers. Hence, multiphoton lithography is a technique for creating small features in a photosensitive material, without the use of excimer lasers or photomasks. This method relies on a multi-photon absorption process in a material that is transparent at the wavelength of the laser used for creating the pattern. By scanning and properly modulating the laser, a chemical change (usually polymerization) occurs at the focal spot of the laser and can be controlled to create an arbitrary three-dimensional pattern. This method has been used for rapid prototyping o ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |