Focused ion beam on:

[Wikipedia]

[Google]

[Amazon]

Focused ion beam, also known as FIB, is a technique used particularly in the

Focused ion beam, also known as FIB, is a technique used particularly in the

Focused ion beam (FIB) systems have been produced commercially since the 1990s, primarily for large semiconductor manufacturers. FIB systems operate in a similar fashion to a scanning electron microscope (SEM) except, rather than a beam of electrons and as the name implies, FIB systems use a finely focused beam of ions (usually gallium) that can be operated at low beam currents for imaging or at high beam currents for site specific

Focused ion beam (FIB) systems have been produced commercially since the 1990s, primarily for large semiconductor manufacturers. FIB systems operate in a similar fashion to a scanning electron microscope (SEM) except, rather than a beam of electrons and as the name implies, FIB systems use a finely focused beam of ions (usually gallium) that can be operated at low beam currents for imaging or at high beam currents for site specific

FIB secondary electron images show intense grain orientation contrast. As a result, grain morphology can be readily imaged without resorting to chemical etching. Grain boundary contrast can also be enhanced through careful selection of imaging parameters. FIB secondary ion images also reveal chemical differences, and are especially useful in corrosion studies, as secondary ion yields of metals can increase by three orders of magnitude in the presence of oxygen, clearly revealing the presence of corrosion.

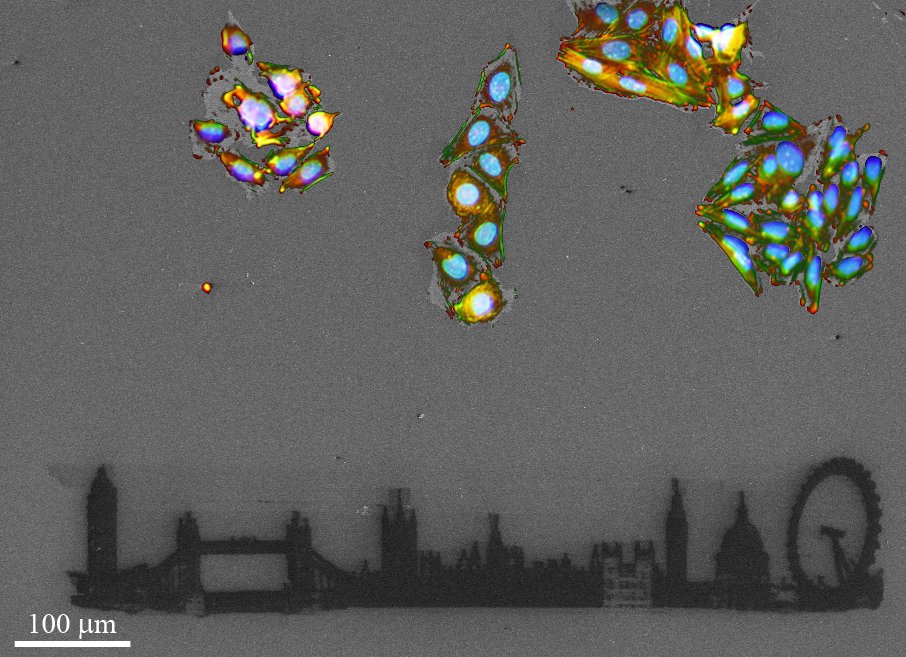

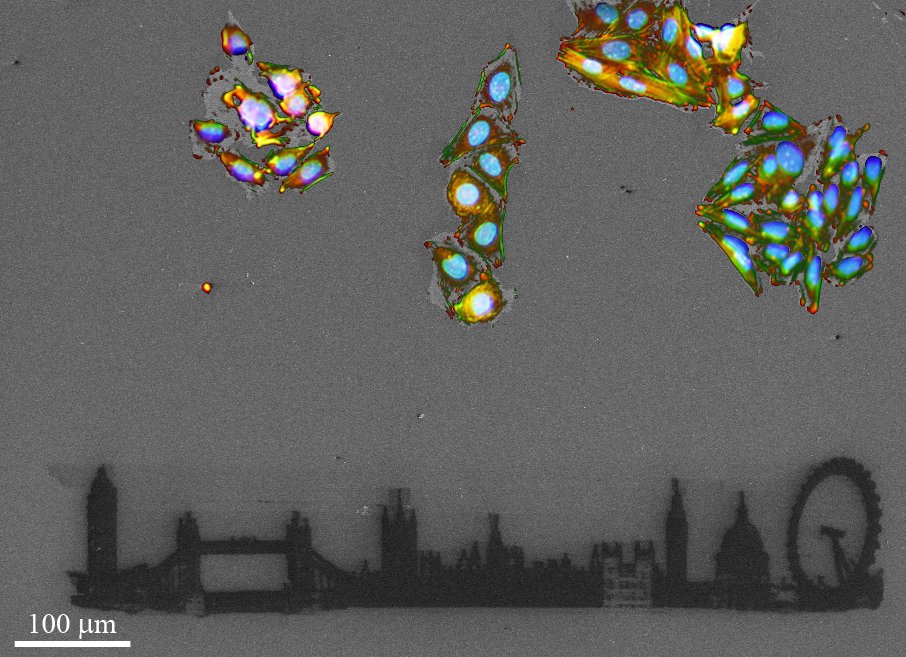

Another advantage of FIB secondary electron imaging is the fact that the ion beam does not alter the signal from fluorescent probes used in the labelling of proteins, thus creating the opportunity to correlate FIB secondary electron images with images obtained by fluorescence microscopes.

FIB secondary electron images show intense grain orientation contrast. As a result, grain morphology can be readily imaged without resorting to chemical etching. Grain boundary contrast can also be enhanced through careful selection of imaging parameters. FIB secondary ion images also reveal chemical differences, and are especially useful in corrosion studies, as secondary ion yields of metals can increase by three orders of magnitude in the presence of oxygen, clearly revealing the presence of corrosion.

Another advantage of FIB secondary electron imaging is the fact that the ion beam does not alter the signal from fluorescent probes used in the labelling of proteins, thus creating the opportunity to correlate FIB secondary electron images with images obtained by fluorescence microscopes.

The FIB is also commonly used to prepare samples for the

The FIB is also commonly used to prepare samples for the

Imaging and milling with Ga ions always result in Ga incorporation near the sample surface. As the sample surface is sputtered away at a rate proportional to the sputtering yield and the ion flux (ions per area per time), the Ga is implanted further into the sample, and a steady-state profile of Ga is reached. This implantation is often a problem in the range of the semiconductor where silicon can be amorphised by the gallium. In order to get an alternative solution to Ga LMI sources, mass-filtered columns have been developed, based on a Wien filter technology. Such sources include Au-Si, Au-Ge and Au-Si-Ge sources providing Si, Cr, Fe, Co, Ni, Ge, In, Sn, Au, Pb and other elements.

The principle of a Wien filter is based on the equilibrium of the opposite forces induced by perpendicular electrostatic and a magnetic fields acting on accelerated particles. The proper mass trajectory remains straight and passes through the mass selection aperture while the other masses are stopped.

Besides allowing the use of sources others than gallium, these columns can switch from different species simply by adjusting the properties of the Wien filter. Larger ions can be used to make rapid milling before refining the contours with smaller ones. Users also benefits from the possibility to dope their samples with elements of suitable alloy sources.

The latter property has found great interests in the investigation of magnetic materials and devices. Khizroev and Litvinov have shown, with the help of magnetic force microscopy (MFM), that there is a critical dose of ions that a magnetic material can be exposed to without experiencing a change in the magnetic properties. Exploiting FIB from such an unconventional perspective is especially favourable today when the future of so many novel technologies depends on the ability to rapidly fabricate prototype nanoscale magnetic devices.

Imaging and milling with Ga ions always result in Ga incorporation near the sample surface. As the sample surface is sputtered away at a rate proportional to the sputtering yield and the ion flux (ions per area per time), the Ga is implanted further into the sample, and a steady-state profile of Ga is reached. This implantation is often a problem in the range of the semiconductor where silicon can be amorphised by the gallium. In order to get an alternative solution to Ga LMI sources, mass-filtered columns have been developed, based on a Wien filter technology. Such sources include Au-Si, Au-Ge and Au-Si-Ge sources providing Si, Cr, Fe, Co, Ni, Ge, In, Sn, Au, Pb and other elements.

The principle of a Wien filter is based on the equilibrium of the opposite forces induced by perpendicular electrostatic and a magnetic fields acting on accelerated particles. The proper mass trajectory remains straight and passes through the mass selection aperture while the other masses are stopped.

Besides allowing the use of sources others than gallium, these columns can switch from different species simply by adjusting the properties of the Wien filter. Larger ions can be used to make rapid milling before refining the contours with smaller ones. Users also benefits from the possibility to dope their samples with elements of suitable alloy sources.

The latter property has found great interests in the investigation of magnetic materials and devices. Khizroev and Litvinov have shown, with the help of magnetic force microscopy (MFM), that there is a critical dose of ions that a magnetic material can be exposed to without experiencing a change in the magnetic properties. Exploiting FIB from such an unconventional perspective is especially favourable today when the future of so many novel technologies depends on the ability to rapidly fabricate prototype nanoscale magnetic devices.

Focused ion beam, also known as FIB, is a technique used particularly in the

Focused ion beam, also known as FIB, is a technique used particularly in the semiconductor

A semiconductor is a material with electrical conductivity between that of a conductor and an insulator. Its conductivity can be modified by adding impurities (" doping") to its crystal structure. When two regions with different doping level ...

industry, materials science

Materials science is an interdisciplinary field of researching and discovering materials. Materials engineering is an engineering field of finding uses for materials in other fields and industries.

The intellectual origins of materials sci ...

and increasingly in the biological field for site-specific analysis, deposition, and ablation of materials. A FIB setup is a scientific instrument that resembles a scanning electron microscope

A scanning electron microscope (SEM) is a type of electron microscope that produces images of a sample by scanning the surface with a focused beam of electrons. The electrons interact with atoms in the sample, producing various signals that ...

(SEM). However, while the SEM uses a focused beam of electrons to image the sample in the chamber, a FIB setup uses a focused beam of ion

An ion () is an atom or molecule with a net electrical charge. The charge of an electron is considered to be negative by convention and this charge is equal and opposite to the charge of a proton, which is considered to be positive by convent ...

s instead. FIB can also be incorporated in a system with both electron and ion beam columns, allowing the same feature to be investigated using either of the beams. FIB should not be confused with using a beam of focused ions for direct write lithography

Lithography () is a planographic method of printing originally based on the miscibility, immiscibility of oil and water. The printing is from a stone (lithographic limestone) or a metal plate with a smooth surface. It was invented in 1796 by ...

(such as in proton beam writing). These are generally quite different systems where the material is modified by other mechanisms.

Ion beam source

Most widespread instruments are using liquid metal ion sources (LMIS), especiallygallium

Gallium is a chemical element; it has Chemical symbol, symbol Ga and atomic number 31. Discovered by the French chemist Paul-Émile Lecoq de Boisbaudran in 1875,

elemental gallium is a soft, silvery metal at standard temperature and pressure. ...

ion sources. Ion sources based on elemental gold and iridium are also available. In a gallium LMIS, gallium metal is placed in contact with a tungsten

Tungsten (also called wolfram) is a chemical element; it has symbol W and atomic number 74. It is a metal found naturally on Earth almost exclusively in compounds with other elements. It was identified as a distinct element in 1781 and first ...

needle, and heated gallium wets

Wets and dries are British political terms that refer to opposing factions within the Conservative Party. The terms originated in the 1980s during the premiership of Margaret Thatcher: those who opposed some of Thatcher's more hard-line polic ...

the tungsten and flows to the tip of the needle, where the opposing forces of surface tension and electric field form the gallium into a cusp shaped tip called a Taylor cone. The tip radius of this cone is extremely small (~2 nm). The huge electric field

An electric field (sometimes called E-field) is a field (physics), physical field that surrounds electrically charged particles such as electrons. In classical electromagnetism, the electric field of a single charge (or group of charges) descri ...

at this small tip (greater than volts per centimeter) causes ionization and field emission of the gallium atoms.

Source ions are then generally accelerated to an energy of , and focused onto the sample by electrostatic lenses. LMIS produce high current density ion beams with very small energy spread. A modern FIB can deliver tens of nanoamperes of current to a sample, or can image the sample with a spot size on the order of a few nanometers.

More recently, instruments using plasma beams of noble gas ions, such as xenon, have become available more widely.

Principle

sputtering

In physics, sputtering is a phenomenon in which microscopic particles of a solid material are ejected from its surface, after the material is itself bombarded by energetic particles of a plasma or gas. It occurs naturally in outer space, and c ...

or milling.

As the diagram on the right shows, the gallium (Ga+) primary ion beam hits the sample surface and sputters a small amount of material, which leaves the surface as either secondary ions (i+ or i−) or neutral atoms (n0). The primary beam also produces secondary electrons (e−). As the primary beam rasters on the sample surface, the signal from the sputtered ions or secondary electrons is collected to form an image.

At low primary beam currents, very little material is sputtered and modern FIB systems can easily achieve 5 nm imaging resolution (imaging resolution with Ga ions is limited to ~5 nm by sputtering and detector efficiency). At higher primary currents, a great deal of material can be removed by sputtering, allowing precision milling of the specimen down to a sub micrometer or even a nano scale.

If the sample is non-conductive, a low energy electron flood gun can be used to provide charge neutralization. In this manner, by imaging with positive secondary ions using the positive primary ion beam, even highly insulating samples may be imaged and milled without a conducting surface coating, as would be required in an SEM.

Until recently, the overwhelming usage of FIB has been in the semiconductor industry. Such applications as defect analysis, circuit modification, photomask

A photomask (also simply called a mask) is an opaque plate with transparent areas that allow light to shine through in a defined pattern. Photomasks are commonly used in photolithography for the production of integrated circuits (ICs or "chips") ...

repair and transmission electron microscope (TEM) sample preparation of site specific locations on integrated circuits have become commonplace procedures. The latest FIB systems have high resolution imaging capability; this capability coupled with in situ sectioning has eliminated the need, in many cases, to examine FIB sectioned specimens in a separate SEM instrument. SEM imaging is still required for the highest resolution imaging and to prevent damage to sensitive samples. However, the combination of SEM and FIB columns onto the same chamber enables the benefits of both to be utilized.

Operation modes

FIB imaging

At lower beam currents, FIB imaging resolution begins to rival the more familiar scanning electron microscope (SEM) in terms of imaging topography, however the FIB's two imaging modes, using secondary electrons and secondary ions, both produced by the primary ion beam, offer many advantages over SEM. FIB secondary electron images show intense grain orientation contrast. As a result, grain morphology can be readily imaged without resorting to chemical etching. Grain boundary contrast can also be enhanced through careful selection of imaging parameters. FIB secondary ion images also reveal chemical differences, and are especially useful in corrosion studies, as secondary ion yields of metals can increase by three orders of magnitude in the presence of oxygen, clearly revealing the presence of corrosion.

Another advantage of FIB secondary electron imaging is the fact that the ion beam does not alter the signal from fluorescent probes used in the labelling of proteins, thus creating the opportunity to correlate FIB secondary electron images with images obtained by fluorescence microscopes.

FIB secondary electron images show intense grain orientation contrast. As a result, grain morphology can be readily imaged without resorting to chemical etching. Grain boundary contrast can also be enhanced through careful selection of imaging parameters. FIB secondary ion images also reveal chemical differences, and are especially useful in corrosion studies, as secondary ion yields of metals can increase by three orders of magnitude in the presence of oxygen, clearly revealing the presence of corrosion.

Another advantage of FIB secondary electron imaging is the fact that the ion beam does not alter the signal from fluorescent probes used in the labelling of proteins, thus creating the opportunity to correlate FIB secondary electron images with images obtained by fluorescence microscopes.

Etching

Unlike an electron microscope, FIB is inherently destructive to the specimen. When the high-energy gallium ions strike the sample, they willsputter

In physics, sputtering is a phenomenon in which microscopic particles of a solid material are ejected from its surface, after the material is itself bombarded by energetic particles of a plasma or gas. It occurs naturally in outer space, and c ...

atoms from the surface. Gallium atoms will also be implanted into the top few nanometers of the surface, and the surface will be made amorphous

In condensed matter physics and materials science, an amorphous solid (or non-crystalline solid) is a solid that lacks the long-range order that is a characteristic of a crystal. The terms "glass" and "glassy solid" are sometimes used synonymousl ...

.

Because of the sputtering capability, the FIB is used as a micro- and nano-machining tool, to modify or machine materials at the micro- and nanoscale. FIB micro machining has become a broad field of its own, but nano machining with FIB is a field that is still developing. Commonly the smallest beam size for imaging is 2.5–6 nm. The smallest milled features are somewhat larger (10–15 nm) as this is dependent on the total beam size and interactions with the sample being milled.

FIB tools are designed to etch or machine surfaces, an ideal FIB might machine away one atom layer without any disruption of the atoms in the next layer, or any residual disruptions above the surface. Yet currently because of the sputter the machining typically roughens surfaces at the sub-micrometer length scales.

Deposition

A FIB can also be used to deposit material via ion beam induced deposition. FIB-assistedchemical vapor deposition

Chemical vapor deposition (CVD) is a vacuum deposition method used to produce high-quality, and high-performance, solid materials. The process is often used in the semiconductor industry to produce thin films.

In typical CVD, the wafer (electro ...

occurs when a gas, such as tungsten hexacarbonyl

Tungsten hexacarbonyl (also called tungsten carbonyl) is an organometallic compound with the formula W(CO)6. This complex gave rise to the first example of a dihydrogen complex.Kubas, G. J., Metal Dihydrogen and σ-Bond Complexes, Kluwer Academic ...

(W(CO)6) is introduced to the vacuum chamber and allowed to chemisorb onto the sample. By scanning an area with the beam, the precursor gas will be decomposed into volatile and non-volatile components; the non-volatile component, such as tungsten, remains on the surface as a deposition. This is useful, as the deposited metal can be used as a sacrificial layer, to protect the underlying sample from the destructive sputtering of the beam. From nanometers to hundred of micrometers in length, tungsten metal deposition allows metal lines to be put right where needed. Other materials such as platinum

Platinum is a chemical element; it has Symbol (chemistry), symbol Pt and atomic number 78. It is a density, dense, malleable, ductility, ductile, highly unreactive, precious metal, precious, silverish-white transition metal. Its name origina ...

, cobalt, carbon, gold, etc., can also be locally deposited.

FIB is often used in the semiconductor industry

The semiconductor industry is the aggregate of companies engaged in the design and fabrication of semiconductors and semiconductor devices, such as transistors and integrated circuits. Its roots can be traced to the invention of the transistor ...

to patch or modify an existing semiconductor device

A semiconductor device is an electronic component that relies on the electronic properties of a semiconductor material (primarily silicon, germanium, and gallium arsenide, as well as organic semiconductors) for its function. Its conductivit ...

. For example, in an integrated circuit

An integrated circuit (IC), also known as a microchip or simply chip, is a set of electronic circuits, consisting of various electronic components (such as transistors, resistors, and capacitors) and their interconnections. These components a ...

, the gallium beam could be used to cut unwanted electrical connections, and/or to deposit conductive material in order to make a connection. The high level of surface interaction is exploited in patterned doping of semiconductors. FIB is also used for maskless implantation.

Applications

For TEM preparation

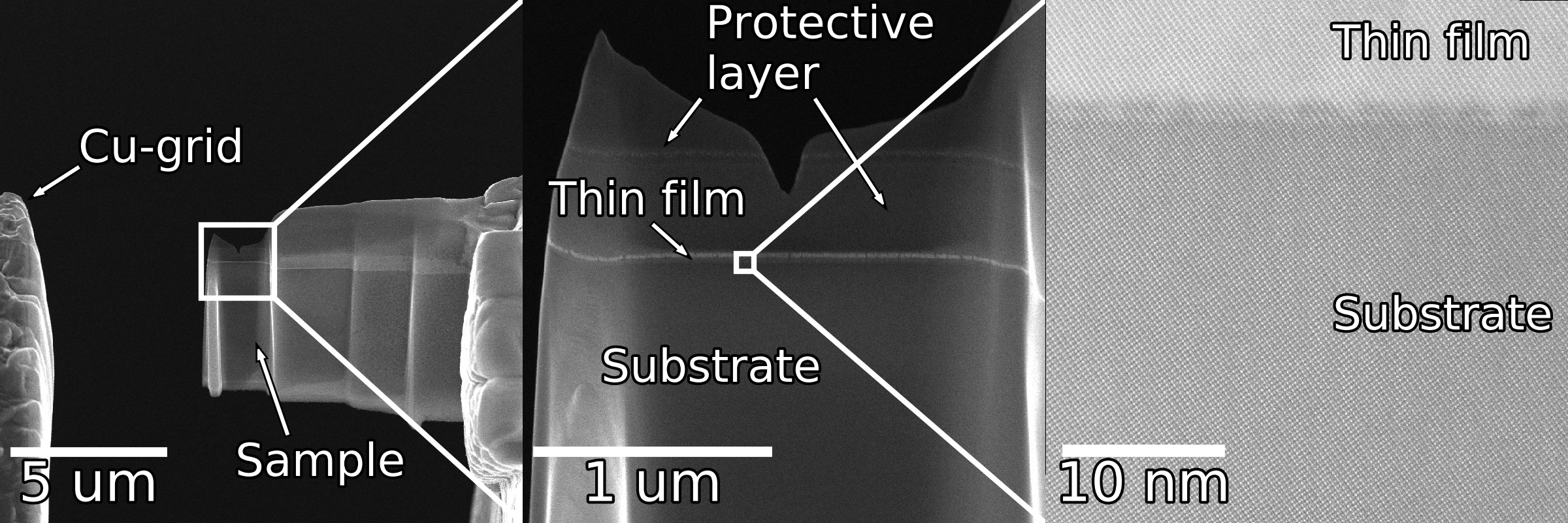

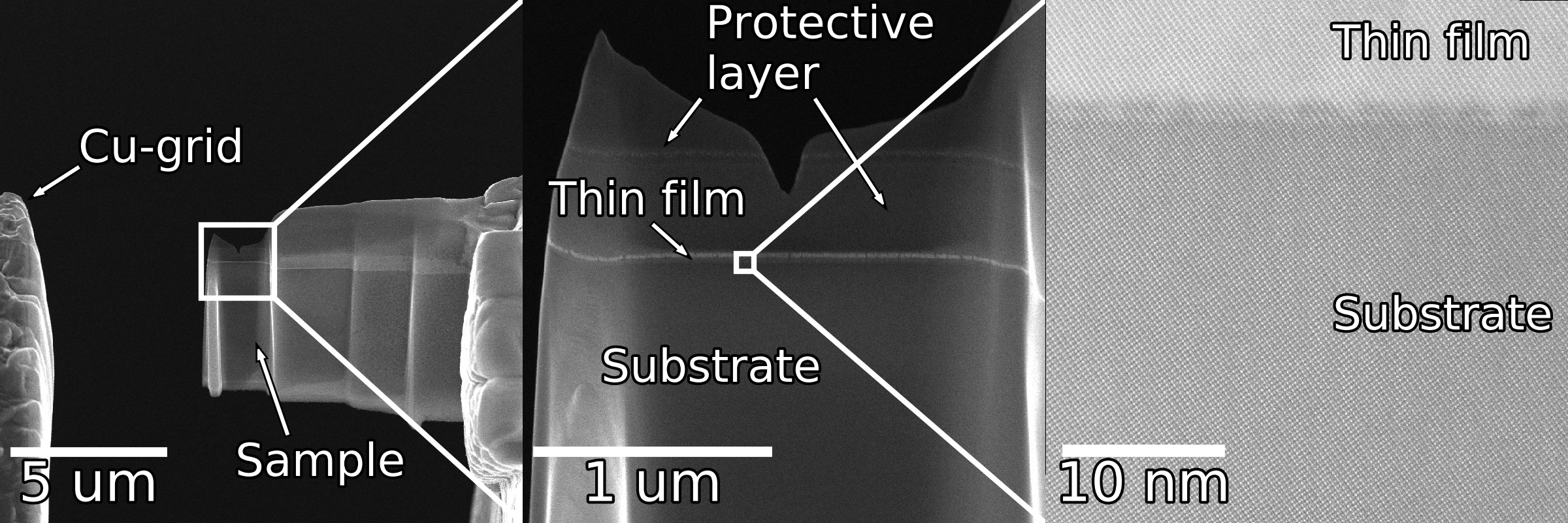

The FIB is also commonly used to prepare samples for the

The FIB is also commonly used to prepare samples for the transmission electron microscope

Transmission electron microscopy (TEM) is a microscopy technique in which a beam of electrons is transmitted through a specimen to form an image. The specimen is most often an ultrathin section less than 100 nm thick or a suspension on a gr ...

. The TEM requires very thin samples, typically ~100 nanometers or less. Other techniques, such as ion milling or electropolishing

Electropolishing principle: 1. Electrolyte 2. Cathode 3. Workpiece to polish (Anode) 4. Particle moving from the work-piece to the cathode 5. Surface before polishing 6. Surface after polishing

Electropolishing, also known as electrochemical poli ...

can be used to prepare such thin samples. However, the nanometer-scale resolution of the FIB allows the exact region of interest to be chosen, such as perhaps a grain boundary or defect in a material. This is vital, for example, in integrated circuit failure analysis. If a particular transistor out of several million on a chip is bad, the only tool capable of preparing an electron microscope sample of that single transistor is the FIB.

The same protocol used for preparing samples to transmission electron microscopy can also be used to select a micro area of a sample, extract it and prepare it for analysis using secondary ion mass spectrometry

Secondary-ion mass spectrometry (SIMS) is a technique used to analyze the composition of solid surfaces and thin films by sputtering the surface of the specimen with a focused primary ion beam and collecting and analyzing ejected secondary ions ...

(SIMS).

The drawbacks to FIB sample preparation are the above-mentioned surface damage and implantation, which produce noticeable effects when using techniques such as high-resolution "lattice imaging" TEM or electron energy loss spectroscopy. This damaged layer can be minimized by FIB milling with lower beam voltages, or by further milling with a low-voltage argon ion beam after completion of the FIB process.

FIB preparation can be used with cryogenically frozen samples in a suitably equipped instrument, allowing cross sectional analysis of samples containing liquids or fats, such as biological samples, pharmaceuticals, foams, inks, and food products.

FIB is also used for secondary ion mass spectrometry

Secondary-ion mass spectrometry (SIMS) is a technique used to analyze the composition of solid surfaces and thin films by sputtering the surface of the specimen with a focused primary ion beam and collecting and analyzing ejected secondary ions ...

(SIMS). The ejected secondary ions are collected and analyzed after the surface of the specimen has been sputtered with a primary focused ion beam.

For transfer of sensitive samples

For a minimal introduction of stress and bending totransmission electron microscopy

Transmission electron microscopy (TEM) is a microscopy technique in which a beam of electrons is transmitted through a specimen to form an image. The specimen is most often an ultrathin section less than 100 nm thick or a suspension on a g ...

(TEM) samples (lamellae

Lamella (: lamellae) means a small plate or flake in Latin, and in English may refer to:

Biology

* Lamella (mycology), a papery rib beneath a mushroom cap

* Lamella (botany)

* Lamella (surface anatomy), a plate-like structure in an animal

* Lame ...

, thin films

A thin film is a layer of materials ranging from fractions of a nanometer ( monolayer) to several micrometers in thickness. The controlled synthesis of materials as thin films (a process referred to as deposition) is a fundamental step in many ...

, and other mechanically and beam sensitive samples), when transferring inside a focused ion beam (FIB), flexible metallic nanowires

upright=1.2, Crystalline 2×2-atom tin selenide nanowire grown inside a single-wall carbon nanotube (tube diameter ≈1 nm).

A nanowire is a nanostructure in the form of a wire with the diameter of the order of a nanometre (10−9 m). Mor ...

can be attached to a typically rigid micromanipulator.

The main advantages of this method include a significant reduction of sample preparation time (quick welding and cutting of nanowire

file:[email protected], upright=1.2, Crystalline 2×2-atom tin selenide nanowire grown inside a single-wall carbon nanotube (tube diameter ≈1 nm).

A nanowire is a nanostructure in the form of a wire with the diameter of the order of a nanometre ( ...

at low beam current), and minimization of stress-induced bending, Pt contamination, and ion beam damage.

This technique is particularly suitable for in situ electron microscopy sample preparation.

For atom probe sample preparation

The same successive milling steps applied when making TEM samples can be applied to make conical samples for atom probe tomography. In this case the ion moved in an annular milling pattern with the inner milling circle being made progressively smaller. The beam current is generally reduced the smaller the inner circle becomes to avoid damaging or destroying the sample.FIB-SEM tomography

The focused ion beam has become a powerful tool for site-specific 3D imaging of sub-micron features in a sample. In this FIB tomography technique, the sample is sequentially milled using an ion beam perpendicular to the specimen while imaging the newly exposed surface using an electron beam. This so-called "slice and view" approach allows larger scale nano-structures to be characterized across the many imaging modes available to an SEM, including secondary electron, backscattered electron, and energy dispersive x-ray measurement. The process is destructive, since the specimen is being sequentially milled away after each image is collected. The collected series of images is then reconstructed to a 3D volume by registering the image stack and removing artifacts. The predominant artifact that degrades FIB-SEM is ion mill curtaining, where mill patterns form large aperiodic stripes in each image. The ion mill curtaining can be removed using destriping algorithms. FIB-SEM can be done at both room and cryo temperatures as well as on both materials and biological samples. It is one of several approaches in volume electron microscopy.History

History of FIB technology *1975: The first FIB systems based on field emission technology were developed by Levi-Setti and by Orloff and Swanson and used gas field ionization sources (GFISs). *1978: The first FIB based on an LMIS was built by Seliger et al. Physics of LMIS *1600: Gilbert documented that fluid under high tension forms a cone. *1914: Zeleny observed and filmed cones and jets *1959: Feynman suggested the use of ion beams. *1964: Taylor produced exactly conical solution to equations of electro hydrodynamics (EHD) *1975: Krohn and Ringo produced first high brightness ion source: LMIS Some pioneers of LMIS and FIB *Mahoney (1969) *Sudraud ''et al.'' Paris XI Orsay (1974) *Hughes Research Labs, Seliger (1978) *Hughes Research Labs, Kubena (1978–1993) *University of Oxford Mair (1980) *Culham UK, Roy Clampitt Prewett (1980) *Oregon Graduate Center

The Oregon Graduate Center was a unique, private, postgraduate-only research university in Washington County, Oregon, on the west side of Portland, from 1963 to 2001. The center was renamed the Oregon Graduate Institute in 1989. The Institute ...

, L. Swanson (1980)

*Oregon Graduate Center, J. Orloff (1974)

*MIT, J. Melngailis (1980)

Helium ion microscope (HeIM)

Another ion source seen in commercially available instruments is ahelium

Helium (from ) is a chemical element; it has chemical symbol, symbol He and atomic number 2. It is a colorless, odorless, non-toxic, inert gas, inert, monatomic gas and the first in the noble gas group in the periodic table. Its boiling point is ...

ion source, which is inherently less damaging to the sample than Ga ions although it will still sputter small amounts of material especially at high magnifications and long scan times. As helium ions can be focused into a small probe size and provide a much smaller sample interaction than high energy (>1 kV) electrons in the SEM, the He ion microscope can generate equal or higher resolution images with good material contrast and a higher depth of focus. Commercial instruments are capable of sub 1 nm resolution.

Wien filter in focused ion beam setup

Imaging and milling with Ga ions always result in Ga incorporation near the sample surface. As the sample surface is sputtered away at a rate proportional to the sputtering yield and the ion flux (ions per area per time), the Ga is implanted further into the sample, and a steady-state profile of Ga is reached. This implantation is often a problem in the range of the semiconductor where silicon can be amorphised by the gallium. In order to get an alternative solution to Ga LMI sources, mass-filtered columns have been developed, based on a Wien filter technology. Such sources include Au-Si, Au-Ge and Au-Si-Ge sources providing Si, Cr, Fe, Co, Ni, Ge, In, Sn, Au, Pb and other elements.

The principle of a Wien filter is based on the equilibrium of the opposite forces induced by perpendicular electrostatic and a magnetic fields acting on accelerated particles. The proper mass trajectory remains straight and passes through the mass selection aperture while the other masses are stopped.

Besides allowing the use of sources others than gallium, these columns can switch from different species simply by adjusting the properties of the Wien filter. Larger ions can be used to make rapid milling before refining the contours with smaller ones. Users also benefits from the possibility to dope their samples with elements of suitable alloy sources.

The latter property has found great interests in the investigation of magnetic materials and devices. Khizroev and Litvinov have shown, with the help of magnetic force microscopy (MFM), that there is a critical dose of ions that a magnetic material can be exposed to without experiencing a change in the magnetic properties. Exploiting FIB from such an unconventional perspective is especially favourable today when the future of so many novel technologies depends on the ability to rapidly fabricate prototype nanoscale magnetic devices.

Imaging and milling with Ga ions always result in Ga incorporation near the sample surface. As the sample surface is sputtered away at a rate proportional to the sputtering yield and the ion flux (ions per area per time), the Ga is implanted further into the sample, and a steady-state profile of Ga is reached. This implantation is often a problem in the range of the semiconductor where silicon can be amorphised by the gallium. In order to get an alternative solution to Ga LMI sources, mass-filtered columns have been developed, based on a Wien filter technology. Such sources include Au-Si, Au-Ge and Au-Si-Ge sources providing Si, Cr, Fe, Co, Ni, Ge, In, Sn, Au, Pb and other elements.

The principle of a Wien filter is based on the equilibrium of the opposite forces induced by perpendicular electrostatic and a magnetic fields acting on accelerated particles. The proper mass trajectory remains straight and passes through the mass selection aperture while the other masses are stopped.

Besides allowing the use of sources others than gallium, these columns can switch from different species simply by adjusting the properties of the Wien filter. Larger ions can be used to make rapid milling before refining the contours with smaller ones. Users also benefits from the possibility to dope their samples with elements of suitable alloy sources.

The latter property has found great interests in the investigation of magnetic materials and devices. Khizroev and Litvinov have shown, with the help of magnetic force microscopy (MFM), that there is a critical dose of ions that a magnetic material can be exposed to without experiencing a change in the magnetic properties. Exploiting FIB from such an unconventional perspective is especially favourable today when the future of so many novel technologies depends on the ability to rapidly fabricate prototype nanoscale magnetic devices.

See also

*Confocal microscopy

Confocal microscopy, most frequently confocal laser scanning microscopy (CLSM) or laser scanning confocal microscopy (LSCM), is an optical imaging technique for increasing optical resolution and contrast (vision), contrast of a micrograph by me ...

* Ion milling machine Ion milling is a specialized physical etching technique that is a crucial step in the preparation of material analysis techniques. After a specimen goes through ion milling, the surface becomes much smoother and more defined, which allows scientists ...

* Powder diffraction

Powder diffraction is a scientific technique using X-ray, neutron, or electron diffraction on powder or microcrystalline samples for structural characterization of materials. An instrument dedicated to performing such powder measurements is ca ...

* Ultrafast x-ray

* X-ray crystallography

X-ray crystallography is the experimental science of determining the atomic and molecular structure of a crystal, in which the crystalline structure causes a beam of incident X-rays to Diffraction, diffract in specific directions. By measuring th ...

* X-ray scattering techniques

References

*Further reading

* * * {{Electron microscopy Electron microscopy Scientific techniques Semiconductor device fabrication Thin film deposition