|

Broach (metalwork)

Broaching is a machining process that uses a toothed tool, called a broach, to remove material. There are two main types of broaching: ''linear'' and ''rotary''. In linear broaching, which is the more common process, the broach is run linearly against a surface of the workpiece to produce the cut. Linear broaches are used in a broaching machine, which is also sometimes shortened to ''broach''. In rotary broaching, the broach is rotated and pressed into the workpiece to cut an axisymmetric shape. A rotary broach is used in a lathe or screw machine. In both processes the cut is performed in one pass of the broach, which makes it very efficient. Broaching is used when precision machining is required, especially for odd shapes. Commonly machined surfaces include circular and non-circular holes, splines, keyways, and flat surfaces. Typical workpieces include small to medium-sized castings, forgings, screw machine parts, and stampings. Even though broaches can be expensive, broach ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fixture (tool)

A fixture is a work-holding or support device used in the manufacturing industry. Fixtures are used to securely locate (position in a specific location or orientation) and support the work, ensuring that all parts produced using the fixture will maintain conformity and interchangeability. Using a fixture improves the economy of production by allowing smooth operation and quick transition from part to part, reducing the requirement for skilled labor by simplifying how workpieces are mounted, and increasing conformity across a production run. Compared with a jig A fixture differs from a jig in that when a fixture is used, the tool must move relative to the workpiece; a jig moves the piece while the tool remains stationary. Purpose A fixture's primary purpose is to create a secure mounting point for a workpiece, allowing for support during operation and increased accuracy, precision, reliability, and interchangeability in the finished parts. It also serves to reduce working tim ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rubber

Rubber, also called India rubber, latex, Amazonian rubber, ''caucho'', or ''caoutchouc'', as initially produced, consists of polymers of the organic compound isoprene, with minor impurities of other organic compounds. Types of polyisoprene that are used as natural rubbers are classified as elastomers. Currently, rubber is harvested mainly in the form of the latex from the Hevea brasiliensis, Pará rubber tree (''Hevea brasiliensis'') or others. The latex is a sticky, milky and white colloid drawn off by making incisions in the bark and collecting the fluid in vessels in a process called "tapping". Manufacturers refine this latex into the rubber that is ready for commercial processing. Natural rubber is used extensively in many applications and products, either alone or in combination with other materials. In most of its useful forms, it has a large stretch ratio and high resilience and also is buoyant and water-proof. Industrial demand for rubber-like materials began to out ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

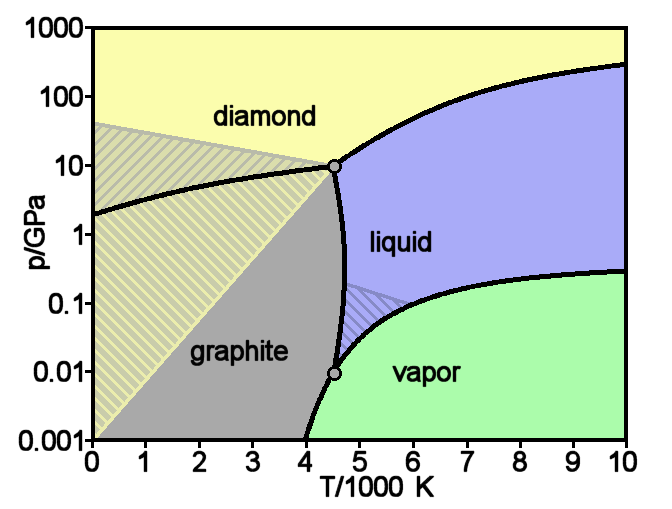

Graphite

Graphite () is a Crystallinity, crystalline allotrope (form) of the element carbon. It consists of many stacked Layered materials, layers of graphene, typically in excess of hundreds of layers. Graphite occurs naturally and is the most stable form of carbon under standard conditions. Synthetic and natural graphite are consumed on a large scale (1.3million metric tons per year in 2022) for uses in many critical industries including refractories (50%), lithium-ion batteries (18%), foundries (10%), and lubricants (5%), among others (17%). Graphite converts to diamond under extremely high pressure and temperature. Graphite's low cost, thermal and chemical inertness and characteristic conductivity of heat and electricity finds numerous applications in high energy and high temperature processes. Types and varieties Graphite can occur naturally or be produced synthetically. Natural graphite is obtained from naturally occurring geologic deposits and synthetic graphite is produced t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Aluminium

Aluminium (or aluminum in North American English) is a chemical element; it has chemical symbol, symbol Al and atomic number 13. It has a density lower than that of other common metals, about one-third that of steel. Aluminium has a great affinity towards oxygen, passivation (chemistry), forming a protective layer of aluminium oxide, oxide on the surface when exposed to air. It visually resembles silver, both in its color and in its great ability to reflect light. It is soft, magnetism, nonmagnetic, and ductility, ductile. It has one stable isotope, 27Al, which is highly abundant, making aluminium the abundance of the chemical elements, 12th-most abundant element in the universe. The radioactive decay, radioactivity of aluminium-26, 26Al leads to it being used in radiometric dating. Chemically, aluminium is a post-transition metal in the boron group; as is common for the group, aluminium forms compounds primarily in the +3 oxidation state. The aluminium cation Al3+ ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Copper Alloy

Copper alloys are metal alloys that have copper as their principal component. They have high resistance against corrosion. Of the large number of different types, the best known traditional types are bronze, where tin is a significant addition, and brass, using zinc instead. Both of these are imprecise terms. Latten is a further term, mostly used for coins with a very high copper content. Today the term ''copper alloy'' tends to be substituted for all of these, especially by museums. Copper deposits are abundant in most parts of the world (globally 70 parts per million), and it has therefore always been a relatively cheap metal. By contrast, tin is relatively rare (2 parts per million), and in Europe and the Mediterranean region, and even in prehistoric times had to be traded considerable distances, and was expensive, sometimes virtually unobtainable. Zinc is even more common at 75 parts per million, but is harder to extract from its ores. Bronze with the ideal percentage of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bronze

Bronze is an alloy consisting primarily of copper, commonly with about 12–12.5% tin and often with the addition of other metals (including aluminium, manganese, nickel, or zinc) and sometimes non-metals (such as phosphorus) or metalloids (such as arsenic or silicon). These additions produce a range of alloys some of which are harder than copper alone or have other useful properties, such as strength, ductility, or machinability. The archaeological period during which bronze was the hardest metal in widespread use is known as the Bronze Age. The beginning of the Bronze Age in western Eurasia is conventionally dated to the mid-4th millennium BCE (~3500 BCE), and to the early 2nd millennium BCE in China; elsewhere it gradually spread across regions. The Bronze Age was followed by the Iron Age, which started about 1300 BCE and reaching most of Eurasia by about 500 BCE, although bronze continued to be much more widely used than it is in modern times. Because historica ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Brass

Brass is an alloy of copper and zinc, in proportions which can be varied to achieve different colours and mechanical, electrical, acoustic and chemical properties, but copper typically has the larger proportion, generally copper and zinc. In use since prehistoric times, it is a substitutional alloy: atoms of the two constituents may replace each other within the same crystal structure. Brass is similar to bronze, a copper alloy that contains tin instead of zinc. Both bronze and brass may include small proportions of a range of other Chemical element, elements including arsenic, lead, phosphorus, aluminium, manganese and silicon. Historically, the distinction between the two alloys has been less consistent and clear, and increasingly museums use the more general term "list of copper alloys, copper alloy". Brass has long been a popular material for its bright gold-like appearance and is still used for drawer pulls and door handle, doorknobs. It has also been widely used to ma ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Burr (edge)

A burr is a raised edge or small piece of material that remains attached to a workpiece after a modification process. It is usually an unwanted piece of material and is removed with a deburring tool in a process called deburring. Burrs are most commonly created by machining operations, such as grinding, drilling, milling, engraving or turning. It may be present in the form of a fine wire on the edge of a freshly sharpened tool or as a raised portion of a surface; this type of burr is commonly formed when a hammer strikes a surface. Deburring accounts for a significant portion of manufacturing costs. In the printmaking technique of drypoint, burr, which gives a rich fuzzy quality to the engraved line, is highly desirable—the great problem with the drypoint medium is that the burr rapidly diminishes after as few as ten impressions are printed. Types There are three types of burrs that can be formed from machining operations: ''Poisson burr'', ''rollover burr'', and ''breako ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

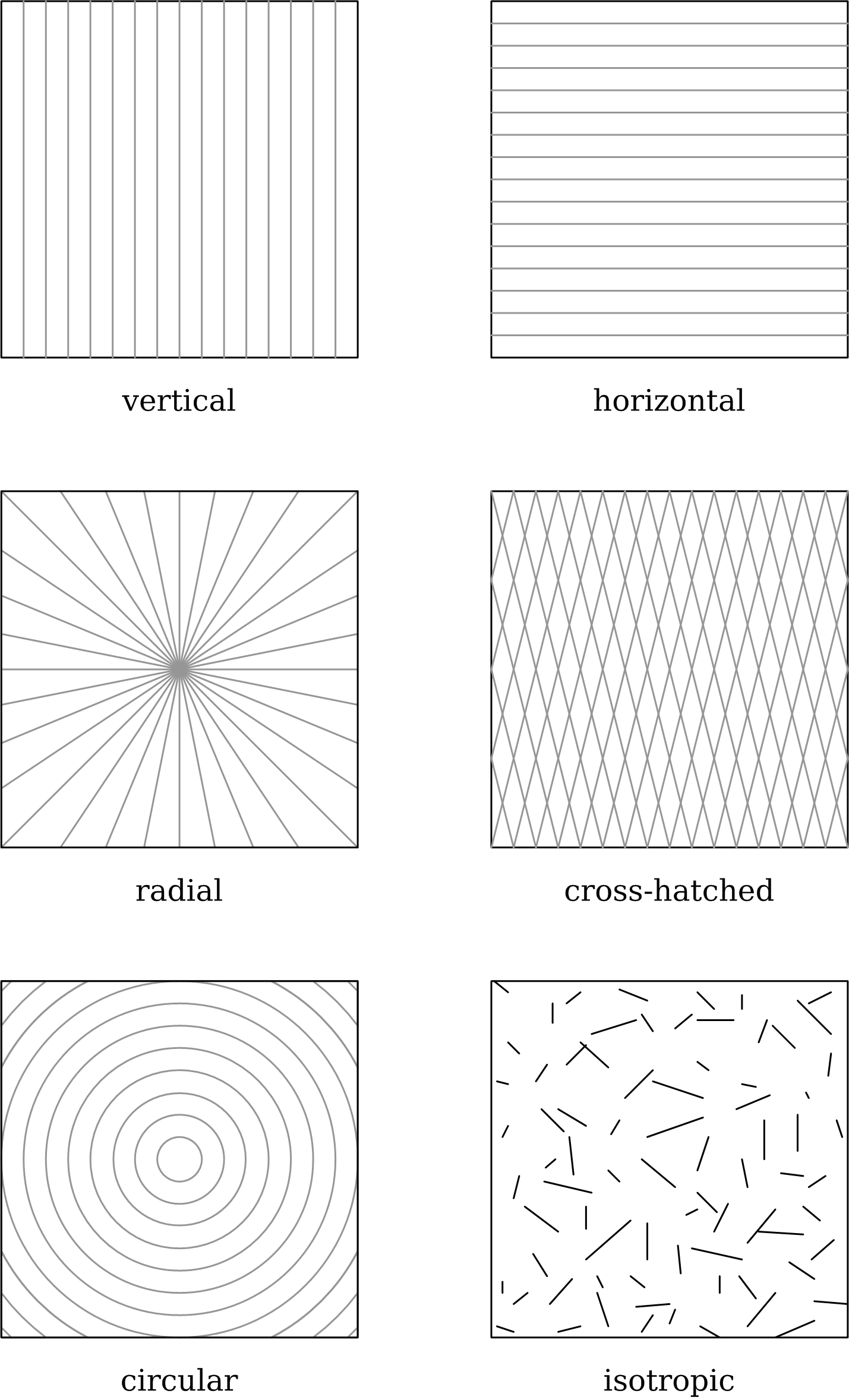

Surface Finish

Surface finish, also known as surface texture or surface topography, is the nature of a interface (matter), surface as defined by the three characteristics of lay, surface roughness, and waviness.. It comprises the small, local deviations of a surface from the perfectly Flat space, flat ideal (a true plane (geometry), plane). Surface texture is one of the important factors that control friction and transfer layer formation during sliding. Considerable efforts have been made to study the influence of surface texture on friction and wear during sliding conditions. Surface textures can be isotropy, isotropic or anisotropy, anisotropic. Sometimes, stick-slip friction phenomena can be observed during sliding, depending on surface texture. Each manufacturing process (such as the many kinds of machining) produces a surface texture. The process is usually optimized to ensure that the resulting texture is usable. If necessary, an additional process will be added to modify the initial te ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Engineering Tolerance

Engineering tolerance is the permissible limit or limits of variation in: # a physical dimension; # a measured value or physical property of a material, manufactured object, system, or service; # other measured values (such as temperature, humidity, etc.); # in engineering and safety, a physical distance or space (tolerance), as in a truck (lorry), train or boat under a bridge as well as a train in a tunnel (see structure gauge and loading gauge); # in mechanical engineering, the space between a bolt and a nut or a hole, etc. Dimensions, properties, or conditions may have some variation without significantly affecting functioning of systems, machines, structures, etc. A variation beyond the tolerance (for example, a temperature that is too hot or too cold) is said to be noncompliant, rejected, or exceeding the tolerance. Considerations when setting tolerances A primary concern is to determine how wide the tolerances may be without affecting other factors or the outcome of a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Surface Feet Per Minute

Surface feet per minute (SFPM or SFM) is the combination of a physical quantity (''surface speed'') and an imperial and American customary unit (''feet per minute'' or ''FPM''). It is defined as the number of linear feet that a location on a rotating component travels in one minute. Its most common use is in the measurement of cutting speed (surface speed) in machining. It is a unit of velocity that describes how fast the cutting edge of the cutting tool travels. It correlates directly to the machinability of the workpiece material and the hardness of the cutting tool material. It relates to spindle speed via variables such as cutter diameter (for rotating cutters) or workpiece diameter (for lathe work). SFM is a combination of ''diameter'' and the ''velocity'' ( RPM) of the material measured in feet-per-minute as the spindle of a milling machine Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a workpiece. This ma ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |