Metallography on:

[Wikipedia]

[Google]

[Amazon]

Metallography is the study of the physical structure and components of

After mounting, the specimen is wet ground to reveal the surface of the metal. The specimen is successively ground with finer and finer abrasive media.

After mounting, the specimen is wet ground to reveal the surface of the metal. The specimen is successively ground with finer and finer abrasive media.

Some of the most basic measurements include determination of the

Some of the most basic measurements include determination of the

An Introduction to Sample Preparation for Metallography

Cambridge University. * Video on metallograph

Metallography Part I - Macroscopic Techniques

Karlsruhe University of Applied Sciences. * Video on metallograph

Metallography Part II - Microscopic Techniques

Karlsruhe University of Applied Sciences. {{Authority control Materials testing Metallurgy

metal

A metal () is a material that, when polished or fractured, shows a lustrous appearance, and conducts electrical resistivity and conductivity, electricity and thermal conductivity, heat relatively well. These properties are all associated wit ...

s, by using microscopy

Microscopy is the technical field of using microscopes to view subjects too small to be seen with the naked eye (objects that are not within the resolution range of the normal eye). There are three well-known branches of microscopy: optical mic ...

.

Ceramic

A ceramic is any of the various hard, brittle, heat-resistant, and corrosion-resistant materials made by shaping and then firing an inorganic, nonmetallic material, such as clay, at a high temperature. Common examples are earthenware, porcela ...

and polymer

A polymer () is a chemical substance, substance or material that consists of very large molecules, or macromolecules, that are constituted by many repeat unit, repeating subunits derived from one or more species of monomers. Due to their br ...

ic materials may also be prepared using metallographic techniques, hence the terms ceramography

Ceramography is the art and science of preparation, examination and evaluation of ceramic microstructures. Ceramography can be thought of as the metallography of ceramics. The microstructure is the structure level of approximately 0.1 to 100 Microm ...

, plastography and, collectively, materialography.

Preparing metallographic specimens

The surface of a metallographic specimen is prepared by various methods of grinding,polishing

Polishing is the process of creating a smooth and shiny surface by rubbing it or by applying a chemical treatment, leaving a clean surface with a significant specular reflection (still limited by the index of refraction of the material accordi ...

, and etching

Etching is traditionally the process of using strong acid or mordant to cut into the unprotected parts of a metal surface to create a design in intaglio (incised) in the metal. In modern manufacturing, other chemicals may be used on other type ...

. After preparation, it is often analyzed using optical

Optics is the branch of physics that studies the behaviour and properties of light, including its interactions with matter and the construction of instruments that use or detect it. Optics usually describes the behaviour of visible, ultravio ...

or electron microscopy

An electron microscope is a microscope that uses a beam of electrons as a source of illumination. It uses electron optics that are analogous to the glass lenses of an optical light microscope to control the electron beam, for instance focusing i ...

. Using only metallographic techniques, a skilled technician can identify alloy

An alloy is a mixture of chemical elements of which in most cases at least one is a metal, metallic element, although it is also sometimes used for mixtures of elements; herein only metallic alloys are described. Metallic alloys often have prop ...

s and predict material properties

A material property is an intensive property of a material, i.e., a physical property or chemical property that does not depend on the amount of the material. These quantitative properties may be used as a metric by which the benefits of one ma ...

.

Mechanical preparation is the most common preparation method. Successively finer abrasive

An abrasive is a material, often a mineral, that is used to shape or finish a workpiece through rubbing which leads to part of the workpiece being worn away by friction. While finishing a material often means polishing it to gain a smooth, reflec ...

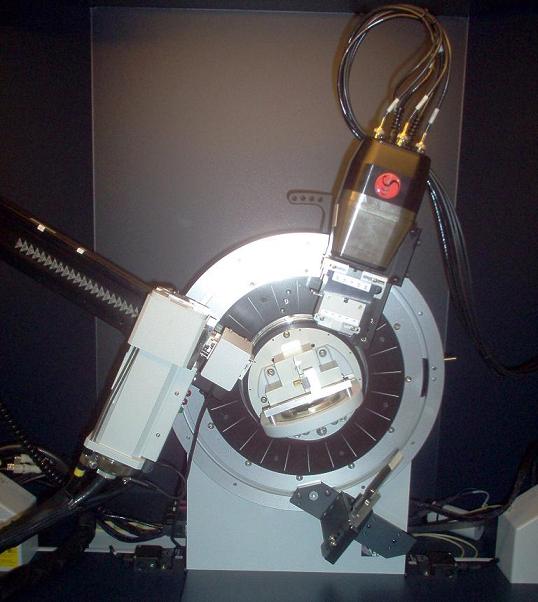

particles are used to remove material from the sample surface until the desired surface quality is achieved. Many different machines are available for doing this grinding and polishing, which are able to meet different demands for quality, capacity, and reproducibility.

A systematic preparation method is the easiest way to achieve the true structure. Sample preparation must therefore pursue rules which are suitable for most materials. Different materials with similar properties (hardness

In materials science, hardness (antonym: softness) is a measure of the resistance to plastic deformation, such as an indentation (over an area) or a scratch (linear), induced mechanically either by Pressing (metalworking), pressing or abrasion ...

and ductility

Ductility refers to the ability of a material to sustain significant plastic Deformation (engineering), deformation before fracture. Plastic deformation is the permanent distortion of a material under applied stress, as opposed to elastic def ...

) will respond alike and thus require the same consumables

Consumables (also known as consumable goods, non-durable goods, or soft goods) are goods that are intended to be consumed. People have, for example, always consumed food and water. Consumables are in contrast to durable goods. Disposable product ...

during preparation.

Metallographic specimens are typically "mounted" using a hot compression thermosetting resin. In the past, phenolic thermosetting resins have been used, but modern epoxy

Epoxy is the family of basic components or Curing (chemistry), cured end products of epoxy Resin, resins. Epoxy resins, also known as polyepoxides, are a class of reactive prepolymers and polymers which contain epoxide groups. The epoxide fun ...

is becoming more popular because reduced shrinkage during curing results in a better mount with superior edge retention. A typical mounting cycle will compress the specimen and mounting media to and heat to a temperature of . When specimens are very sensitive to temperature, "cold mounts" may be made with a two-part epoxy resin. Mounting a specimen provides a safe, standardized, and ergonomic

Ergonomics, also known as human factors or human factors engineering (HFE), is the application of psychological and physiological principles to the engineering and design of products, processes, and systems. Primary goals of human factors engi ...

way by which to hold a sample during the grinding and polishing operations.

Silicon carbide

Silicon carbide (SiC), also known as carborundum (), is a hard chemical compound containing silicon and carbon. A wide bandgap semiconductor, it occurs in nature as the extremely rare mineral moissanite, but has been mass-produced as a powder a ...

abrasive paper was the first method of grinding and is still used today. Many metallographers, however, prefer to use a diamond grit suspension which is dosed onto a reusable fabric pad throughout the polishing process. Diamond grit in suspension might start at 9 micrometre

The micrometre (English in the Commonwealth of Nations, Commonwealth English as used by the International Bureau of Weights and Measures; SI symbol: μm) or micrometer (American English), also commonly known by the non-SI term micron, is a uni ...

s and finish at one micrometre. Generally, polishing with diamond suspension gives finer results than using silicon carbide papers (SiC papers), especially with revealing porosity

Porosity or void fraction is a measure of the void (i.e. "empty") spaces in a material, and is a fraction of the volume of voids over the total volume, between 0 and 1, or as a percentage between 0% and 100%. Strictly speaking, some tests measure ...

, which silicon carbide paper sometimes "smear" over. After grinding the specimen, polishing is performed. Typically, a specimen is polished with a slurry

A slurry is a mixture of denser solids suspended in liquid, usually water. The most common use of slurry is as a means of transporting solids or separating minerals, the liquid being a carrier that is pumped on a device such as a centrifugal pu ...

of alumina

Aluminium oxide (or aluminium(III) oxide) is a chemical compound of aluminium and oxygen with the chemical formula . It is the most commonly occurring of several aluminium oxides, and specifically identified as aluminium oxide. It is commonly ...

, silica

Silicon dioxide, also known as silica, is an oxide of silicon with the chemical formula , commonly found in nature as quartz. In many parts of the world, silica is the major constituent of sand. Silica is one of the most complex and abundant f ...

, or diamond

Diamond is a Allotropes of carbon, solid form of the element carbon with its atoms arranged in a crystal structure called diamond cubic. Diamond is tasteless, odourless, strong, brittle solid, colourless in pure form, a poor conductor of e ...

on a napless cloth to produce a scratch-free mirror finish, free from smear, drag, or pull-outs and with minimal deformation remaining from the preparation process.

After polishing, certain microstructural constituents can be seen with the microscope, e.g., inclusions and nitrides. If the crystal structure is non-cubic (e.g., a metal with a hexagonal-closed packed crystal structure, such as Ti or Zr) the microstructure can be revealed without etching using crossed polarized light (light microscopy). Otherwise, the microstructural constituents of the specimen are revealed by using a suitable chemical or electrolytic etchant.

Non-destructive surface analysis techniques can involve applying a thin film or varnish that can be peeled off after drying and examined under a microscope. The technique was developed by Pierre Armand Jacquet and others in 1957.

Analysis techniques

Many differentmicroscopy

Microscopy is the technical field of using microscopes to view subjects too small to be seen with the naked eye (objects that are not within the resolution range of the normal eye). There are three well-known branches of microscopy: optical mic ...

techniques are used in metallographic analysis.

Prepared specimens should be examined with the unaided eye after etching to detect any visible areas that have responded to the etchant differently from the norm as a guide to where microscopical examination should be employed. Light optical microscopy (LOM) examination should always be performed prior to any electron metallographic (EM) technique, as these are more time-consuming to perform and the instruments are much more expensive.

Further, certain features can be best observed with the LOM, e.g., the natural color of a constituent can be seen with the LOM but not with EM systems. Also, image contrast of microstructures at relatively low magnifications, e.g., <500X, is far better with the LOM than with the scanning electron microscope

A scanning electron microscope (SEM) is a type of electron microscope that produces images of a sample by scanning the surface with a focused beam of electrons. The electrons interact with atoms in the sample, producing various signals that ...

(SEM), while transmission electron microscopes (TEM) generally cannot be utilized at magnifications below about 2000 to 3000X. LOM examination is fast and can cover a large area. Thus, the analysis can determine if the more expensive, more time-consuming examination techniques using the SEM or the TEM are required and where on the specimen the work should be concentrated.

Design, resolution, and image contrast

Light microscopes are designed for placement of the specimen's polished surface on the specimen stage either upright or inverted. Each type has advantages and disadvantages. Most LOM work is done at magnifications between 50 and 1000X. However, with a good microscope, it is possible to perform examination at higher magnifications, e.g., 2000X, and even higher, as long asdiffraction

Diffraction is the deviation of waves from straight-line propagation without any change in their energy due to an obstacle or through an aperture. The diffracting object or aperture effectively becomes a secondary source of the Wave propagation ...

fringes are not present to distort the image. However, the resolution limit of the LOM will not be better than about 0.2 to 0.3 micrometers. Special methods are used at magnifications below 50X, which can be very helpful when examining the microstructure of cast specimens where greater spatial coverage in the field of view may be required to observe features such as dendrites

A dendrite (from Greek δένδρον ''déndron'', "tree") or dendron is a branched cytoplasmic process that extends from a nerve cell that propagates the electrochemical stimulation received from other neural cells to the cell body, or soma ...

.

Besides considering the resolution of the optics, one must also maximize visibility by maximizing image contrast. A microscope with excellent resolution may not be able to image a structure, that is there is no visibility, if image contrast is poor. Image contrast depends upon the quality of the optics, coatings on the lenses, and reduction of flare and glare

Glare may refer to:

* Glare (vision), difficulty seeing in the presence of very bright light

* Glaring, a facial expression of squinted eyes and look of contempt

* A call collision in telecommunications

* GLARE, Glass reinforced aluminium, an ...

; but, it also requires proper specimen preparation and good etching techniques. So, obtaining good images requires maximum resolution and image contrast.

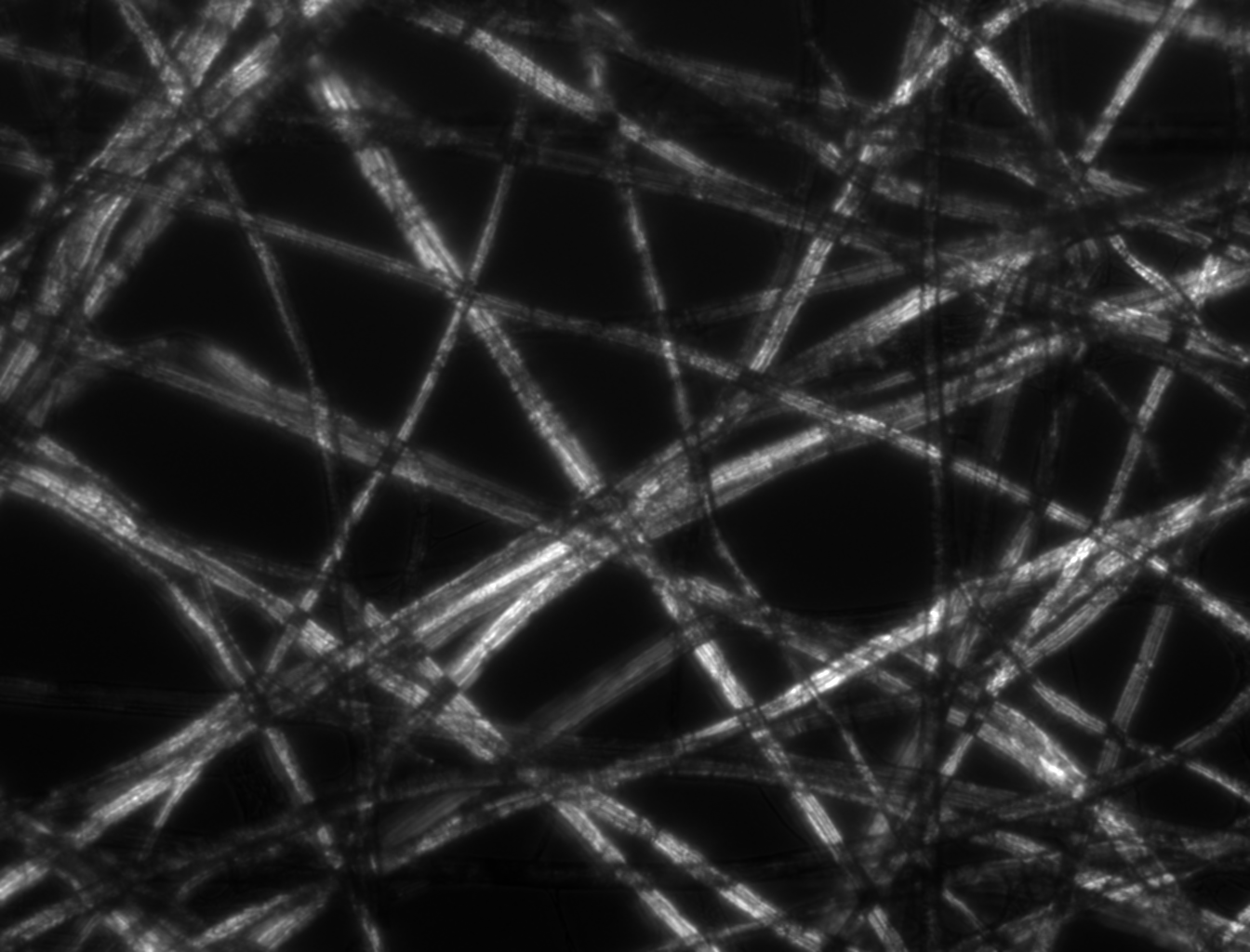

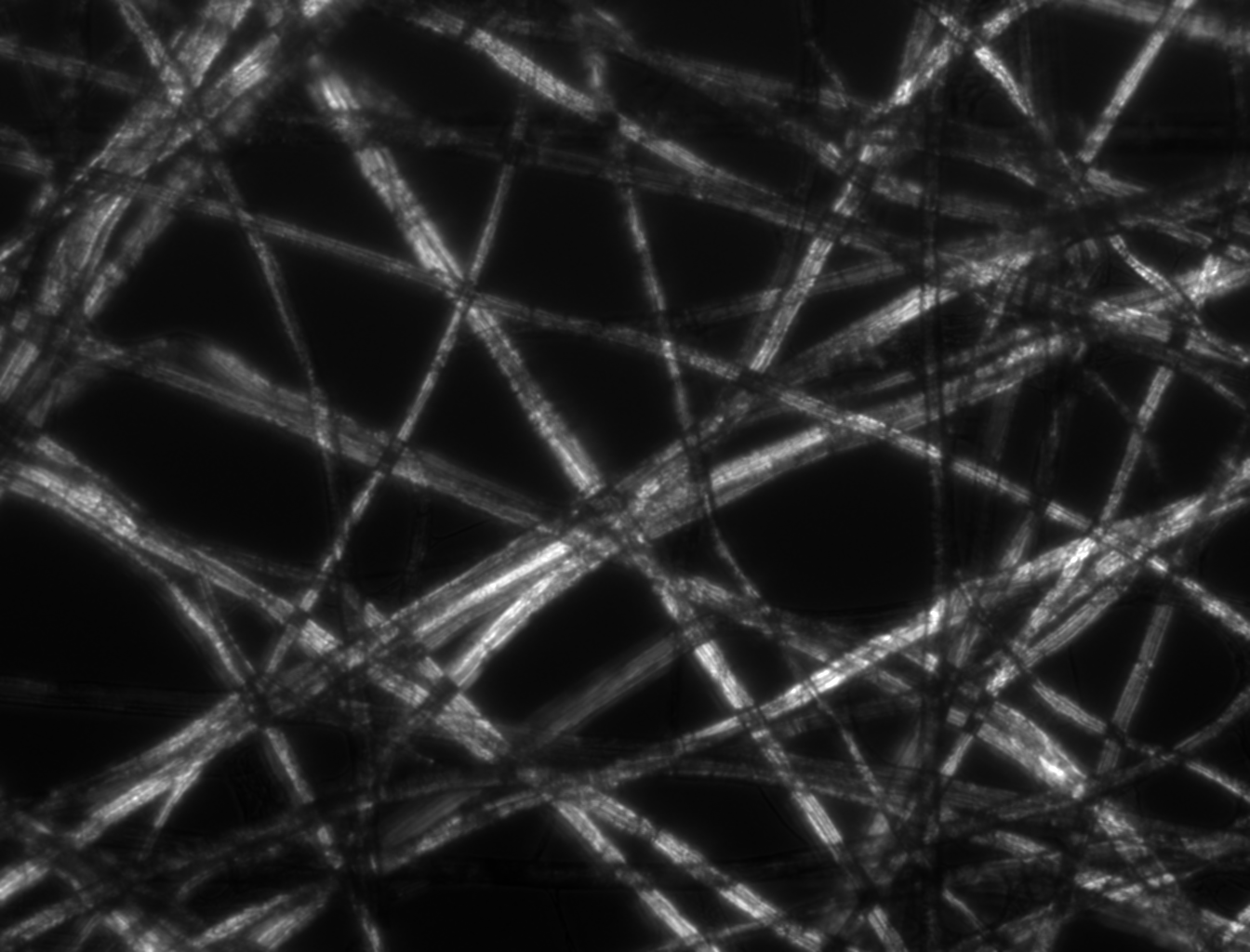

Bright- and dark-field microscopy

Most LOM observations are conducted using bright-field (BF) illumination, where the image of any flat feature perpendicular to the incident light path is bright, or appears to be white. But, other illumination methods can be used and, in some cases, may provide superior images with greater detail.Dark-field microscopy

Dark-field microscopy, also called dark-ground microscopy, describes microscopy methods, in both light and electron microscopy, which exclude the unscattered beam from the image. Consequently, the field around the specimen (i.e., where there is ...

(DF), is an alternative method of observation that provides high-contrast images and actually greater resolution than bright-field. In dark-field illumination, the light from features perpendicular to the optical axis is blocked and appears dark while the light from features inclined to the surface, which look dark in BF, appear bright, or "self-luminous" in DF. Grain boundaries

In materials science, a grain boundary is the interface between two grains, or crystallites, in a polycrystalline material. Grain boundaries are two-dimensional crystallographic defect, defects in the crystal structure, and tend to decrease the ...

, for example, are more vivid in DF than BF.

Polarized light microscopy

Polarized light

, or , is a property of transverse waves which specifies the geometrical orientation of the oscillations. In a transverse wave, the direction of the oscillation is perpendicular to the direction of motion of the wave. One example of a polarize ...

(PL) is very useful when studying the structure of metals with non-cubic crystal structure

In crystallography, crystal structure is a description of ordered arrangement of atoms, ions, or molecules in a crystalline material. Ordered structures occur from intrinsic nature of constituent particles to form symmetric patterns that repeat ...

s (mainly metals with hexagonal close-packed

In geometry, close-packing of equal spheres is a dense arrangement of congruent spheres in an infinite, regular arrangement (or Lattice (group), lattice). Carl Friedrich Gauss proved that the highest average density – that is, the greatest fract ...

(hcp) crystal structures). If the specimen is prepared with minimal damage to the surface, the structure can be seen vividly in cross-polarized light (the optic axis of the polarizer and analyzer are 90 degrees to each other, i.e., crossed). In some cases, an hcp metal can be chemically etched and then examined more effectively with PL. Tint etched surfaces, where a thin film (such as a sulfide

Sulfide (also sulphide in British English) is an inorganic anion of sulfur with the chemical formula S2− or a compound containing one or more S2− ions. Solutions of sulfide salts are corrosive. ''Sulfide'' also refers to large families o ...

, molybdate

In chemistry, a molybdate is a compound containing an oxyanion with molybdenum in its highest oxidation state of +6: . Molybdenum can form a very large range of such oxyanions, which can be discrete structures or polymeric extended structures, ...

, chromate or elemental selenium

Selenium is a chemical element; it has symbol (chemistry), symbol Se and atomic number 34. It has various physical appearances, including a brick-red powder, a vitreous black solid, and a grey metallic-looking form. It seldom occurs in this elem ...

film) is grown epitaxially on the surface to a depth where interference effects are created when examined with BF producing color images, can be improved with PL. If it is difficult to get a good interference film with good coloration, the colors can be improved by examination in PL using a sensitive tint (ST) filter.

Differential interference contrast microscopy

Another useful imaging mode is differential interference contrast (DIC), which is usually obtained with a system designed by the Polish physicist Georges Nomarski. This system gives the best detail. DIC converts minor height differences on the plane-of-polish, invisible in BF, into visible detail. The detail in some cases can be quite striking and very useful. If an ST filter is used along with aWollaston prism

A Wollaston prism is an optical device, invented by William Hyde Wollaston, that manipulates polarized light. It separates light into two separate linearly polarized outgoing beams with orthogonal polarization. The two beams are polarized accor ...

, color is introduced. The colors are controlled by the adjustment of the Wollaston prism, and have no specific physical meaning, per se. But, visibility may be better.

Oblique illumination

DIC has largely replaced the older oblique illumination (OI) technique, which was available on reflected light microscopes prior to about 1975. In OI, the vertical illuminator is offset from perpendicular, producing shading effects that reveal height differences. This procedure reduces resolution and yields uneven illumination across the field of view. Nevertheless, OI was useful when people needed to know if a second phase particle was standing above or was recessed below the plane-of-polish, and is still available on a few microscopes. OI can be created on any microscope by placing a piece of paper under one corner of the mount so that the plane-of-polish is no longer perpendicular to the optical axis.SRAS microscopy

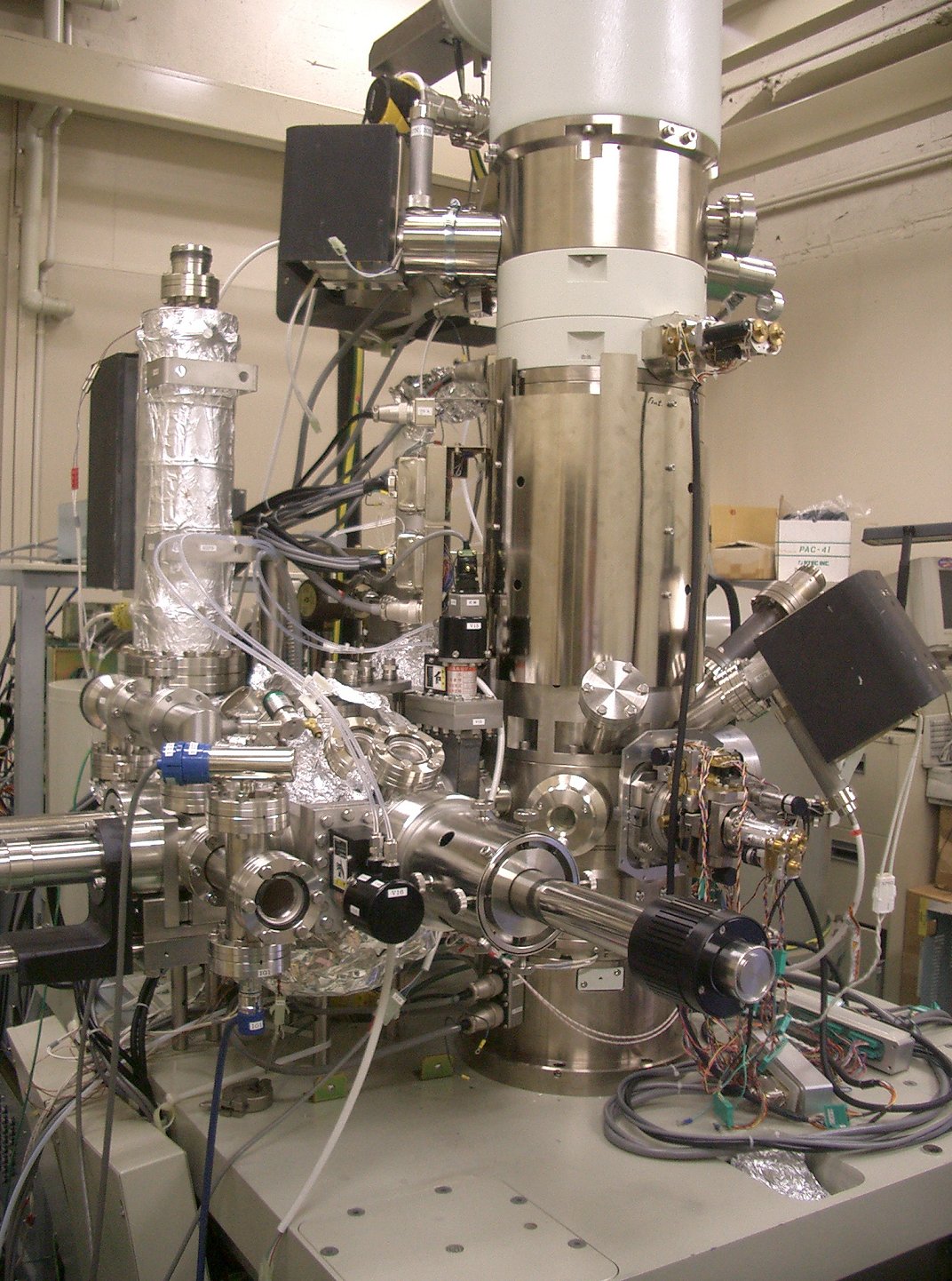

Spatially resolve acoustic spectroscopy ( SRAS) is an optical technique that uses optically generated high frequency surface acoustic waves to probe the direction elastic parameters of the surface and, as such, it can vividly reveal the surface microstructure of metals. It can also image the crystallographic orientation and determine the single crystal elasticity matrix of the material.Scanning electron and transmission electron microscopes

If a specimen must be observed at higher magnification, it can be examined with a scanning electron microscope (SEM), or a transmission electron microscope (TEM). When equipped with an energy dispersive spectrometer (EDS), the chemical composition of the microstructural features can be determined. The ability to detect low-atomic number elements, such ascarbon

Carbon () is a chemical element; it has chemical symbol, symbol C and atomic number 6. It is nonmetallic and tetravalence, tetravalent—meaning that its atoms are able to form up to four covalent bonds due to its valence shell exhibiting 4 ...

, oxygen

Oxygen is a chemical element; it has chemical symbol, symbol O and atomic number 8. It is a member of the chalcogen group (periodic table), group in the periodic table, a highly reactivity (chemistry), reactive nonmetal (chemistry), non ...

, and nitrogen

Nitrogen is a chemical element; it has Symbol (chemistry), symbol N and atomic number 7. Nitrogen is a Nonmetal (chemistry), nonmetal and the lightest member of pnictogen, group 15 of the periodic table, often called the Pnictogen, pnictogens. ...

, depends upon the nature of the detector used. But, quantification of these elements by EDS is difficult and their minimum detectable limits are higher than when a wavelength-dispersive spectrometer (WDS) is used. But quantification of composition by EDS has improved greatly over time. The WDS system has historically had better sensitivity (ability to detect low amounts of an element) and ability to detect low-atomic weight elements, as well as better quantification of compositions, compared to EDS, but it was slower to use. Again, in recent years, the speed required to perform WDS analysis has improved substantially. Historically, EDS was used with the SEM while WDS was used with the electron microprobe analyzer (EMPA). Today, EDS and WDS is used with both the SEM and the EMPA. However, a dedicated EMPA is not as common as an SEM.

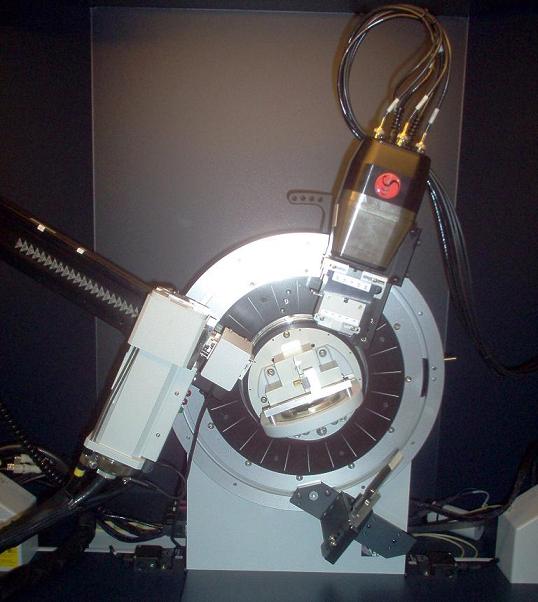

X-ray diffraction techniques

Characterization of microstructures has also been performed usingx-ray diffraction

X-ray diffraction is a generic term for phenomena associated with changes in the direction of X-ray beams due to interactions with the electrons around atoms. It occurs due to elastic scattering, when there is no change in the energy of the waves. ...

(XRD) techniques for many years. XRD can be used to determine the percentages of various phases present in a specimen if they have different crystal structures. For example, the amount of retained austenite

Austenite, also known as gamma-phase iron (γ-Fe), is a metallic, non-magnetic allotrope of iron or a solid solution of iron with an alloying element. In plain-carbon steel, austenite exists above the critical eutectoid temperature of 1000 ...

in a hardened steel

The term hardened steel is often used for a plain-carbon steel, medium or high carbon steel that has been given heat treatment and then quenching followed by tempering (metallurgy), tempering. The quenching results in the formation of metastable ma ...

is best measured using XRD (ASTM E 975). If a particular phase can be chemically extracted from a bulk specimen, it can be identified using XRD based on the crystal structure and lattice dimensions. This work can be complemented by EDS and/or WDS analysis where the chemical composition is quantified. But EDS and WDS are difficult to apply to particles less than 2-3 micrometers in diameter. For smaller particles, diffraction techniques can be performed using the TEM for identification and EDS can be performed on small particles if they are extracted from the matrix using replication methods to avoid detection of the matrix along with the precipitate.

Quantitative metallography

A number of techniques exist to quantitatively analyze metallographic specimens. These techniques are valuable in the research and production of allmetal

A metal () is a material that, when polished or fractured, shows a lustrous appearance, and conducts electrical resistivity and conductivity, electricity and thermal conductivity, heat relatively well. These properties are all associated wit ...

s and alloy

An alloy is a mixture of chemical elements of which in most cases at least one is a metal, metallic element, although it is also sometimes used for mixtures of elements; herein only metallic alloys are described. Metallic alloys often have prop ...

s and non-metallic or composite materials

A composite or composite material (also composition material) is a material which is produced from two or more constituent materials. These constituent materials have notably dissimilar chemical or physical properties and are merged to create a ...

.

Microstructural quantification is performed on a prepared, two-dimensional plane through the three-dimensional part or component. Measurements may involve simple metrology

Metrology is the scientific study of measurement. It establishes a common understanding of Unit of measurement, units, crucial in linking human activities. Modern metrology has its roots in the French Revolution's political motivation to stan ...

techniques, e.g., the measurement of the thickness of a surface coating, or the apparent diameter of a discrete second-phase particle, (for example, spheroid

A spheroid, also known as an ellipsoid of revolution or rotational ellipsoid, is a quadric surface (mathematics), surface obtained by Surface of revolution, rotating an ellipse about one of its principal axes; in other words, an ellipsoid with t ...

al graphite

Graphite () is a Crystallinity, crystalline allotrope (form) of the element carbon. It consists of many stacked Layered materials, layers of graphene, typically in excess of hundreds of layers. Graphite occurs naturally and is the most stable ...

in ductile iron

Ductile iron, also known as ductile cast iron, nodular cast iron, spheroidal graphite iron, spheroidal graphite cast iron and SG iron, is a type of graphite-rich cast iron discovered in 1943 by Keith Millis. While most varieties of cast iron are ...

). Measurement may also require application of stereology

Stereology is the three-dimensional interpretation of two-dimensional cross sections of materials or tissues. It provides practical techniques for extracting quantitative information about a three-dimensional material from measurements made on two ...

to assess matrix and second-phase structures. Stereology is the field of taking 0-, 1- or 2-dimensional measurements on the two-dimensional sectioning plane and estimating the amount, size, shape or distribution of the microstructure in three dimensions. These measurements may be made using manual procedures with the aid of templates overlaying the microstructure, or with automated image analyzers. In all cases, adequate sampling must be made to obtain a proper statistical basis for the measurement. Efforts to eliminate bias are required.

Some of the most basic measurements include determination of the

Some of the most basic measurements include determination of the volume fraction

In chemistry and fluid mechanics, the volume fraction \varphi_i is defined as the volume of a constituent ''V'i'' divided by the volume of all constituents of the mixture ''V'' prior to mixing:

:\varphi_i = \frac .

Being dimensionless quantit ...

of a phase or constituent, measurement of the grain size

Grain size (or particle size) is the diameter of individual grains of sediment, or the lithified particles in clastic rocks. The term may also be applied to other granular materials. This is different from the crystallite size, which ...

in polycrystal

A crystallite is a small or even microscopic crystal which forms, for example, during the cooling of many materials. Crystallites are also referred to as grains.

Bacillite is a type of crystallite. It is rodlike with parallel longulites.

S ...

line metals and alloys, measurement of the size and size distribution of particles, assessment of the shape of particles, and spacing between particles.

Standards organizations

A standards organization, standards body, standards developing organization (SDO), or standards setting organization (SSO) is an organization whose primary function is developing, coordinating, promulgating, revising, amending, reissuing, interpr ...

, including ASTM International

ASTM International, formerly known as American Society for Testing and Materials, is a standards organization that develops and publishes voluntary consensus technical international standards for a wide range of materials, products, systems and s ...

's Committee E-4 on Metallography and some other national and international organizations, have developed standard test methods describing how to characterize microstructure

Microstructure is the very small scale structure of a material, defined as the structure of a prepared surface of material as revealed by an optical microscope above 25× magnification. The microstructure of a material (such as metals, polymer ...

s quantitatively.

For example, the amount of a phase or constituent, that is, its volume fraction, is defined in ASTM E 562; manual grain size measurements are described in ASTM E 112 ( equiaxed grain structures with a single size distribution) and E 1182 (specimens with a bi-modal grain size distribution); while ASTM E 1382 describes how any grain size type or condition can be measured using image analysis methods. Characterization of nonmetallic inclusions using standard charts is described in ASTM E 45 (historically, E 45 covered only manual chart methods and an image analysis method for making such chart measurements was described in ASTM E 1122. The image analysis methods are currently being incorporated into E 45). A stereological method for characterizing discrete second-phase particles, such as nonmetallic inclusions, carbides, graphite, etc., is presented in ASTM E 1245.

See also

* Henry Clifton Sorby * Holger F. StruerReferences

* "Metallographic and Materialographic Specimen Preparation, Light Microscopy, Image Analysis and Hardness Testing", Kay Geels in collaboration with Struers A/S, ASTM International 2006. * Metallography and Microstructures, Vol. 9, ASM Handbook, ASM International, Materials Park, OH, 2005. * Metallography: Principles and Practice, G. F. Vander Voort, ASM International, Materials Park, OH, 1999. * Vol. 03.01 of the ASTM Standards covers standards devoted to metallography (and mechanical property testing) * G. Petzow, ''Metallographic Etching'', 2nd Ed., ASM International, 1999. * Metalog Guide, L. Bjerregaard, K. Geels, B. Ottesen, M. Rückert, Struers A/S, Copenhagen, Denmark, 2000.External links

* HKDH BhadeshiAn Introduction to Sample Preparation for Metallography

Cambridge University. * Video on metallograph

Metallography Part I - Macroscopic Techniques

Karlsruhe University of Applied Sciences. * Video on metallograph

Metallography Part II - Microscopic Techniques

Karlsruhe University of Applied Sciences. {{Authority control Materials testing Metallurgy