|

Indexing (motion)

Indexing in reference to motion is moving (or being moved) into a new position or location quickly and easily but also precisely. When indexing a machine part, its new location is known to within a few hundredths of a millimeter (thousandths of an inch), or often even to within a few thousandths of a millimeter (ten-thousandths of an inch), despite the fact that no elaborate measuring or layout was needed to establish that location. In reference to multi-edge Cutting tool (machining)#Cutting tools with inserts (indexable tools), cutting inserts, indexing is the process of exposing a new cutting edge for use. Indexing is a necessary kind of motion in many areas of mechanical engineering and machining. An object that indexes, or can be indexed, is said to be indexable. Usually when the word ''indexing'' is used, it refers specifically to rotation. That is, indexing is most often the quick and easy but precise rotation of a machine part through a certain known number of Degree (angle), ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Cutting Tool (machining)

Cutting is the separation or opening of a physical object, into two or more portions, through the application of an acutely directed force. Implements commonly used for wikt:cut, cutting are the knife and saw, or in medicine and science the scalpel and microtome. However, any sufficiently sharp object is capable of cutting if it has a hardness sufficiently larger than the object being cut, and if it is applied with sufficient force. Even liquids can be used to cut things when applied with sufficient force (see water jet cutter). Cutting is a compression (physical), compressive and shearing (physics), shearing phenomenon, and occurs only when the total stress (physics), stress generated by the cutting implement exceeds the ultimate Strength of materials, strength of the material of the object being cut. The simplest applicable equation is: :\text = or \tau=\frac The stress generated by a cutting implement is directly proportional to the force with which it is applied, and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Industrial Revolution

The Industrial Revolution, sometimes divided into the First Industrial Revolution and Second Industrial Revolution, was a transitional period of the global economy toward more widespread, efficient and stable manufacturing processes, succeeding the Second Agricultural Revolution. Beginning in Kingdom of Great Britain, Great Britain around 1760, the Industrial Revolution had spread to continental Europe and the United States by about 1840. This transition included going from craft production, hand production methods to machines; new Chemical industry, chemical manufacturing and Puddling (metallurgy), iron production processes; the increasing use of Hydropower, water power and Steam engine, steam power; the development of machine tools; and rise of the mechanisation, mechanised factory system. Output greatly increased, and the result was an unprecedented rise in population and population growth. The textile industry was the first to use modern production methods, and textiles b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Servomechanism

In mechanical and control engineering, a servomechanism (also called servo system, or simply servo) is a control system for the position and its time derivatives, such as velocity, of a mechanical system. It often includes a servomotor, and uses closed-loop control to reduce steady-state error and improve dynamic response. In closed-loop control, error-sensing negative feedback is used to correct the action of the mechanism. In displacement-controlled applications, it usually includes a built-in encoder or other position feedback mechanism to ensure the output is achieving the desired effect. Following a specified motion trajectory is called servoing, where "servo" is used as a verb. The ''servo'' prefix originates from the Latin word ''servus'' meaning slave. The term correctly applies only to systems where the feedback or error-correction signals help control mechanical position, speed, attitude or any other measurable variables. For example, an automotive power win ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

World War II

World War II or the Second World War (1 September 1939 – 2 September 1945) was a World war, global conflict between two coalitions: the Allies of World War II, Allies and the Axis powers. World War II by country, Nearly all of the world's countries participated, with many nations mobilising all resources in pursuit of total war. Tanks in World War II, Tanks and Air warfare of World War II, aircraft played major roles, enabling the strategic bombing of cities and delivery of the Atomic bombings of Hiroshima and Nagasaki, first and only nuclear weapons ever used in war. World War II is the List of wars by death toll, deadliest conflict in history, causing World War II casualties, the death of 70 to 85 million people, more than half of whom were civilians. Millions died in genocides, including the Holocaust, and by massacres, starvation, and disease. After the Allied victory, Allied-occupied Germany, Germany, Allied-occupied Austria, Austria, Occupation of Japan, Japan, a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

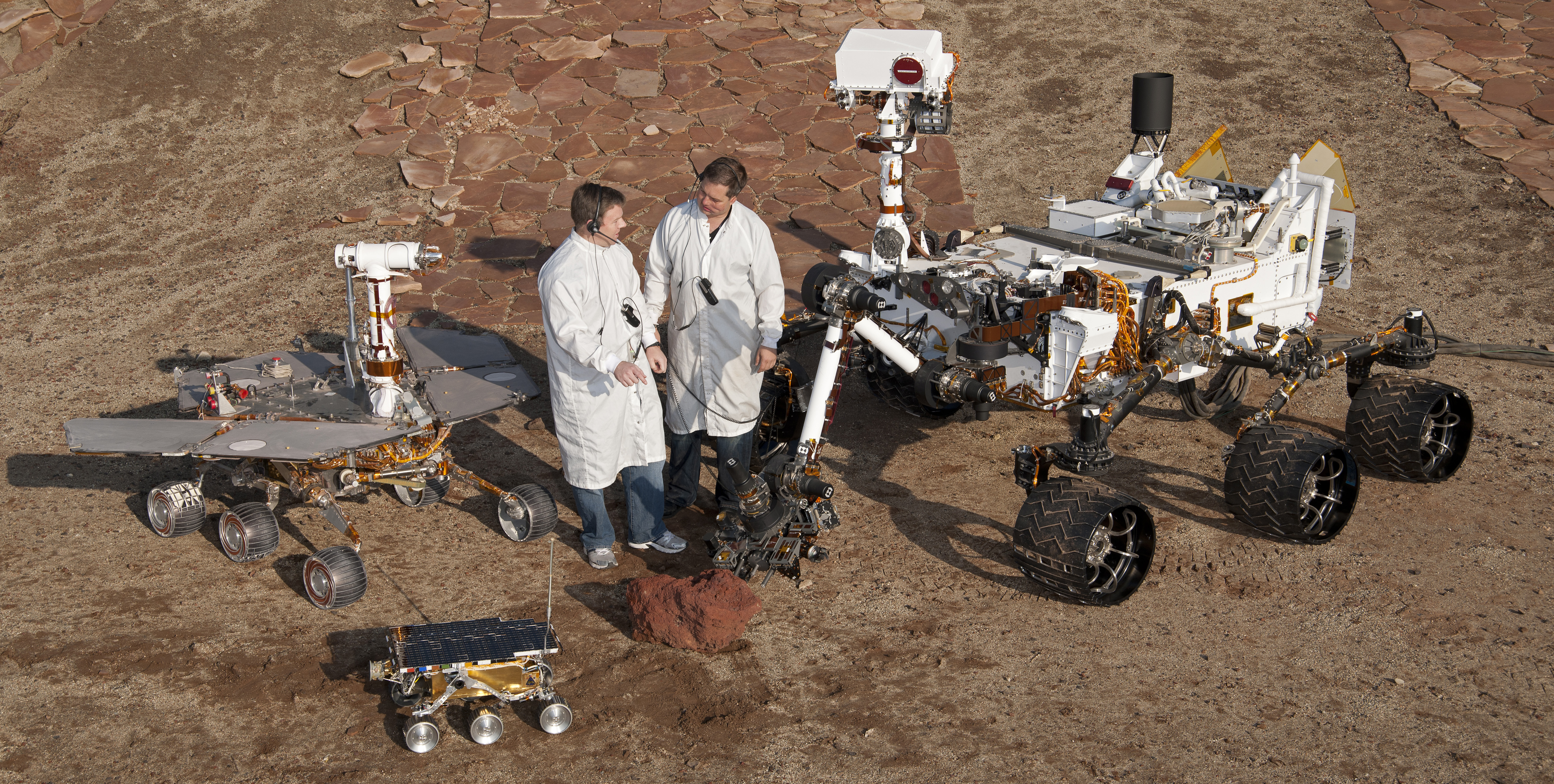

Robotics

Robotics is the interdisciplinary study and practice of the design, construction, operation, and use of robots. Within mechanical engineering, robotics is the design and construction of the physical structures of robots, while in computer science, robotics focuses on robotic automation algorithms. Other disciplines contributing to robotics include electrical engineering, electrical, control engineering, control, software engineering, software, Information engineering (field), information, electronics, electronic, telecommunications engineering, telecommunication, computer engineering, computer, mechatronic, and materials engineering, materials engineering. The goal of most robotics is to design machines that can help and assist humans. Many robots are built to do jobs that are hazardous to people, such as finding survivors in unstable ruins, and exploring space, mines and shipwrecks. Others replace people in jobs that are boring, repetitive, or unpleasant, such as cleaning, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Numerical Control

Computer numerical control (CNC) or CNC machining is the automated control of machine tools by a computer. It is an evolution of numerical control (NC), where machine tools are directly managed by data storage media such as punched cards or punched tape. Because CNC allows for easier programming, modification, and real-time adjustments, it has gradually replaced NC as computing costs declined. A CNC machine is a motorized maneuverable tool and often a motorized maneuverable platform, which are both controlled by a computer, according to specific input instructions. Instructions are delivered to a CNC machine in the form of a sequential program of machine control instructions such as G-code and M-code, and then executed. The program can be written by a person or, far more often, generated by graphical computer-aided design (CAD) or computer-aided manufacturing (CAM) software. In the case of 3D printers, the part to be printed is "sliced" before the instructions (or the prog ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

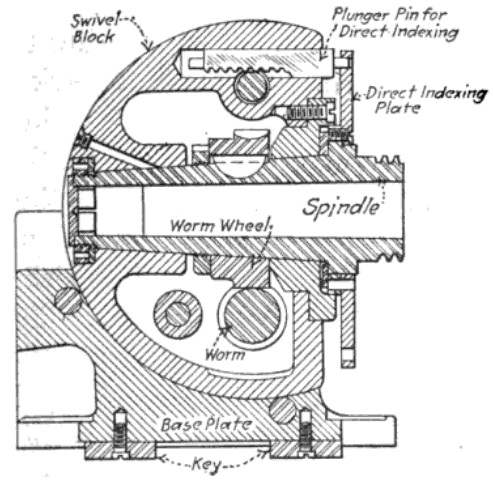

Rotary Table

A rotary table is a precision work positioning device used in metalworking. It enables the operator to drill or cut work at exact intervals around a fixed (usually horizontal or vertical) axis. Some rotary tables allow the use of index plates for indexing operations, and some can also be fitted with dividing plates that enable regular work positioning at divisions for which indexing plates are not available. A rotary fixture used in this fashion is more appropriately called a dividing head ( indexing head). Construction The table shown is a manually operated type. Powered tables under the control of CNC machines are now available, and provide a fourth axis to CNC milling machines. Rotary tables are made with a solid base, which has provision for clamping onto another table or fixture. The actual table is a precision-machined disc to which the work piece is clamped ( T slots are generally provided for this purpose). This disc can rotate freely, for indexing, or under the con ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Milling Machine

Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a workpiece. This may be done by varying directions on one or several axes, cutter head speed, and pressure. Milling covers a wide variety of different operations and machines, on scales from small individual parts to large, heavy-duty gang milling operations. It is one of the most commonly used processes for machining custom parts to precise tolerances. Milling can be done with a wide range of machine tools. The original class of machine tools for milling was the milling machine (often called a mill). After the advent of computer numerical control (CNC) in the 1960s, milling machines evolved into ''machining centers'': milling machines augmented by automatic tool changers, tool magazines or carousels, CNC capability, coolant systems, and enclosures. Milling centers are generally classified as vertical machining centers (VMCs) or horizontal machining centers (HMCs). The integr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Indexing Head

An indexing head, also known as a dividing head or spiral head, is a specialized tool that allows a workpiece to be circularly indexed; that is, easily and precisely rotated to preset angles or circular divisions. Indexing heads are usually used on the tables of milling machines, but may be used on many other machine tools including drill presses, grinders, and boring machines. Common jobs for a dividing head include machining the flutes of a milling cutter, cutting the teeth of a gear, milling curved slots, or drilling a bolt hole circle around the circumference of a part. The tool is similar to a rotary table except that it is designed to be tilted as well as rotated and often allows positive locking at finer gradations of rotation, including through differential indexing. Most adjustable designs allow the head to be tilted from 10° below horizontal to 90° vertical, at which point the head is parallel with the machine table. The workpiece is held in the indexing head in ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Drill Jig

A drill is a tool used for making round holes or driving fasteners. It is fitted with a drill bit for making holes, or a screwdriver bit for securing fasteners. Historically, they were powered by hand, and later mains power, but cordless battery-powered drills are proliferating due to increased efficiency and ease of use. Drills are commonly used in woodworking, metalworking, construction, machine tool fabrication, and utility projects. Specially designed versions are made for surgery, dentistry, miniatures, and other applications. History Around 35,000 BC, ''Homo sapiens'' discovered the benefits of the application of rotary tools. This would have rudimentarily consisted of a pointed rock being spun between the hands to bore a hole through another material. This led to the hand drill, a smooth stick, that was sometimes attached to flint point, and was rubbed between the palms. This was used by many ancient civilizations around the world including the Mayans. The earli ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Fixture (tool)

A fixture is a work-holding or support device used in the manufacturing industry. Fixtures are used to securely locate (position in a specific location or orientation) and support the work, ensuring that all parts produced using the fixture will maintain conformity and interchangeability. Using a fixture improves the economy of production by allowing smooth operation and quick transition from part to part, reducing the requirement for skilled labor by simplifying how workpieces are mounted, and increasing conformity across a production run. Compared with a jig A fixture differs from a jig in that when a fixture is used, the tool must move relative to the workpiece; a jig moves the piece while the tool remains stationary. Purpose A fixture's primary purpose is to create a secure mounting point for a workpiece, allowing for support during operation and increased accuracy, precision, reliability, and interchangeability in the finished parts. It also serves to reduce working tim ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Jig (tool)

A jig is a type of custom-made tool used to control the location and/or motion of parts or other tools. Description A jig's primary purpose is to provide repeatability, accuracy, and interchangeability in the manufacturing of products.. An example of a jig is when a key is duplicated; the original is used as a jig so the new key can have the same path as the old one. Since the advent of automation and computer numerical controlled (CNC) machines, jigs are often not required because the tool path is digitally programmed and stored in memory. Jigs may be made for reforming plastics. Jigs or templates have been known long before the industrial age. There are many types of jigs, and each one is custom-tailored to do a specific job. Drill jig A ''drill jig'' is a type of jig that expedites repetitive hole center location on multiple interchangeable parts by acting as a template to guide the twist drill or other boring device into the precise location of each intended hole cen ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |