|

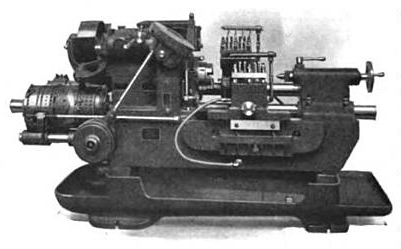

Fay Automatic Lathe

The Fay automatic lathe was an automatic lathe tailored to cutting workpieces that were mounted on Lathe center, centers (tools with pointed ends to accurately position a Drill bit#Center and spotting drill bit, center-drilled workpiece about an axis, either directly or by using a mandrel). It could also do chucking work. (feeding of unformed blanks or pieces of stock from a magazine to be automatically gripped by the machine for turning). Examples of workpieces included automotive steering knuckles and transmission gears, and such work done on mandrels as flanges, disks, and hubs. The machine tool was developed by F.C. Fay of Philadelphia and improved by Otto A. Schaum. It was originally manufactured by the Fay & Scott Machine Shop. James Hartness acquired manufacturing rights on behalf of the Jones & Lamson Machine Company. and manufactured an improved version, developed under the management of Ralph Flanders.. In 1937 Roe, writing for the American Society of Mechanical Engineer ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Automatic Lathe

In metalworking and woodworking, an automatic lathe is a lathe with an automatically controlled cutting process. Automatic lathes were first developed in the 1870s and were mechanically controlled. From the advent of NC and CNC in the 1950s, the term automatic lathe has generally been used for only mechanically controlled lathes, although some manufacturers (e.g., DMG Mori and Tsugami) market Swiss-type CNC lathes as 'automatic'. CNC has not yet entirely displaced mechanically automated lathes, as although no longer in production, many mechanically automated lathes remain in service. General nomenclature The term "automatic lathe" is still often used in manufacturing in its earlier sense, referring to automated lathes of non- CNC types. The first automatic lathes were mechanically automated and controlled by cams or tracers and pantographs. Thus, before electronic automation via numerical control, the "automatic" in the term "automatic machine tool" always referred implicit ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

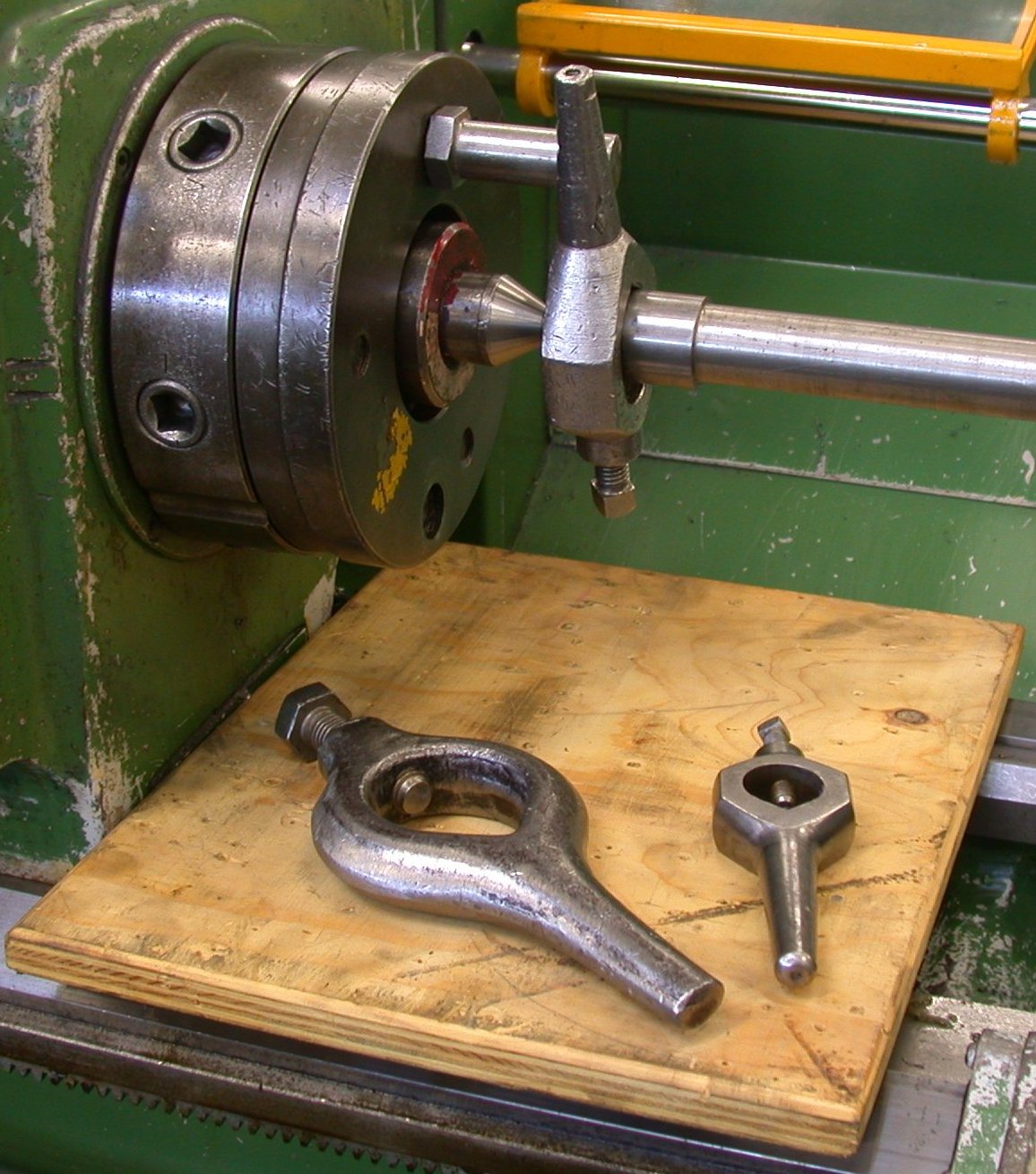

Lathe Center

A lathe center, often shortened to center, is a tool that has been ground to a point to accurately position a workpiece on an axis. They usually have an included angle of 60°, but in heavy machining situations an angle of 75° is used. The primary use of a center is to ensure concentric work is produced; this allows the workpiece to be transferred between machining (or inspection) operations without any loss of accuracy. A part may be ''turned'' in a lathe, sent off for hardening and tempering and then ground ''between centers'' in a cylindrical grinder. The preservation of concentricity between the turning and grinding operations is crucial for quality work. When turning between centres, a steady can be used to support longer workpieces where the cutting forces would deflect the work excessively, reducing the finish and accuracy of the workpiece, or creating a hazardous situation. A center lathe has applications anywhere that a ''centered'' workpiece may be used; this is not ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Drill Bit

Drill bits are cutting tools used in a drill to remove material to create holes, almost always of circular cross-section. Drill bits come in many sizes and shapes and can create different kinds of holes in many different materials. In order to create holes drill bits are usually attached to a drill, which powers them to cut through the workpiece, typically by rotation. The drill will grasp the upper end of a bit called the ''shank'' in the chuck. Drills come in standardized drill bit sizes. A comprehensive drill bit and tap size chart lists metric and imperial sized drills alongside the required screw tap sizes. There are also certain specialized drill bits that can create holes with a non-circular cross-section. Characteristics Drill geometry has several characteristics: *The spiral (or rate of twist) in the drill bit controls the rate of chip removal. A fast spiral (high twist rate or "compact flute") drill bit is used in high feed rate applications under low spi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mandrel

A mandrel, mandril, or arbor is a gently tapered cylinder against which material can be forged or shaped (e.g., a ring mandrel - also called a triblet - used by jewelers to increase the diameter of a wedding ring), or a flanged or tapered or threaded bar that grips a workpiece to be machined in a lathe. A flanged mandrel is a parallel bar of a specific diameter with an integral flange towards one end, and threaded at the opposite end. Work is gripped between the flange and a nut on the thread. A tapered mandrel (often called a plain mandrel) has a taper of approximately 0.005 inches per foot and is designed to hold work by being driven into an accurate hole on the work, gripping the work by friction. A threaded mandrel may have a male or female thread, and work which has an identical thread is screwed onto the mandrel. On a lathe, mandrels are commonly mounted between centres and driven by a lathe dog (typically the flanged or tapered mandrels), but may also be gripped in a ch ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Philadelphia

Philadelphia, often called Philly, is the largest city in the Commonwealth of Pennsylvania, the sixth-largest city in the U.S., the second-largest city in both the Northeast megalopolis and Mid-Atlantic regions after New York City. Since 1854, the city has been coextensive with Philadelphia County, the most populous county in Pennsylvania and the urban core of the Delaware Valley, the nation's seventh-largest and one of world's largest metropolitan regions, with 6.245 million residents . The city's population at the 2020 census was 1,603,797, and over 56 million people live within of Philadelphia. Philadelphia was founded in 1682 by William Penn, an English Quaker. The city served as capital of the Pennsylvania Colony during the British colonial era and went on to play a historic and vital role as the central meeting place for the nation's founding fathers whose plans and actions in Philadelphia ultimately inspired the American Revolution and the nation's inde ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

James Hartness

James Hartness (September 3, 1861 – February 2, 1934) was an American inventor, mechanical engineer, entrepreneur, amateur astronomer, and politician who served as the 58th governor of Vermont from 1921 to 1923. Early life and education Hartness was born in Schenectady, New York, one of three sons. His family moved to Cleveland, Ohio, in 1863 where his father was a foreman in local machine shops and Hartness attended public school. Career Hartness worked up through the ranks in machine shops in Connecticut before moving to Springfield, Vermont. He became one of the nation's first aviators and became a one-term governor of the state of Vermont. He had two daughters, Anna and Helen. His daughter, Helen ( Helen Hartness Flanders), was a noted folk song collector who married Ralph Flanders, a U.S. Senator from Vermont Hartness died in Springfield in 1934. He is buried in the Summer Hill Cemetery in Springfield, not far from his mansion. He built his Springfield home in 1904, w ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ralph Flanders

Ralph Edward Flanders (September 28, 1880 – February 19, 1970) was an American mechanical engineer, industrialist and politician who served as a Republican U.S. Senator from the state of Vermont. He grew up on subsistence farms in Vermont and Rhode Island and was an apprentice machinist and draftsman before training as a mechanical engineer. He spent five years in New York City as an editor for a machine tool magazine. After moving back to Vermont, he managed and then became president of a successful machine tool company. Flanders used his experience as an industrialist to advise state and national commissions in Vermont, New England and Washington, D.C. on industrial and economic policy. He was president of the Boston Federal Reserve Bank for two years before being elected U.S. Senator from Vermont. Flanders was noted for introducing a 1954 motion in the Senate to censure Senator Joseph McCarthy. McCarthy had made sensational claims that there were large numbers of Commun ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

American Society Of Mechanical Engineers

The American Society of Mechanical Engineers (ASME) is an American professional association that, in its own words, "promotes the art, science, and practice of multidisciplinary engineering and allied sciences around the globe" via "continuing education, training and professional development, codes and standards, research, conferences and publications, government relations, and other forms of outreach." ASME is thus an engineering society, a standards organization, a research and development organization, an advocacy organization, a provider of training and education, and a nonprofit organization. Founded as an engineering society focused on mechanical engineering in North America, ASME is today multidisciplinary and global. ASME has over 85,000 members in more than 135 countries worldwide. ASME was founded in 1880 by Alexander Lyman Holley, Henry Rossiter Worthington, John Edison Sweet and Matthias N. Forney in response to numerous steam boiler pressure vessel failures. K ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Christopher Miner Spencer

Christopher Miner Spencer (June 20, 1833 – January 14, 1922) was an American inventor, from Manchester, Connecticut, who invented the Spencer repeating rifle, one of the earliest models of lever-action rifle, a steam powered "horseless carriage", and several other inventions. He developed the first fully automatic turret lathe, which in its small- to medium-sized form is also known as a screw machine. Early years Spencer worked for Samuel Colt’s factory, where he learned the arms-making trade.pp. 174–177 Civil War Although the Spencer rifle had been developed as early as 1859, it was not initially used by the Union. On August 18, 1863, Christopher Spencer walked into the White House carrying one of his rifles and a supply of cartridges. He walked past the sentries, and into Abraham Lincoln's office. After some discussion, he returned the following afternoon, when Spencer and Lincoln were joined by Edwin Stanton, Secretary of War and other officials, and the group ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Turret Lathe

The turret lathe is a form of metalworking lathe that is used for repetitive production of duplicate parts, which by the nature of their cutting process are usually interchangeable. It evolved from earlier lathes with the addition of the ''turret'', which is an indexable toolholder that allows multiple cutting operations to be performed, each with a different cutting tool, in easy, rapid succession, with no need for the operator to perform set-up tasks in between (such as installing or uninstalling tools) or to control the toolpath. The latter is due to the toolpath's being controlled by the machine, either in jig-like fashion, via the mechanical limits placed on it by the turret's slide and stops, or via digitally-directed servomechanisms for computer numerical control lathes. The name derives from the way early turrets took the general form of a flattened cylindrical block mounted to the lathe's cross-slide, capable of rotating about the vertical axis and with toolholders p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Automation

Automation describes a wide range of technologies that reduce human intervention in processes, namely by predetermining decision criteria, subprocess relationships, and related actions, as well as embodying those predeterminations in machines. Automation has been achieved by various means including mechanical, hydraulic, pneumatic, electrical, electronic devices, and computers, usually in combination. Complicated systems, such as modern factories, airplanes, and ships typically use combinations of all of these techniques. The benefit of automation includes labor savings, reducing waste, savings in electricity costs, savings in material costs, and improvements to quality, accuracy, and precision. Automation includes the use of various equipment and control systems such as machinery, processes in factories, boilers, and heat-treating ovens, switching on telephone networks, steering, and stabilization of ships, aircraft, and other applications and vehicles with reduced hu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

_pg328_AMERICAN_SOCIETY_OF_MECHANICAL_ENGINEERS._12_WEST_31ST_STREET.jpg)