|

Derwent Iron Company

The Consett Iron Company Ltd was an industrial business based in the Consett area of County Durham in the United Kingdom. The company owned coal mines and limestone quarries, and manufactured iron and steel. It was registered on 4 April 1864 as successor to the Derwent and Consett Iron Company. This in turn was the successor to the Derwent Iron Company, founded in 1840. The company's seven collieries and various coke ovens came into the ownership of the National Coal Board, when British coal companies were nationalised in 1947. The Consett Iron Company itself was nationalised in 1951, becoming part of the Iron and Steel Corporation of Great Britain. It was denationalised shortly afterwards, then renationalised in 1967. The Consett Iron Company was absorbed into British Steel Corporation in 1967, and the location became known as the Consett Steel Works. British Steel Consett Works was closed in 1980. Early history In 1840 a group of local businessmen led by Jonathan Richards ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Consett

Consett is a town in the County Durham (district), County Durham district, in the ceremonial county of County Durham, Durham, England, about south-west of Newcastle upon Tyne. It had a population of 27,394 in 2001 and an estimate of 25,812 in 2019. History Consett sits high on the edge of the Pennines. Its name originates in the Old English ''Cunecesheafod'' (''heafod'' means headland, the meaning of ''cunec'' is less clear but is thought to derive from the Brittonic languages, Brittonic ''conyge'' or "hill"), first recorded in the 13th century. In 1841, it was a village community of only 145, but it was about to become a Boomtown, boom town: below the ground were Bituminous coal#Coking coal, coking coal and blackband iron ore, and nearby was limestone. These three ingredients were needed for blast furnaces to produce pig iron, iron and steelmaking, steel. The town is perched on the steep eastern bank of the River Derwent, North East England, River Derwent and owes its origins ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

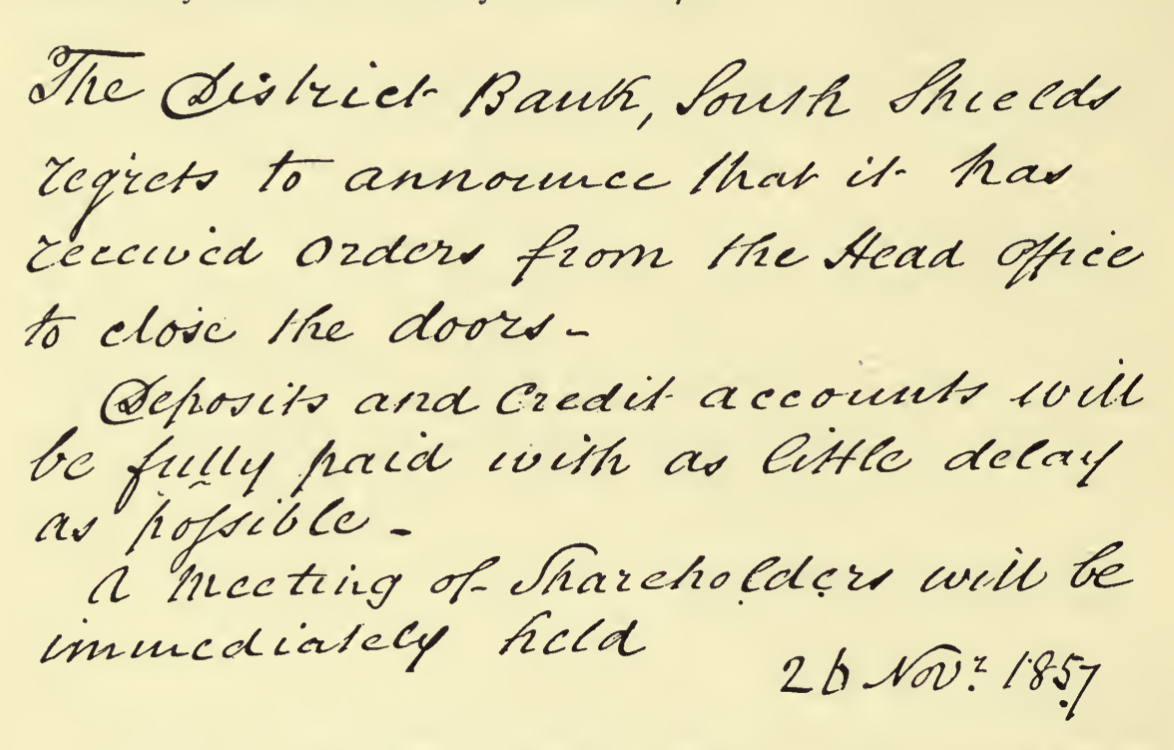

Northumberland And Durham District Bank

The Northumberland and Durham District Bank was a joint stock bank created in Newcastle upon Tyne, England, in 1836, which operated across the north-east of England. It was the area's largest such bank in its period, but failed in 1857 and was liquidated at enormous cost to its shareholders between then and 1865. A modern analysis of the bank's failure suggests the cause of its collapse was its own thorough incompetence, rather than an exogenous shock such as a monetary panic or bank run. Background The landscape of banking in England and Wales changed enormously in the early 19th-century, notably with the passing of the Country Bankers Act 1826 which for the first time allowed joint-stock banks with more than six partners to be created and to issue bank notes, as long as they were located more than from London. [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Girders

A girder () is a beam used in construction. It is the main horizontal support of a structure which supports smaller beams. Girders often have an I-beam cross section composed of two load-bearing ''flanges'' separated by a stabilizing ''web'', but may also have a box shape, Z shape, or other forms. Girders are commonly used to build bridges. A girt is a vertically aligned girder placed to resist shear loads. Small steel girders are rolled into shape. Larger girders (1 m/3 feet deep or more) are made as plate girders, welded or bolted together from separate pieces of steel plate. The Warren type girder replaces the solid web with an open latticework truss between the flanges. This arrangement combines strength with economy of materials, minimizing weight and thereby reducing loads and expense. Patented in 1848 by its designers James Warren and Willoughby Theobald Monzani, its structure consists of longitudinal members joined only by angled cross-members, forming ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Open Hearth Furnaces

An open-hearth furnace or open hearth furnace is any of several kinds of industrial Industrial furnace, furnace in which excess carbon and other impurities are burnt out of pig iron to Steelmaking, produce steel. Because steel is difficult to manufacture owing to its high melting point, normal fuels and furnaces were insufficient for mass production of steel, and the open-hearth type of furnace was one of several technologies developed in the nineteenth century to overcome this difficulty. Compared with the Bessemer process, which it displaced, its main advantages were that it did not Embrittlement, embrittle the steel from excessive nitrogen exposure, was easier to control, and permitted the melting and refining of large amounts of scrap, scrap iron and steel. The open-hearth furnace was first developed by German/British engineer Carl Wilhelm Siemens. In 1865, the French engineer Pierre-Émile Martin took out a licence from Siemens and first applied his regenerative furnace for ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Siemens-Martin Process

An open-hearth furnace or open hearth furnace is any of several kinds of industrial furnace in which excess carbon and other impurities are burnt out of pig iron to produce steel. Because steel is difficult to manufacture owing to its high melting point, normal fuels and furnaces were insufficient for mass production of steel, and the open-hearth type of furnace was one of several technologies developed in the nineteenth century to overcome this difficulty. Compared with the Bessemer process, which it displaced, its main advantages were that it did not embrittle the steel from excessive nitrogen exposure, was easier to control, and permitted the melting and refining of large amounts of scrap iron and steel. The open-hearth furnace was first developed by German/British engineer Carl Wilhelm Siemens. In 1865, the French engineer Pierre-Émile Martin took out a licence from Siemens and first applied his regenerative furnace for making steel. Their process was known as the Sieme ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Shipbuilding

Shipbuilding is the construction of ships and other Watercraft, floating vessels. In modern times, it normally takes place in a specialized facility known as a shipyard. Shipbuilders, also called shipwrights, follow a specialized occupation that traces its roots to before recorded history. Until recently, with the development of complex non-maritime technologies, a ship has often represented the most advanced structure that the society building it could produce. Some key industrial advances were developed to support shipbuilding, for instance the sawing of timbers by Saw#Mechanically powered saws, mechanical saws propelled by windmills in Dutch shipyards during the first half of the 17th century. The design process saw the early adoption of the logarithm (invented in 1615) to generate the curves used to produce the shape of a hull (watercraft), hull, especially when scaling up these curves accurately in the mould Lofting, loft. Shipbuilding and ship repairs, both commercial an ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Malleable Iron

Malleable iron is cast as white iron, the structure being a metastable carbide in a pearlitic matrix. Through an annealing heat treatment, the brittle structure as first cast is transformed into the malleable form. Carbon agglomerates into small roughly spherical aggregates of graphite, leaving a matrix of ferrite or pearlite according to the exact heat treatment used. Three basic types of malleable iron are recognized within the casting industry: blackheart, whiteheart, and pearlitic. History Malleable iron was used as early as the 4th century BCE, and archaeologists have found malleable iron artifacts made in China between 4th century BCE and 9th century CE. By the Tang dynasty, the use of malleable iron in China waned, although there are malleable iron artifacts dating to the 9th century. Malleable iron is mentioned in England in a patent dating to the 1670s. Réaumur conducted extensive research on malleable iron in 1720. He discovered that iron castings which were to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Capital (economics)

In economics, capital goods or capital are "those durable produced goods that are in turn used as productive inputs for further production" of goods and services. A typical example is the machinery used in a factory. At the macroeconomic level, "the nation's capital stock includes buildings, equipment, software, and inventories during a given year." The means of production is as a "... series of heterogeneous commodities, each having specific technical characteristics ..." "capital goods", are one of the three types of intermediate goods used in the production process, the other two being land and labour. The three are also known collectively as "primary factors of production". This classification originated during the classical economics period and has remained the dominant method for classification. Capital can be increased by the use of a production process (see production function and factors of production). Outputs of the production process are normally classif ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

William Jenkins General Manager Consett Iron Company Ca 1892

William is a masculine given name of Germanic origin. It became popular in England after the Norman conquest in 1066,All Things William"Meaning & Origin of the Name"/ref> and remained so throughout the Middle Ages and into the modern era. It is sometimes abbreviated "Wm." Shortened familiar versions in English include Will or Wil, Wills, Willy, Willie, Bill, Billie, and Billy. A common Irish form is Liam. Scottish diminutives include Wull, Willie or Wullie (as in Oor Wullie). Female forms include Willa, Willemina, Wilma and Wilhelmina. Etymology William is related to the German given name ''Wilhelm''. Both ultimately descend from Proto-Germanic ''*Wiljahelmaz'', with a direct cognate also in the Old Norse name ''Vilhjalmr'' and a West Germanic borrowing into Medieval Latin ''Willelmus''. The Proto-Germanic name is a compound of *''wiljô'' "will, wish, desire" and *''helmaz'' "helm, helmet".Hanks, Hardcastle and Hodges, ''Oxford Dictionary of First Names'', Oxford Univers ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pig Iron

Pig iron, also known as crude iron, is an intermediate good used by the iron industry in the production of steel. It is developed by smelting iron ore in a blast furnace. Pig iron has a high carbon content, typically 3.8–4.7%, along with silica and other dross, which makes it brittle and not useful directly as a material except for limited applications. Etymology The traditional shape of the molds used for pig iron ingots is a branching structure formed in sand, with many individual ingots at right angles to a central channel or "runner", resembling a litter of piglets being nursed by a sow. When the metal had cooled and hardened, the smaller ingots (the "pigs") were simply broken from the runner (the "sow"), hence the name "pig iron". As pig iron is intended for remelting, the uneven size of the ingots and the inclusion of small amounts of sand are insignificant issues when compared to the ease of casting and handling. History The Chinese were already making pig ir ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Blast Furnace

A blast furnace is a type of metallurgical furnace used for smelting to produce industrial metals, generally pig iron, but also others such as lead or copper. ''Blast'' refers to the combustion air being supplied above atmospheric pressure. In a blast furnace, fuel ( coke), ores, and flux (limestone) are continuously supplied through the top of the furnace, while a hot blast of (sometimes oxygen enriched) air is blown into the lower section of the furnace through a series of pipes called tuyeres, so that the chemical reactions take place throughout the furnace as the material falls downward. The end products are usually molten metal and slag phases tapped from the bottom, and flue gases exiting from the top. The downward flow of the ore along with the flux in contact with an upflow of hot, carbon monoxide-rich combustion gases is a countercurrent exchange and chemical reaction process. In contrast, air furnaces (such as reverberatory furnaces) are naturally aspirated, usu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

John Henderson (1807–1884)

John Henderson (2 May 1807 – 4 April 1884) was an English businessman and Liberal politician who sat in the House of Commons from 1864 to 1874. Henderson was the son of Gilbert Henderson of Durham, and his wife Ann Robinson. He was educated at the Grammar School, Durham. He was a carpet manufacturer and coal owner. He was a Deputy Lieutenant and J.P. for County Durham County Durham, officially simply Durham, is a ceremonial county in North East England.UK General Acts 1997 c. 23Lieutenancies Act 1997 Schedule 1(3). From legislation.gov.uk, retrieved 6 April 2022. The county borders Northumberland and Tyne an ... Henderson was elected as a Member of Parliament (MP) for City of Durham at a by-election in 1864. He held the seat until 1874. Henderson married Hannah Chipchase, daughter of Alderman Thomas Chipchase, of Durham in 1840. References External links * 1807 births 1884 deaths Liberal Party (UK) MPs for English constituencies UK MPs 1859–1865 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |