|

Polymer Devolatilization

Polymer devolatilization, also known as polymer degassing, is the process of removing low-molecular-weight components such as residual monomers, solvents, reaction by-products and water from polymers. Motivation When exiting a reactor after a polymerization reaction, many polymers still contain undesired low-molecular weight components. These component may make the product unusable for further processing (for example, a polymer solution cannot directly be used for plastics processing), may be toxic, may cause bad sensory properties such as an unpleasant smell or worsen the properties of the polymer. It may also be desirable to recycle monomers and solvents to the process. Plastic recycling can also involve removal of water and volatile degradation products. Basic process types Devolatilization can be carried out when a polymer is in the solid or liquid phase, with the volatile components going into a liquid or gas phase. Examples are: * Solid polymer, liquid phase: Extraction ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Marcel Dekker

Marcel Dekker was a journal and encyclopedia publishing company with editorial boards found in New York City. Dekker encyclopedias are now published by CRC Press, part of the Taylor and Francis publishing group. History Initially a textbook publisher, the company added journal publishing in the 1970s, and encyclopedia publishing in the early 1980s. Serving mathematics, it published a series of ''Lecture Notes in Pure and Applied Mathematics''. The company was purchased by Taylor and Francis in 2003. At that time, it published 78 journals and 300 new books annually. The imprint closed in 2005. As of 2008, they have a total of 26 encyclopedias available. These encyclopedias deal with scientific issues such as |

Heat Transfer Coefficient

In thermodynamics, the heat transfer coefficient or film coefficient, or film effectiveness, is the proportionality constant between the heat flux and the thermodynamic driving force for the flow of heat (i.e., the temperature difference, ). It is used in calculating the heat transfer, typically by convection or phase transition between a fluid and a solid. The heat transfer coefficient has SI units in watts per square meter kelvin (W/m2/K). The overall heat transfer rate for combined modes is usually expressed in terms of an overall conductance or heat transfer coefficient, . In that case, the heat transfer rate is: :\dot=hA(T_2-T_1) where (in SI units): *: surface area where the heat transfer takes place (m2) *: temperature of the surrounding fluid (K) *: temperature of the solid surface (K) The general definition of the heat transfer coefficient is: :h = \frac where: *: heat flux (W/m2); i.e., thermal power per unit area, q = d\dot/dA *: difference in temperature bet ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chemical Engineering

Chemical engineering is an engineering field which deals with the study of operation and design of chemical plants as well as methods of improving production. Chemical engineers develop economical commercial processes to convert raw materials into useful products. Chemical engineering uses principles of chemistry, physics, mathematics, biology, and economics to efficiently use, produce, design, transport and transform energy and materials. The work of chemical engineers can range from the utilization of nanotechnology and nanomaterials in the laboratory to large-scale industrial processes that convert chemicals, raw materials, living cells, microorganisms, and energy into useful forms and products. Chemical engineers are involved in many aspects of plant design and operation, including safety and hazard assessments, process design and analysis, modeling, control engineering, chemical reaction engineering, nuclear engineering, biological engineering, construction specificati ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Synthetic Rubber

A synthetic rubber is an artificial elastomer. They are polymers synthesized from petroleum byproducts. About 32-million metric tons of rubbers are produced annually in the United States, and of that amount two thirds are synthetic. Synthetic rubber, just like natural rubber, has many uses in the automotive industry for tires, door and window profiles, seals such as O-rings and gaskets, hoses, belts, matting, and flooring. They offer a different range of physical and chemical properties, so can improve the reliability of a given product or application. Synthetic rubbers are superior to natural rubbers in two major respects, thermal stability and resistance to oils and related compounds. They are more resistant to oxidizing agents, such as oxygen and ozone which can reduce the life of products like tires. History of synthetic rubber The expanded use of bicycles, and particularly their pneumatic tires, starting in the 1890s, created increased demand for rubber. In 1909, a team he ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Latices

Latex is an emulsion (stable dispersion) of polymer microparticles in water. Latexes are found in nature, but synthetic latexes are common as well. In nature, latex is found as a milky fluid found in 10% of all flowering plants (angiosperms). It is a complex emulsion that coagulates on exposure to air, consisting of proteins, alkaloids, starches, sugars, oils, tannins, resins, and gums. It is usually exuded after tissue injury. In most plants, latex is white, but some have yellow, orange, or scarlet latex. Since the 17th century, latex has been used as a term for the fluid substance in plants, deriving from the Latin word for "liquid". It serves mainly as defense against herbivorous insects. Latex is not to be confused with plant sap; it is a distinct substance, separately produced, and with different functions. The word latex is also used to refer to natural latex rubber, particularly non-vulcanized rubber. Such is the case in products like latex gloves, latex condoms and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Extruder

Extrusion is a process used to create objects of a fixed cross-sectional profile by pushing material through a die of the desired cross-section. Its two main advantages over other manufacturing processes are its ability to create very complex cross-sections; and to work materials that are brittle, because the material encounters only compressive and shear stresses. It also creates excellent surface finish and gives considerable freedom of form in the design process. Drawing is a similar process, using the tensile strength of the material to pull it through the die. It limits the amount of change that can be performed in one step, so it is limited to simpler shapes, and multiple stages are usually needed. Drawing is the main way to produce wire. Metal bars and tubes are also often drawn. Extrusion may be continuous (theoretically producing indefinitely long material) or semi-continuous (producing many pieces). It can be done with hot or cold material. Commonly extruded mat ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

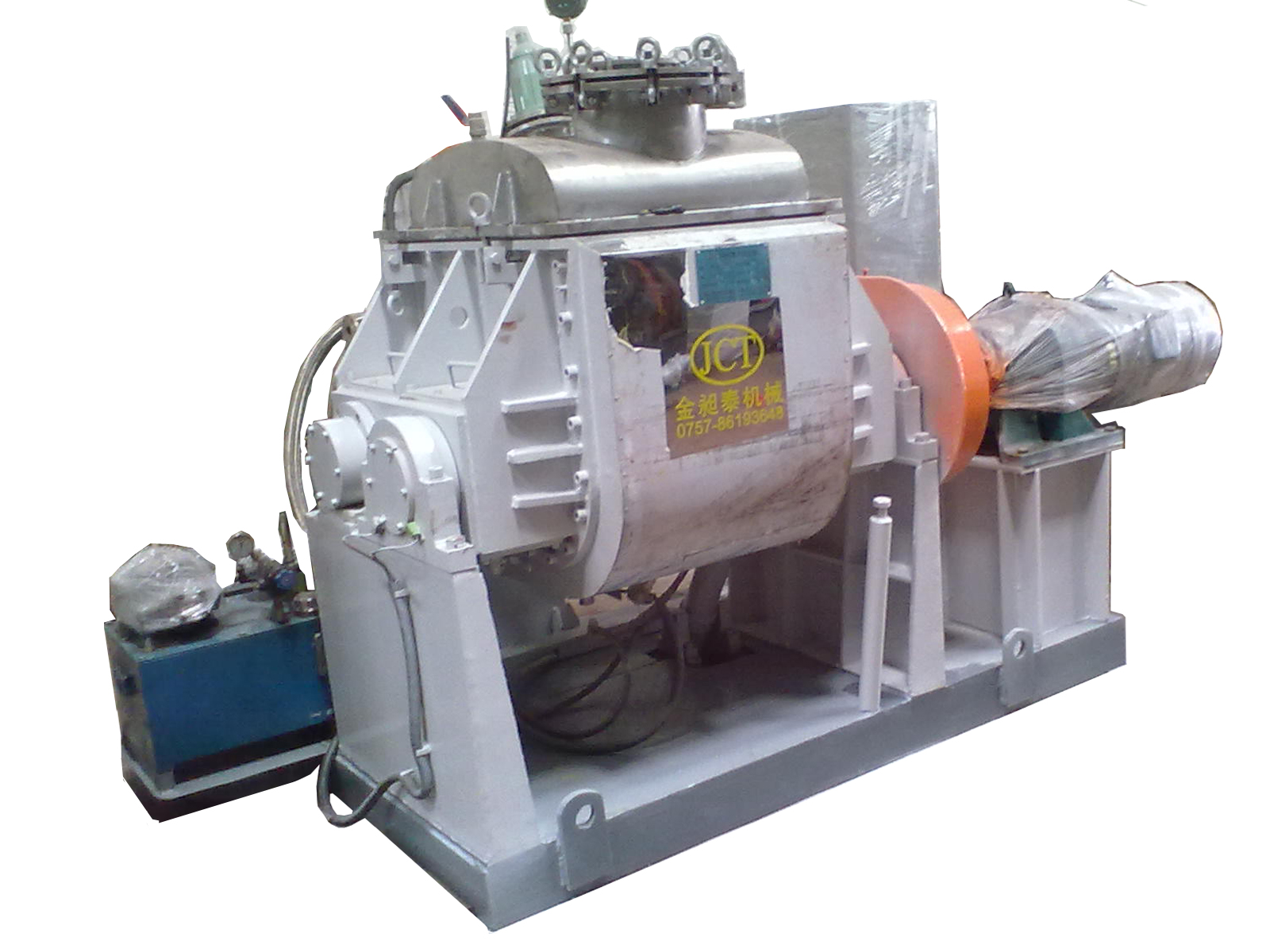

Kneader Reactor

A kneader reactor (or kneading reactor) is a device used for mixing and kneading substances with high viscosity. Many industries, such as the food processing, utilize kneader reactors to produce goods, as for example, polymers or chewing gum. Although the machine has existed for decades, kneader reactors are only recently gaining popularity in the processing industry. Description The kneading reactor is a horizontal mixing machine with two Sigma, or Z-type blades. These blades are driven by separate gears at different speeds, one running 1.5 times faster than the other. The reactor has one powerful motor and a speed reducer to drive the two blades. The kneader reactor usually has a W-type barrel with a hydraulic tilt that turns it, and a heating jacket outside. Usage The kneader reactor uses very high viscosity materials such as chewing gum, dough, toffee, Plasticine, rubber, silicone, adhesive or resin. These materials have a viscosity of approximately 1,000,000 cps. The ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Evaporator

An evaporator is a device used to turn the liquid form of a chemical substance, such as water, into a vapor. Uses Air conditioning and refrigeration Some air conditioners and refrigerators use a compressed liquid with a low boiling point, such as chlorodifluoromethane or R-410A, that vaporizes within the system while emitting heat to its surroundings. Food industry and synthetic chemistry Evaporators are used to concentrate a solution. One example is the climbing/falling film plate evaporator, which is used to make condensed milk. Similarly, reduction (cooking) is a process of evaporating liquids from a solution to produce a "reduced" food product, such as wine reduction. Evaporation is the main process behind distillation, which is used to concentrate alcohol, isolate liquid chemical products, or recover solvents in chemical reactions (green chemistry). The fragrance and essential oil industry uses distillation to purify compounds. Each application uses speciali ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Carl Hanser Verlag

The Carl Hanser Verlag was founded in 1928 by Carl Hanser in Munich and is one of the few medium-sized publishing companies in the German-speaking area still owned by the founding family. History From the very beginning, the publishing house has been active in the two fields of fiction and literature, with fictional fiction being published from 1933 to 1946. The foundation stones of the publishing house were laid with the participation of the magazine "Betriebsstechnik", which was incorporated into the publishing house in 1933. The activities in the field of trade journals, with 21 publications, play an important role in addition to the literature and specialist books. The founder, Carl Hanser, withdrew from the active publishing management in 1976. In 1985 Carl Hanser died. Wolfgang Beisler, a grandson of Carl Hanser, became a member of the management in 1996. Michael Krüger was Managing Director of Carl Hanser Verlag until 2013 when Jo Lendle took over. In 1961, Carl Hanse ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Flash Evaporation

Flash evaporation (or partial evaporation) is the partial vapor that occurs when a saturated liquid stream undergoes a reduction in pressure by passing through a throttling valve or other throttling device. This process is one of the simplest unit operations. If the throttling valve or device is located at the entry into a pressure vessel so that the flash evaporation occurs within the vessel, then the vessel is often referred to as a flash drum. If the saturated liquid is a single-component liquid (for example, propane or liquid ammonia), a part of the liquid immediately "flashes" into vapor. Both the vapor and the residual liquid are cooled to the saturation temperature of the liquid at the reduced pressure. This is often referred to as "auto-refrigeration" and is the basis of most conventional vapor compression refrigeration systems. If the saturated liquid is a multi-component liquid (for example, a mixture of propane, isobutane and normal butane), the flashed vapor is r ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Shell And Tube Heat Exchanger

A shell and tube heat exchanger is a class of heat exchanger designs. It is the most common type of heat exchanger in oil refineries and other large chemical processes, and is suited for higher-pressure applications. As its name implies, this type of heat exchanger consists of a shell (a large pressure vessel) with a bundle of tubes inside it. One fluid runs through the tubes, and another fluid flows over the tubes (through the shell) to transfer heat between the two fluids. The set of tubes is called a tube bundle, and may be composed of several types of tubes: plain, longitudinally finned, etc. Theory and application Two fluids, of different starting temperatures, flow through the heat exchanger. One flows through the tubes (the tube side) and the other flows outside the tubes but inside the shell (the shell side). Heat is transferred from one fluid to the other through the tube walls, either from tube side to shell side or vice versa. The fluids can be either liquids or ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Falling Film Evaporator

A falling film evaporator is an industrial device to concentrate solutions, especially with heat sensitive components. The evaporator is a special type of heat exchanger. General In general evaporation takes place inside vertical tubes, but there are also applications where the process fluid evaporates on the outside of horizontal or vertical tubes. In all cases, the process fluid to be evaporated flows downwards by gravity as a continuous film. The fluid will create a film along the tube walls, progressing downwards (falling) - hence the name. The fluid distributor has to be designed carefully in order to maintain an even liquid distribution for all tubes along which the solution falls. A typical distributor is shown in Fig. 2; these distributors are usually called ferrules due to their concentric shape. In the majority of applications the heating medium is placed on the outside of the tubes. High heat transfer coefficients are required in order to achieve equally balanced heat ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

_(cropped).jpg)