|

Semi-steel

Semi-steel casting is a lower cost method to produce a casting that is not quite as strong as a steel casting but less expensive to manufacture. It was used more commonly as a marketing term. The carbon and silicon percentages are reduced to the amount approximately consistent with those in steel. This is done using pig iron or gray iron casting scrap and reducing the relative amount of carbon through the addition of relatively pure steel or wrought iron scrap in a well heated cupola furnace. The percentage of carbon is typically between foundry cast iron and wrought iron. 6-pounder and 12-pounder Wiard rifles designed by Norman Wiard and used in the American Civil War (1861–1865) were made of semi-steel ( puddled wrought iron Wrought iron is an iron alloy with a very low carbon content (less than 0.05%) in contrast to that of cast iron (2.1% to 4.5%), or 0.25 for low carbon "mild" steel. Wrought iron is manufactured by heating and melting high carbon cast iron in an ...) ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Norman Wiard

The Wiard rifle refers to several weapons invented by Norman Wiard, most commonly a semi-steel light artillery piece in six-pounder and twelve-pounder calibers. About 60 were manufactured between 1861 and 1862 during the American Civil War, at O'Donnell's Foundry, New York City: "although apparently excellent weapons, heydo not seem to have been very popular". Wiard also designed a rifled steel version of the Dahlgren boat howitzer (a 12-pounder (5.44 kg) weapon with a bore), among other gun types.Olmstead 1997, pp. 177-178 Further, Wiard unsuccessfully attempted to develop a rifled gun for the US Navy and proposed a gun. In 1881 he unsuccessfully proposed various "combined rifle and smoothbore" weapon conversions of Rodman guns and Parrott rifles.Olmstead 1997, pp. 144-146 Wiard described two calibers: a six-pounder (2.72 kg) rifle with a bore, and a twelve-pounder (5.44 kg) smoothbore weapon with a bore. All survivors are rifled, though this may have occurred long afte ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Casting

Casting is a manufacturing process in which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape, and then allowed to solidify. The solidified part is also known as a casting, which is ejected or broken out of the mold to complete the process. Casting materials are usually metals or various time setting materials that cure after mixing two or more components together; examples are epoxy, concrete, plaster and clay. Casting is most often used for making complex shapes that would be otherwise difficult or uneconomical to make by other methods. Heavy equipment like machine tool beds, ships' propellers, etc. can be cast easily in the required size, rather than fabricating by joining several small pieces. Casting is a 7,000-year-old process. The oldest surviving casting is a copper frog from 3200 BC. History Throughout history, metal casting has been used to make tools, weapons, and religious objects. Metal casting history and develo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Steel Casting

Steel casting is a specialized form of casting involving various types of steel cast to either final/net or near-net shape. Steel castings are used when iron castings cannot deliver enough strength or shock resistance.Oberg, p. 1332 Examples of items that are steel castings include: hydroelectric turbine wheels, forging presses, gears, railroad truck frames, valve bodies, pump casings, mining machinery, marine equipment, turbocharger turbines and engine cylinder blocks. Steel castings are categorized into two general groups: carbon steels and alloy steels. Steel castability Steel is more difficult to cast than iron. It has a higher melting point and greater shrinkage rate, which requires consideration during mold design. Risers should be given more capacity to draw from as the metal cools and shrinks. Attention should be paid to the thickness of mold cavities, as thinner areas will cool quicker than thicker areas, which can create internal stress points that can lead to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Carbon

Carbon () is a chemical element; it has chemical symbol, symbol C and atomic number 6. It is nonmetallic and tetravalence, tetravalent—meaning that its atoms are able to form up to four covalent bonds due to its valence shell exhibiting 4 electrons. It belongs to group 14 of the periodic table. Carbon makes up about 0.025 percent of Earth's crust. Three Isotopes of carbon, isotopes occur naturally, carbon-12, C and carbon-13, C being stable, while carbon-14, C is a radionuclide, decaying with a half-life of 5,700 years. Carbon is one of the timeline of chemical element discoveries#Pre-modern and early modern discoveries, few elements known since antiquity. Carbon is the 15th abundance of elements in Earth's crust, most abundant element in the Earth's crust, and the abundance of the chemical elements, fourth most abundant element in the universe by mass after hydrogen, helium, and oxygen. Carbon's abundance, its unique diversity of organic compounds, and its unusual abi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Silicon

Silicon is a chemical element; it has symbol Si and atomic number 14. It is a hard, brittle crystalline solid with a blue-grey metallic lustre, and is a tetravalent metalloid (sometimes considered a non-metal) and semiconductor. It is a member of group 14 in the periodic table: carbon is above it; and germanium, tin, lead, and flerovium are below it. It is relatively unreactive. Silicon is a significant element that is essential for several physiological and metabolic processes in plants. Silicon is widely regarded as the predominant semiconductor material due to its versatile applications in various electrical devices such as transistors, solar cells, integrated circuits, and others. These may be due to its significant band gap, expansive optical transmission range, extensive absorption spectrum, surface roughening, and effective anti-reflection coating. Because of its high chemical affinity for oxygen, it was not until 1823 that Jöns Jakob Berzelius was first able to p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pig Iron

Pig iron, also known as crude iron, is an intermediate good used by the iron industry in the production of steel. It is developed by smelting iron ore in a blast furnace. Pig iron has a high carbon content, typically 3.8–4.7%, along with silica and other dross, which makes it brittle and not useful directly as a material except for limited applications. Etymology The traditional shape of the molds used for pig iron ingots is a branching structure formed in sand, with many individual ingots at right angles to a central channel or "runner", resembling a litter of piglets being nursed by a sow. When the metal had cooled and hardened, the smaller ingots (the "pigs") were simply broken from the runner (the "sow"), hence the name "pig iron". As pig iron is intended for remelting, the uneven size of the ingots and the inclusion of small amounts of sand are insignificant issues when compared to the ease of casting and handling. History The Chinese were already making pig ir ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gray Iron

Gray iron, or grey cast iron, is a type of cast iron that has a graphitic microstructure. It is named after the gray color of the fracture it forms, which is due to the presence of graphite.. It is the most common cast iron and the most widely used cast material based on weight.. It is used for housings where the stiffness of the component is more important than its tensile strength, such as internal combustion engine cylinder blocks, pump housings, valve bodies, electrical boxes, and decorative castings. Grey cast iron's high thermal conductivity and specific heat capacity are often exploited to make cast iron cookware and disc brake rotors. on brakes in freight trains has been greatly reduced in the European Union over concerns regarding noise pollution. Deutsche Bahn for example had replaced grey iron brakes on 53,000 of its freight cars (85% of their fleet) with newer, quieter models by 2019—in part to comply with a law that came into force in December 2020. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cupola Furnace

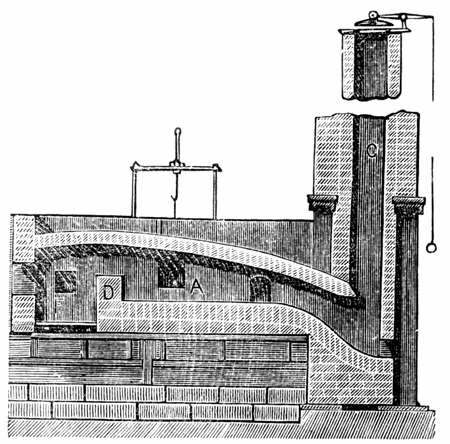

A cupola or cupola furnace is a melting device used in foundries that can be used to melt cast iron, Ni-resist iron and some bronzes. The cupola can be made almost any practical size. The size of a cupola is expressed in diameters and can range from . The overall shape is cylindrical and the equipment is arranged vertically, usually supported by four legs. The overall look is similar to a large smokestack. The bottom of the cylinder is fitted with doors which swing down and out to 'drop bottom'. The top where gases escape can be open or fitted with a cap to prevent rain from entering the cupola. To control emissions a cupola may be fitted with a cap that is designed to pull the gases into a device to cool the gases and remove particulate matter. The shell of the cupola, being usually made of steel, has refractory brick and plastic refractory patching material lining it. The bottom is lined in a similar manner but often a clay and sand mixture ("bod") may be used, as this lin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Puddling (metallurgy)

Puddling is the process of converting pig iron to bar (wrought) iron in a coal fired reverberatory furnace. It was developed in England during the 1780s. The molten pig iron was stirred in a reverberatory furnace, in an Redox, oxidizing environment to burn the carbon, resulting in wrought iron. It was one of the most important processes for making the first appreciable volumes of valuable and useful wrought iron, bar iron (malleable wrought iron) without the use of charcoal. Eventually, the furnace would be used to make small quantities of specialty steels. Though it was not the first process to produce bar iron without charcoal, puddling was by far the most successful, and replaced the earlier potting and stamping processes, as well as the much older charcoal finery forge, finery and bloomery processes. This enabled a great expansion of iron production to take place in Great Britain, and shortly afterwards, in North America. That expansion constitutes the beginnings of the Ind ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wrought Iron

Wrought iron is an iron alloy with a very low carbon content (less than 0.05%) in contrast to that of cast iron (2.1% to 4.5%), or 0.25 for low carbon "mild" steel. Wrought iron is manufactured by heating and melting high carbon cast iron in an open charcoal or coke hearth or furnace in a process known as puddling. The high temperatures cause the excess carbon to oxidise, the iron being stirred or puddled during the process in order to achieve this. As the carbon content reduces, the melting point of the iron increases, ultimately to a level which is higher than can be achieved by the hearth, hence the wrought iron is never fully molten and many impurities remain. The primary advantage of wrought iron over cast iron is its malleability - where cast iron is too brittle to bend or shape without breaking, wrought iron is highly malleable, and much easier to bend. Wrought iron is a semi-fused mass of iron with fibrous slag inclusions (up to 2% by weight), which give it ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |