|

Lathe Center

A lathe center, often shortened to center, is a tool that has been ground to a point to accurately position a workpiece on an axis. They usually have an included angle of 60°, but in heavy machining situations an angle of 75° is used. The primary use of a center is to ensure concentric work is produced; this allows the workpiece to be transferred between machining (or inspection) operations without any loss of accuracy. A part may be ''turned'' in a lathe, sent off for hardening and tempering and then ground ''between centers'' in a cylindrical grinder. The preservation of concentricity between the turning and grinding operations is crucial for quality work. When turning between centers, a steady rest can be used to support longer workpieces where the cutting forces would deflect the work excessively, reducing the finish and accuracy of the workpiece, or creating a hazardous situation. A lathe center has applications anywhere that a ''centered'' workpiece may be used; this i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

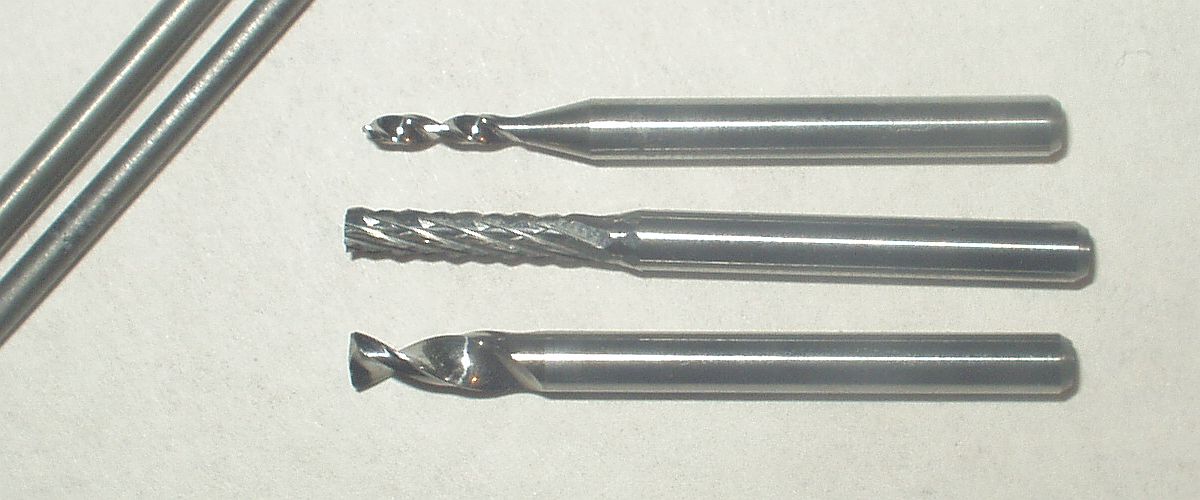

Tungsten Carbide

Tungsten carbide (chemical formula: ) is a carbide containing equal parts of tungsten and carbon atoms. In its most basic form, tungsten carbide is a fine gray powder, but it can be pressed and formed into shapes through sintering for use in industrial machinery, engineering facilities, molding blocks, cutting tools, chisels, abrasives, armor-piercing bullets and jewelry. Tungsten carbide is approximately three times as stiff as steel, with a Young's modulus of approximately 530–700 GPa, and is twice as dense as steel. It is comparable with corundum (α- ) in hardness, approaching that of a diamond, and can be polished and finished only with abrasives of superior hardness such as cubic boron nitride and diamond. Tungsten carbide tools can be operated at cutting speeds much higher than high-speed steel (a special steel blend for cutting tools). Tungsten carbide powder was first synthesized by H. Moissan in 1893, and the industrial production of the cemented form starte ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Woodworking

Woodworking is the skill of making items from wood, and includes cabinetry, furniture making, wood carving, joinery, carpentry, and woodturning. History Along with stone, clay and animal parts, wood was one of the first materials worked by early humans. Microwear analysis of the Mousterian stone tools used by the Neanderthals show that many were used to work wood. The development of civilization was closely tied to the development of increasingly greater degrees of skill in working these materials. Among the earlliest finds of woodworking are shaped sticks displaying notches from Kalambo Falls in southen Africa, dating to around 476,000 years ago. The Clacton spearhead from Clacton-on-Sea, England, dating to around 400,000 years ago,Allington-Jones, L., (2015) ''Archaeological Journal'', 172 (2) 273–296 The Clacton Spear – The Last One Hundred Years the Schöningen spears, from Schöningen (Germany) dating around 300,000 years ago and the Lehringen spear from no ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

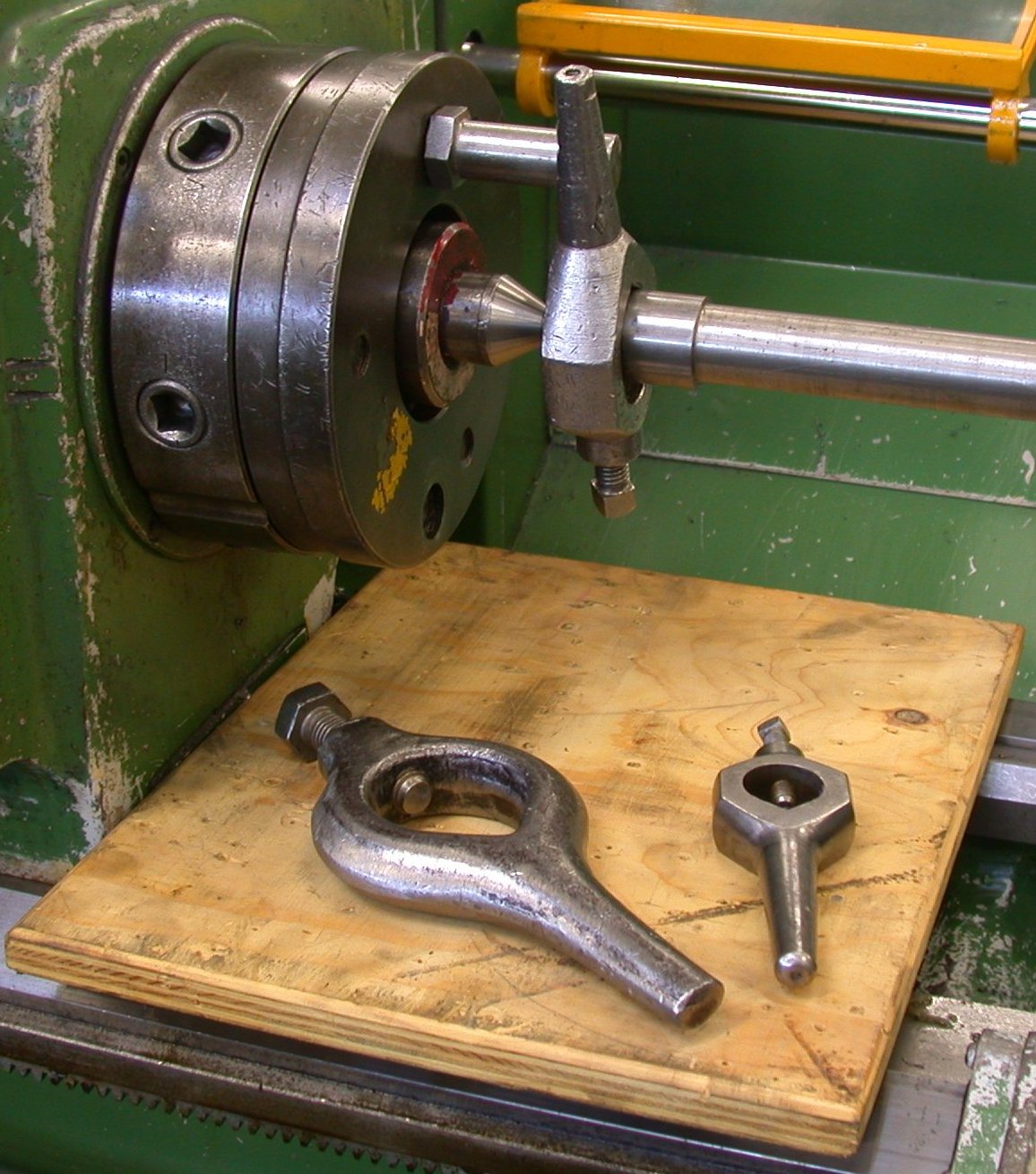

Lathe Carrier

A lathe () is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, deformation, facing, threading and turning, with tools that are applied to the workpiece to create an object with symmetry about that axis. Lathes are used in woodturning, metalworking, metal spinning, thermal spraying, reclamation, and glass-working. Lathes can be used to shape pottery, the best-known design being the Potter's wheel. Most suitably equipped metalworking lathes can also be used to produce most solids of revolution, plane surfaces and screw threads or helices. Ornamental lathes can produce three-dimensional solids of incredible complexity. The workpiece is usually held in place by either one or two ''centers'', at least one of which can typically be moved horizontally to accommodate varying workpiece lengths. Other work-holding methods include clamping the work about the axis of rotation using a chuck or ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Anchor

An anchor is a device, normally made of metal, used to secure a vessel to the bed of a body of water to prevent the craft from drifting due to wind or current. The word derives from Latin ', which itself comes from the Greek (). Anchors can either be temporary or permanent. Permanent anchors are used in the creation of a mooring, and are rarely moved; a specialist service is normally needed to move or maintain them. Vessels carry one or more temporary anchors, which may be of different designs and weights. A sea anchor is a drag device, not in contact with the seabed, used to minimize drift of a vessel relative to the water. A drogue is a drag device used to slow or help steer a vessel running before a storm in a following or overtaking sea, or when crossing a bar in a breaking sea. Anchoring Anchors achieve holding power either by "hooking" into the seabed, or weight, or a combination of the two. The weight of the anchor chain can be more than that of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

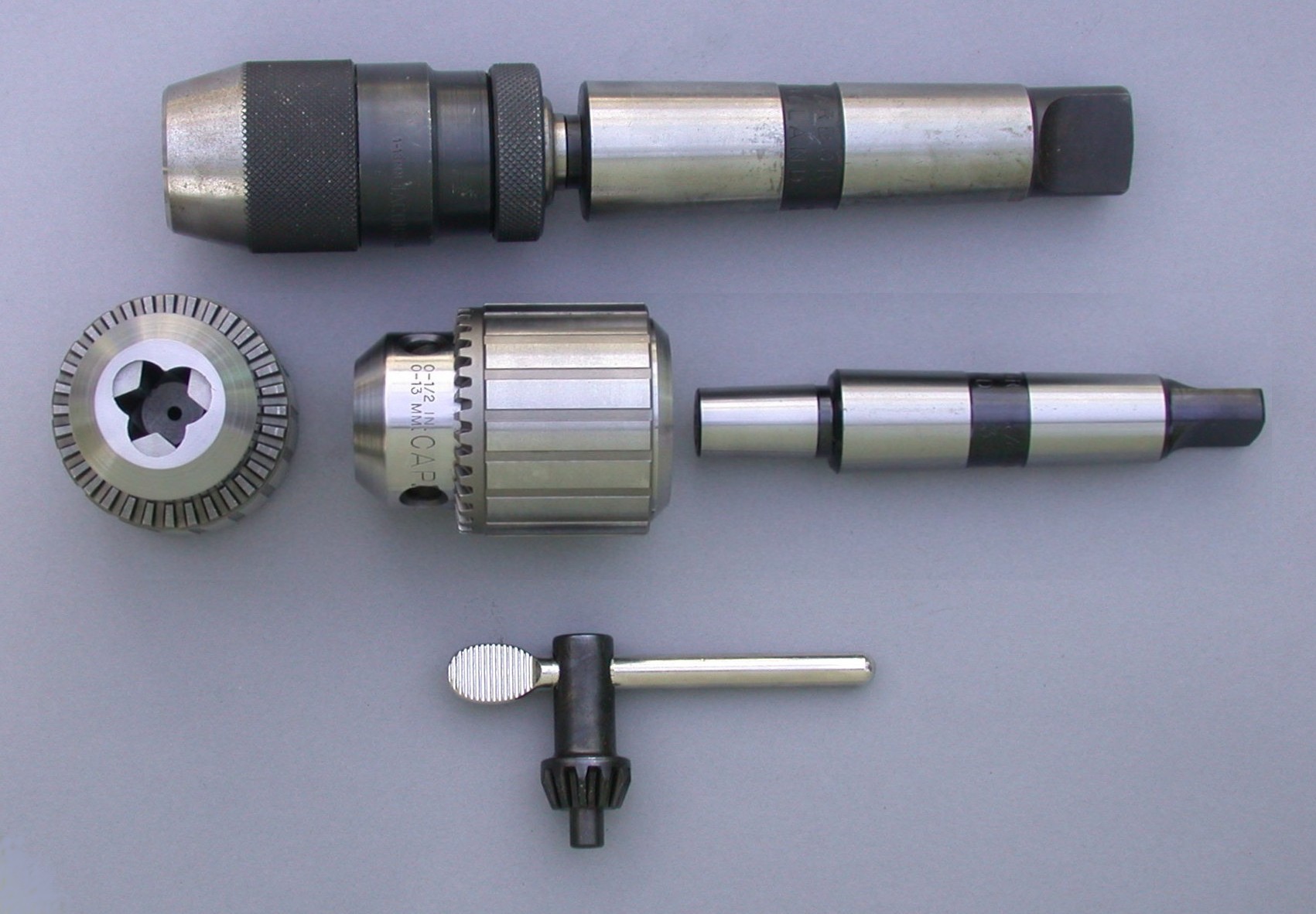

Chuck (engineering)

A chuck is a specialized type of clamp (tool), clamp used to hold an object with rotational symmetry, radial symmetry, especially a cylinder (geometry), cylinder. In a drill, a Milling (machining), mill and a transmission (mechanics), transmission, a chuck holds the rotating tool bit, tool; in a lathe, it holds the rotating workpiece. Chucks commonly use jaws to hold the tool or workpiece. The jaws are typically arranged in a radially symmetrical pattern like the points of a star (polygon), star. Jawed chucks may require a Wrench#Other types of keys, wrench-like device called a ''chuck key'' to be tightened or loosened, but other jawed chucks may be tightened or loosened by hand force alone, offering convenience at the expense of gripping force. Chucks on some lathes have jaws that move independently, allowing them to hold irregularly shaped objects. More complex designs might include specially shaped jaws, greater numbers of jaws, or quick-release mechanisms. Instead of jaws, a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

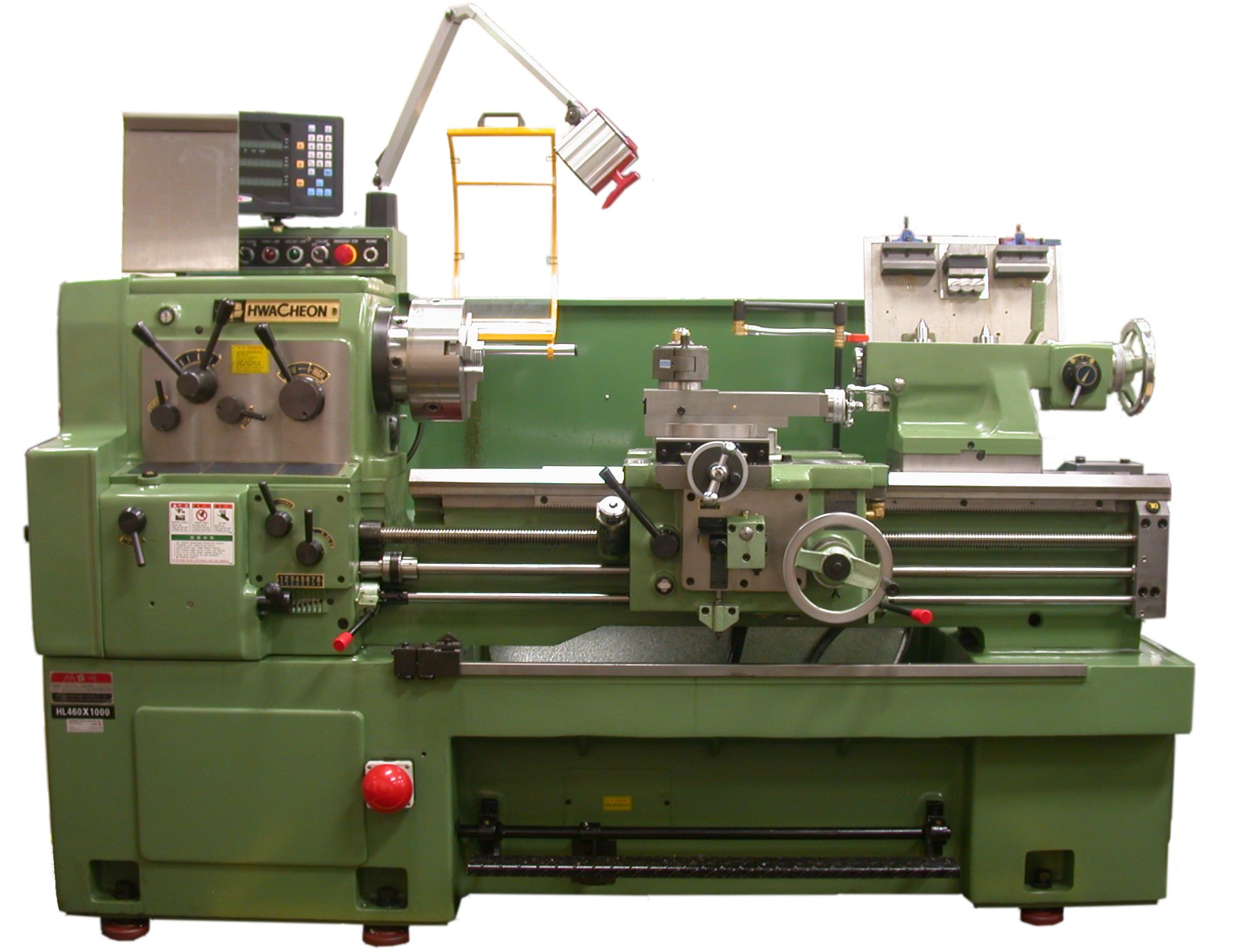

Lathe (metal)

In machining, a metal lathe or metalworking lathe is a large class of lathes designed for precisely machining relatively hard materials. They were originally designed to machine metals; however, with the advent of plastics and other materials, and with their inherent versatility, they are used in a wide range of applications, and a broad range of materials. In machining jargon, where the larger context is already understood, they are usually simply called ''lathes'', or else referred to by more-specific subtype names ('' toolroom lathe'', '' turret lathe'', etc.). These rigid machine tools remove material from a rotating workpiece via the (typically linear) movements of various cutting tools, such as tool bits and drill bits. Metal lathes can vary greatly, but the most common design is known as the universal lathe or parallel lathe. Construction The design of lathes can vary greatly depending on the intended application; however, basic features are common to most types. These ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Turning Between Centers

Turning is a machining process in which a cutting tool, typically a non-rotary tool bit, describes a helix toolpath by moving more or less linearly while the workpiece rotates. Usually the term "turning" is reserved for the generation of ''external'' surfaces by this cutting action, whereas this same essential cutting action when applied to ''internal'' surfaces (holes, of one kind or another) is called " boring". Thus the phrase "turning and boring" categorizes the larger family of processes known as lathing. The cutting of faces on the workpiece, whether with a turning or boring tool, is called "facing", and may be lumped into either category as a subset. Turning can be done manually, in a traditional form of lathe, which frequently requires continuous supervision by the operator, or by using an automated lathe which does not. Today the most common type of such automation is computer numerical control, better known as CNC. (CNC is also commonly used with many other types ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Machine Taper

A machine taper is a system for securing cutting tools or toolholders in the spindle of a machine tool or power tool. A male member of conical form (that is, with a taper) fits into the female socket, which has a matching taper of equal angle. Almost all machine tool spindles, and many power tool spindles, have a taper as their primary method of attachment for tools. Even on many drill presses, handheld drills, and lathes, which have chucks (such as a drill chuck or collet chuck), the chuck is attached by a taper. On drills, drill presses, and milling machines, the male member is the tool shank or toolholder shank, and the female socket is integral with the spindle. On lathes, the male may belong to the tool or to the spindle; spindle noses may have male tapers, female tapers, or both. Explanation Machine tool operators must be able to install or remove tool bits quickly and easily. A lathe, for example, has a rotating spindle in its headstock, to which one may wa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Concentric

In geometry, two or more objects are said to be ''concentric'' when they share the same center. Any pair of (possibly unalike) objects with well-defined centers can be concentric, including circles, spheres, regular polygons, regular polyhedra, parallelograms, cones, conic sections, and quadrics. Geometric objects are '' coaxial'' if they share the same axis (line of symmetry). Geometric objects with a well-defined axis include circles (any line through the center), spheres, cylinders, conic sections, and surfaces of revolution. Concentric objects are often part of the broad category of '' whorled patterns'', which also includes '' spirals'' (a curve which emanates from a point, moving farther away as it revolves around the point). Geometric properties In the Euclidean plane, two circles that are concentric necessarily have different radii from each other.. However, circles in three-dimensional space may be concentric, and have the same radius as each other, but nevert ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |