sulfite process on:

[Wikipedia]

[Google]

[Amazon]

The sulfite process produces wood pulp that is almost pure

'Charles Fenerty and his Paper Invention''. Toronto: Peter Burger, 2007. pp.25–30 and by F. G. Keller in

cellulose

Cellulose is an organic compound with the formula , a polysaccharide consisting of a linear chain of several hundred to many thousands of β(1→4) linked D-glucose units. Cellulose is an important structural component of the primary cell wall ...

fibers by treating wood chips with solutions of sulfite and bisulfite ions. These chemicals cleave the bonds between the cellulose and lignin components of the lignocellulose. A variety of sulfite/bisulfite salts are used, including sodium

Sodium is a chemical element with the symbol Na (from Latin ''natrium'') and atomic number 11. It is a soft, silvery-white, highly reactive metal. Sodium is an alkali metal, being in group 1 of the periodic table. Its only stable ...

(Na+), calcium

Calcium is a chemical element with the symbol Ca and atomic number 20. As an alkaline earth metal, calcium is a reactive metal that forms a dark oxide-nitride layer when exposed to air. Its physical and chemical properties are most similar t ...

(Ca2+), potassium

Potassium is the chemical element with the symbol K (from Neo-Latin '' kalium'') and atomic number19. Potassium is a silvery-white metal that is soft enough to be cut with a knife with little force. Potassium metal reacts rapidly with atmosp ...

(K+), magnesium (Mg2+), and ammonium (NH4+). The lignin is converted to lignosulfonate

Lignosulfonates (LS) are water-soluble anionic polyelectrolyte polymers: they are byproducts from the production of wood pulp using sulfite process, sulfite pulping. Most delignification in sulfite pulping involves acidic cleavage of ether bonds, ...

s, which are soluble and can be separated from the cellulose fibers. For the production of cellulose, the sulfite process competes with the Kraft process

The kraft process (also known as kraft pulping or sulfate process) is a process for conversion of wood into wood pulp, which consists of almost pure cellulose fibres, the main component of paper. The kraft process involves treatment of wood ...

which produces stronger fibers and is less environmentally costly.

History

The use of wood to make pulp for paper began with the development of mechanical pulping in the 1840s by Charles Fenerty inNova Scotia

Nova Scotia ( ; ; ) is one of the thirteen provinces and territories of Canada. It is one of the three Maritime provinces and one of the four Atlantic provinces. Nova Scotia is Latin for "New Scotland".

Most of the population are native En ...

Burger, Peter'Charles Fenerty and his Paper Invention''. Toronto: Peter Burger, 2007. pp.25–30 and by F. G. Keller in

Germany

Germany, officially the Federal Republic of Germany (FRG),, is a country in Central Europe. It is the most populous member state of the European Union. Germany lies between the Baltic and North Sea to the north and the Alps to the sou ...

. Chemical processes quickly followed, first with Julius Roth

The gens Julia (''gēns Iūlia'', ) was one of the most prominent patrician families in ancient Rome. Members of the gens attained the highest dignities of the state in the earliest times of the Republic. The first of the family to obtain the ...

's use of sulfurous acid to treat wood in 1857, followed by Benjamin Chew Tilghman's US patent on the use of calcium bisulfite, Ca(HSO3)2, to pulp wood in 1867. Almost a decade later in 1874 the first commercial sulfite pulp mill was built in Sweden. It used magnesium as the counter ion and was based on work by Carl Daniel Ekman

Carl Daniel Ekman (March 17, 1845 – November 3, 1904) was a Swedish chemical engineer who invented the form of the sulfite process of wood pulp manufacturing which was first established on a firm commercial basis, helping to replace rags as the ...

.

By 1900 sulfite pulping had become the dominant means of producing wood pulp, surpassing mechanical pulping methods. The competing chemical pulping process, the sulfate or kraft process

The kraft process (also known as kraft pulping or sulfate process) is a process for conversion of wood into wood pulp, which consists of almost pure cellulose fibres, the main component of paper. The kraft process involves treatment of wood ...

was developed by Carl F. Dahl in 1879 and the first kraft mill started (in Sweden) in 1890. The first sulphite mill in the United States was the Richmond Paper Company in Rumford, Rhode Island

Rumford is the northern section of the city of East Providence, Rhode Island, USA. The Rumford section of East Providence borders Seekonk, Massachusetts, Pawtucket, Rhode Island and the Ten Mile River (Seekonk River). Rumford has been part of ...

in the mid-1880s. The invention of the recovery boiler by G. H. Tomlinson in the early 1930s allowed kraft mills to recycle almost all of their pulping chemicals. This, along with the ability of the kraft process to accept a wider variety of types of wood and produce stronger fibers made the kraft process the dominant pulping process starting in the 1940s. Sulfite pulps now account for less than 10% of the total chemical pulp production and the number of sulfite mills continues to decrease.

Magnesium was the standard counter ion until calcium replaced it in the 1950s.

Pulping liquor preparation

The pulping liquor for most sulfite mills is treating various bases (alkali metal or alkaline earth hydroxides) with sulfur dioxide: :SO2 + MOH → MHSO3 :MHSO3 + MOH → M2SO3 + H2O Similar reactions are effected with divalent cations (Mg2+, Ca2+) and using carbonates in place of hydroxide. The ratio of sulfite to bisulfite depends on pH; above pH=7, sulfite predominates. ;Calcium-based The earliest process used calcium, obtained as inexpensive calcium carbonate, and there was little incentive to recover the inorganic materials. At least in Sweden the brown liquor from this process was previously frequently used for producing ethanol, while with other brown liquors the fermentable hexose sugars are left to contribute to the energy needed in the recovery process. Calcium sulfite, which is poorly soluble, converts to calcium bisulfite only at low pH. Therefore calcium-based sulfite processes require acidic conditions. ;Ammonia-based Ammonia-based processes do not allow recovery of the pulping chemicals since ammonia or ammonium salts are oxidized tonitrogen

Nitrogen is the chemical element with the symbol N and atomic number 7. Nitrogen is a nonmetal and the lightest member of group 15 of the periodic table, often called the pnictogens. It is a common element in the universe, estimated at seve ...

and nitrogen oxides when burned.

;Magnesium-based

The recovery process used in magnesium-based sulfite pulping the "Magnefite" process is well developed. The concentrated brown liquor is burned in a recovery boiler, producing magnesium oxide and sulfur dioxide

Sulfur dioxide ( IUPAC-recommended spelling) or sulphur dioxide (traditional Commonwealth English) is the chemical compound with the formula . It is a toxic gas responsible for the odor of burnt matches. It is released naturally by volcanic ...

, both of which are recovered from the flue gases. Magnesium oxide is recovered in a wet scrubber to give a slurry of magnesium hydroxide.

:MgO + H2O → Mg(OH)2

This magnesium hydroxide slurry is then used in another scrubber to absorb sulfur dioxide

Sulfur dioxide ( IUPAC-recommended spelling) or sulphur dioxide (traditional Commonwealth English) is the chemical compound with the formula . It is a toxic gas responsible for the odor of burnt matches. It is released naturally by volcanic ...

from the flue gases producing a magnesium bisulfite solution that is clarified, filtered and used as the pulping liquor.

:Mg(OH)2 + 2 SO2 → Mg(HSO3)2

;Sodium-based

Sodium-based processes use a recovery system similar to that used in the kraft recovery process, except that there is no "lime cycle".

Processes involved in sulfite pulping

The process is conducted in large pressure vessels called digesters. Sulfite pulping is carried out between pH 1.5 and 5. The pulp is in contact with the pulping chemicals for 4 to 14 hours and at temperatures ranging from 130 to 160°C

The degree Celsius is the unit of temperature on the Celsius scale (originally known as the centigrade scale outside Sweden), one of two temperature scales used in the International System of Units (SI), the other being the Kelvin scale. The d ...

(266 to 320 °F

The Fahrenheit scale () is a temperature scale based on one proposed in 1724 by the physicist Daniel Gabriel Fahrenheit (1686–1736). It uses the degree Fahrenheit (symbol: °F) as the unit. Several accounts of how he originally defined his ...

), again depending on the chemicals used.

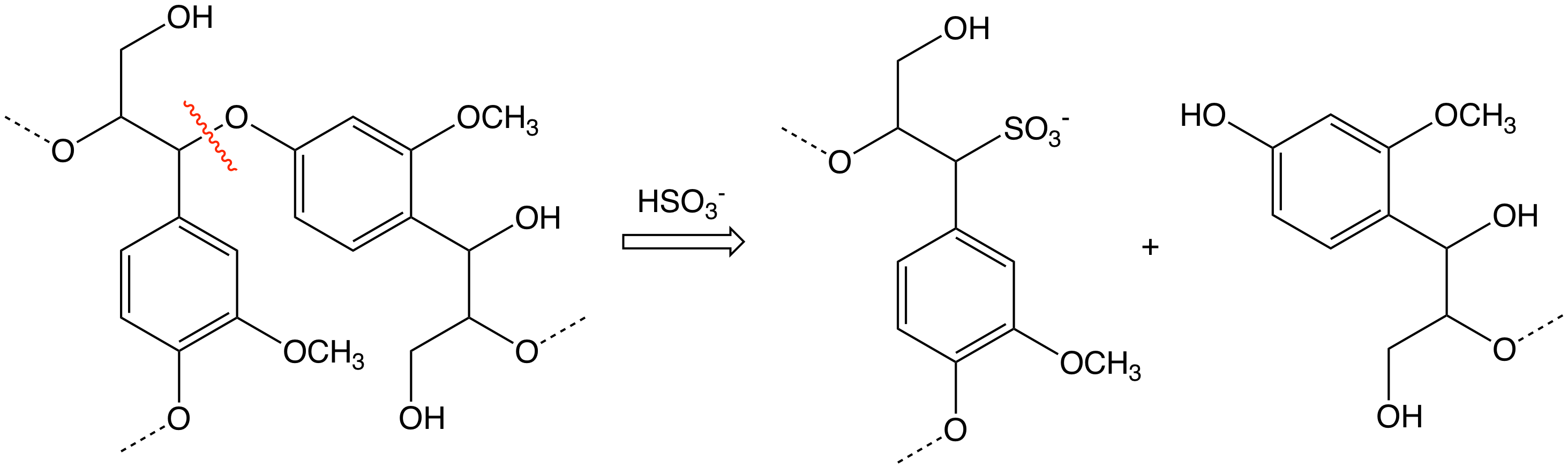

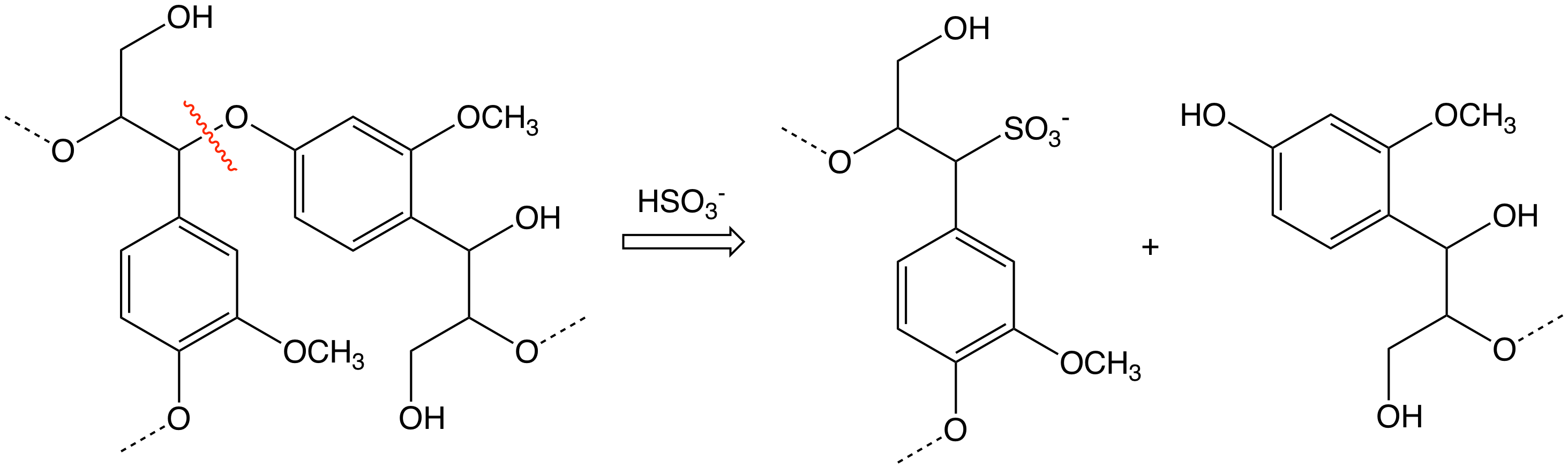

Most of the intermediates involved in delignification in sulfite pulping are resonance-stabilized carbocations formed either by protonation of carbon-carbon double bonds or acidic cleavage of ether bonds which connect many of the constituents of lignin. It is the latter reaction which is responsible for most lignin degradation in the sulfite process. The electrophilic carbocations react with bisulfite ions (HSO3−)to give sulfonates.

:R-O-R' + H+ → R+ + R'OH

:R+ + HSO3− → R-SO3H

The sulfite process does not degrade lignin

Lignin is a class of complex organic polymers that form key structural materials in the support tissues of most plants. Lignins are particularly important in the formation of cell walls, especially in wood and bark, because they lend rigidity ...

to the same extent that the kraft process

The kraft process (also known as kraft pulping or sulfate process) is a process for conversion of wood into wood pulp, which consists of almost pure cellulose fibres, the main component of paper. The kraft process involves treatment of wood ...

does and the lignosulfonate

Lignosulfonates (LS) are water-soluble anionic polyelectrolyte polymers: they are byproducts from the production of wood pulp using sulfite process, sulfite pulping. Most delignification in sulfite pulping involves acidic cleavage of ether bonds, ...

s from the sulfite process are useful byproducts.

Chemical recovery

The spent cooking liquor from sulfite pulping is usually called brown liquor, but the terms red liquor, thick liquor and sulfite liquor are also used (compared toblack liquor

In industrial chemistry, black liquor is the by-product from the kraft process when digesting pulpwood into paper pulp removing lignin, hemicelluloses and other extractives from the wood to free the cellulose fibers.

The equivalent material i ...

in the kraft process

The kraft process (also known as kraft pulping or sulfate process) is a process for conversion of wood into wood pulp, which consists of almost pure cellulose fibres, the main component of paper. The kraft process involves treatment of wood ...

). Pulp washers, using countercurrent flow, remove the spent cooking chemicals and degraded lignin and hemicellulose. The extracted brown liquor is concentrated, in multiple effect evaporators. The concentrated brown liquor can be burned in the recovery boiler to generate steam and recover the inorganic chemicals for reuse in the pulping process or it can be neutralized to recover the useful byproducts of pulping. Recent developments in Chemrec's black liquor gasification process, adapting the technology to use in the sulfite pulping process, could make second generation biofuels production an alternative to the conventional recovery boiler technology. Around 1906 Gösta Ekström a Swedish engineer patented a process of ethanol generation from the residual 2-2.5% fermentable hexose sugars in the spent liquor.

The sulfite process can use calcium

Calcium is a chemical element with the symbol Ca and atomic number 20. As an alkaline earth metal, calcium is a reactive metal that forms a dark oxide-nitride layer when exposed to air. Its physical and chemical properties are most similar t ...

, ammonium, magnesium or sodium

Sodium is a chemical element with the symbol Na (from Latin ''natrium'') and atomic number 11. It is a soft, silvery-white, highly reactive metal. Sodium is an alkali metal, being in group 1 of the periodic table. Its only stable ...

as a base.

Applications

The sulfite process is acidic and one of the drawbacks is that the acidic conditions hydrolyze some of the cellulose, which means that sulfite pulp fibers are not as strong as kraft pulp fibers. The yield of pulp (based on wood used) is higher than for kraft pulping and sulfite pulp is easier to bleach.Commodity

Sulfite pulp remains an important commodity, especially for specialty papers and as a source of cellulose for non-paper applications. It is used to make fine paper, tissue, glassine, and to add strength to newsprint.Dissolving pulp

A special grade of bleached sulfite pulp is known as ''dissolving pulp'' which is the raw material for a wide variety of cellulose derivatives, for example rayon, cellophane, cellulose acetate and methylcellulose. Rayon is a reconstituted cellulose fiber used to make many fabrics. Cellophane is a clear reconstituted cellulose film used in wrapping and windows in envelopes. Cellulose acetate was used to make flexible films for photographic use, computer tapes and so on and also to make fibers. Methylcellulose and other cellulose ether derivatives are used in a wide range of everyday products from adhesives to baked goods to pharmaceuticals.Byproducts

Sulfite pulping is generally less destructive than kraft pulping, so there are more usable byproducts.Lignosulfonates

Chief among sulfite process byproducts are lignosulfonates, which find a wide variety of uses where a relatively inexpensive agent is needed to make a water dispersion of a water-insoluble material. Lignosulfonates are used intanning

Tanning may refer to:

* Tanning (leather), treating animal skins to produce leather

* Sun tanning, using the sun to darken pale skin

** Indoor tanning, the use of artificial light in place of the sun

** Sunless tanning, application of a stain or d ...

leather, making concrete

Concrete is a composite material composed of fine and coarse aggregate bonded together with a fluid cement (cement paste) that hardens (cures) over time. Concrete is the second-most-used substance in the world after water, and is the most ...

, drilling mud, drywall and so on.

Oxidation of lignosulfonates was used to produce vanillin (artificial vanilla), and this process is still used by one supplier (Borregaard

Borregaard is a Norwegian company, established in 1889 in the southeastern town of Sarpsborg in Østfold county. Its main products were traditionally pulp and paper. The company later started producing chemicals based on timber as a raw ma ...

, Norway) while all North American production by this route ceased in the 1990s.

Other byproducts

Acid hydrolysis of hemicelluloses during sulfite pulping produces monosaccharides, predominantly mannose for softwoods and xylose for hardwoods, which can be fermented to produceethanol

Ethanol (abbr. EtOH; also called ethyl alcohol, grain alcohol, drinking alcohol, or simply alcohol) is an organic compound. It is an alcohol with the chemical formula . Its formula can be also written as or (an ethyl group linked to a h ...

.

See also

* Pulp millReferences

{{Authority control Papermaking Pulp and paper industry Chemical processes