|

Composite Propeller

Marine composite propellers are ship propellers made from fiber composites. These composites are made from materials like glass or carbon fibers and infused with a high-strength resin like epoxy or polyimide. Attributes Composite propellers can be made using a lay-up process, leading to anisotropic Anisotropy () is the structural property of non-uniformity in different directions, as opposed to isotropy. An anisotropic object or pattern has properties that differ according to direction of measurement. For example, many materials exhibit ver ... properties. This can create a passive adaptation of self-twisting propeller blades, which are considered more energy-efficient when compared to rigid propeller blades. Longevity Composite materials may be considered an environmentally friendly option for propeller blades in some applications. While the composite blades are more resistant to corrosion and impact damage than many metal-alloy propeller blades, the water saturation and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

|

|

Propeller

A propeller (often called a screw if on a ship or an airscrew if on an aircraft) is a device with a rotating hub and radiating blades that are set at a pitch to form a helical spiral which, when rotated, exerts linear thrust upon a working fluid such as water or air. Propellers are used to pump fluid through a pipe or duct, or to create thrust to propel a boat through water or an aircraft through air. The blades are shaped so that their rotational motion through the fluid causes a pressure difference between the two surfaces of the blade by Bernoulli's principle which exerts force on the fluid. Most marine propellers are screw propellers with helical blades rotating on a propeller shaft (ship), propeller shaft with an approximately horizontal axis. History Early developments The principle employed in using a screw propeller is derived from stern sculling. In sculling, a single blade is moved through an arc, from side to side taking care to keep presenting the blade to the wat ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

|

Fibre-composite

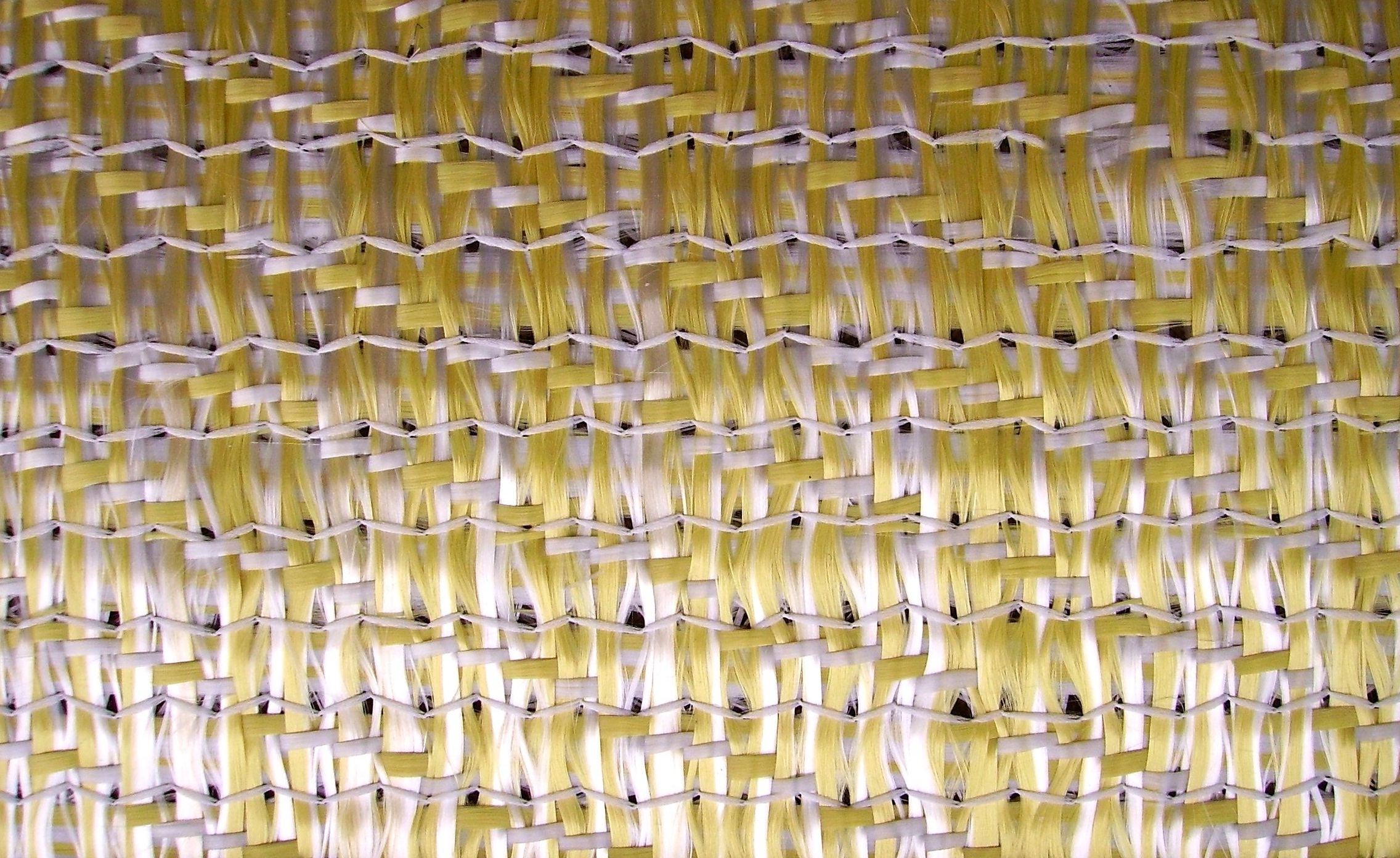

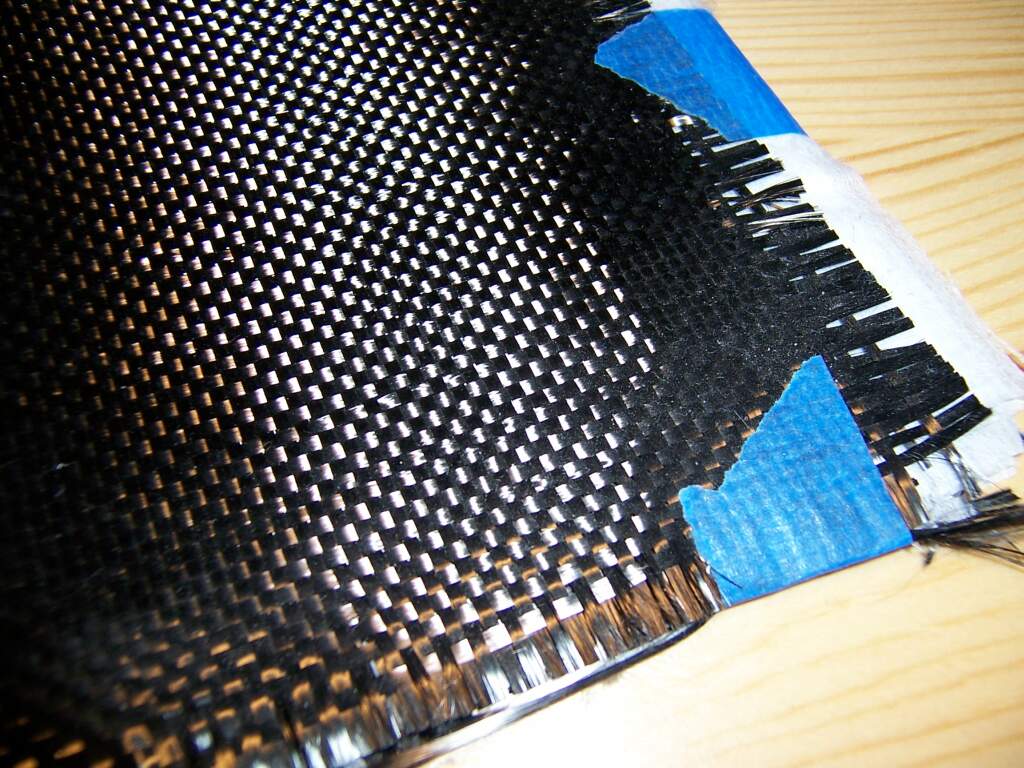

Fibre-reinforced plastic (FRP; also called fibre-reinforced polymer, or in American English ''fiber'') is a composite material made of a polymer matrix reinforced with fibres. The fibres are usually glass (in fibreglass), carbon (in carbon-fibre-reinforced polymer), aramid, or basalt. Rarely, other fibres such as paper, wood, boron, or asbestos have been used. The polymer is usually an epoxy, vinyl ester, or polyester thermosetting plastic, though phenol formaldehyde resins are still in use. FRPs are commonly used in the aerospace, automotive, marine, and construction industries. They are commonly found in ballistic armour and cylinders for self-contained breathing apparatuses. History Bakelite was the first fibre-reinforced plastic. Leo Baekeland had originally set out to find a replacement for shellac (made from the excretion of lac bugs). Chemists had begun to recognize that many natural resins and fibres were polymers, and Baekeland investigated the reactions of phenol and f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

|

Glass Fiber

Glass fiber ( or glass fibre) is a material consisting of numerous extremely fine fibers of glass. Glassmakers throughout history have experimented with glass fibers, but mass manufacture of glass fiber was only made possible with the invention of finer machine tooling. In 1893, Edward Drummond Libbey exhibited a dress at the World's Columbian Exposition incorporating glass fibers with the diameter and texture of silk fibers. Glass fibers can also occur naturally, as Pele's hair. Glass wool, which is one product called "fiberglass" today, was invented some time between 1932 and 1933 by Games Slayter of Owens-Illinois, as a material to be used as thermal building insulation. It is marketed under the trade name Fiberglas, which has become a genericized trademark. Glass fiber, when used as a thermal insulating material, is specially manufactured with a bonding agent to trap many small air cells, resulting in the characteristically air-filled low-density "glass wool" family of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

|

Carbon Fibers

Carbon fibers American and British English spelling differences, or carbon fibres (alternatively CF, graphite fiber or graphite fibre) are fibers about in diameter and composed mostly of carbon atoms. Carbon fibers have several advantages: high stiffness, high tensile strength, high strength to weight ratio, high chemical resistance, high-temperature tolerance, and low thermal expansion. These properties have made carbon fiber very popular in aerospace, civil engineering, military, motorsports, and other competition sports. However, they are relatively expensive compared to similar fibers, such as glass fiber, basalt fibers, or plastic fibers. To produce a carbon fiber, the carbon atoms are bonded together in crystals that are more or less aligned parallel to the fiber's long axis as the crystal alignment gives the fiber a high strength-to-volume ratio (in other words, it is strong for its size). Several thousand carbon fibers are bundled together to form a tow (fibre), tow, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

|

Resin

A resin is a solid or highly viscous liquid that can be converted into a polymer. Resins may be biological or synthetic in origin, but are typically harvested from plants. Resins are mixtures of organic compounds, predominantly terpenes. Common resins include amber, hashish, frankincense, myrrh and the animal-derived resin, shellac. Resins are used in varnishes, adhesives, food additives, incenses and perfumes. Resins protect plants from insects and pathogens, and are secreted in response to injury. Resins repel herbivores, insects, and pathogens, while the volatile natural phenol, phenolic compounds may attract benefactors such as predators of insects that attack the plant. Composition Most plant resins are composed of terpenes. Specific components are alpha-Pinene, alpha-pinene, pinene, beta-pinene, carene, delta-3 carene, and sabinene, the monocyclic terpenes limonene and terpinolene, and smaller amounts of the tricyclic sesquiterpenes, longifolene, caryophyllene, and cad ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

|

|

Epoxy

Epoxy is the family of basic components or Curing (chemistry), cured end products of epoxy Resin, resins. Epoxy resins, also known as polyepoxides, are a class of reactive prepolymers and polymers which contain epoxide groups. The epoxide functional group is also collectively called ''epoxy''. The IUPAC name for an epoxide group is an oxirane. Epoxy resins may be reacted (cross-linked) either with themselves through catalytic homopolymerisation, or with a wide range of co-reactants including polyfunctional amines, acids (and acid anhydrides), phenols, alcohols and thiols (sometimes called mercaptans). These co-reactants are often referred to as hardeners or curatives, and the cross-linking reaction is commonly referred to as Curing (chemistry), curing. Reaction of polyepoxides with themselves or with polyfunctional hardeners forms a thermosetting polymer, often with favorable mechanical properties and high thermal and chemical resistance. Epoxy has a wide range of application ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

|

Polyimide

Polyimide (sometimes abbreviated PI) is a monomer containing imide groups belonging to the class of high-performance plastics. With their high heat-resistance, polyimides enjoy diverse applications in roles demanding rugged organic materials, such as high temperature fuel cells, displays, and various military roles. A classic polyimide is Kapton, which is produced by condensation of pyromellitic dianhydride and 4,4'-oxydianiline.Wright, Walter W. and Hallden-Abberton, Michael (2002) "Polyimides" in ''Ullmann's Encyclopedia of Industrial Chemistry'', Wiley-VCH, Weinheim. History The first polyimide was discovered in 1908 by Bogart and Renshaw. They found that 4-amino phthalic anhydride does not melt when heated but does release water upon the formation of a high molecular weight polyimide. The first semialiphatic polyimide was prepared by Edward and Robinson by melt fusion of diamines and tetra acids or diamines and diacids/diester. However, the first polyimide of significant co ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

|

|

Propeller

A propeller (often called a screw if on a ship or an airscrew if on an aircraft) is a device with a rotating hub and radiating blades that are set at a pitch to form a helical spiral which, when rotated, exerts linear thrust upon a working fluid such as water or air. Propellers are used to pump fluid through a pipe or duct, or to create thrust to propel a boat through water or an aircraft through air. The blades are shaped so that their rotational motion through the fluid causes a pressure difference between the two surfaces of the blade by Bernoulli's principle which exerts force on the fluid. Most marine propellers are screw propellers with helical blades rotating on a propeller shaft (ship), propeller shaft with an approximately horizontal axis. History Early developments The principle employed in using a screw propeller is derived from stern sculling. In sculling, a single blade is moved through an arc, from side to side taking care to keep presenting the blade to the wat ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

|

|

Anisotropy

Anisotropy () is the structural property of non-uniformity in different directions, as opposed to isotropy. An anisotropic object or pattern has properties that differ according to direction of measurement. For example, many materials exhibit very different physical or mechanical properties when measured along different axes, e.g. absorbance, refractive index, conductivity, and tensile strength. An example of anisotropy is light coming through a polarizer. Another is wood, which is easier to split along its grain than across it because of the directional non-uniformity of the grain (the grain is the same in one direction, not all directions). Fields of interest Computer graphics In the field of computer graphics, an anisotropic surface changes in appearance as it rotates about its geometric normal, as is the case with velvet. Anisotropic filtering (AF) is a method of enhancing the image quality of textures on surfaces that are far away and viewed at a shallow angle. Older ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

|

Energy Efficiency In Transport

The energy efficiency in transport is the useful travelled distance, of passengers, goods or any type of load; divided by the total energy put into the transport propulsion means. The energy input might be rendered in several different types depending on the type of propulsion, and normally such energy is presented in liquid fuels, electrical energy or food energy. The Efficient energy use, energy efficiency is also occasionally known as energy intensity. The Multiplicative inverse, inverse of the energy efficiency in transport is the energy consumption in transport. Energy efficiency in transport is often described in terms of fuel consumption, fuel consumption being the reciprocal of Fuel efficiency, fuel economy. Nonetheless, fuel consumption is linked with a means of propulsion which uses liquid fuels, whilst energy efficiency is applicable to any sort of propulsion. To avoid said confusion, and to be able to compare the energy efficiency in any type of vehicle, experts tend t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

|

|

Metal Alloy

An alloy is a mixture of chemical elements of which in most cases at least one is a metallic element, although it is also sometimes used for mixtures of elements; herein only metallic alloys are described. Metallic alloys often have properties that differ from those of the pure elements from which they are made. The vast majority of metals used for commercial purposes are alloyed to improve their properties or behavior, such as increased strength, hardness or corrosion resistance. Metals may also be alloyed to reduce their overall cost, for instance alloys of gold and copper. A typical example of an alloy is 304 grade stainless steel which is commonly used for kitchen utensils, pans, knives and forks. Sometime also known as 18/8, it as an alloy consisting broadly of 74% iron, 18% chromium and 8% nickel. The chromium and nickel alloying elements add strength and hardness to the majority iron element, but their main function is to make it resistant to rust/corrosion. In an al ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |