|

Digester

A digester (alternative: digestor) is a huge vessel where chemical or biological reactions are carried out. These are used in different types of process industries. Processes where digesters are used * Anaerobic digestion * Bayer process * Kraft process * Sulfite process * Soda process Soda pulping is a chemical process for making wood pulp with sodium hydroxide as the cooking chemical. In the ''Soda-AQ'' process, anthraquinone (AQ) may be used as a pulping additive to decrease the carbohydrate degradation. The soda process gives ... Chemical process engineering de:Faulturm {{chem-stub ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Anaerobic Digestion

Anaerobic digestion is a sequence of processes by which microorganisms break down biodegradable material in the absence of oxygen. The process is used for industrial or domestic purposes to manage waste or to produce fuels. Much of the fermentation used industrially to produce food and drink products, as well as home fermentation, uses anaerobic digestion. Anaerobic digestion occurs naturally in some soils and in lake and oceanic basin sediments, where it is usually referred to as "anaerobic activity". This is the source of marsh gas methane as discovered by Alessandro Volta in 1776. The digestion process begins with bacterial hydrolysis of the input materials. Insoluble organic polymers, such as carbohydrates, are broken down to soluble derivatives that become available for other bacteria. Acidogenic bacteria then convert the sugars and amino acids into carbon dioxide, hydrogen, ammonia, and organic acids. In acetogenesis, bacteria convert these resulting organic ac ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Kraft Process

The kraft process (also known as kraft pulping or sulfate process) is a process for conversion of wood into wood pulp, which consists of almost pure cellulose fibres, the main component of paper. The kraft process involves treatment of wood chips with a hot mixture of water, sodium hydroxide (NaOH), and sodium sulfide (Na2S), known as white liquor, that breaks the bonds that link lignin, hemicellulose, and cellulose. The technology entails several steps, both mechanical and chemical. It is the dominant method for producing paper. In some situations, the process has been controversial because kraft plants can release odorous products and in some situations produce substantial liquid wastes. The process name is derived from German word ''Kraft'', meaning "strength" in this context, due to the strength of the kraft paper produced using this process. History A precursor of the Kraft process was used during the Napoleonic Wars in England. The kraft process (so called be ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

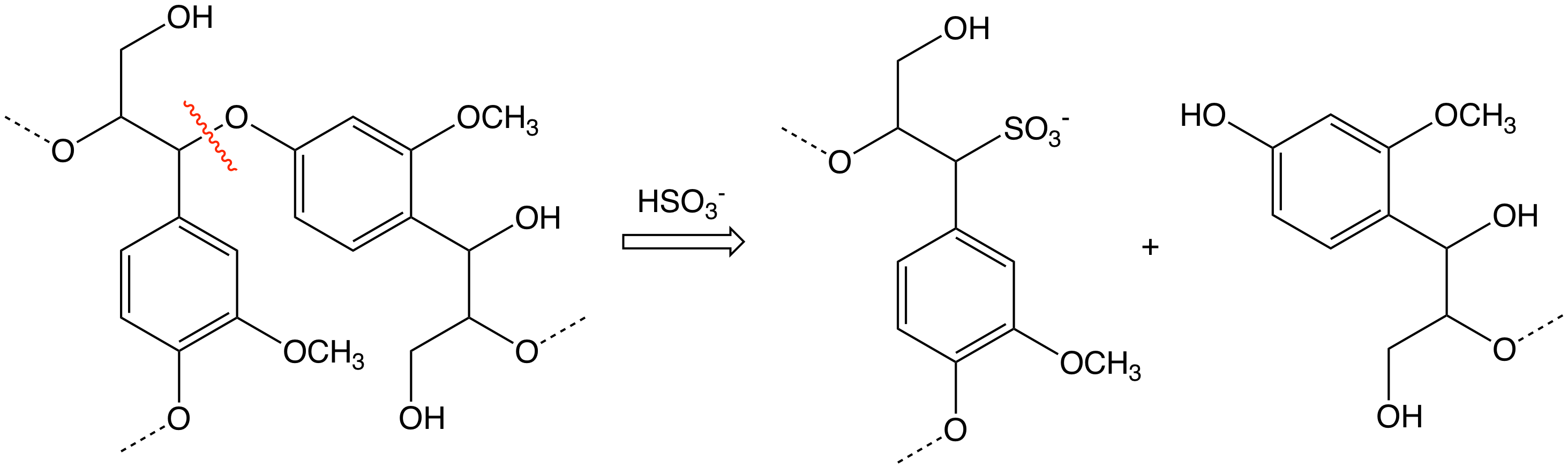

Sulfite Process

The sulfite process produces wood pulp that is almost pure cellulose fibers by treating wood chips with solutions of sulfite and bisulfite ions. These chemicals cleave the bonds between the cellulose and lignin components of the lignocellulose. A variety of sulfite/bisulfite salts are used, including sodium (Na+), calcium (Ca2+), potassium (K+), magnesium (Mg2+), and ammonium (NH4+). The lignin is converted to lignosulfonates, which are soluble and can be separated from the cellulose fibers. For the production of cellulose, the sulfite process competes with the Kraft process which produces stronger fibers and is less environmentally costly. History The use of wood to make pulp for paper began with the development of mechanical pulping in the 1840s by Charles Fenerty in Nova ScotiaBurger, Peter 'Charles Fenerty and his Paper Invention''. Toronto ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Process Industries

Process manufacturing is a branch of manufacturing that is associated with formulas and manufacturing recipes,Difference Between Discrete and Process Manufacturing BatchMaster Blog. and can be contrasted with , which is concerned with discrete units, bills of materials and the assembly of components. Process manufacturing is also referred to as a 'process industry' which is defined as an industry, such as the chemical or petrochemical industry, that is concerned with the processing of bulk resources into other products. Process manufacturing is common [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bayer Process

The Bayer process is the principal industrial means of refining bauxite to produce alumina (aluminium oxide) and was developed by Carl Josef Bayer. Bauxite, the most important ore of aluminium, contains only 30–60% aluminium oxide (Al2O3), the rest being a mixture of silica, various iron oxides, and titanium dioxide. The aluminium oxide must be further purified before it can be refined into aluminium metal. Process Bauxite ore is a mixture of hydrated aluminium oxides and compounds of other elements such as iron. The aluminium compounds in the bauxite may be present as gibbsite 2(Al(OH)3), böhmite (γ-AlO(OH)) or diaspore (α-AlO(OH)); the different forms of the aluminium component and the impurities dictate the extraction conditions. Aluminum oxides and hydroxides are amphoteric, meaning that they are both acidic and basic. The solubility of Al(III) in water is very low but increases substantially at either high or low pH. In the Bayer process, bauxite ore is heated ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Soda Process

Soda pulping is a chemical process for making wood pulp with sodium hydroxide as the cooking chemical. In the ''Soda-AQ'' process, anthraquinone (AQ) may be used as a pulping additive to decrease the carbohydrate degradation. The soda process gives pulp with lower tear strength than other chemical pulping processes (sulfite process and kraft process), but has still limited use for easily-pulped materials like straw and some hardwoods. History A precursor to the soda pulping process was the paper making process developed by Matthias Koops in 1801 which involved washing wood shavings in limewater, adding soda crystals and then boiling the mixture. Soda pulping was one of the first chemical pulping methods and was invented in 1851 by Burgess (United States) and Watts (England). In France in 1852 Coupier and Mellier patented a soda process based on a 1851 invention the patent of which preceded that of Watt and Burgess, which was filed in 1854. The first mill was started in 1866 in the U ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chemical Process Engineering

A chemical substance is a form of matter having constant chemical composition and characteristic properties. Some references add that chemical substance cannot be separated into its constituent elements by physical separation methods, i.e., without breaking chemical bonds. Chemical substances can be simple substances (substances consisting of a single chemical element), chemical compounds, or alloys. Chemical substances are often called 'pure' to set them apart from mixtures. A common example of a chemical substance is pure water; it has the same properties and the same ratio of hydrogen to oxygen whether it is isolated from a river or made in a laboratory. Other chemical substances commonly encountered in pure form are diamond (carbon), gold, table salt (sodium chloride) and refined sugar (sucrose). However, in practice, no substance is entirely pure, and chemical purity is specified according to the intended use of the chemical. Chemical substances exist as solids, liquids ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |