|

Twybil

A twybil is a hand tool used for green woodworking. It is used for chopping out mortises when timber framing, or making smaller pieces such as gates. It combines chopping and levering functions in a single tool. The appearance of a twybil is that of a T-shaped double-edged axe with unusually long blades and a very short handle. This appearance is deceptive, as they are actually derived from a large double-ended chisel with a side handle added for better control. The geometry of a twybil, particularly the long straight blades, makes it unworkable as an axe. Unfortunately many old examples have been damaged by such misuse. The related mortising axe is similar, but single-sided and is forged and tempered to survive the shock loads of swinging as an axe. Twybils always have two working ends and these are always different. The first is an axe-like blade, with the edge arranged parallel to the handle. The second edge is crossways, as for an adze. This is used for prying and leveri ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Slick (tool)

A slick is a large chisel, characterized by a wide (2-4 inches, 5–10 cm), heavy blade, and a long, frequently slender, socketed handle. A long, flat metal plate fitted with an offset handle. The combined blade and handle can reach two feet (60 cm) in length. The blade of a slick is slightly curved lengthwise, and/or the handle socket is cranked upward, such that the handle and socket clear the surface of the work when the edge is touching. This distinguishes the slick from the similarly sized, short-handled millwright's chisel. Use A slick is always pushed; never struck (thus the slender handle). Using a combination of the tool's weight and bracing the handle against the shoulder or upper arm, fine paring cuts are made. Slicks are typically used by shipwright Shipbuilding is the construction of ships and other floating vessels. It normally takes place in a specialized facility known as a shipyard. Shipbuilders, also called shipwrights, follow a specialized occu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Encyclopédie

''Encyclopédie, ou dictionnaire raisonné des sciences, des arts et des métiers'' (English: ''Encyclopedia, or a Systematic Dictionary of the Sciences, Arts, and Crafts''), better known as ''Encyclopédie'', was a general encyclopedia published in France between 1751 and 1772, with later supplements, revised editions, and translations. It had many writers, known as the Encyclopédistes. It was edited by Denis Diderot and, until 1759, co-edited by Jean le Rond d'Alembert. The ''Encyclopédie'' is most famous for representing the thought of the Enlightenment. According to Denis Diderot in the article "Encyclopédie", the ''Encyclopédies aim was "to change the way people think" and for people ( bourgeoisie) to be able to inform themselves and to know things. He and the other contributors advocated for the secularization of learning away from the Jesuits. Diderot wanted to incorporate all of the world's knowledge into the ''Encyclopédie'' and hoped that the text could dissem ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fulcrum (mechanics)

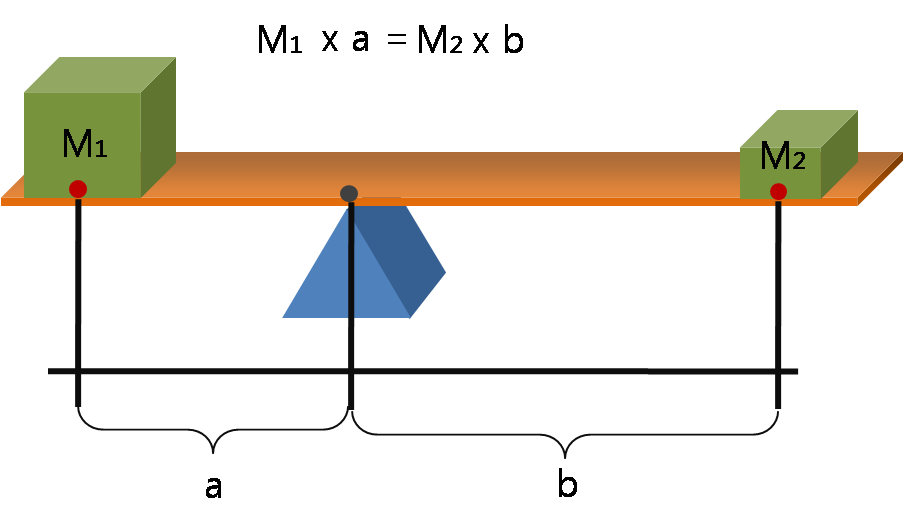

A lever is a simple machine consisting of a beam or rigid rod pivoted at a fixed hinge, or '' fulcrum''. A lever is a rigid body capable of rotating on a point on itself. On the basis of the locations of fulcrum, load and effort, the lever is divided into three types. Also, leverage is mechanical advantage gained in a system. It is one of the six simple machines identified by Renaissance scientists. A lever amplifies an input force to provide a greater output force, which is said to provide leverage. The ratio of the output force to the input force is the mechanical advantage of the lever. As such, the lever is a mechanical advantage device, trading off force against movement. Etymology The word "lever" entered English around 1300 from Old French, in which the word was ''levier''. This sprang from the stem of the verb ''lever'', meaning "to raise". The verb, in turn, goes back to the Latin ''levare'', itself from the adjective ''levis'', meaning "light" (as in "not heavy") ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bevel (sharpening)

A bevelled edge (UK) or beveled edge (US) is an edge of a structure that is not perpendicular to the faces of the piece. The words bevel and chamfer overlap in usage; in general usage they are often interchanged, while in technical usage they may sometimes be differentiated as shown in the image at right. A bevel is typically used to soften the edge of a piece for the sake of safety, wear resistance, or aesthetics; or to facilitate mating with another piece. Applications Cutting tools Most cutting tools have a bevelled edge which is apparent when one examines the grind. Bevel angles can be duplicated using a sliding T bevel. Graphic design Typographic bevels are shading and artificial shadows that emulate the appearance of a 3-dimensional letter. The bevel is a relatively common effect in graphic editors such as Photoshop. As such, it is in widespread use in mainstream logos and other design elements. Glass and mirrors Bevelled edges are a common aesthetic nicety add ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mortise Chisel

A chisel is a tool with a characteristically shaped cutting edge (such that wood chisels have lent part of their name to a particular grind) of blade on its end, for carving or cutting a hard material such as wood, stone, or metal by hand, struck with a mallet, or mechanical power. The handle and blade of some types of chisel are made of metal or of wood with a sharp edge in it. Chiselling use involves forcing the blade into some material to cut it. The driving force may be applied by pushing by hand, or by using a mallet or hammer. In industrial use, a hydraulic ram or falling weight (' trip hammer') may be used to drive a chisel into the material. A gouge (one type of chisel) serves to carve small pieces from the material, particularly in woodworking, woodturning and sculpture. Gouges most frequently produce concave surfaces. A gouge typically has a 'U'-shaped cross-section. Etymology ''Chisel'' comes from the Old French ''cisel'', modern ''ciseau'', Late Lati ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ashley Iles

Ashley is a place name derived from the Old English words '' æsc'' (“ash”) and '' lēah'' (“meadow”). It may refer to: People and fictional characters * Ashley (given name), a list of people and fictional characters with the given name * Ashley (surname), a list of people * Ashley (singer) (born 1975), Puerto Rican singer * Ashley, South Korean singer and leader of Ladies' Code Places Australia * Ashley, New South Wales England * Ashley, Cambridgeshire * Ashley, Cheshire * Ashley, Gloucestershire * Ashley, East Hampshire * Ashley, New Forest, Hampshire * Ashley, Test Valley, Hampshire * Ashley, Kent * Ashley, Northamptonshire * Ashley, Staffordshire * Ashley, Wiltshire Ashley is a small village in the civil parish of Box in Wiltshire, England. Its nearest town is Corsham, which lies approximately east from the village. The village is on the A4 which links Bath with Corsham and Chippenham. Ashley Manor is fro ... * Ashley (Bristol ward) New Zealand * ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

:category:green Woodworking Tools

Tools used for the practice of green woodworking Green woodworking is a form of wood craft or in broad terms, carpentry, that works ''unseasoned'' or "green" timber into finished items. Unseasoned wood is wood that has been freshly felled or preserved by storing it in a water-filled trough or po ..., the working of unseasoned timber. Many of these simple tools are widely used for both green and seasoned timber, but have a particular use when working green wood. {{Commons cat, Green woodworking tools Green woodworking Woodworking hand tools Woodworking tools ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Leaf Spring

A leaf spring is a simple form of spring commonly used for the suspension in wheeled vehicles. Originally called a ''laminated'' or ''carriage spring'', and sometimes referred to as a semi-elliptical spring, elliptical spring, or cart spring, it is one of the oldest forms of vehicle suspension. A leaf spring is one or more narrow, arc-shaped, thin plates which are attached to the axle and chassis in a way that allows the leaf spring to flex vertically in response to irregularities in the road surface. Lateral leaf springs are the most commonly used arrangement, running the length of the vehicle and mounted perpendicular to the wheel axle, but numerous examples of transverse leaf springs exist as well. Leaf springs can serve multiple suspension functions: location, springing, and to some extent damping as well, through interleaf friction. However, this friction is not well controlled, resulting in stiction and irregular suspension motions. For this reason, some manufacturers ha ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Forge Welding

Forge welding (FOW), also called fire welding, is a solid-state welding process that joins two pieces of metal by heating them to a high temperature and then hammering them together. It may also consist of heating and forcing the metals together with presses or other means, creating enough pressure to cause plastic deformation at the weld surfaces. The process is one of the simplest methods of joining metals and has been used since ancient times, being a staple of traditional blacksmithing. Forge welding is versatile, being able to join a host of similar and dissimilar metals. With the invention of electrical welding and gas welding methods during the Industrial Revolution, manual forge-welding has been largely replaced, although automated forge-welding is a common manufacturing process. Introduction Forge welding is a process of joining metals by heating them beyond a certain threshold and forcing them together with enough pressure to cause deformation of the weld surfaces, crea ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wrought Iron

Wrought iron is an iron alloy with a very low carbon content (less than 0.08%) in contrast to that of cast iron (2.1% to 4%). It is a semi-fused mass of iron with fibrous slag inclusions (up to 2% by weight), which give it a wood-like "grain" that is visible when it is etched, rusted, or bent to failure. Wrought iron is tough, malleable, ductile, corrosion resistant, and easily forge welded, but is more difficult to weld electrically. Before the development of effective methods of steelmaking and the availability of large quantities of steel, wrought iron was the most common form of malleable iron. It was given the name ''wrought'' because it was hammered, rolled, or otherwise worked while hot enough to expel molten slag. The modern functional equivalent of wrought iron is mild steel, also called low-carbon steel. Neither wrought iron nor mild steel contain enough carbon to be hardenable by heating and quenching. Wrought iron is highly refined, with a small amount of silic ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)

.jpg)