|

Cupola Furnace

A cupola or cupola furnace is a melting device used in foundries that can be used to melt cast iron, Ni-resist iron and some bronzes. The cupola can be made almost any practical size. The size of a cupola is expressed in diameters and can range from . The overall shape is cylindrical and the equipment is arranged vertically, usually supported by four legs. The overall look is similar to a large smokestack. The bottom of the cylinder is fitted with doors which swing down and out to 'drop bottom'. The top where gases escape can be open or fitted with a cap to prevent rain from entering the cupola. To control emissions a cupola may be fitted with a cap that is designed to pull the gases into a device to cool the gases and remove particulate matter. The shell of the cupola, being usually made of steel, has refractory brick and plastic refractory patching material lining it. The bottom is lined in a similar manner but often a clay and sand mixture ("bod") may be used, as this lin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cupola Furnace Iron

In architecture, a cupola () is a relatively small, usually dome-like structure on top of a building often crowning a larger roof or dome. Cupolas often serve as a roof lantern to admit light and air or as a lookout. The word derives, via Italian, from lower Latin ''cupula'' (classical Latin ''cupella''), (Latin ''cupa''), indicating a vault resembling an upside-down cup. The cylindrical drum underneath a larger cupola is called a tholobate. Background The cupola evolved during the Renaissance from the older oculus. Being weatherproof, the cupola was better suited to the wetter climates of northern Europe. The chhatri, seen in Indian architecture, fits the definition of a cupola when it is used atop a larger structure. Cupolas often serve as a belfry, belvedere, or roof lantern above a main roof. In other cases they may crown a spire, tower, or turret. Barns often have cupolas for ventilation. Cupolas can also appear as small buildings in their own right. The square, do ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Blast Furnace

A blast furnace is a type of metallurgical furnace used for smelting to produce industrial metals, generally pig iron, but also others such as lead or copper. ''Blast'' refers to the combustion air being supplied above atmospheric pressure. In a blast furnace, fuel ( coke), ores, and flux (limestone) are continuously supplied through the top of the furnace, while a hot blast of (sometimes oxygen enriched) air is blown into the lower section of the furnace through a series of pipes called tuyeres, so that the chemical reactions take place throughout the furnace as the material falls downward. The end products are usually molten metal and slag phases tapped from the bottom, and flue gases exiting from the top. The downward flow of the ore along with the flux in contact with an upflow of hot, carbon monoxide-rich combustion gases is a countercurrent exchange and chemical reaction process. In contrast, air furnaces (such as reverberatory furnaces) are naturally aspirated, usu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Silicon Carbide

Silicon carbide (SiC), also known as carborundum (), is a hard chemical compound containing silicon and carbon. A wide bandgap semiconductor, it occurs in nature as the extremely rare mineral moissanite, but has been mass-produced as a powder and crystal since 1893 for use as an abrasive. Grains of silicon carbide can be bonded together by sintering to form very hard ceramics that are widely used in applications requiring high endurance, such as car brakes, car clutches and ceramic plates in bulletproof vests. Large single crystals of silicon carbide can be grown by the Lely method and they can be cut into gems known as synthetic moissanite. Electronic applications of silicon carbide such as light-emitting diodes (LEDs) and Cat's whisker detector, detectors in early radios were first demonstrated around 1907. SiC is used in semiconductor electronics devices that operate at high temperatures or high voltages, or both. Natural occurrence Naturally occurring moissanite is found ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Carbon Dioxide

Carbon dioxide is a chemical compound with the chemical formula . It is made up of molecules that each have one carbon atom covalent bond, covalently double bonded to two oxygen atoms. It is found in a gas state at room temperature and at normally-encountered concentrations it is odorless. As the source of carbon in the carbon cycle, atmospheric is the primary carbon source for life on Earth. In the air, carbon dioxide is transparent to visible light but absorbs infrared, infrared radiation, acting as a greenhouse gas. Carbon dioxide is soluble in water and is found in groundwater, lakes, ice caps, and seawater. It is a trace gas Carbon dioxide in Earth's atmosphere, in Earth's atmosphere at 421 parts per million (ppm), or about 0.042% (as of May 2022) having risen from pre-industrial levels of 280 ppm or about 0.028%. Burning fossil fuels is the main cause of these increased concentrations, which are the primary cause of climate change.IPCC (2022Summary for pol ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Carbon Monoxide

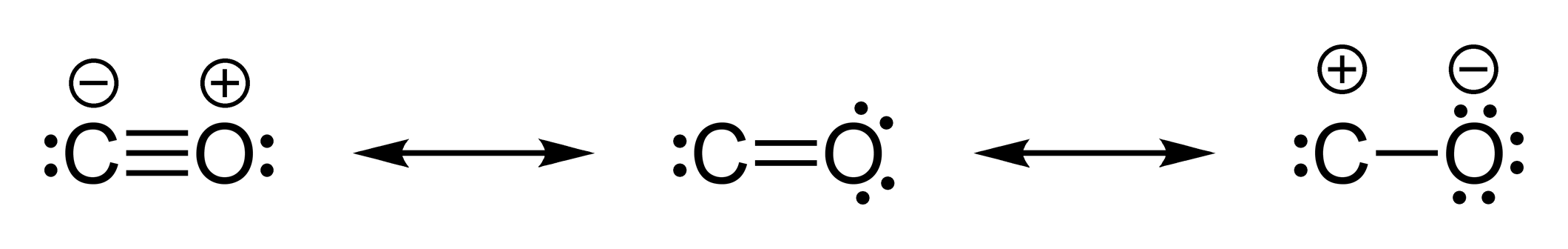

Carbon monoxide (chemical formula CO) is a poisonous, flammable gas that is colorless, odorless, tasteless, and slightly less dense than air. Carbon monoxide consists of one carbon atom and one oxygen atom connected by a triple bond. It is the simplest oxocarbon, carbon oxide. In coordination complexes, the carbon monoxide ligand is called ''metal carbonyl, carbonyl''. It is a key ingredient in many processes in industrial chemistry. The most common source of carbon monoxide is the partial combustion of carbon-containing compounds. Numerous environmental and biological sources generate carbon monoxide. In industry, carbon monoxide is important in the production of many compounds, including drugs, fragrances, and fuels. Indoors CO is one of the most acutely toxic contaminants affecting indoor air quality. CO may be emitted from tobacco smoke and generated from malfunctioning fuel-burning stoves (wood, kerosene, natural gas, propane) and fuel-burning heating systems (wood, oil, n ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Carbon

Carbon () is a chemical element; it has chemical symbol, symbol C and atomic number 6. It is nonmetallic and tetravalence, tetravalent—meaning that its atoms are able to form up to four covalent bonds due to its valence shell exhibiting 4 electrons. It belongs to group 14 of the periodic table. Carbon makes up about 0.025 percent of Earth's crust. Three Isotopes of carbon, isotopes occur naturally, carbon-12, C and carbon-13, C being stable, while carbon-14, C is a radionuclide, decaying with a half-life of 5,700 years. Carbon is one of the timeline of chemical element discoveries#Pre-modern and early modern discoveries, few elements known since antiquity. Carbon is the 15th abundance of elements in Earth's crust, most abundant element in the Earth's crust, and the abundance of the chemical elements, fourth most abundant element in the universe by mass after hydrogen, helium, and oxygen. Carbon's abundance, its unique diversity of organic compounds, and its unusual abi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Flux (metallurgy)

In metallurgy, a flux is a chemical reducing agent, flowing agent, or purifying agent. Fluxes may have more than one function at a time. They are used in both extractive metallurgy and metal joining. Some of the earliest known fluxes were sodium carbonate, potash, charcoal, coke, borax, lime, lead sulfide and certain minerals containing phosphorus. Iron ore was also used as a flux in the smelting of copper. These agents served various functions, the simplest being a reducing agent, which prevented oxides from forming on the surface of the molten metal, while others absorbed impurities into slag, which could be scraped off molten metal. Fluxes are also used in foundries for removing impurities from molten nonferrous metals such as aluminium, or for adding desirable trace elements such as titanium. As reducing agents, fluxes facilitate soldering, brazing, and welding by removing oxidation from the metals to be joined. In some applications molten flux also serves as ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Limestone

Limestone is a type of carbonate rock, carbonate sedimentary rock which is the main source of the material Lime (material), lime. It is composed mostly of the minerals calcite and aragonite, which are different Polymorphism (materials science), crystal forms of calcium carbonate . Limestone forms when these minerals Precipitation (chemistry), precipitate out of water containing dissolved calcium. This can take place through both biological and nonbiological processes, though biological processes, such as the accumulation of corals and shells in the sea, have likely been more important for the last 540 million years. Limestone often contains fossils which provide scientists with information on ancient environments and on the evolution of life. About 20% to 25% of sedimentary rock is carbonate rock, and most of this is limestone. The remaining carbonate rock is mostly Dolomite (rock), dolomite, a closely related rock, which contains a high percentage of the mineral Dolomite (mine ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tuyeres

A tuyere or tuyère (; ) is a tube, nozzle or pipe allowing the blowing of air into a furnace or hearth.W. K. V. Gale, The iron and Steel industry: a dictionary of terms (David and Charles, Newton Abbot 1972), 216–217. Air or oxygen is injected into a hearth under pressure from bellows or a blowing engine or other devices. This causes the fire to become hotter in front of the blast than it would otherwise have been, enabling metals to be smelted or melted or made hot enough to be worked in a forge, though these are blown only with air. This applies to any process where a blast is delivered under pressure to make a fire hotter. Archeologists have discovered tuyeres dating from the Iron Age; one example dates from between 770 BCE and 515 BCE. Following the introduction of hot blast, tuyeres are often water-cooled. Around the year 1500 new ironmaking techniques, including the blast furnace and finery forge, were introduced into England from France, along with the French ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hot Blast

Hot blast is the preheated air blown into a blast furnace or other metallurgical process. This technology, which considerably reduces the fuel consumed, was one of the most important technologies developed during the Industrial Revolution. Hot blast also allowed higher furnace temperatures, which increased the capacity of furnaces. As first developed, it worked by alternately storing heat from the furnace flue gas in a firebrick-lined vessel with multiple chambers, then blowing combustion air through the hot chamber. This is known as regenerative heating. Hot blast was invented and patented for iron furnaces by James Beaumont Neilson in 1828 at Wilsontown Ironworks in Scotland, but was later applied in other contexts, including late bloomeries. Later the carbon monoxide in the flue gas was burned to provide additional heat. History Invention and spread James Beaumont Neilson, previously foreman at Glasgow gas works, invented the system of preheating the blast for a furna ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pig Iron

Pig iron, also known as crude iron, is an intermediate good used by the iron industry in the production of steel. It is developed by smelting iron ore in a blast furnace. Pig iron has a high carbon content, typically 3.8–4.7%, along with silica and other dross, which makes it brittle and not useful directly as a material except for limited applications. Etymology The traditional shape of the molds used for pig iron ingots is a branching structure formed in sand, with many individual ingots at right angles to a central channel or "runner", resembling a litter of piglets being nursed by a sow. When the metal had cooled and hardened, the smaller ingots (the "pigs") were simply broken from the runner (the "sow"), hence the name "pig iron". As pig iron is intended for remelting, the uneven size of the ingots and the inclusion of small amounts of sand are insignificant issues when compared to the ease of casting and handling. History The Chinese were already making pig ir ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |