|

Microvoid Coalescence

Microvoid coalescence (MVC) is a high energy microscopic fracture mechanism observed in the majority of metallic alloys and in some engineering plastics. Fracture process MVC proceeds in three stages: nucleation, growth, and coalescence of microvoids. The nucleation of microvoids can be caused by particle cracking or interfacial failure between precipitate particles and the matrix. Additionally, microvoids often form at grain boundaries or inclusions within the material. Microvoids grow during plastic flow of the matrix, and microvoids coalesce when adjacent microvoids link together or the material between microvoids experiences necking. Microvoid coalescence leads to fracture. Void growth rates can be predicted assuming continuum plasticity using the Rice-Tracey model: \ln\left(\frac\right) = \int\limits_^ A\left(\frac\right)d\epsilon_v^p where A is a constant typically equal to 0.283 (but dependent upon the stress triaxiality), \sigma_ is the yield stress, \sigma_m is t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ductile Fracture Surface 6061-T6 Al SEM

Ductility refers to the ability of a material to sustain significant plastic deformation before fracture. Plastic deformation is the permanent distortion of a material under applied stress, as opposed to elastic deformation, which is reversible upon removing the stress. Ductility is a critical mechanical performance indicator, particularly in applications that require materials to bend, stretch, or deform in other ways without breaking. The extent of ductility can be quantitatively assessed using the percent elongation at break, given by the equation: \% \mathrm= \left ( \frac \right )\times100 where l_ is the length of the material after fracture and l_0 is the original length before testing. This formula helps in quantifying how much a material can stretch under tensile stress before failure, providing key insights into its ductile behavior. Ductility is an important consideration in engineering and manufacturing. It defines a material's suitability for certain manufactur ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fracture

Fracture is the appearance of a crack or complete separation of an object or material into two or more pieces under the action of stress (mechanics), stress. The fracture of a solid usually occurs due to the development of certain displacement discontinuity surfaces within the solid. If a displacement develops perpendicular to the surface, it is called a normal tensile crack or simply a crack; if a displacement develops tangentially, it is called a shear crack, slip band, or dislocation. #Brittle, Brittle fractures occur without any apparent deformation before fracture. #Ductile, Ductile fractures occur after visible deformation. Fracture strength, or breaking strength, is the stress when a specimen fails or fractures. The detailed understanding of how a fracture occurs and develops in materials is the object of fracture mechanics. Strength Fracture strength, also known as breaking strength, is the stress at which a specimen structural integrity and failure, fails via fra ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Alloy

An alloy is a mixture of chemical elements of which in most cases at least one is a metal, metallic element, although it is also sometimes used for mixtures of elements; herein only metallic alloys are described. Metallic alloys often have properties that differ from those of the pure elements from which they are made. The vast majority of metals used for commercial purposes are alloyed to improve their properties or behavior, such as increased strength, hardness or corrosion resistance. Metals may also be alloyed to reduce their overall cost, for instance alloys of gold and Copper(II) sulfate, copper. A typical example of an alloy is SAE 304 stainless steel, 304 grade stainless steel which is commonly used for kitchen utensils, pans, knives and forks. Sometime also known as 18/8, it as an alloy consisting broadly of 74% iron, 18% chromium and 8% nickel. The chromium and nickel alloying elements add strength and hardness to the majority iron element, but their main function is ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plastics

Plastics are a wide range of synthetic or semisynthetic materials composed primarily of polymers. Their defining characteristic, plasticity, allows them to be molded, extruded, or pressed into a diverse range of solid forms. This adaptability, combined with a wide range of other properties such as low weight, durability, flexibility, chemical resistance, low toxicity, and low-cost production, has led to their widespread use around the world. While most plastics are produced from natural gas and petroleum, a growing minority are produced from renewable resources like polylactic acid. Between 1950 and 2017, 9.2 billion metric tons of plastic are estimated to have been made, with more than half of this amount being produced since 2004. In 2023 alone, preliminary figures indicate that over 400 million metric tons of plastic were produced worldwide. If global trends in plastic demand continue, it is projected that annual global plastic production will exceed 1.3 billion tons ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Precipitation Hardening

Precipitation hardening, also called age hardening or particle hardening, is a heat treatment technique used to increase the yield strength of malleable materials, including most structural alloys of aluminium, magnesium, nickel, titanium, and some steels, stainless steels, and duplex stainless steel. In superalloys, it is known to cause yield strength anomaly providing excellent high-temperature strength. Precipitation hardening relies on changes in solid solubility with temperature to produce fine particles of an impurity phase, which impede the movement of dislocations, or defects in a crystal's lattice. Since dislocations are often the dominant carriers of plasticity, this serves to harden the material. The impurities play the same role as the particle substances in particle-reinforced composite materials. Just as the formation of ice in air can produce clouds, snow, or hail, depending upon the thermal history of a given portion of the atmosphere, precipitation in solids ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Necking (engineering)

In engineering and materials science, necking is a mode of tensile Deformation (engineering), deformation where relatively large amounts of Deformation (mechanics), strain localize disproportionately in a small region of the material. The resulting prominent decrease in local cross-sectional area provides the basis for the name "neck". Because the local strains in the neck are large, necking is often closely associated with Yield (engineering), yielding, a form of Plasticity (physics), plastic deformation associated with ductile materials, often metals or polymers. Once necking has begun, the neck becomes the exclusive location of yielding in the material, as the reduced area gives the neck the largest local Stress (mechanics), stress. Formation Necking results from an instability during tensile deformation when the cross-sectional area of the sample decreases by a greater proportion than the material Strain hardening, strain hardens. :fr:Armand Consid%C3%A8re, Armand Considè ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Yield Stress

In materials science and engineering, the yield point is the point on a stress–strain curve that indicates the limit of elasticity (physics), elastic behavior and the beginning of plasticity (physics), plastic behavior. Below the yield point, a material will deformation (engineering)#elastic deformation, deform elastically and will return to its original shape when the applied stress (mechanics), stress is removed. Once the yield point is passed, some fraction of the deformation will be permanent and non-reversible and is known as Deformation (engineering)#plastic deformation, plastic deformation. The yield strength or yield stress is a List of materials properties, material property and is the stress corresponding to the yield point at which the material begins to deform plastically. The yield strength is often used to determine the maximum allowable Structural load, load in a mechanical component, since it represents the upper limit to forces that can be applied without pro ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hydrostatic Stress

In continuum mechanics, hydrostatic stress, also known as isotropic stress or volumetric stress, is a component of stress which contains uniaxial stresses, but not shear stresses. A specialized case of hydrostatic stress contains isotropic compressive stress, which changes only in volume, but not in shape. Pure hydrostatic stress can be experienced by a point in a fluid such as water. It is often used interchangeably with "mechanical pressure" and is also known as confining stress, particularly in the field of geomechanics. Hydrostatic stress is equivalent to the average of the uniaxial stresses along three orthogonal axes, so it is one third of the first invariant of the stress tensor (i.e. the trace of the stress tensor): \sigma_h = \frac= \frac 1 3 \operatorname (\boldsymbol \sigma) For example in cartesian coordinates (x,y,z) the hydrostatic stress is simply: \sigma_h = \frac Hydrostatic stress and thermodynamic pressure In the particular case of an incompressible flui ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tension (physics)

Tension is the pulling or stretching force transmitted axially along an object such as a string, rope, chain, rod, truss member, or other object, so as to stretch or pull apart the object. In terms of force, it is the opposite of ''compression''. Tension might also be described as the action-reaction pair of forces acting at each end of an object. At the atomic level, when atoms or molecules are pulled apart from each other and gain potential energy with a restoring force still existing, the restoring force might create what is also called tension. Each end of a string or rod under such tension could pull on the object it is attached to, in order to restore the string/rod to its relaxed length. Tension (as a transmitted force, as an action-reaction pair of forces, or as a restoring force) is measured in newtons in the International System of Units (or pounds-force in Imperial units). The ends of a string or other object transmitting tension will exert forces on the objects ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Shear Stress

Shear stress (often denoted by , Greek alphabet, Greek: tau) is the component of stress (physics), stress coplanar with a material cross section. It arises from the shear force, the component of force vector parallel to the material cross section. ''Normal stress'', on the other hand, arises from the force vector component perpendicular to the material cross section on which it acts. General shear stress The formula to calculate average shear stress or force per unit area is: \tau = ,where is the force applied and is the cross-sectional area. The area involved corresponds to the material face (geometry), face parallel to the applied force vector, i.e., with surface normal vector perpendicular to the force. Other forms Wall shear stress Wall shear stress expresses the retarding force (per unit area) from a wall in the layers of a fluid flowing next to the wall. It is defined as:\tau_w := \mu\left.\frac\_,where is the dynamic viscosity, is the flow velocity, and is the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

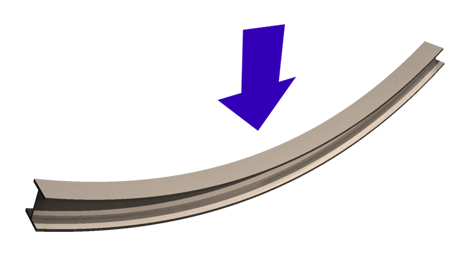

Bending

In applied mechanics, bending (also known as flexure) characterizes the behavior of a slender structural element subjected to an external Structural load, load applied perpendicularly to a longitudinal axis of the element. The structural element is assumed to be such that at least one of its dimensions is a small fraction, typically 1/10 or less, of the other two.Boresi, A. P. and Schmidt, R. J. and Sidebottom, O. M., 1993, Advanced mechanics of materials, John Wiley and Sons, New York. When the length is considerably longer than the width and the thickness, the element is called a Beam (structure), beam. For example, a closet rod Deflection (engineering), sagging under the weight of clothes on clothes hangers is an example of a beam experiencing bending. On the other hand, a wikt:shell, shell is a structure of any geometric form where the length and the width are of the same order of magnitude but the thickness of the structure (known as the 'wall') is considerably smaller. A l ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |