Carbon Fibers on:

[Wikipedia]

[Google]

[Amazon]

Carbon fibers or carbon fibres (alternatively CF, graphite fiber or graphite fibre) are

Carbon fibers or carbon fibres (alternatively CF, graphite fiber or graphite fibre) are

During the 1960s, experimental work to find alternative raw materials led to the introduction of carbon fibers made from a petroleum pitch derived from oil processing. These fibers contained about 85% carbon and had excellent flexural strength. Also, during this period, the Japanese Government heavily supported carbon fiber development at home and several Japanese companies such as Toray, Nippon Carbon, Toho Rayon and

During the 1960s, experimental work to find alternative raw materials led to the introduction of carbon fibers made from a petroleum pitch derived from oil processing. These fibers contained about 85% carbon and had excellent flexural strength. Also, during this period, the Japanese Government heavily supported carbon fiber development at home and several Japanese companies such as Toray, Nippon Carbon, Toho Rayon and

Carbon fiber is frequently supplied in the form of a continuous tow wound onto a reel. The tow is a bundle of thousands of continuous individual carbon filaments held together and protected by an organic coating, or size, such as polyethylene oxide (PEO) or polyvinyl alcohol (PVA). The tow can be conveniently unwound from the reel for use. Each carbon filament in the tow is a continuous cylinder with a diameter of 5–10 micrometers and consists almost exclusively of

Carbon fiber is frequently supplied in the form of a continuous tow wound onto a reel. The tow is a bundle of thousands of continuous individual carbon filaments held together and protected by an organic coating, or size, such as polyethylene oxide (PEO) or polyvinyl alcohol (PVA). The tow can be conveniently unwound from the reel for use. Each carbon filament in the tow is a continuous cylinder with a diameter of 5–10 micrometers and consists almost exclusively of

Carbon fiber can have higher cost than other materials which has been one of the limiting factors of adoption. In a comparison between

Carbon fiber can have higher cost than other materials which has been one of the limiting factors of adoption. In a comparison between

Precursors for carbon fibers are

Precursors for carbon fibers are

Despite being known for their electrical conductivity, carbon fibers can carry only very low currents on their own. When woven into larger fabrics, they can be used to reliably provide (infrared) heating in applications requiring flexible electrical heating elements and can easily sustain temperatures past 100 °C. Many examples of this type of application can be seen in DIY heated articles of clothing and blankets. Due to its chemical inertness, it can be used relatively safely amongst most fabrics and materials; however, shorts caused by the material folding back on itself will lead to increased heat production and can lead to a fire.

Despite being known for their electrical conductivity, carbon fibers can carry only very low currents on their own. When woven into larger fabrics, they can be used to reliably provide (infrared) heating in applications requiring flexible electrical heating elements and can easily sustain temperatures past 100 °C. Many examples of this type of application can be seen in DIY heated articles of clothing and blankets. Due to its chemical inertness, it can be used relatively safely amongst most fabrics and materials; however, shorts caused by the material folding back on itself will lead to increased heat production and can lead to a fire.

Each carbon filament is produced from a

Each carbon filament is produced from a

A common method of manufacture involves heating the spun PAN filaments to approximately 300 °C in air, which breaks many of the hydrogen bonds and oxidizes the material. During this process, fibers tend to shrink. The resulting chemical composition and mechanical properties of the fiber are dependent on the time and temperature of the process, as well as on the tension applied to the fiber during oxidation. The

A common method of manufacture involves heating the spun PAN filaments to approximately 300 °C in air, which breaks many of the hydrogen bonds and oxidizes the material. During this process, fibers tend to shrink. The resulting chemical composition and mechanical properties of the fiber are dependent on the time and temperature of the process, as well as on the tension applied to the fiber during oxidation. The

Making Carbon Fiber

* {{DEFAULTSORT:Carbon Fiber British inventions Allotropes of carbon Synthetic fibers Woven fabrics Nonwoven fabrics Net fabrics

Carbon fibers or carbon fibres (alternatively CF, graphite fiber or graphite fibre) are

Carbon fibers or carbon fibres (alternatively CF, graphite fiber or graphite fibre) are fiber

Fiber (spelled fibre in British English; from ) is a natural or artificial substance that is significantly longer than it is wide. Fibers are often used in the manufacture of other materials. The strongest engineering materials often inco ...

s about in diameter and composed mostly of carbon

Carbon () is a chemical element; it has chemical symbol, symbol C and atomic number 6. It is nonmetallic and tetravalence, tetravalent—meaning that its atoms are able to form up to four covalent bonds due to its valence shell exhibiting 4 ...

atoms. Carbon fibers have several advantages: high stiffness, high tensile strength, high strength to weight ratio, high chemical resistance, high-temperature tolerance, and low thermal expansion. These properties have made carbon fiber very popular in aerospace, civil engineering, military, motorsports, and other competition sports. However, they are relatively expensive compared to similar fibers, such as glass fiber, basalt fibers, or plastic fibers.

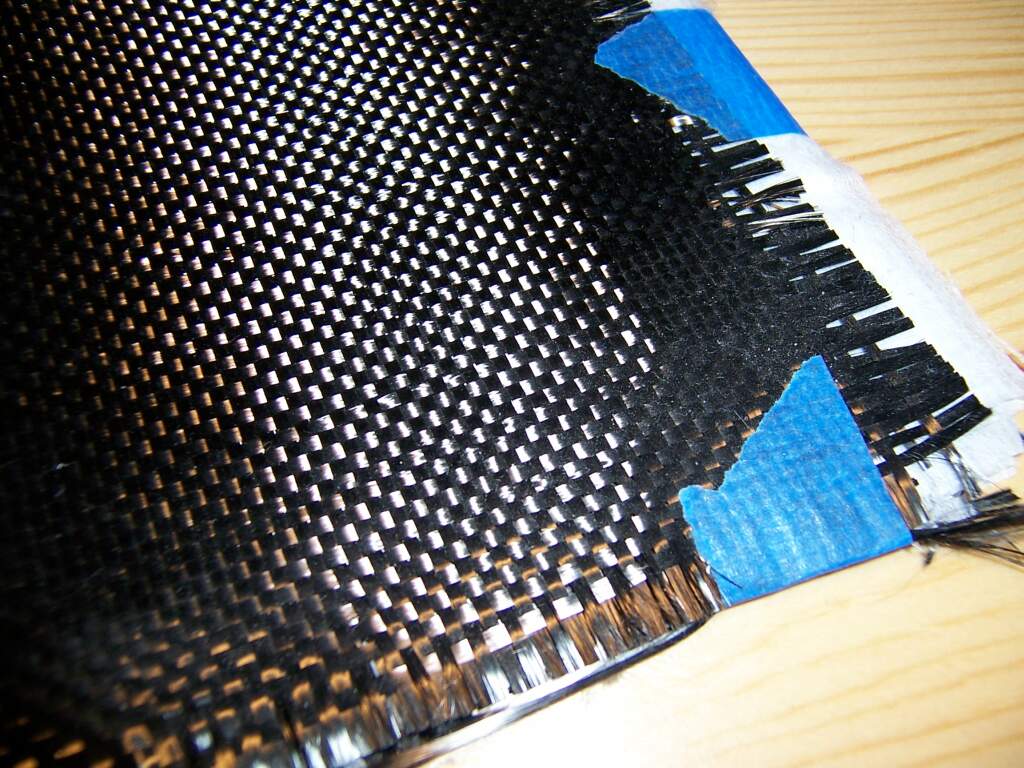

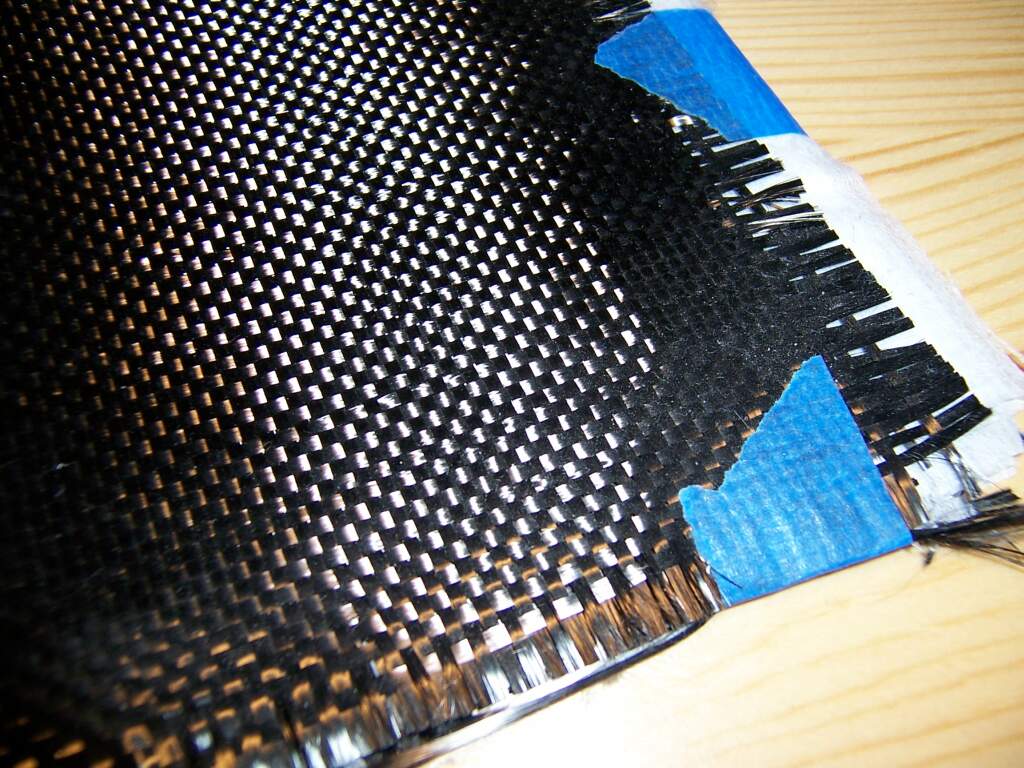

To produce a carbon fiber, the carbon atoms are bonded together in crystals that are more or less aligned parallel to the fiber's long axis as the crystal alignment gives the fiber a high strength-to-volume ratio (in other words, it is strong for its size). Several thousand carbon fibers are bundled together to form a tow, which may be used by itself or woven into a fabric.

Carbon fibers are usually combined with other materials to form a composite. For example, when permeated with a plastic resin and baked, it forms carbon-fiber-reinforced polymer

Carbon fiber-reinforced polymers (American English), carbon-fibre-reinforced polymers ( Commonwealth English), carbon-fiber-reinforced plastics, carbon-fiber reinforced-thermoplastic (CFRP, CRP, CFRTP), also known as carbon fiber, carbon comp ...

(often referred to as carbon fiber), which has a very high strength-to-weight ratio and is extremely rigid although somewhat brittle. Carbon fibers are also composited with other materials, such as graphite

Graphite () is a Crystallinity, crystalline allotrope (form) of the element carbon. It consists of many stacked Layered materials, layers of graphene, typically in excess of hundreds of layers. Graphite occurs naturally and is the most stable ...

, to form reinforced carbon-carbon composites, which have a very high heat tolerance.

Carbon fiber-reinforced materials are used to make aircraft and spacecraft parts, racing car bodies, golf club shafts, bicycle frames, fishing rods, automobile springs, sailboat masts, and many other components where light weight and high strength are needed.

History

In 1860, Joseph Swan produced carbon fibers for the first time, for use in light bulbs. In 1879,Thomas Edison

Thomas Alva Edison (February11, 1847October18, 1931) was an American inventor and businessman. He developed many devices in fields such as electric power generation, mass communication, sound recording, and motion pictures. These inventions, ...

baked cotton threads or bamboo slivers at high temperatures carbonizing them into an all-carbon fiber filament used in one of the first incandescent light bulbs to be heated by electricity. In 1880, Lewis Latimer developed a reliable carbon wire filament for the incandescent light bulb, heated by electricity.

In 1958, Roger Bacon

Roger Bacon (; or ', also '' Rogerus''; ), also known by the Scholastic accolades, scholastic accolade ''Doctor Mirabilis'', was a medieval English polymath, philosopher, scientist, theologian and Franciscans, Franciscan friar who placed co ...

created high-performance carbon fibers at the Union Carbide Parma Technical Center located outside of Cleveland

Cleveland is a city in the U.S. state of Ohio and the county seat of Cuyahoga County. Located along the southern shore of Lake Erie, it is situated across the Canada–U.S. maritime border and approximately west of the Ohio-Pennsylvania st ...

, Ohio

Ohio ( ) is a U.S. state, state in the Midwestern United States, Midwestern region of the United States. It borders Lake Erie to the north, Pennsylvania to the east, West Virginia to the southeast, Kentucky to the southwest, Indiana to the ...

. Those fibers were manufactured by heating strands of rayon

Rayon, also called viscose and commercialised in some countries as sabra silk or cactus silk, is a semi-synthetic fiber made from natural sources of regenerated cellulose fiber, cellulose, such as wood and related agricultural products. It has t ...

until they carbonized. This process proved to be inefficient, as the resulting fibers contained only about 20% carbon. In the early 1960s, a process was developed by Dr. Akio Shindo at Agency of Industrial Science and Technology of Japan, using polyacrylonitrile

Polyacrylonitrile (PAN) is a synthetic, semicrystalline organic polymer resin, with the linear formula (CH2CHCN)n. Almost all PAN resins are copolymers with acrylonitrile as the main monomer. PAN is used to produce large variety of products in ...

(PAN) as a raw material. This had produced a carbon fiber that contained about 55% carbon. In 1960 Richard Millington of H.I. Thompson Fiberglas Co. developed a process (US Patent No. 3,294,489) for producing a high carbon content (99%) fiber using rayon as a precursor. These carbon fibers had sufficient strength (modulus of elasticity and tensile strength) to be used as a reinforcement for composites having high strength to weight properties and for high temperature resistant applications.

The high potential strength of carbon fiber was realized in 1963 in a process developed by W. Watt, L. N. Phillips, and W. Johnson at the Royal Aircraft Establishment

The Royal Aircraft Establishment (RAE) was a British research establishment, known by several different names during its history, that eventually came under the aegis of the Ministry of Defence (United Kingdom), UK Ministry of Defence (MoD), bef ...

at Farnborough, Hampshire

Farnborough is a town located in the Rushmoor district of Hampshire, England. It has a population of around 57,486 as of the 2011 census and is an important centre of aviation, engineering and technology. The town is probably best known for it ...

. The process was patented by the UK Ministry of Defence, then licensed by the British National Research Development Corporation to three companies: Rolls-Royce

Rolls-Royce (always hyphenated) may refer to:

* Rolls-Royce Limited, a British manufacturer of cars and later aero engines, founded in 1906, now defunct

Automobiles

* Rolls-Royce Motor Cars, the current car manufacturing company incorporated in ...

, who were already making carbon fiber; Morganite; and Courtaulds. Within a few years, after successful use in 1968 of a ''Hyfil'' carbon-fiber fan assembly in the Rolls-Royce Conway jet engines of the Vickers VC10, Rolls-Royce took advantage of the new material's properties to break into the American market with its RB-211 aero-engine with carbon-fiber compressor blades. Unfortunately, the blades proved vulnerable to damage from bird impact. This problem and others caused Rolls-Royce such setbacks that the company was nationalized in 1971. The carbon-fiber production plant was sold off to form ''Bristol Composite Materials Engineering Ltd'' (often referred to as Bristol Composites).

In the late 1960s, the Japanese took the lead in manufacturing PAN-based carbon fibers. A 1970 joint technology agreement allowed Union Carbide to manufacture Japan's Toray Industries

is a multinational corporation headquartered in Japan that specializes in industrial products centered on technologies in organic synthetic chemistry, polymer chemistry, and biochemistry.

Its founding business areas were fibers and textiles, ...

product. Morganite decided that carbon-fiber production was peripheral to its core business, leaving Courtaulds as the only big UK manufacturer. Courtaulds's water-based inorganic process made the product susceptible to impurities that did not affect the organic process used by other carbon-fiber manufacturers, leading Courtaulds ceasing carbon-fiber production in 1991.

During the 1960s, experimental work to find alternative raw materials led to the introduction of carbon fibers made from a petroleum pitch derived from oil processing. These fibers contained about 85% carbon and had excellent flexural strength. Also, during this period, the Japanese Government heavily supported carbon fiber development at home and several Japanese companies such as Toray, Nippon Carbon, Toho Rayon and

During the 1960s, experimental work to find alternative raw materials led to the introduction of carbon fibers made from a petroleum pitch derived from oil processing. These fibers contained about 85% carbon and had excellent flexural strength. Also, during this period, the Japanese Government heavily supported carbon fiber development at home and several Japanese companies such as Toray, Nippon Carbon, Toho Rayon and Mitsubishi

The is a group of autonomous Japanese multinational companies in a variety of industries.

Founded by Yatarō Iwasaki in 1870, the Mitsubishi Group traces its origins to the Mitsubishi zaibatsu, a unified company that existed from 1870 to 194 ...

started their own development and production. Since the late 1970s, further types of carbon fiber yarn entered the global market, offering higher tensile strength and higher elastic modulus. For example, T400 from Toray with a tensile strength

Ultimate tensile strength (also called UTS, tensile strength, TS, ultimate strength or F_\text in notation) is the maximum stress that a material can withstand while being stretched or pulled before breaking. In brittle materials, the ultimate ...

of 4,000 MPa and M40, a modulus of 400 GPa. Intermediate carbon fibers, such as IM 600 from Toho Rayon with up to 6,000 MPa were developed. Carbon fibers from Toray, Celanese and Akzo found their way to aerospace application from secondary to primary parts first in military and later in civil aircraft as in McDonnell Douglas, Boeing, Airbus, and United Aircraft Corporation planes. In 1988, Dr. Jacob Lahijani invented balanced ultra-high Young's modulus (greater than 100 Mpsi) and high tensile strength pitch carbon fiber (greater than 500 kpsi) used extensively in automotive and aerospace applications. In March 2006, the patent was assigned to the University of Tennessee

The University of Tennessee, Knoxville (or The University of Tennessee; UT; UT Knoxville; or colloquially UTK or Tennessee) is a Public university, public Land-grant university, land-grant research university in Knoxville, Tennessee, United St ...

Research Foundation.

Structure and properties

Carbon fiber is frequently supplied in the form of a continuous tow wound onto a reel. The tow is a bundle of thousands of continuous individual carbon filaments held together and protected by an organic coating, or size, such as polyethylene oxide (PEO) or polyvinyl alcohol (PVA). The tow can be conveniently unwound from the reel for use. Each carbon filament in the tow is a continuous cylinder with a diameter of 5–10 micrometers and consists almost exclusively of

Carbon fiber is frequently supplied in the form of a continuous tow wound onto a reel. The tow is a bundle of thousands of continuous individual carbon filaments held together and protected by an organic coating, or size, such as polyethylene oxide (PEO) or polyvinyl alcohol (PVA). The tow can be conveniently unwound from the reel for use. Each carbon filament in the tow is a continuous cylinder with a diameter of 5–10 micrometers and consists almost exclusively of carbon

Carbon () is a chemical element; it has chemical symbol, symbol C and atomic number 6. It is nonmetallic and tetravalence, tetravalent—meaning that its atoms are able to form up to four covalent bonds due to its valence shell exhibiting 4 ...

. The earliest generation (e.g. T300, HTA and AS4) had diameters of 16–22 micrometers. Later fibers (e.g. IM6 or IM600) have diameters that are approximately 5 micrometers.

The atomic structure of carbon fiber is similar to that of graphite

Graphite () is a Crystallinity, crystalline allotrope (form) of the element carbon. It consists of many stacked Layered materials, layers of graphene, typically in excess of hundreds of layers. Graphite occurs naturally and is the most stable ...

, consisting of sheets of carbon atoms

Atoms are the basic particles of the chemical elements. An atom consists of a nucleus of protons and generally neutrons, surrounded by an electromagnetically bound swarm of electrons. The chemical elements are distinguished from each other ...

arranged in a regular hexagonal pattern (graphene

Graphene () is a carbon allotrope consisting of a Single-layer materials, single layer of atoms arranged in a hexagonal lattice, honeycomb planar nanostructure. The name "graphene" is derived from "graphite" and the suffix -ene, indicating ...

sheets), the difference being in the way these sheets interlock. Graphite is a crystalline

A crystal or crystalline solid is a solid material whose constituents (such as atoms, molecules, or ions) are arranged in a highly ordered microscopic structure, forming a crystal lattice that extends in all directions. In addition, macrosc ...

material in which the sheets are stacked parallel to one another in regular fashion. The intermolecular forces between the sheets are relatively weak Van der Waals force

In molecular physics and chemistry, the van der Waals force (sometimes van der Waals' force) is a distance-dependent interaction between atoms or molecules. Unlike ionic or covalent bonds, these attractions do not result from a chemical elec ...

s, giving graphite its soft and brittle characteristics.

Depending upon the precursor to make the fiber, carbon fiber may be turbostratic or graphitic, or have a hybrid structure with both graphitic and turbostratic parts present. In turbostratic carbon fiber the sheets of carbon atoms are haphazardly folded, or crumpled, together. Carbon fibers derived from polyacrylonitrile (PAN) are turbostratic, whereas carbon fibers derived from mesophase pitch are graphitic after heat treatment at temperatures exceeding 2200 °C. Turbostratic carbon fibers tend to have high ultimate tensile strength

Ultimate tensile strength (also called UTS, tensile strength, TS, ultimate strength or F_\text in notation) is the maximum stress that a material can withstand while being stretched or pulled before breaking. In brittle materials, the ultimate ...

, whereas heat-treated mesophase-pitch-derived carbon fibers have high Young's modulus

Young's modulus (or the Young modulus) is a mechanical property of solid materials that measures the tensile or compressive stiffness when the force is applied lengthwise. It is the modulus of elasticity for tension or axial compression. Youn ...

(i.e., high stiffness or resistance to extension under load) and high thermal conductivity

The thermal conductivity of a material is a measure of its ability to heat conduction, conduct heat. It is commonly denoted by k, \lambda, or \kappa and is measured in W·m−1·K−1.

Heat transfer occurs at a lower rate in materials of low ...

.

Applications

Carbon fiber can have higher cost than other materials which has been one of the limiting factors of adoption. In a comparison between

Carbon fiber can have higher cost than other materials which has been one of the limiting factors of adoption. In a comparison between steel

Steel is an alloy of iron and carbon that demonstrates improved mechanical properties compared to the pure form of iron. Due to steel's high Young's modulus, elastic modulus, Yield (engineering), yield strength, Fracture, fracture strength a ...

and carbon fiber materials for automotive materials, carbon fiber may be 10-12x more expensive. However, this cost premium has come down over the past decade from estimates of 35x more expensive than steel in the early 2000s.

Composite materials

Carbon fiber is most notably used to reinforcecomposite material

A composite or composite material (also composition material) is a material which is produced from two or more constituent materials. These constituent materials have notably dissimilar chemical or physical properties and are merged to create a ...

s, particularly the class of materials known as carbon fiber or graphite reinforced polymers. Non-polymer materials can also be used as the matrix for carbon fibers. Due to the formation of metal carbide

In chemistry, a carbide usually describes a compound composed of carbon and a metal. In metallurgy, carbiding or carburizing is the process for producing carbide coatings on a metal piece.

Interstitial / Metallic carbides

The carbides of th ...

s and corrosion

Corrosion is a natural process that converts a refined metal into a more chemically stable oxide. It is the gradual deterioration of materials (usually a metal) by chemical or electrochemical reaction with their environment. Corrosion engine ...

considerations, carbon has seen limited success in metal matrix composite

In materials science, a metal matrix composite (MMC) is a composite material with fibers or particles dispersed in a metallic matrix, such as copper, aluminum, or steel. The secondary phase is typically a ceramic (such as alumina or silicon carb ...

applications. Reinforced carbon-carbon (RCC) consists of carbon fiber-reinforced graphite, and is used structurally in high-temperature applications. The fiber also finds use in filtration

Filtration is a physical separation process that separates solid matter and fluid from a mixture using a ''filter medium'' that has a complex structure through which only the fluid can pass. Solid particles that cannot pass through the filte ...

of high-temperature gases, as an electrode

An electrode is an electrical conductor used to make contact with a nonmetallic part of a circuit (e.g. a semiconductor, an electrolyte, a vacuum or a gas). In electrochemical cells, electrodes are essential parts that can consist of a varie ...

with high surface area and impeccable corrosion

Corrosion is a natural process that converts a refined metal into a more chemically stable oxide. It is the gradual deterioration of materials (usually a metal) by chemical or electrochemical reaction with their environment. Corrosion engine ...

resistance, and as an anti- static component. Molding a thin layer of carbon fibers significantly improves fire resistance of polymers or thermoset composites because a dense, compact layer of carbon fibers efficiently reflects heat.

The increasing use of carbon fiber composites is displacing aluminum from aerospace applications in favor of other metals because of galvanic corrosion

Galvanic corrosion (also called bimetallic corrosion or dissimilar metal corrosion) is an electrochemical process in which one metal corrodes preferentially when it is in electrical contact with another, different metal, when both in the prese ...

issues. Note, however, that carbon fiber does not eliminate the risk of galvanic corrosion. In contact with metal, it forms "a perfect galvanic corrosion cell ..., and the metal will be subjected to galvanic corrosion attack" unless a sealant is applied between the metal and the carbon fiber.

Carbon fiber can be used as an additive to asphalt to make electrically conductive asphalt concrete. Using this composite material in the transportation infrastructure, especially for airport pavement, decreases some winter maintenance problems that lead to flight cancellation or delay due to the presence of ice and snow. Passing current through the composite material 3D network of carbon fibers dissipates thermal energy that increases the surface temperature of the asphalt, which is able to melt ice and snow above it.

Textiles

Precursors for carbon fibers are

Precursors for carbon fibers are polyacrylonitrile

Polyacrylonitrile (PAN) is a synthetic, semicrystalline organic polymer resin, with the linear formula (CH2CHCN)n. Almost all PAN resins are copolymers with acrylonitrile as the main monomer. PAN is used to produce large variety of products in ...

(PAN), rayon

Rayon, also called viscose and commercialised in some countries as sabra silk or cactus silk, is a semi-synthetic fiber made from natural sources of regenerated cellulose fiber, cellulose, such as wood and related agricultural products. It has t ...

and pitch. Carbon fiber filament yarns are used in several processing techniques: the direct uses are for prepregging, filament winding, pultrusion, weaving, braiding, etc. Carbon fiber yarn is rated by the linear density (weight per unit length; i.e., 1 g/1000 m = 1 tex

Tex, TeX, TEX, may refer to:

People and fictional characters

* Tex (nickname), a list of people and fictional characters with the nickname

* Tex Earnhardt (1930–2020), U.S. businessman

* Joe Tex (1933–1982), stage name of American soul singer ...

) or by number of filaments per yarn count, in thousands. For example, 200 tex for 3,000 filaments of carbon fiber is three times as strong as 1,000 carbon filament yarn, but is also three times as heavy. This thread can then be used to weave a carbon fiber filament fabric

Textile is an umbrella term that includes various fiber-based materials, including fibers, yarns, filaments, threads, and different types of fabric. At first, the word "textiles" only referred to woven fabrics. However, weaving is no ...

or cloth

Textile is an umbrella term that includes various fiber-based materials, including fibers, yarns, filaments, threads, and different types of fabric. At first, the word "textiles" only referred to woven fabrics. However, weaving is n ...

. The appearance of this fabric generally depends on the linear density of the yarn and the weave chosen. Some commonly used types of weave are twill

Twill is a type of textile

Textile is an Hyponymy and hypernymy, umbrella term that includes various Fiber, fiber-based materials, including fibers, yarns, Staple (textiles)#Filament fiber, filaments, Thread (yarn), threads, and d ...

, satin

A satin weave is a type of Textile, fabric weave that produces a characteristically glossy, smooth or lustrous material, typically with a glossy top surface and a dull back; it is not durable, as it tends to snag. It is one of three fundamen ...

and plain

In geography, a plain, commonly known as flatland, is a flat expanse of land that generally does not change much in elevation, and is primarily treeless. Plains occur as lowlands along valleys or at the base of mountains, as coastal plains, and ...

. Carbon filament yarns can also be knitted or braided. Dry fabric carbon fiber composites (CFRP) are typically cut using CNC digital cutting systems equipped with rotating machine knives and ultrasonic cutting method.

Microelectrodes

Carbon fibers are used for fabrication of carbon-fiber microelectrodes. In this application typically a single carbon fiber with diameter of 5–7 μm is sealed in a glass capillary. At the tip the capillary is either sealed with epoxy and polished to make a carbon-fiber disk microelectrode, or the fiber is cut to a length of 75–150 μm to make a carbon-fiber cylinder electrode. Carbon-fiber microelectrodes are used either in amperometry or fast-scan cyclic voltammetry for detection of biochemical signaling.Flexible heating

Despite being known for their electrical conductivity, carbon fibers can carry only very low currents on their own. When woven into larger fabrics, they can be used to reliably provide (infrared) heating in applications requiring flexible electrical heating elements and can easily sustain temperatures past 100 °C. Many examples of this type of application can be seen in DIY heated articles of clothing and blankets. Due to its chemical inertness, it can be used relatively safely amongst most fabrics and materials; however, shorts caused by the material folding back on itself will lead to increased heat production and can lead to a fire.

Despite being known for their electrical conductivity, carbon fibers can carry only very low currents on their own. When woven into larger fabrics, they can be used to reliably provide (infrared) heating in applications requiring flexible electrical heating elements and can easily sustain temperatures past 100 °C. Many examples of this type of application can be seen in DIY heated articles of clothing and blankets. Due to its chemical inertness, it can be used relatively safely amongst most fabrics and materials; however, shorts caused by the material folding back on itself will lead to increased heat production and can lead to a fire.

Synthesis

polymer

A polymer () is a chemical substance, substance or material that consists of very large molecules, or macromolecules, that are constituted by many repeat unit, repeating subunits derived from one or more species of monomers. Due to their br ...

such as polyacrylonitrile

Polyacrylonitrile (PAN) is a synthetic, semicrystalline organic polymer resin, with the linear formula (CH2CHCN)n. Almost all PAN resins are copolymers with acrylonitrile as the main monomer. PAN is used to produce large variety of products in ...

(PAN), rayon

Rayon, also called viscose and commercialised in some countries as sabra silk or cactus silk, is a semi-synthetic fiber made from natural sources of regenerated cellulose fiber, cellulose, such as wood and related agricultural products. It has t ...

, or petroleum pitch. All these polymers are known as a precursor. For synthetic polymers such as PAN or rayon, the precursor is first spun into filament yarns, using chemical and mechanical processes to initially align the polymer molecules in a way to enhance the final physical properties of the completed carbon fiber. Precursor compositions and mechanical processes used during spinning filament yarns may vary among manufacturers. After drawing or spinning, the polymer filament yarns are then heated to drive off non-carbon atoms (carbonization

Carbonization or carbonisation is the conversion of organic matters like plants and dead animal remains into carbon through destructive distillation.

Complexity in carbonization

Carbonization is a pyrolytic reaction, therefore, is considered a ...

), producing the final carbon fiber. The carbon fibers filament yarns may be further treated to improve handling qualities, then wound on to bobbins.

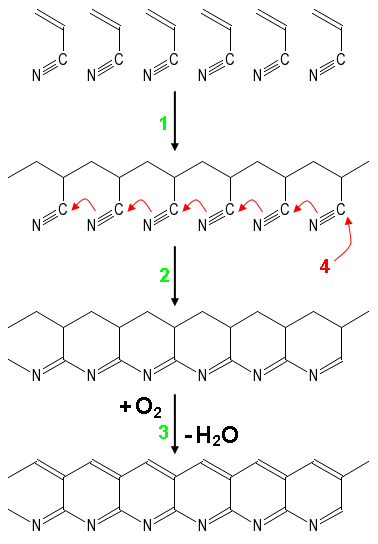

A common method of manufacture involves heating the spun PAN filaments to approximately 300 °C in air, which breaks many of the hydrogen bonds and oxidizes the material. During this process, fibers tend to shrink. The resulting chemical composition and mechanical properties of the fiber are dependent on the time and temperature of the process, as well as on the tension applied to the fiber during oxidation. The

A common method of manufacture involves heating the spun PAN filaments to approximately 300 °C in air, which breaks many of the hydrogen bonds and oxidizes the material. During this process, fibers tend to shrink. The resulting chemical composition and mechanical properties of the fiber are dependent on the time and temperature of the process, as well as on the tension applied to the fiber during oxidation. The oxidized

Redox ( , , reduction–oxidation or oxidation–reduction) is a type of chemical reaction in which the oxidation states of the reactants change. Oxidation is the loss of electrons or an increase in the oxidation state, while reduction is ...

PAN is then placed into a furnace having an inert atmosphere of a gas such as argon

Argon is a chemical element; it has symbol Ar and atomic number 18. It is in group 18 of the periodic table and is a noble gas. Argon is the third most abundant gas in Earth's atmosphere, at 0.934% (9340 ppmv). It is more than twice as abu ...

, and heated to approximately 2000 °C, which induces graphitization

Graphitization is a process of transforming a carbonaceous material, such as coal or the carbon in certain forms of iron alloys, into graphite.

Process

The graphitization process involves a restructuring of the molecular structure of the carbon ...

of the material, changing the molecular bond structure. When heated in the correct conditions, these chains bond side-to-side (ladder polymers), forming narrow graphene

Graphene () is a carbon allotrope consisting of a Single-layer materials, single layer of atoms arranged in a hexagonal lattice, honeycomb planar nanostructure. The name "graphene" is derived from "graphite" and the suffix -ene, indicating ...

sheets which eventually merge to form a single, columnar filament. The result is usually 93–95% carbon. Lower-quality fiber can be manufactured using pitch or rayon

Rayon, also called viscose and commercialised in some countries as sabra silk or cactus silk, is a semi-synthetic fiber made from natural sources of regenerated cellulose fiber, cellulose, such as wood and related agricultural products. It has t ...

as the precursor instead of PAN. The carbon can become further enhanced, as high modulus, or high strength carbon, by heat treatment processes. Carbon heated in the range of 1500–2000 °C (carbonization) exhibits the highest tensile strength

Ultimate tensile strength (also called UTS, tensile strength, TS, ultimate strength or F_\text in notation) is the maximum stress that a material can withstand while being stretched or pulled before breaking. In brittle materials, the ultimate ...

(5,650 MPa, or 820,000 psi), while carbon fiber heated from 2500 to 3000 °C (graphitizing) exhibits a higher modulus of elasticity (531GPa, or 77,000,000psi).

See also

* Basalt fiber *Carbon fiber reinforced polymer

Carbon fiber-reinforced polymers (American English), carbon-fibre-reinforced polymers ( Commonwealth English), carbon-fiber-reinforced plastics, carbon-fiber reinforced-thermoplastic (CFRP, CRP, CFRTP), also known as carbon fiber, carbon comp ...

* Carbon fiber reinforced ceramic material

* Carbon nanotube

A carbon nanotube (CNT) is a tube made of carbon with a diameter in the nanometre range ( nanoscale). They are one of the allotropes of carbon. Two broad classes of carbon nanotubes are recognized:

* ''Single-walled carbon nanotubes'' (''S ...

* ESD materials

* Graphene

Graphene () is a carbon allotrope consisting of a Single-layer materials, single layer of atoms arranged in a hexagonal lattice, honeycomb planar nanostructure. The name "graphene" is derived from "graphite" and the suffix -ene, indicating ...

References

External links

Making Carbon Fiber

* {{DEFAULTSORT:Carbon Fiber British inventions Allotropes of carbon Synthetic fibers Woven fabrics Nonwoven fabrics Net fabrics