|

Microstructures

Microstructure is the very small scale structure of a material, defined as the structure of a prepared surface of material as revealed by an optical microscope above 25× magnification. The microstructure of a material (such as Metallography, metals, polymers, Ceramography, ceramics or Composite material, composites) can strongly influence physical properties such as strength, toughness, ductility, hardness, corrosion resistance, high/low temperature behaviour or wear resistance. These properties in turn govern the application of these materials in industrial practice. Microstructure at scales smaller than can be viewed with optical microscopes is often called nanostructure, while the structure in which individual atoms are arranged is known as crystal structure. The nanostructure of biological specimens is referred to as ultrastructure. A microstructure's influence on the mechanical and physical properties of a material is primarily governed by the different defects present or ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

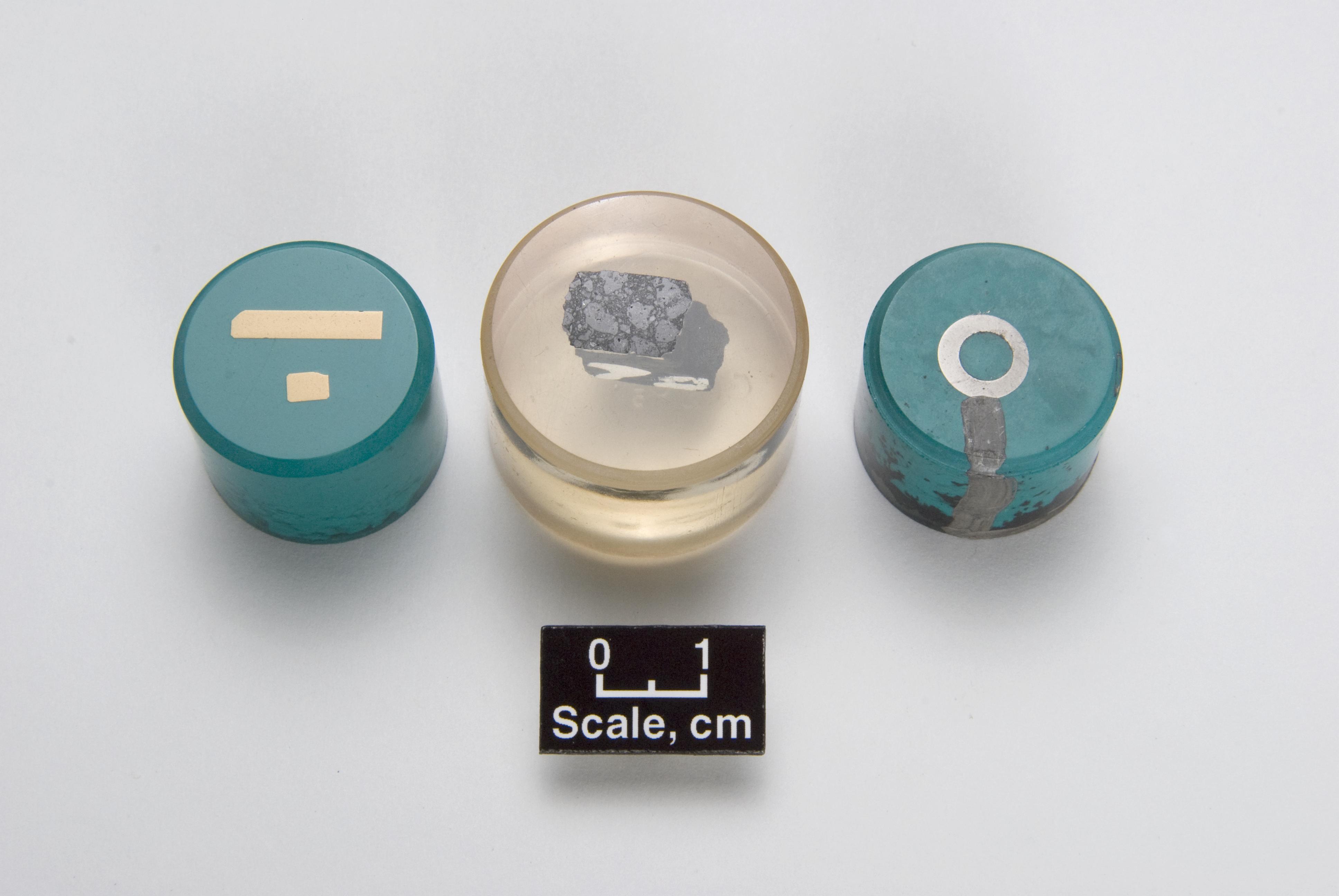

Ceramography

Ceramography is the art and science of preparation, examination and evaluation of ceramic microstructures. Ceramography can be thought of as the metallography of ceramics. The microstructure is the structure level of approximately 0.1 to 100 Micrometre, μm, between the minimum wavelength of Visible spectrum, visible light and the resolution limit of the naked eye. The microstructure includes most grains, secondary phases, Grain boundary, grain boundaries, pores, micro-cracks and hardness microindentations. Most bulk mechanical, optical, thermal, Electroceramics, electrical and magnetic properties are significantly affected by the microstructure. The fabrication method and process conditions are generally indicated by the microstructure. The root cause of many ceramic failures is evident in the microstructure. Ceramography is part of the broader field of materialography, which includes all the microscopic techniques of material analysis, such as metallography, petrography and plastog ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ceramic

A ceramic is any of the various hard, brittle, heat-resistant, and corrosion-resistant materials made by shaping and then firing an inorganic, nonmetallic material, such as clay, at a high temperature. Common examples are earthenware, porcelain, and brick. The earliest ceramics made by humans were fired clay bricks used for building house walls and other structures. Other pottery objects such as pots, vessels, vases and figurines were made from clay, either by itself or mixed with other materials like silica, hardened by sintering in fire. Later, ceramics were glazed and fired to create smooth, colored surfaces, decreasing porosity through the use of glassy, amorphous ceramic coatings on top of the crystalline ceramic substrates. Ceramics now include domestic, industrial, and building products, as well as a wide range of materials developed for use in advanced ceramic engineering, such as semiconductors. The word '' ceramic'' comes from the Ancient Greek word (), meaning ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metallography

Metallography is the study of the physical structure and components of metals, by using microscopy. Ceramic and polymeric materials may also be prepared using metallographic techniques, hence the terms ceramography, plastography and, collectively, materialography. Preparing metallographic specimens The surface of a metallographic specimen is prepared by various methods of grinding (abrasive cutting), grinding, polishing, and Industrial etching, etching. After preparation, it is often analyzed using optical microscope, optical or electron microscopy. Using only metallographic techniques, a skilled technician can identify alloys and predict List of materials properties, material properties. Mechanical preparation is the most common preparation method. Successively finer abrasive particles are used to remove material from the sample surface until the desired surface quality is achieved. Many different machines are available for doing this Abrasive machining, grinding and po ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Galvanization

Galvanization ( also spelled galvanisation) is the process of applying a protective zinc coating to steel or iron, to prevent rusting. The most common method is hot-dip galvanizing, in which the parts are coated by submerging them in a bath of hot, molten zinc. Protective action The zinc coating, when intact, prevents corrosive substances from reaching the underlying iron. It's main function is to act as a sacrificial anode to prevent the iron from rusting by cathodic protection. Zinc is more reactive than iron, so the zinc coating preferentially oxidizes to zinc carbonate, preventing the iron from corroding, even if there are gaps in the zinc coating. Additional electroplating such as a chromate conversion coating may be applied to provide further surface passivation to the substrate material. History and etymology The process is named after the Italian physician, physicist, biologist and philosopher Luigi Galvani (9 September 1737 – 4 December 1798). The earliest kno ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Copper Alloy Microstructure

Copper is a chemical element; it has Chemical symbol, symbol Cu (from Latin ) and atomic number 29. It is a soft, malleable, and ductility, ductile metal with very high thermal conductivity, thermal and electrical conductivity. A freshly exposed surface of pure copper has a Copper (color), pinkish-orange color. Copper is used as a conductor of heat and electricity, as a building material#Metal, building material, and as a constituent of various metal alloys, such as sterling silver used in jewelry, cupronickel used to make marine hardware and coins, and constantan used in strain gauges and thermocouples for temperature measurement. Copper is one of the few metals that can occur in nature in a directly usable, unalloyed metallic form. This means that copper is a native metal. This led to very early human use in several regions, from . Thousands of years later, it was the first metal to be Smelting, smelted from sulfide ores, ; the first metal to be cast into a shape in a mold, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

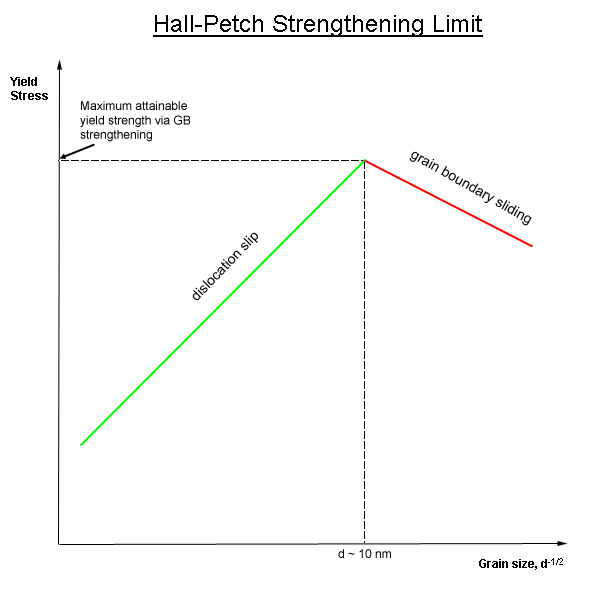

Hall-Petch Strengthening

In materials science, grain-boundary strengthening (or Hall–Petch strengthening) is a method of strengthening materials by changing their average crystallite (grain) size. It is based on the observation that grain boundaries are insurmountable borders for dislocations and that the number of dislocations within a grain has an effect on how stress builds up in the adjacent grain, which will eventually activate dislocation sources and thus enabling deformation in the neighbouring grain as well. By changing grain size, one can influence the number of dislocations piled up at the grain boundary and yield strength. For example, heat treatment after plastic deformation and changing the rate of solidification are ways to alter grain size.W.D. Callister. Fundamentals of Materials Science and Engineering, 2nd ed. Wiley & Sons. pp. 252. Theory In grain-boundary strengthening, the grain boundaries act as pinning points impeding further dislocation propagation. Since the lattice structu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Crystal Lattice

In crystallography, crystal structure is a description of ordered arrangement of atoms, ions, or molecules in a crystal, crystalline material. Ordered structures occur from intrinsic nature of constituent particles to form symmetric patterns that repeat along the principal directions of Three-dimensional space (mathematics), three-dimensional space in matter. The smallest group of particles in a material that constitutes this repeating pattern is the unit cell of the structure. The unit cell completely reflects the symmetry and structure of the entire crystal, which is built up by repetitive Translation (geometry), translation of the unit cell along its principal axes. The translation vectors define the nodes of the Bravais lattice. The lengths of principal axes/edges, of the unit cell and angles between them are lattice constants, also called ''lattice parameters'' or ''cell parameters''. The symmetry properties of a crystal are described by the concept of space groups. All possi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Zinc

Zinc is a chemical element; it has symbol Zn and atomic number 30. It is a slightly brittle metal at room temperature and has a shiny-greyish appearance when oxidation is removed. It is the first element in group 12 (IIB) of the periodic table. In some respects, zinc is chemically similar to magnesium: both elements exhibit only one normal oxidation state (+2), and the Zn2+ and Mg2+ ions are of similar size. Zinc is the 24th most abundant element in Earth's crust and has five stable isotopes. The most common zinc ore is sphalerite (zinc blende), a zinc sulfide mineral. The largest workable lodes are in Australia, Asia, and the United States. Zinc is refined by froth flotation of the ore, roasting, and final extraction using electricity ( electrowinning). Zinc is an essential trace element for humans, animals, plants and for microorganisms and is necessary for prenatal and postnatal development. It is the second most abundant trace metal in humans after iron, an import ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Crystal Structure

In crystallography, crystal structure is a description of ordered arrangement of atoms, ions, or molecules in a crystalline material. Ordered structures occur from intrinsic nature of constituent particles to form symmetric patterns that repeat along the principal directions of three-dimensional space in matter. The smallest group of particles in a material that constitutes this repeating pattern is the unit cell of the structure. The unit cell completely reflects the symmetry and structure of the entire crystal, which is built up by repetitive translation of the unit cell along its principal axes. The translation vectors define the nodes of the Bravais lattice. The lengths of principal axes/edges, of the unit cell and angles between them are lattice constants, also called ''lattice parameters'' or ''cell parameters''. The symmetry properties of a crystal are described by the concept of space groups. All possible symmetric arrangements of particles in three-dimensional space ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ultrastructure

Ultrastructure (or ultra-structure) is the architecture of cells and biomaterials that is visible at higher magnifications than found on a standard optical light microscope. This traditionally meant the resolution and magnification range of a conventional transmission electron microscope (TEM) when viewing biological specimens such as cells, tissue, or organs. Ultrastructure can also be viewed with scanning electron microscopy and super-resolution microscopy, although TEM is a standard histology technique for viewing ultrastructure. Such cellular structures as organelles, which allow the cell to function properly within its specified environment, can be examined at the ultrastructural level. Ultrastructure, along with molecular phylogeny, is a reliable phylogenetic way of classifying organisms. Features of ultrastructure are used industrially to control material properties and promote biocompatibility. History In 1931, German engineers Max Knoll and Ernst Ruska invente ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |