Copper extraction on:

[Wikipedia]

[Google]

[Amazon]

Copper extraction is the multi-stage process of obtaining

Copper extraction is the multi-stage process of obtaining

The Old Copper Complex in North America has been radiometrically dated to 9500 BP—i.e., about 7480 BCE—making it one of the oldest known examples of copper extraction in the world. The earliest evidence of the cold-hammering of native copper comes from the excavation at Çayönü Tepesi in eastern

The Old Copper Complex in North America has been radiometrically dated to 9500 BP—i.e., about 7480 BCE—making it one of the oldest known examples of copper extraction in the world. The earliest evidence of the cold-hammering of native copper comes from the excavation at Çayönü Tepesi in eastern

In froth flotation, the crushed ore is wetted, suspended in a slurry, and mixed with reagents that render the sulfide particles

In froth flotation, the crushed ore is wetted, suspended in a slurry, and mixed with reagents that render the sulfide particles

Secondary sulfides—those formed by supergene secondary enrichment—are resistant (''

Secondary sulfides—those formed by supergene secondary enrichment—are resistant (''

The initial melting of the material to be smelted is usually referred to as the ''

The initial melting of the material to be smelted is usually referred to as the ''

The matte, which is produced in the smelter, contains 30–70% copper (depending on the process used and the operating philosophy of the smelter), primarily as copper sulfide, as well as iron sulfide. The sulfur is removed at a high temperature as sulfur dioxide by blowing air through molten matte:

:2 CuS + 3 O2 → 2 CuO + 2 SO2

:CuS + O2 → Cu + SO2

In a parallel reaction the iron sulfide is converted to slag:

:2 FeS + 3 O2 → 2 FeO + 2 SO2

:2 FeO + SiO2 → Fe2SiO4

The purity of this product is 98%, it is known as ''blister'' because of the broken surface created by the escape of sulfur dioxide gas as blister copper ''pigs'' or

The matte, which is produced in the smelter, contains 30–70% copper (depending on the process used and the operating philosophy of the smelter), primarily as copper sulfide, as well as iron sulfide. The sulfur is removed at a high temperature as sulfur dioxide by blowing air through molten matte:

:2 CuS + 3 O2 → 2 CuO + 2 SO2

:CuS + O2 → Cu + SO2

In a parallel reaction the iron sulfide is converted to slag:

:2 FeS + 3 O2 → 2 FeO + 2 SO2

:2 FeO + SiO2 → Fe2SiO4

The purity of this product is 98%, it is known as ''blister'' because of the broken surface created by the escape of sulfur dioxide gas as blister copper ''pigs'' or

The blister copper is put into an anode furnace, a furnace that refines the blister copper to anode-grade copper in two stages by removing most of the remaining sulfur and iron, and then removing oxygen introduced during the first stage. This second stage, often referred to as '' poling'' is done by blowing

The blister copper is put into an anode furnace, a furnace that refines the blister copper to anode-grade copper in two stages by removing most of the remaining sulfur and iron, and then removing oxygen introduced during the first stage. This second stage, often referred to as '' poling'' is done by blowing

The final stage in the production of copper is refining. Refining is achieved by

The final stage in the production of copper is refining. Refining is achieved by

Copper.org

* * * The Copper Development Association'

page.

from an online text on metals, Illinois Sustainable Technology Center,

National Pollutant Inventory – Copper and copper compounds fact sheet

* University of Pittsburgh School of Engineering Chemical and Petroleum Engineering Department

Froth Flotation

Lab notes.

Copper Mine

college course syllabus, emphasis on chemistry, last updated 2000

Copper extraction is the multi-stage process of obtaining

Copper extraction is the multi-stage process of obtaining copper

Copper is a chemical element; it has symbol Cu (from Latin ) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pinkish-orang ...

from its ores. The conversion of copper ores consists of a series of physical, chemical, and electrochemical processes. Methods have evolved and vary with country depending on the ore source, local environmental regulations, and other factors. The copper smelters with the highest production capacity (metric tons of copper yearly) lie in China, Chile, India, Germany, Japan, Peru and Russia. China alone has over half of the world's production capacity and is also the world's largest consumer of refined copper.

Precious metal

Precious metals are rare, naturally occurring metallic chemical elements of high Value (economics), economic value. Precious metals, particularly the noble metals, are more corrosion resistant and less reactivity (chemistry), chemically reac ...

s and sulfuric acid

Sulfuric acid (American spelling and the preferred IUPAC name) or sulphuric acid (English in the Commonwealth of Nations, Commonwealth spelling), known in antiquity as oil of vitriol, is a mineral acid composed of the elements sulfur, oxygen, ...

are often valuable by-products of copper refining. Arsenic

Arsenic is a chemical element; it has Symbol (chemistry), symbol As and atomic number 33. It is a metalloid and one of the pnictogens, and therefore shares many properties with its group 15 neighbors phosphorus and antimony. Arsenic is not ...

is the main type of impurity found in copper concentrates to enter smelting facilities. There has been an increase in arsenic in copper concentrates over the years since shallow, low-arsenic copper deposits have been progressively depleted.

History

Prehistory

The Old Copper Complex in North America has been radiometrically dated to 9500 BP—i.e., about 7480 BCE—making it one of the oldest known examples of copper extraction in the world. The earliest evidence of the cold-hammering of native copper comes from the excavation at Çayönü Tepesi in eastern

The Old Copper Complex in North America has been radiometrically dated to 9500 BP—i.e., about 7480 BCE—making it one of the oldest known examples of copper extraction in the world. The earliest evidence of the cold-hammering of native copper comes from the excavation at Çayönü Tepesi in eastern Anatolia

Anatolia (), also known as Asia Minor, is a peninsula in West Asia that makes up the majority of the land area of Turkey. It is the westernmost protrusion of Asia and is geographically bounded by the Mediterranean Sea to the south, the Aegean ...

, which dates between 7200 and 6600 BCE. Among the various items considered to be votive or amulets, there was one that looked like a fishhook and one like an awl. Another find, at Shanidar Cave in Mergasur, Iraq, contained copper beads, and dates back to 8,700 BCE.

One of the world's oldest known copper mines, as opposed to usage of surface deposits, is at Timna Valley, Israel, and has been used since the fourth millennium BC, with surface deposit usage occurring in the fifth and sixth millennium.

The Pločnik archaeological site in southeastern Europe (Serbia

, image_flag = Flag of Serbia.svg

, national_motto =

, image_coat = Coat of arms of Serbia.svg

, national_anthem = ()

, image_map =

, map_caption = Location of Serbia (gree ...

) contains the oldest securely dated evidence of copper making at high temperature, from 5,000 BCE. The find in June 2010 extends for an additional 500 years, dated to 5th millennium BCE, representing the earlier record of copper smelting from Rudna Glava (Serbia

, image_flag = Flag of Serbia.svg

, national_motto =

, image_coat = Coat of arms of Serbia.svg

, national_anthem = ()

, image_map =

, map_caption = Location of Serbia (gree ...

).

The earliest copper work in the Atacama Desert

The Atacama Desert () is a desert plateau located on the Pacific Ocean, Pacific coast of South America, in the north of Chile. Stretching over a strip of land west of the Andes Mountains, it covers an area of , which increases to if the barre ...

and the Andean world as whole dates to 1432–1132 BC. Ice core studies in Bolivia suggest copper smelting may have begun as early as 700 BC, over 2700 years ago. Various sites of Pre-Hispanic mines and metallurgical workshops have been identified in Atacama Desert including those with remnants of chisels, casting waste and workshop debris. Tin broze, arsenical bronze

Arsenical bronze is an alloy in which arsenic, as opposed to or in addition to tin or other constituent metals, is combined with copper to make bronze. The use of arsenic with copper, either as the secondary constituent or with another component ...

, and arsenical copper were valuable goods produced in the Inca Empire

The Inca Empire, officially known as the Realm of the Four Parts (, ), was the largest empire in pre-Columbian America. The administrative, political, and military center of the empire was in the city of Cusco. The History of the Incas, Inca ...

. About 74 km northeast of the Chilean city of Copiapó

Copiapó () is a List of cities in Chile, city and communes of Chile, commune in northern Chile, located about 65 kilometers east of the coastal List of towns in Chile, town of Caldera, Chile, Caldera. Founded on December 8, 1744, it is the capi ...

in Viña del Cerro the Incas had one of their largest mining and metallurgy

Metallurgy is a domain of materials science and engineering that studies the physical and chemical behavior of metallic elements, their inter-metallic compounds, and their mixtures, which are known as alloys.

Metallurgy encompasses both the ...

centres at Qullasuyu. There is evidence of gold, silver and copper metallurgy at the site, including the production of bronze

Bronze is an alloy consisting primarily of copper, commonly with about 12–12.5% tin and often with the addition of other metals (including aluminium, manganese, nickel, or zinc) and sometimes non-metals (such as phosphorus) or metalloid ...

. When conquistador

Conquistadors (, ) or conquistadores (; ; ) were Spanish Empire, Spanish and Portuguese Empire, Portuguese colonizers who explored, traded with and colonized parts of the Americas, Africa, Oceania and Asia during the Age of Discovery. Sailing ...

Diego de Almagro traversed the Atacama Desert in 1536 his men readilly obtained copper horseshoe

A horseshoe is a product designed to protect a horse hoof from wear. Shoes are attached on the palmar surface (ground side) of the hooves, usually nailed through the insensitive hoof wall that is anatomically akin to the human toenail, altho ...

s for their horses.

Copper smelting technology gave rise to the Copper Age

The Chalcolithic ( ) (also called the Copper Age and Eneolithic) was an archaeological period characterized by the increasing use of smelted copper. It followed the Neolithic and preceded the Bronze Age. It occurred at different periods in dif ...

, aka Chalcolithic Age, and then the Bronze Age

The Bronze Age () was a historical period characterised principally by the use of bronze tools and the development of complex urban societies, as well as the adoption of writing in some areas. The Bronze Age is the middle principal period of ...

. The Bronze Age would not have been possible without the development of smelting technology.

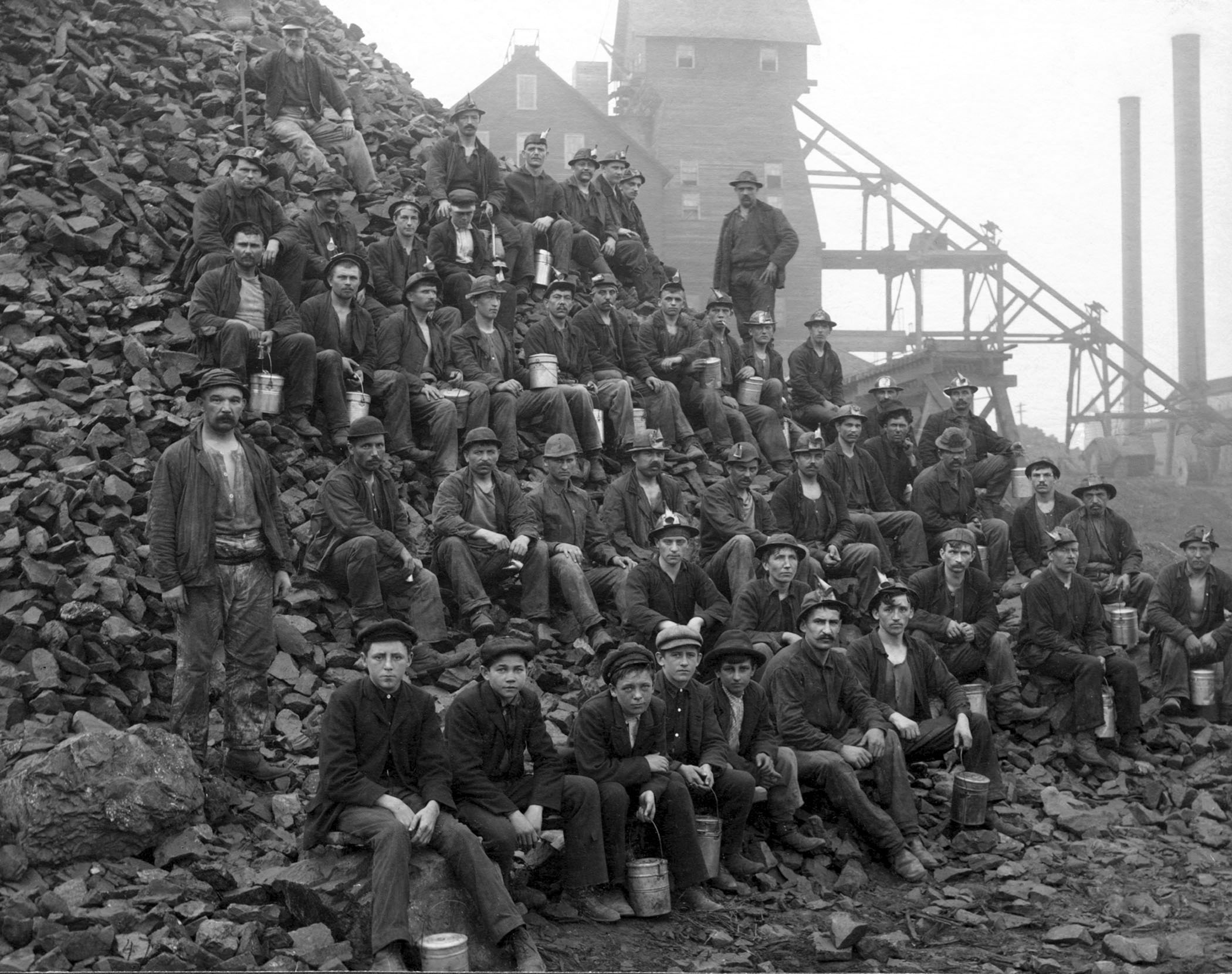

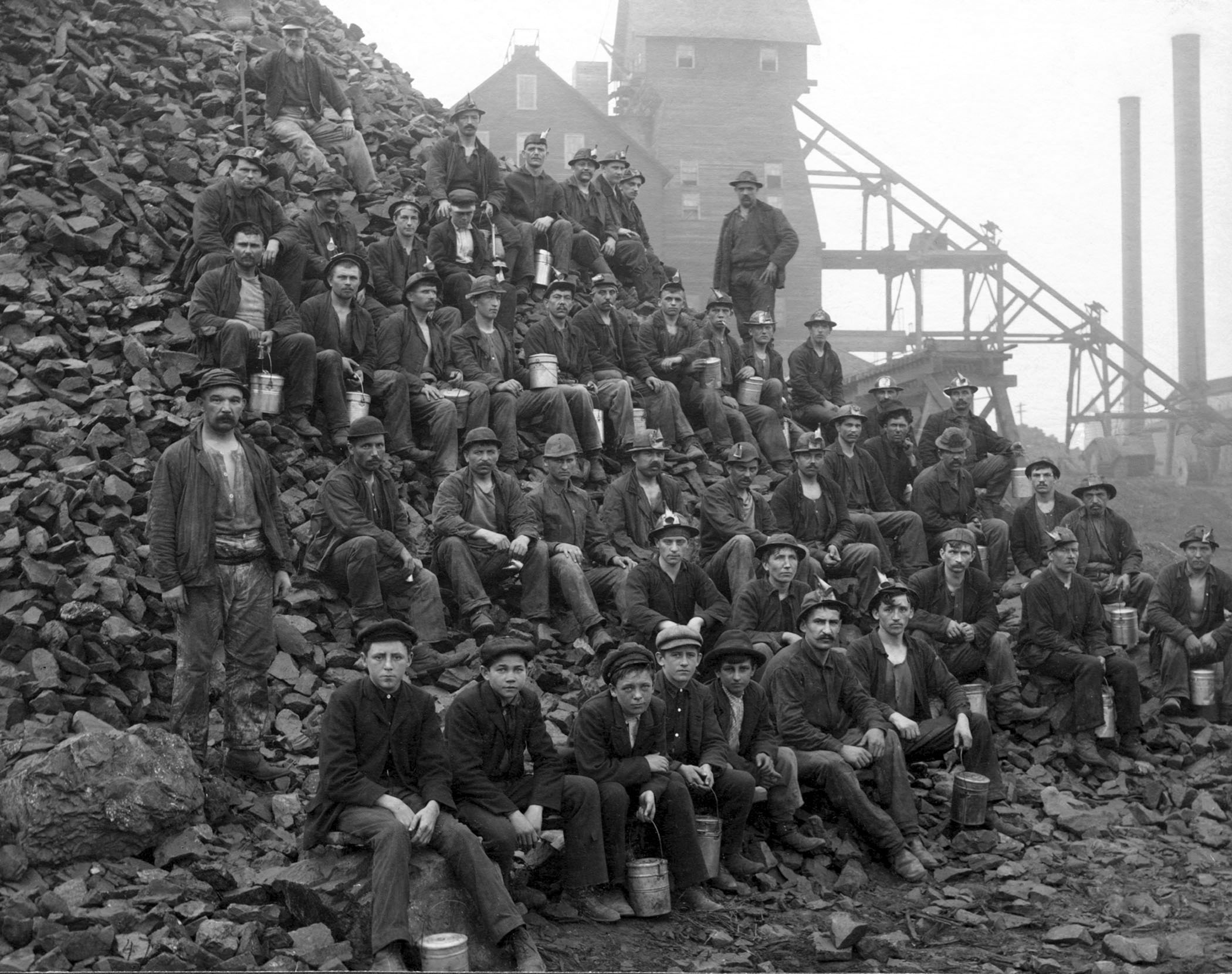

19th century

The introduction ofreverberatory furnace

A reverberatory furnace is a metallurgy, metallurgical or process Metallurgical furnace, furnace that isolates the material being processed from contact with the fuel, but not from contact with combustion gases. The term ''reverberation'' is use ...

s to Chile

Chile, officially the Republic of Chile, is a country in western South America. It is the southernmost country in the world and the closest to Antarctica, stretching along a narrow strip of land between the Andes, Andes Mountains and the Paci ...

around 1830 by Charles Saint Lambert revolutionized Chilean copper mining. In addition to this there was improvements of transport caused by the development of railroads and steam navigation. Prospector José Tomás Urmeneta discovered rich orebodies at Tamaya in 1850, a site that became one of Chile's main copper mines. All of this made Chile supply 18% of the copper produced worldwide in the 19th century and the country was from the 1850s to the 1870s the world's top producer. In some years Chile's copper production made up about 60% of the worlds output and its export tariff made up more than half the state's income.

Lambert's success in modernising the Chilean copper industry during the second quarter of the nineteenth century is thought to have sowed the seeds for the later demise of his own copper smelting business (among others) in Swansea

Swansea ( ; ) is a coastal City status in the United Kingdom, city and the List of urban areas in the United Kingdom, second-largest city of Wales. It forms a Principal areas of Wales, principal area, officially known as the City and County of ...

.

By the late 19th century the Chilean mining industry once again lagged behind technological developments (e.g. flotation, leaching, large-scale open-pit mining

Open-pit mining, also known as open-cast or open-cut mining and in larger contexts mega-mining, is a surface mining technique that extracts rock (geology), rock or minerals from the earth.

Open-pit mines are used when deposits of commercially ...

) contributing to the drop of its share of the world production to 5–6% in the 1890s and similar shares remained in the 1900s and 1910s reaching a low of 4.3% in 1914. Up to the 1940s and 1950s there was also a notable lack of major copper exploration efforts by large mining companies that relied on purchasing prospects already known from the activity of small-scale miners and pirquineros.

Smelting

Until the latter half of the 20th century,smelting

Smelting is a process of applying heat and a chemical reducing agent to an ore to extract a desired base metal product. It is a form of extractive metallurgy that is used to obtain many metals such as iron-making, iron, copper extraction, copper ...

sulfide ores was almost the sole means of producing copper metal from mined ores (''primary'' copper production). As of 2002, 80% of global primary copper production was from copper–iron–sulfur minerals, and the vast majority of these were treated by smelting.W G Davenport, M King, M Schlesinger and A K Biswas, ''Extractive Metallurgy of Copper, Fourth Edition'' (Elsevier Science Limited: Kidlington, Oxford, England, 2002).

Copper was initially recovered from sulfide ores by directly smelting the ore in a furnace. The smelters were initially located near the mines to minimize the cost of transport. This avoided the prohibitive costs of transporting the waste minerals and the sulfur and iron present in the copper-containing minerals. However, as the concentration of copper in the ore bodies decreased, the energy costs of smelting the whole ore also became prohibitive, and it became necessary to concentrate the ores first.

Initial concentration techniques included hand-sortingC B Gill, ''Non-ferrous Extractive Metallurgy'' (John Wiley & Sons, New York, 1980) p. 32 and gravity concentration. These resulted in high losses of copper. Consequently, the development of the froth flotation process was a major step forward in mineral processing. The modern froth flotation process was independently invented in the early 1900s in Australia by C.V Potter and around the same time by G. D. Delprat. It made the development of the giant Bingham Canyon mine in Utah possible.

In the twentieth century, most ores were concentrated before smelting. Smelting was initially undertaken using sinter plant

Sinter plants agglomerate iron ore

Iron ores are rocks and minerals from which metallic iron can be economically extracted. The ores are usually rich in iron oxides and vary in color from dark grey, bright yellow, or deep purple to rusty r ...

s and blast furnaces

A blast furnace is a type of metallurgical furnace used for smelting to produce industrial metals, generally pig iron, but also others such as lead or copper. ''Blast'' refers to the combustion air being supplied above atmospheric pressure.

In a ...

, or with roasters and reverberatory furnace

A reverberatory furnace is a metallurgy, metallurgical or process Metallurgical furnace, furnace that isolates the material being processed from contact with the fuel, but not from contact with combustion gases. The term ''reverberation'' is use ...

s. Roasting and reverberatory furnace smelting dominated primary copper production until the 1960s.

Late 20th century trends

In the 1960s and 1970s large copper mining operations by U.S. companies were nationalized in many of the main copper producing countries. Thus by the 1980s state owned enterprises overtook the dominant role U.S. companies like Anaconda Copper and Kennecott had had until then. In the late 1970s and early 1980s various oil companies like ARCO, Exxon ( Exxon Minerals) andStandard Oil Company

Standard Oil Company was a corporate trust in the petroleum industry that existed from 1882 to 1911. The origins of the trust lay in the operations of the Standard Oil Company (Ohio), which had been founded in 1870 by John D. Rockefeller. The ...

expanded into copper mining for a few years before selling their copper assets. Reportedly gains were not as high as anticipated. Investments in copper mining concentrated in Chile in the 1980s and 1990s given that copper mining in other countries faced problems like political instability (Peru

Peru, officially the Republic of Peru, is a country in western South America. It is bordered in the north by Ecuador and Colombia, in the east by Brazil, in the southeast by Bolivia, in the south by Chile, and in the south and west by the Pac ...

), increased environmental requirements (developed countries) or overall disinterest in foreign investment in a nationalized mining industry (Zaire

Zaire, officially the Republic of Zaire, was the name of the Democratic Republic of the Congo from 1971 to 18 May 1997. Located in Central Africa, it was, by area, the third-largest country in Africa after Sudan and Algeria, and the 11th-la ...

, Zambia

Zambia, officially the Republic of Zambia, is a landlocked country at the crossroads of Central Africa, Central, Southern Africa, Southern and East Africa. It is typically referred to being in South-Central Africa or Southern Africa. It is bor ...

).

21st century

In the 2013-2023 period the copper smelting capacity in China and Zambia have increased while the capacity in Chile and the United States have decreased. China has by far the largest capacity for copper smelting with over half of the world's total. Besides the previously mentioned countries other countries where there is a significant installed cathode production capacity of the world's total as of 2023 are Japan (8%), Russia (5%), Poland (3-4%) and Bulgaria (3-4%). Since the 1990s no new copper smelter have been built in Chile. Following the 2022 closure of Fundición Ventanas in central Chile there have been a public discussion on building a new large copper smelter in Chile.Antofagasta Region

The Antofagasta Region (, ) is one of Chile's Administrative divisions of Chile, sixteen first-order administrative divisions. Being the second-largest region of Chile in area, it comprises three provinces, Antofagasta Province, Antofagasta, El ...

or Atacama Region has been proposed by Chilean industry scholars as viable replacements. Others have argued for keeping smelting in Valparaíso Region given the existence of nearby mines. While some argue the replacement plant should be near the coast, inland Chuquicamata

Chuquicamata ( ; referred to as Chuqui for short) is the largest open-pit mining, open pit copper Mining, mine in terms of excavated volume in the world. It is located in the north of Chile, just outside Calama, Chile, Calama, at above sea level. ...

and El Salvador

El Salvador, officially the Republic of El Salvador, is a country in Central America. It is bordered on the northeast by Honduras, on the northwest by Guatemala, and on the south by the Pacific Ocean. El Salvador's capital and largest city is S ...

have also been proposed as alternatives. The president of the National Mining Society (Sonami), Diego Hernández, estimates the construction period for a new smelter plant to be 5 to 7 years. A 2024 study identified Antofagasta Region as the best place for a new copper smelter given logistical advantages and an existing and expandable supply of copper concentrate from nearby mines.

The Guixi Smelter in inland southeastern China is the world's largest copper smelter by capacity. In 2015 it had an annual production capacity of 900,000 tons of copper.

Concentration (beneficiation)

lang=en, upright=1.35, The decreasing concentration of copper in ores now requires pre-treatment of ores., link=File:Evolution_minerai_cuivre.svg The average grade of copper ores in the 21st century is below 0.6% copper, with a proportion of economic ore minerals being less than 2% of the total volume of the ore rock. Thus, all mining operations, theore

Ore is natural rock or sediment that contains one or more valuable minerals, typically including metals, concentrated above background levels, and that is economically viable to mine and process. The grade of ore refers to the concentration ...

must usually be beneficiated (concentrated). The concentrate is typically sold to distant smelters, although some large mines have smelters located nearby. Such colocation of mines and smelters was more typical in the 19th and early 20th centuries, when smaller smelters could be economic. The subsequent processing techniques depend on the nature of the ore.

In the usual case when it is primarily sulfide copper minerals (such as chalcopyrite

Chalcopyrite ( ) is a copper iron sulfide mineral and the most abundant copper ore mineral. It has the chemical formula CuFeS2 and crystallizes in the tetragonal system. It has a brassy to golden yellow color and a Mohs scale, hardness of 3.5 to 4 ...

, FeCuS2), the ore is treated by '' comminution'', where the rock is crushed to produce small particles (<100 μm) consisting of individual mineral phases. These particles are then ready to be separated to remove gangue

Gangue () is the commercially worthless material that surrounds, or is closely mixed with, a wanted mineral in an ore deposit. It is thus distinct from overburden, which is the waste rock or materials overlying an ore or mineral body that are di ...

(silicate rocks residues) using froth flotation.

Froth flotation

In froth flotation, the crushed ore is wetted, suspended in a slurry, and mixed with reagents that render the sulfide particles

In froth flotation, the crushed ore is wetted, suspended in a slurry, and mixed with reagents that render the sulfide particles hydrophobic

In chemistry, hydrophobicity is the chemical property of a molecule (called a hydrophobe) that is seemingly repelled from a mass of water. In contrast, hydrophiles are attracted to water.

Hydrophobic molecules tend to be nonpolar and, thu ...

. Typical reagents ("collectors") include potassium ethylxanthate and sodium ethylxanthate, but dithiophosphates and dithiocarbamates are also used. The slurry is introduced to a water-filled aeration tank containing a surfactant

Surfactants are chemical compounds that decrease the surface tension or interfacial tension between two liquids, a liquid and a gas, or a liquid and a solid. The word ''surfactant'' is a Blend word, blend of "surface-active agent",

coined in ...

such as methylisobutyl carbinol (MIBC). Air is constantly forced through the slurry. The air bubbles attach to the hydrophobic copper sulfide particles, which are conveyed to the surface where the froth is skimmed off. These skimmings are generally subjected to a cleaner-scavenger cell to remove excess silicates and to remove other sulfide minerals that can deleteriously impact the concentrate quality (typically, galena

Galena, also called lead glance, is the natural mineral form of lead(II) sulfide (PbS). It is the most important ore of lead and an important source of silver.

Galena is one of the most abundant and widely distributed sulfide minerals. It crysta ...

), and the final concentrate is sent for smelting. The rock that has not floated off in the flotation cell is either discarded as tailings

In mining, tailings or tails are the materials left over after the process of separating the valuable fraction from the uneconomic fraction (gangue) of an ore. Tailings are different from overburden, which is the waste rock or other material ...

or further processed to extract other metals such as lead (from galena) and zinc (from sphalerite

Sphalerite is a sulfide mineral with the chemical formula . It is the most important ore of zinc. Sphalerite is found in a variety of deposit types, but it is primarily in Sedimentary exhalative deposits, sedimentary exhalative, Carbonate-hoste ...

), should they exist. A variety of measures are taken to improve the efficiency of the froth flotation. Lime is used to raise the pH of the water bath, causing the collector to bond more efficiently to the copper sulfides. The process can produce concentrates with 27–29% and 37–40% copper contents from chalcopyrite

Chalcopyrite ( ) is a copper iron sulfide mineral and the most abundant copper ore mineral. It has the chemical formula CuFeS2 and crystallizes in the tetragonal system. It has a brassy to golden yellow color and a Mohs scale, hardness of 3.5 to 4 ...

and chalcocite, respectively.

Hydrometallurgy

Oxidised copper ores include carbonates such asazurite

Azurite or '' Azure spar'Krivovichev V. G.'' Mineralogical glossary. Scientific editor A. G. Bulakh. — St.Petersburg: St.Petersburg Univ. Publ. House. 2009. — 556 p. — ISBN 978-5-288-04863-0. ''(in Russian)'' is a soft, deep-blue copp ...

and malachite

Malachite () is a copper Carbonate mineral, carbonate hydroxide mineral, with the chemical formula, formula Basic copper carbonate, Cu2CO3(OH)2. This opaque, green-banded mineral crystallizes in the monoclinic crystal system, and most often for ...

, the silicate chrysocolla, and sulfates such as atacamite. In some cases, sulfide ores are allowed to degrade to oxides. Such ores are amenable to hydrometallurgy. Specifically, such oxide ores are usually extracted into aqueous sulfuric acid

Sulfuric acid (American spelling and the preferred IUPAC name) or sulphuric acid (English in the Commonwealth of Nations, Commonwealth spelling), known in antiquity as oil of vitriol, is a mineral acid composed of the elements sulfur, oxygen, ...

, usually in a heap leaching or dump leaching. The resulting pregnant leach solution is purified by solvent extraction (SX). It is treated with an organic solvent and an organic chelators. The chelators bind the copper ions (and no other ions, ideally), the resulting complexes dissolve in the organic phase. This organic solvent is evaporated, leaving a residue of the copper complexes. The copper ions are liberated from the residue with sulfuric acid. The barred (denuded) sulfuric acid recycled back on to the heaps. The organic ligands are recovered and recycled as well. Alternatively, the copper can be precipitated out of the pregnant solution by contacting it with scrap iron; a process called cementation. Cement copper is normally less pure than SX-EW copper.

Specialized ores

Secondary sulfides—those formed by supergene secondary enrichment—are resistant (''

Secondary sulfides—those formed by supergene secondary enrichment—are resistant (''refractory

In materials science, a refractory (or refractory material) is a material that is resistant to decomposition by heat or chemical attack and that retains its strength and rigidity at high temperatures. They are inorganic, non-metallic compound ...

'') to sulfuric leaching. Secondary copper sulfides are dominated by the mineral chalcocite; a mineral formed from primary sulfides, like chalcopyrite

Chalcopyrite ( ) is a copper iron sulfide mineral and the most abundant copper ore mineral. It has the chemical formula CuFeS2 and crystallizes in the tetragonal system. It has a brassy to golden yellow color and a Mohs scale, hardness of 3.5 to 4 ...

, that undergo chemical processes such as oxidation or reduction. Typically, secondary sulfide ores are concentrated using froth flotation. Other extraction processes like leaching are effectively used for the extraction of secondary copper sulfides, but as demand for copper rises, extraction processes tailored for low-grade ores are required, due to the depletion of copper resources. Processes including in situ, dump, and heap leaching are cost-effective methods that are suitable for extracting copper from low-grade ores.

Extraction processes for secondary copper sulfides and low-grade ores includes the process of heap bioleaching. Heap bioleaching presents a cost efficient extraction method that requires a less intensive energy input resulting in a higher profit. This extraction process can be applied to large quantities of low-grade ores, at a lower capital cost with minimal environmental impact.

Generally, direct froth flotation is not used to concentrate copper oxide ores, as a result of the largely ionic and hydrophilic structure of the copper oxide mineral surface. Copper oxide ores are typically treated via chelating-reagent flotation and fatty-acid flotation, which use organic reagents to ensure adsorption onto the mineral surface through the formation of hydrophobic compounds on the mineral surface.

Some supergene sulfide deposits can be leached using a bacterial oxidation heap leach process to oxidize the sulfides to sulfuric acid, which also allows for simultaneous leaching with sulfuric acid to produce a copper sulfate Copper sulfate may refer to:

* Copper(II) sulfate, CuSO4, a common, greenish blue compound used as a fungicide and herbicide

* Copper(I) sulfate, Cu2SO4, an unstable white solid which is uncommonly used

{{chemistry index

Copper compounds ...

solution. For oxide ores, solvent extraction and electrowinning technologies are used to recover the copper from the pregnant leach solution. To ensure the best recovery of copper, it is important to acknowledge the effect copper dissolution, acid consumption, and gangue mineral composition has on the efficacy of extraction.

Supergene sulfide ores rich in native copper are refractory to treatment with sulfuric acid leaching on all practicable time scales, and the dense metal particles do not react with froth flotation media. Typically, if native copper is a minor part of a supergene profile it will not be recovered and will report to the tailings

In mining, tailings or tails are the materials left over after the process of separating the valuable fraction from the uneconomic fraction (gangue) of an ore. Tailings are different from overburden, which is the waste rock or other material ...

. When rich enough, native copper ore bodies may be treated to recover the contained copper by gravity separation. Often, the nature of the gangue is important, as clay-rich native copper ores prove difficult to liberate. This is because clay minerals interact with flotation reagents used in extraction processes, that are then consumed, which results in minimal recovery of a high grade copper concentrate.

Roasting

The roasting process is generally undertaken in combination withreverberatory furnace

A reverberatory furnace is a metallurgy, metallurgical or process Metallurgical furnace, furnace that isolates the material being processed from contact with the fuel, but not from contact with combustion gases. The term ''reverberation'' is use ...

s. In the roaster, the copper concentrate is partially oxidised to produce " calcine". Sulfur dioxide

Sulfur dioxide (IUPAC-recommended spelling) or sulphur dioxide (traditional Commonwealth English) is the chemical compound with the formula . It is a colorless gas with a pungent smell that is responsible for the odor of burnt matches. It is r ...

is liberated. The stoichiometry

Stoichiometry () is the relationships between the masses of reactants and Product (chemistry), products before, during, and following chemical reactions.

Stoichiometry is based on the law of conservation of mass; the total mass of reactants must ...

of the reaction is:

:

Roasting generally leaves more sulfur in the calcined product (15% in the case of the roaster at Mount Isa Mines

Mount Isa Mines Limited ("MIM") operates the Mount Isa copper, lead, zinc and silver mines near Mount Isa, Queensland, Australia as part of the Glencore group of companies. For a brief period in 1980, MIM was Australia's largest company. It has ...

) than a sinter plant leaves in the sintered product (about 7% in the case of the Electrolytic Refining and Smelting smelter).

As of 2005, roasting is no longer common in copper concentrate treatment because its combination with reverberatory furnaces is not energy efficient and the SO2 concentration in the roaster offgas is too dilute for cost-effective capture. Direct smelting is now favored, and uses the following smelting technologies: flash smelting, Isasmelt, Noranda, Mitsubishi or El Teniente furnaces.

Smelting

upright=1.3, Replacement of reverberatory furnace smelting by flash smelting, related to the number of copper smelters using this technology. , link=File:Evolution_copper_smelting.svg The initial melting of the material to be smelted is usually referred to as the ''

The initial melting of the material to be smelted is usually referred to as the ''smelting

Smelting is a process of applying heat and a chemical reducing agent to an ore to extract a desired base metal product. It is a form of extractive metallurgy that is used to obtain many metals such as iron-making, iron, copper extraction, copper ...

'' or ''matte smelting'' stage. It can be undertaken in a variety of furnaces, including the largely obsolete blast furnaces

A blast furnace is a type of metallurgical furnace used for smelting to produce industrial metals, generally pig iron, but also others such as lead or copper. ''Blast'' refers to the combustion air being supplied above atmospheric pressure.

In a ...

and reverberatory furnace

A reverberatory furnace is a metallurgy, metallurgical or process Metallurgical furnace, furnace that isolates the material being processed from contact with the fuel, but not from contact with combustion gases. The term ''reverberation'' is use ...

s, as well as flash furnaces, Isasmelt furnaces, etc. The product of this smelting stage is a mixture of copper, iron and sulfur that is enriched in copper, which is called '' matte'' or ''copper matte''. The term ''matte grade'' is normally used to refer to the copper content of the matte.W G Davenport, M King, M Schlesinger and A K Biswas, ''Extractive Metallurgy of Copper, Fourth Edition'' (Elsevier Science Limited: Kidlington, Oxford, England, 2002), pp. 57–72.

The purpose of the matte smelting stage is to eliminate as much of the unwanted iron, sulfur and ''gangue'' minerals (such as silica, magnesia, alumina and limestone) as possible, while minimizing the loss of copper. This is achieved by reacting iron sulfides with oxygen (in air or oxygen enriched air) to produce iron oxides (mainly as FeO, but with some magnetite

Magnetite is a mineral and one of the main iron ores, with the chemical formula . It is one of the iron oxide, oxides of iron, and is ferrimagnetism, ferrimagnetic; it is attracted to a magnet and can be magnetization, magnetized to become a ...

(Fe3O4)) and sulfur dioxide

Sulfur dioxide (IUPAC-recommended spelling) or sulphur dioxide (traditional Commonwealth English) is the chemical compound with the formula . It is a colorless gas with a pungent smell that is responsible for the odor of burnt matches. It is r ...

.

Copper sulfide and iron oxide can mix, but when sufficient silica is added, a separate slag

The general term slag may be a by-product or co-product of smelting (pyrometallurgical) ores and recycled metals depending on the type of material being produced. Slag is mainly a mixture of metal oxides and silicon dioxide. Broadly, it can be c ...

layer is formed.P C Hayes, ''Process Principles in Minerals and Materials Production'' (Hayes Publishing Company: Brisbane, 1993), pp. 173–179. Adding silica also reduces the melting point (or, more properly, the liquidus temperature) of the slag, meaning that the smelting process can be operated at a lower temperature.

The slag forming reaction is:

:FeO + SiO2 → FeO.SiO2

Slag is less dense than matte, so it forms a layer that floats on top of the matte.

Copper can be lost from the matte in three ways: as cuprous oxide (Cu2O) dissolved in the slag, as sulfide copper dissolved in the slag or as tiny droplets (or '' prills'') of matte suspended in the slag.B J Elliott, J B See, and W J Rankin, "Effect of slag composition on copper losses to silica-saturated iron silicate slags," ''Transactions of the Institution of Mining and Metallurgy (Section C: Mineral Processing and Extractive Metallurgy),'' September 1978, C–C211.

The amount of copper lost as oxide copper increases as the oxygen potential of the slag increases. The oxygen potential generally increases as the copper content of the matte is increased. Thus, the loss of copper as oxide increases as the copper content of the matte increases.

On the other hand, the solubility of sulfidic copper in slag decreases as the copper content of the matte increases beyond about 40%. Nagamori calculated that more than half the copper dissolved in slags from mattes containing less than 50% copper is sulfidic copper. Above this figure, oxidic copper begins to dominate.

The loss of copper as prills suspended in the slag depends on the size of the prills, the viscosity of the slag and the settling time available. Rosenqvist suggested that about half the copper losses to slag were due to suspended prills.T Rosenqvist (2004) ''Principles of Extractive Metallurgy, Second Edition'', Tapir Academic Press: Trondheim, p. 331, .

The mass of slag generated in the smelting stage depends on the iron content of the material fed into the smelting furnace and the target matte grade. The greater the iron content of the feed, the more iron that will need to be rejected to the slag for a given matte grade. Similarly, increasing the target matte grade requires the rejection of more iron and an increase in the slag volume.

Thus, the two factors that most affect the loss of copper to slag in the smelting stage are:

* matte grade

* mass of slag.

This means that there is a practical limit on how high the matte grade can be if the loss of copper to slag is to be minimized. Therefore, further stages of processing (converting and fire refining) are required.

The following subsections briefly describe some of the processes used in matte smelting.

Reverberatory furnace smelting

Reverberatory furnaces are long furnaces that can treat wet, dry, or roasted concentrate. Most of the reverberatory furnaces used in the latter years treated roasted concentrate because putting dry feed materials into the reverberatory furnace is more energy efficient, and because the elimination of some of the sulfur in the roaster results in higher matte grades. The reverberatory furnace feed is added to the furnace through feed holes along the sides of the furnace, and the solid charge is melted. Additional silica is normally added to help form the slag. The furnace is fired with burners using pulverized coal, fuel oil or natural gas.C B Gill, ''Non-ferrous Extractive Metallurgy'' (John Wiley & Sons, New York, 1980) pp. 29–35 Reverberatory furnaces can additionally be fed with molten slag from the later converting stage to recover the contained copper and other materials with a high copper content. Because the reverberatory furnace bath is quiescent, very little oxidation of the feed occurs (and thus very little sulfur is eliminated from the concentrate). It is essentially a melting process. Consequently, wet-charged reverberatory furnaces have less copper in their matte product than calcine-charged furnaces, and they also have lower copper losses to slag. Gill quotes a copper in slag value of 0.23% for a wet-charged reverberatory furnace vs 0.37% for a calcine-charged furnace. In the case of calcine-charged furnaces, a significant portion of the sulfur has been eliminated during the roasting stage, and the calcine consists of a mixture of copper and iron oxides and sulfides. The reverberatory furnace acts to allow these species to approach chemical equilibrium at the furnaceoperating temperature

An operating temperature is the allowable temperature range of the local ambient environment at which an electrical or mechanical device operates. The device will operate effectively within a specified temperature range which varies based on the de ...

(approximately 1600 °C at the burner end of the furnace and about 1200 °C at the flue end; the matte is about 1100 °C and the slag is about 1195 °C). In this equilibration process, oxygen associated with copper compounds exchanges with sulfur associated with iron compounds, increasing the iron oxide content of the furnace, and the iron oxides interact with silica and other oxide materials to form the slag.

The main equilibration reaction is:

:Cu2O + FeS → Cu2S + FeO

The slag and the matte form distinct layers that can be removed from the furnace as separate streams. The slag layer is periodically allowed to flow through a hole in the wall of the furnace above the height of the matte layer. The matte is removed by draining it through a hole into ladles for it to be carried by crane to the converters. This draining process is known as ''tapping'' the furnace. The matte taphole is normally a hole through a water-cooled copper block that prevents erosion of the refractory bricks lining the furnace. When the removal of the matte or slag is complete, the hole is normally plugged with clay, which is removed when the furnace is ready to be tapped again.

Reverberatory furnaces were often used to treat molten converter slag to recover contained copper. This would be poured into the furnaces from ladles carried by cranes. However, the converter slag is high in magnetiteG E Casley, J Middlin and D White, "Recent developments in reverberatory furnace and converter practice at the Mount Isa Mines copper smelter," in: ''Extractive Metallurgy of Copper, Volume 1,'' (The Metallurgical Society: Warrendale, Pennsylvania, 1976), pp. 117–138. and some of this magnetite would precipitate from the converter slag (due to its higher melting point), forming an accretion on the hearth of the reverberatory furnace and necessitating shut downs of the furnace to remove the accretion. This accretion formation limits the quantity of converter slag that can be treated in a reverberatory furnace.

While reverberatory furnaces have very low copper losses to slag, they are not very energy-efficient and the low concentrations of sulfur dioxide in their off-gases make its capture uneconomic. Consequently, smelter operators devoted a lot of money in the 1970s and 1980s to developing new, more efficient copper smelting processes.P J Mackey and P Tarassoff, "New and emerging technologies in sulphide icsmelting," in: ''Advances in Sulfide Smelting Volume 2: Technology and Practice'', Eds H Y Sohn, D B George and A D Zunkel (The Metallurgical Society of the American Institute of Mining, Metallurgical and Petroleum Engineers: Warrendale, Pennsylvania, 1983), pp. 399–426. In addition, flash smelting technologies had been developed in earlier years and began to replace reverberatory furnaces. By 2002, 20 of the 30 reverberatory furnaces still operating in 1994 had been shut down.

Flash furnace smelting

In flash smelting, the concentrate is dispersed in an air or oxygen stream and the smelting reactions are largely completed while the mineral particles are still in flight. The reacted particles then settle in a bath at the bottom of the furnace, where they behave like calcine in a reverberatory furnace.W G Davenport, M King, M Schlesinger and A K Biswas, ''Extractive Metallurgy of Copper, Fourth Edition'' (Elsevier Science Limited: Kidlington, Oxford, England, 2002), pp. 73–102. A slag layer forms on top of the matte layer, and they can separately be tapped from the furnace.ISASMELT

Converting

The matte, which is produced in the smelter, contains 30–70% copper (depending on the process used and the operating philosophy of the smelter), primarily as copper sulfide, as well as iron sulfide. The sulfur is removed at a high temperature as sulfur dioxide by blowing air through molten matte:

:2 CuS + 3 O2 → 2 CuO + 2 SO2

:CuS + O2 → Cu + SO2

In a parallel reaction the iron sulfide is converted to slag:

:2 FeS + 3 O2 → 2 FeO + 2 SO2

:2 FeO + SiO2 → Fe2SiO4

The purity of this product is 98%, it is known as ''blister'' because of the broken surface created by the escape of sulfur dioxide gas as blister copper ''pigs'' or

The matte, which is produced in the smelter, contains 30–70% copper (depending on the process used and the operating philosophy of the smelter), primarily as copper sulfide, as well as iron sulfide. The sulfur is removed at a high temperature as sulfur dioxide by blowing air through molten matte:

:2 CuS + 3 O2 → 2 CuO + 2 SO2

:CuS + O2 → Cu + SO2

In a parallel reaction the iron sulfide is converted to slag:

:2 FeS + 3 O2 → 2 FeO + 2 SO2

:2 FeO + SiO2 → Fe2SiO4

The purity of this product is 98%, it is known as ''blister'' because of the broken surface created by the escape of sulfur dioxide gas as blister copper ''pigs'' or ingot

An ingot is a piece of relatively pure material, usually metal, that is Casting, cast into a shape suitable for further processing. In steelmaking, it is the first step among semi-finished casting products. Ingots usually require a second procedu ...

s are cooled. By-products generated in the process are sulfur dioxide and slag

The general term slag may be a by-product or co-product of smelting (pyrometallurgical) ores and recycled metals depending on the type of material being produced. Slag is mainly a mixture of metal oxides and silicon dioxide. Broadly, it can be c ...

. The sulfur dioxide is captured and converted to sulfuric acid and either sold on the open market or used in copper leaching processes.

Refining

Fire refining

The blister copper is put into an anode furnace, a furnace that refines the blister copper to anode-grade copper in two stages by removing most of the remaining sulfur and iron, and then removing oxygen introduced during the first stage. This second stage, often referred to as '' poling'' is done by blowing

The blister copper is put into an anode furnace, a furnace that refines the blister copper to anode-grade copper in two stages by removing most of the remaining sulfur and iron, and then removing oxygen introduced during the first stage. This second stage, often referred to as '' poling'' is done by blowing natural gas

Natural gas (also fossil gas, methane gas, and gas) is a naturally occurring compound of gaseous hydrocarbons, primarily methane (95%), small amounts of higher alkanes, and traces of carbon dioxide and nitrogen, hydrogen sulfide and helium ...

, or some other reducing agent, through the molten copper oxide. When this flame burns green, indicating the copper oxidation spectrum, the oxygen has mostly been burned off. This creates copper at about 99% pure.

Electrolysis

The final stage in the production of copper is refining. Refining is achieved by

The final stage in the production of copper is refining. Refining is achieved by electrolysis

In chemistry and manufacturing, electrolysis is a technique that uses Direct current, direct electric current (DC) to drive an otherwise non-spontaneous chemical reaction. Electrolysis is commercially important as a stage in the separation of c ...

, which exploits the easy (low potential) and selective conversion of copper(II) solutions to the metal. The anodes cast from processed blister copper are placed into an aqueous

An aqueous solution is a solution in which the solvent is water. It is mostly shown in chemical equations by appending (aq) to the relevant chemical formula. For example, a solution of table salt, also known as sodium chloride (NaCl), in wat ...

solution of 3–4% copper sulfate Copper sulfate may refer to:

* Copper(II) sulfate, CuSO4, a common, greenish blue compound used as a fungicide and herbicide

* Copper(I) sulfate, Cu2SO4, an unstable white solid which is uncommonly used

{{chemistry index

Copper compounds ...

and 10–16% sulfuric acid

Sulfuric acid (American spelling and the preferred IUPAC name) or sulphuric acid (English in the Commonwealth of Nations, Commonwealth spelling), known in antiquity as oil of vitriol, is a mineral acid composed of the elements sulfur, oxygen, ...

. Cathodes are thin rolled sheets of highly pure copper or, more commonly these days, reusable stainless steel starting sheets (as in the IsaKidd process).Robinson T. (2002). "Electrolytic refining." pp. 265–288 in: ''Extractive Metallurgy of Copper, Fourth Edition''. Eds Davenport W. G., King M., Schlesinger M., and Biswas A. K. (Elsevier Science Limited: Kidlington, Oxford, England). A potential of only 0.2–0.4 volts is required for the process to commence. In industrial plants current densities up to 420 A/m2 are possible.

At the anode

An anode usually is an electrode of a polarized electrical device through which conventional current enters the device. This contrasts with a cathode, which is usually an electrode of the device through which conventional current leaves the devic ...

(oxidation

Redox ( , , reduction–oxidation or oxidation–reduction) is a type of chemical reaction in which the oxidation states of the reactants change. Oxidation is the loss of electrons or an increase in the oxidation state, while reduction is ...

reaction), copper and less noble metals dissolve. More noble metals and less soluble

In chemistry, solubility is the ability of a substance, the solute, to form a solution with another substance, the solvent. Insolubility is the opposite property, the inability of the solute to form such a solution.

The extent of the solubi ...

elements such as silver

Silver is a chemical element; it has Symbol (chemistry), symbol Ag () and atomic number 47. A soft, whitish-gray, lustrous transition metal, it exhibits the highest electrical conductivity, thermal conductivity, and reflectivity of any metal. ...

, gold

Gold is a chemical element; it has chemical symbol Au (from Latin ) and atomic number 79. In its pure form, it is a brightness, bright, slightly orange-yellow, dense, soft, malleable, and ductile metal. Chemically, gold is a transition metal ...

, selenium

Selenium is a chemical element; it has symbol (chemistry), symbol Se and atomic number 34. It has various physical appearances, including a brick-red powder, a vitreous black solid, and a grey metallic-looking form. It seldom occurs in this elem ...

, and tellurium

Tellurium is a chemical element; it has symbol Te and atomic number 52. It is a brittle, mildly toxic, rare, silver-white metalloid. Tellurium is chemically related to selenium and sulfur, all three of which are chalcogens. It is occasionally fou ...

settle to the bottom of the cell as anode slime, which forms a salable by-product. Copper(II) ions migrate through the electrolyte

An electrolyte is a substance that conducts electricity through the movement of ions, but not through the movement of electrons. This includes most soluble Salt (chemistry), salts, acids, and Base (chemistry), bases, dissolved in a polar solven ...

to the cathode. At the cathode

A cathode is the electrode from which a conventional current leaves a polarized electrical device such as a lead-acid battery. This definition can be recalled by using the mnemonic ''CCD'' for ''Cathode Current Departs''. Conventional curren ...

( reduction reaction), ions are reduced in copper metal and Cu(s) plates out, but less noble constituents such as arsenic

Arsenic is a chemical element; it has Symbol (chemistry), symbol As and atomic number 33. It is a metalloid and one of the pnictogens, and therefore shares many properties with its group 15 neighbors phosphorus and antimony. Arsenic is not ...

and zinc

Zinc is a chemical element; it has symbol Zn and atomic number 30. It is a slightly brittle metal at room temperature and has a shiny-greyish appearance when oxidation is removed. It is the first element in group 12 (IIB) of the periodic tabl ...

remain in solution unless a higher voltage is used.Samans, Carl H. (1949). ''Engineering Metals and their Alloys''. MacMillan.

The reactions involving metallic copper and ions at the electrodes are the following:

:

Concentrate and copper marketing

Copper concentrates produced by mines are sold to smelters and refiners who treat the ore and refine the copper and charge for this service via treatment charges (TCs) and refining charges (RCs). The TCs are charged in US$ per tonne of concentrate treated and RCs are charged in cents per pound treated, denominated in US dollars, with benchmark prices set annually by major Japanese smelters. The customer in this case can be a smelter, who on-sells blister copper ingots to a refiner, or a smelter-refiner which is vertically integrated. One prevalent form of copper concentrate contains gold and silver, like the one produced by Bougainville Copper Limited from the Panguna mine from the early 1970s to the late 1980s. The typical contract for a miner is denominated against the London Metal Exchange price, minus the TC-RCs and any applicable penalties or credits. Penalties may be assessed against copper concentrates according to the level of deleterious elements such asarsenic

Arsenic is a chemical element; it has Symbol (chemistry), symbol As and atomic number 33. It is a metalloid and one of the pnictogens, and therefore shares many properties with its group 15 neighbors phosphorus and antimony. Arsenic is not ...

, bismuth

Bismuth is a chemical element; it has symbol Bi and atomic number 83. It is a post-transition metal and one of the pnictogens, with chemical properties resembling its lighter group 15 siblings arsenic and antimony. Elemental bismuth occurs nat ...

, lead

Lead () is a chemical element; it has Chemical symbol, symbol Pb (from Latin ) and atomic number 82. It is a Heavy metal (elements), heavy metal that is density, denser than most common materials. Lead is Mohs scale, soft and Ductility, malleabl ...

or tungsten

Tungsten (also called wolfram) is a chemical element; it has symbol W and atomic number 74. It is a metal found naturally on Earth almost exclusively in compounds with other elements. It was identified as a distinct element in 1781 and first ...

. Because a large portion of copper sulfide ore bodies contain silver

Silver is a chemical element; it has Symbol (chemistry), symbol Ag () and atomic number 47. A soft, whitish-gray, lustrous transition metal, it exhibits the highest electrical conductivity, thermal conductivity, and reflectivity of any metal. ...

or gold

Gold is a chemical element; it has chemical symbol Au (from Latin ) and atomic number 79. In its pure form, it is a brightness, bright, slightly orange-yellow, dense, soft, malleable, and ductile metal. Chemically, gold is a transition metal ...

in appreciable amounts, a credit can be paid to the miner for these metals if their concentration ''within the concentrate'' is above a certain amount. Usually the refiner or smelter charges the miner a fee based on the concentration; a typical contract will specify that a credit is due for every ounce of the metal in the concentrate above a certain concentration; below that, if it is recovered, the smelter will keep the metal and sell it to defray costs.

Copper concentrate is traded either via spot contract

In finance, a spot contract, spot transaction, or simply spot, is a contract of buying or selling a commodity, security or currency for immediate settlement (payment and delivery) on the spot date, which is normally two business days after th ...

s or under long term contracts as an intermediate product in its own right. Often the smelter sells the copper metal itself on behalf of the miner. The miner is paid the price at the time that the smelter-refiner makes the sale, not at the price on the date of delivery of the concentrate. Under a Quotational Pricing system, the price is agreed to be at a fixed date in the future, typically 90 days from time of delivery to the smelter.

A-grade copper cathode is of 99.99% copper in sheets that are approximately 1 meter square; thickness and weight depend on manufacturer. Typical 1 cm thick sheet weighs approximately 200 pounds (about 90 kg). It is a true commodity

In economics, a commodity is an economic goods, good, usually a resource, that specifically has full or substantial fungibility: that is, the Market (economics), market treats instances of the good as equivalent or nearly so with no regard to w ...

, deliverable to and tradeable upon the metal exchanges in New York City

New York, often called New York City (NYC), is the most populous city in the United States, located at the southern tip of New York State on one of the world's largest natural harbors. The city comprises five boroughs, each coextensive w ...

(COMEX), London

London is the Capital city, capital and List of urban areas in the United Kingdom, largest city of both England and the United Kingdom, with a population of in . London metropolitan area, Its wider metropolitan area is the largest in Wester ...

(London Metals Exchange) and Shanghai

Shanghai, Shanghainese: , Standard Chinese pronunciation: is a direct-administered municipality and the most populous urban area in China. The city is located on the Chinese shoreline on the southern estuary of the Yangtze River, with the ...

(Shanghai Futures Exchange). Often copper cathode is traded upon the exchanges indirectly via warrants, options, or swap contracts such that the majority of copper is traded upon the LME/COMEX/SFE, but delivery is achieved directly, logistically moving the physical copper, and transferring the copper sheet from the physical warehouses themselves.

The chemical specification for electrolytic grade copper is ASTM B 115-00 (a standard that specifies the purity and maximum electrical resistivity

Electricity is the set of physical phenomena associated with the presence and motion of matter possessing an electric charge. Electricity is related to magnetism, both being part of the phenomenon of electromagnetism, as described by ...

of the product).

See also

* Biomining * :Copper minerals * Copper mining in the United States * Extractive metallurgy * In-situ leach * List of copper mines *List of countries by copper production

This is a list of countries by mined copper production.

1907

See also

*Copper mining in Chile

Chile is the world's largest producer of copper and has been so uninterruptedly since 1983. This activity provides a substantial part of the ...

* Metallurgy

Metallurgy is a domain of materials science and engineering that studies the physical and chemical behavior of metallic elements, their inter-metallic compounds, and their mixtures, which are known as alloys.

Metallurgy encompasses both the ...

* 2000s commodities boom

The 2000s commodities boom, commodities super cycle or China boom was the rise of many physical commodity prices (such as those of food, oil, metals, chemicals and fuels) during the early 21st century (2000–2014), following the Great Commoditie ...

* Hubbert peak theory

* List of copper alloys

Copper alloys are metal Alloy, alloys that have copper as their principal component. They have high resistance against corrosion. Of the large number of different types, the best known traditional types are bronze, where tin is a significant addi ...

* Mineral resource classification

There are several classification systems for the economic evaluation of mineral deposits worldwide. The most commonly used schemes base on the International Reporting Template, developed by the CRIRSCO – Committee for Mineral Reserves Internat ...

* Peak minerals

References

External links

Copper.org

* * * The Copper Development Association'

page.

from an online text on metals, Illinois Sustainable Technology Center,

University of Illinois

The University of Illinois Urbana-Champaign (UIUC, U of I, Illinois, or University of Illinois) is a public university, public land-grant university, land-grant research university in the Champaign–Urbana metropolitan area, Illinois, United ...

, archived in May 2017

National Pollutant Inventory – Copper and copper compounds fact sheet

* University of Pittsburgh School of Engineering Chemical and Petroleum Engineering Department

Froth Flotation

Lab notes.

Copper Mine

college course syllabus, emphasis on chemistry, last updated 2000

Bibliography

* * Gill, C. B. (1980) ''Nonferrous Extractive Metallurgy'', John Wiley and Sons: New York, * * {{Authority control Metallurgical processes Extraction SmeltingCopper

Copper is a chemical element; it has symbol Cu (from Latin ) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pinkish-orang ...