|

Nanofabrication

Nanolithography (NL) is a growing field of techniques within nanotechnology dealing with the engineering (patterning e.g. etching, depositing, writing, printing etc) of nanometer-scale structures on various materials. The modern term reflects on a design of structures built in range of 10−9 to 10−6 meters, i.e. nanometer scale. Essentially, the field is a derivative of lithography, only covering very small structures. All NL methods can be categorized into four groups: photo lithography, scanning lithography, soft lithography and other miscellaneous techniques. History Nanolithography has evolved from the need to increase the number of sub-micrometer features (e.g. transistors, capacitors etc.) in an integrated circuit in order to keep up with Moore's Law. While lithographic techniques have been around since the late 18th century, none were applied to nanoscale structures until the mid-1950s. With evolution of the semiconductor industry, demand for techniques capable of pr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electron-beam Lithography

Electron-beam lithography (often abbreviated as e-beam lithography or EBL) is the practice of scanning a focused beam of electrons to draw custom shapes on a surface covered with an electron-sensitive film called a resist (exposing). The electron beam changes the solubility of the resist, enabling selective removal of either the exposed or non-exposed regions of the resist by immersing it in a solvent (developing). The purpose, as with photolithography, is to create very small structures in the resist that can subsequently be transferred to the substrate material, often by Etching (microfabrication), etching. The primary advantage of electron-beam lithography is that it can draw custom patterns (direct-write) with sub-10 Nanometre, nm resolution. This form of maskless lithography has high resolution but low throughput, limiting its usage to photomask fabrication, low-volume production of Semiconductor device, semiconductor devices, and research and development. Systems Electr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Maskless Lithography

Maskless lithography (MPL) is a photomask-less photolithography-like technology used to project or focal-spot write the image pattern onto a chemical resist-coated substrate (e.g. wafer) by means of UV radiation or electron beam. In microlithography, typically UV radiation casts an image of a time constant mask onto a photosensitive emulsion (or photoresist). Traditionally, mask aligners, steppers, scanners, and other kinds of non-optical techniques are used for high speed microfabrication of microstructures, but in case of MPL, some of these become redundant. Maskless lithography has two approaches to project a pattern: rasterized and vectorized. In the first one it utilizes generation of a time-variant intermittent image on an electronically modifiable (virtual) mask that is projected with known means (also known as laser direct imaging and other synonyms). In the vectored approach, direct writing is achieved by radiation that is focused to a narrow beam that is scanned ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hydrogen Silsesquioxane

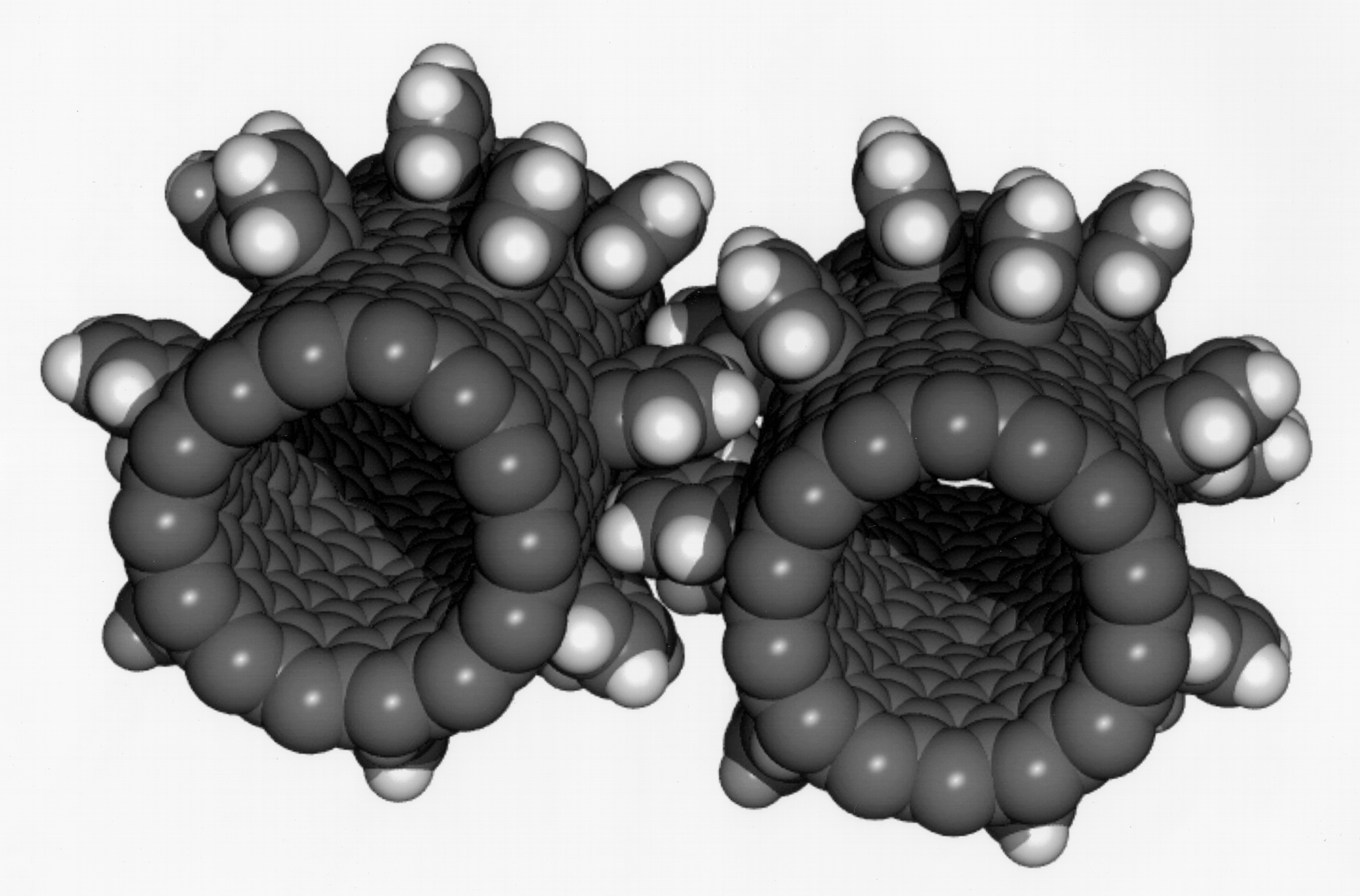

200px, thumbnail, Hydrogen silsesquioxane (R = H). Hydrogen silsesquioxane(s) (HSQ, H-SiOx, THn, H-resin) are inorganic compounds with the empirical formula SiO3/2sub>n. The cubic H8Si8O12 (TH8) is used as the visual representation for HSQ. TH8, TH10, TH12, and TH14 have been characterized by elemental analysis, gas chromatography–mass spectroscopy ( GC-MS), IR spectroscopy, and NMR spectroscopy. High purity semiconductor-grade HSQ has been investigated as a negative resist in photolithography and electron-beam (e-beam) lithography. HSQ is commonly delivered in methyl isobutyl ketone ( MIBK) and can be used to form 0.01–2 μm films on substrates/wafers. When exposed to electrons or extreme ultraviolet radiation (EUV), HSQ cross-links via hydrogen evolution concomitant with Si-O bond crosslinking. Recently, the possibility of crosslinking HSQ using ultrashort laser pulses through multiphoton absorption and its application to 3D printing of silica glass Fused quart ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Multiphoton Lithography

Multiphoton lithography (also known as direct laser lithography or direct laser writing) is similar to standard photolithography techniques; structuring is accomplished by illuminating negative-tone or positive-tone photoresists via light of a well-defined wavelength. The main difference is the avoidance of photomasks. Instead, two-photon absorption is utilized to induce a change in the solubility of the resist for appropriate developers. Hence, multiphoton lithography is a technique for creating small features in a photosensitive material, without the use of excimer lasers or photomasks. This method relies on a multi-photon absorption process in a material that is transparent at the wavelength of the laser used for creating the pattern. By scanning and properly modulating the laser, a chemical change (usually polymerization) occurs at the focal spot of the laser and can be controlled to create an arbitrary three-dimensional pattern. This method has been used for rapid prototyping o ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nanotechnology

Nanotechnology is the manipulation of matter with at least one dimension sized from 1 to 100 nanometers (nm). At this scale, commonly known as the nanoscale, surface area and quantum mechanical effects become important in describing properties of matter. This definition of nanotechnology includes all types of research and technologies that deal with these special properties. It is common to see the plural form "nanotechnologies" as well as "nanoscale technologies" to refer to research and applications whose common trait is scale. An earlier understanding of nanotechnology referred to the particular technological goal of precisely manipulating atoms and molecules for fabricating macroscale products, now referred to as molecular nanotechnology. Nanotechnology defined by scale includes fields of science such as surface science, organic chemistry, molecular biology, semiconductor physics, energy storage, engineering, microfabrication, and molecular engineering. The associated rese ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Next-generation Lithography

Next-generation lithography or NGL is a term used in integrated circuit manufacturing to describe the photolithography, lithography technologies in development which are intended to replace current techniques. Driven by Moore's law in the semiconductor industries, the shrinking of the chip size and critical dimension continues. The term applies to any lithography method which uses a shorter-wavelength light or beam type than the current state of the art, such as X-ray lithography, electron beam lithography, focused ion beam lithography, and nanoimprint lithography. The term may also be used to describe techniques which achieve finer resolution features from an existing light wavelength. Many technologies once termed "next generation" have entered commercial production, and open-air photolithography, with visible light projected through hand-drawn photomasks, has gradually progressed to deep-UV immersion lithography using optical proximity correction, inverse lithography technology ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dip-Pen Nanolithography

Dip pen nanolithography (DPN) is a scanning probe lithography technique where an atomic force microscope (AFM) tip is used to directly create patterns on a substrate. It can be done on a range of substances with a variety of inks. A common example of this technique is exemplified by the use of alkane thiolates to imprint onto a gold surface. This technique allows surface patterning on scales of under 100 nanometers. DPN is the nanotechnology analog of the dip pen (also called the quill pen), where the tip of an atomic force microscope cantilever acts as a "pen", which is coated with a chemical compound or mixture acting as an "ink", and put in contact with a substrate, the "paper". DPN enables direct deposition of nanoscale materials onto a substrate in a flexible manner. Recent advances have demonstrated massively parallel patterning using two-dimensional arrays of 55,000 tips. Applications of this technology currently range through chemistry, materials science, and t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Scanning Probe Microscopy

Scanning probe microscopy (SPM) is a branch of microscopy that forms images of surfaces using a physical probe that scans the specimen. SPM was founded in 1981, with the invention of the scanning tunneling microscope, an instrument for imaging surfaces at the atomic level. The first successful scanning tunneling microscope experiment was done by Gerd Binnig and Heinrich Rohrer. The key to their success was using a feedback loop to regulate gap distance between the sample and the probe. Many scanning probe microscopes can image several interactions simultaneously. The manner of using these interactions to obtain an image is generally called a mode. The resolution varies somewhat from technique to technique, but some probe techniques reach a rather impressive atomic resolution. This is largely because piezoelectricity, piezoelectric actuators can execute motions with a precision and accuracy at the atomic level or better on electronic command. This family of techniques can be cal ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Scanning Probe Lithography

Scanning probe lithography (SPL) describes a set of nanolithographic methods to pattern material on the nanoscale using scanning probes. It is a direct-write, mask-less approach which bypasses the diffraction limit and can reach resolutions below 10 nm. It is considered an alternative lithographic technology often used in academic and research environments. The term ''scanning probe lithography'' was coined after the first patterning experiments with scanning probe microscopes (SPM) in the late 1980s. Classification The different approaches towards SPL can be classified by their goal to either add or remove material, by the general nature of the process either chemical or physical, or according to the driving mechanisms of the probe-surface interaction used in the patterning process: mechanical, thermal, diffusive and electrical. Overview Mechanical/thermo-mechanical Mechanical scanning probe lithography (m-SPL) is a nanomachining or ''nano-scratching'' top-do ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sequential Infiltration Synthesis

Sequential infiltration synthesis (SIS) is a technique derived from atomic layer deposition (ALD) in which a polymer is infused with inorganic material using sequential, self-limiting exposures to gaseous precursors, enabling precise manipulation over the composition, structure, and properties. The technique has applications in fields such as nanotechnology, materials science, and electronics, where precise material engineering is required. This synthesis uses metal-organic vapor-phase precursors and co-reactants that dissolve and diffuse into polymers. These precursors interact with the functional groups of the polymers through reversible complex formation or irreversible chemical reactions, resulting in composite materials that can exhibit nano-structured properties. The metal-organic precursor (A) and co-reactant vapor (B) are supplied in an alternating ABAB sequence. Following SIS, the organic phase may be removed thermally or chemically to leave only the inorganic components ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Semiconductor Device

A semiconductor device is an electronic component that relies on the electronic properties of a semiconductor material (primarily silicon, germanium, and gallium arsenide, as well as organic semiconductors) for its function. Its conductivity lies between conductors and insulators. Semiconductor devices have replaced vacuum tubes in most applications. They conduct electric current in the solid state, rather than as free electrons across a vacuum (typically liberated by thermionic emission) or as free electrons and ions through an ionized gas. Semiconductor devices are manufactured both as single discrete devices and as integrated circuit (IC) chips, which consist of two or more devices—which can number from the hundreds to the billions—manufactured and interconnected on a single semiconductor wafer (also called a substrate). Semiconductor materials are useful because their behavior can be easily manipulated by the deliberate addition of impurities, known as dopin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Photomask

A photomask (also simply called a mask) is an opaque plate with transparent areas that allow light to shine through in a defined pattern. Photomasks are commonly used in photolithography for the production of integrated circuits (ICs or "chips") to produce a pattern on a thin wafer of material (usually silicon). In semiconductor manufacturing, a mask is sometimes called a reticle. In photolithography, several masks are used in turn, each one reproducing a layer of the completed design, and together known as a mask set. A curvilinear photomask has patterns with curves, which is a departure from conventional photomasks which only have patterns that are completely vertical or horizontal, known as manhattan geometry. These photomasks require special equipment to manufacture. History For IC production in the 1960s and early 1970s, an opaque rubylith film laminated onto a transparent mylar sheet was used. The design of one layer was cut into the rubylith, initially by hand on an i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |