|

Surface-mount

Surface-mount technology (SMT), originally called planar mounting, is a method in which the electrical components are mounted directly onto the surface of a printed circuit board (PCB). An electrical component mounted in this manner is referred to as a surface-mount device (SMD). In industry, this approach has largely replaced through-hole technology construction method of fitting components, in large part because SMT allows for increased manufacturing automation which reduces cost and improves quality. It also allows for more components to fit on a given area of substrate. Both technologies can be used on the same board, with the through-hole technology often used for components not suitable for surface mounting such as large transformers and heat-sinked power semiconductors. An SMT component is usually smaller than its through-hole counterpart because it has either smaller leads or no leads at all. It may have short lead (electronics), pins or leads of various styles, flat con ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Reflow Soldering

Reflow soldering is a process in which a solder paste (a sticky mixture of powdered solder and flux (metallurgy), flux) is used to temporarily attach anywhere from one to thousands of tiny electrical components to their contact pads, after which the entire assembly is subjected to controlled heat. The solder paste reflows in a molten state, creating permanent solder joints. Heating may be accomplished by passing the assembly through a reflow oven, under an Infrared heater, infrared lamp, or (mainly for prototyping) by soldering individual joints with a hot air pencil. Reflow soldering with long industrial convection ovens is the preferred method of soldering surface mount technology (SMT) components to a printed circuit board (PCB). Each segment of the oven has a regulated temperature, according to the specific thermal requirements of each assembly. Reflow ovens meant specifically for the soldering of surface mount components may also be used for Through-hole technology, throu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

SMT Placement Equipment

Surface-mount technology (SMT) component placement systems, commonly called pick-and-place machines or P&Ps, are robotic machines which are used to place surface-mount devices (SMDs) onto a printed circuit board (PCB). They are used for high speed, high precision placing of a broad range of electronic components (such as capacitors, resistors, and integrated circuits) onto the PCBs which are in turn used in computers, consumer electronics, and industrial, medical, automotive, military and telecommunications equipment. Similar equipment exists for through-hole components. This type of equipment is sometimes used to package microchips using the flip chip method. History 1980s and 1990s During this time, a typical SMT assembly line employed two different types of pick-and-place (P&P) machines arranged in sequence. The unpopulated board was fed into a rapid placement machine. These machines, sometimes called chip shooters, place mainly low-precision, simple package co ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Printed Circuit Board

A printed circuit board (PCB), also called printed wiring board (PWB), is a Lamination, laminated sandwich structure of electrical conduction, conductive and Insulator (electricity), insulating layers, each with a pattern of traces, planes and other features (similar to wires on a flat surface) Chemical milling, etched from one or more sheet layers of copper laminated onto or between sheet layers of a non-conductive substrate. PCBs are used to connect or Electrical wiring, "wire" Electronic component, components to one another in an electronic circuit. Electrical components may be fixed to conductive pads on the outer layers, generally by soldering, which both electrically connects and mechanically fastens the components to the board. Another manufacturing process adds Via (electronics), vias, metal-lined drilled holes that enable electrical interconnections between conductive layers, to boards with more than a single side. Printed circuit boards are used in nearly all e ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Through-hole Technology

In electronics, through-hole technology (also spelled "thru-hole") is a manufacturing scheme in which leads on the components are inserted through holes drilled in printed circuit boards (PCB) and soldered to pads on the opposite side, either by manual assembly (hand placement) or by the use of automated insertion mount machines. History Through-hole technology almost completely replaced earlier electronics assembly techniques such as point-to-point construction. From the second generation of computers in the 1950s until surface-mount technology (SMT) became popular in the mid 1980s, every component on a typical PCB was a through-hole component. PCBs initially had tracks printed on one side only, later both sides, then multi-layer boards were in use. Through holes became plated-through holes (PTH) in order for the components to make contact with the required conductive layers. Plated-through holes are no longer required with SMT boards for making the component connectio ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Juki KE-2080L By Megger

Juki (stylized as JUKI) is a Japanese multinational manufacturer of industrial sewing machines and domestic sewing machines, as well as high-technology SMT ( surface mount technology) assembly equipment and is headquartered in Tama-shi, Tokyo. It is one of the leading industrial machine manufacturers. JUKI used to rank as the largest industrial sewing machine manufacturer in the world. Headquartered in Japan, the company currently has manufacturing facilities in Japan, China, and Vietnam, and markets its products on six continents, in about 170 countries. Until 1988, the company was known as Tokyo Juki Industrial Company, Ltd. The company motto, which doubles as a customer creed, is "Mind & Technology" (as in "emotionally accessible technology") Production The company produces sewing machines for the home or hobbyist market as well as various machines for the textile industry. In February 2013, Juki and Sony Corp. entered negotiations to discuss a merger of their SMT ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

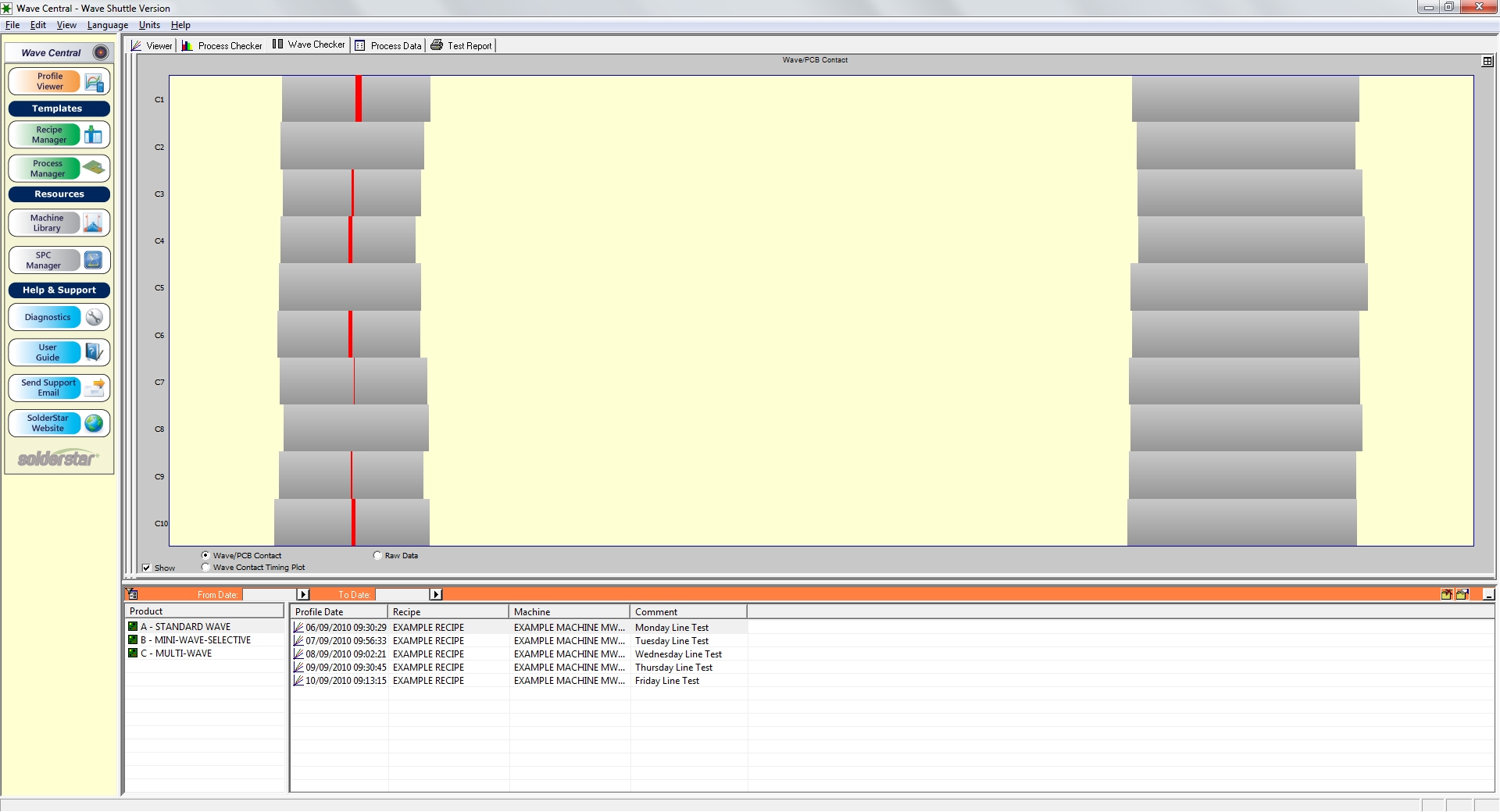

Selective Soldering

Selective soldering is the process of selectively soldering components to printed circuit boards and molded modules that could be damaged by the heat of a reflow oven or wave soldering in a traditional surface-mount technology (SMT) or through-hole technology assembly processes. This usually follows an SMT oven reflow process; parts to be selectively soldered are usually surrounded by parts that have been previously soldered in a surface-mount reflow process, and the selective-solder process must be sufficiently precise to avoid damaging them. Processes Assembly processes used in selective soldering include: * ''Selective aperture tooling over wave solder'': These tools mask off areas previously soldered in the SMT reflow soldering process, exposing only those areas to be selectively soldered in the tool's aperture or window. The tool and printed circuit board (PCB) assembly are then passed over wave soldering equipment to complete the process. Each tool is specific to a PCB assemb ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ball Grid Array

A ball grid array (BGA) is a type of surface-mount packaging (a chip carrier) used for integrated circuits. BGA packages are used to permanently mount devices such as microprocessors. A BGA can provide more interconnection pins than can be put on a dual in-line or flat package. The whole bottom surface of the device can be used, instead of just the perimeter. The traces connecting the package's leads to the wires or balls which connect the die to package are also on average shorter than with a perimeter-only type, leading to better performance at high speeds. Soldering of BGA devices requires precise control and is usually done by automated processes such as in computer-controlled automatic reflow ovens. Description The BGA is descended from the pin grid array (PGA), which is a package with one face covered (or partly covered) with pins in a grid pattern which, in operation, conduct electrical signals between the integrated circuit and the printed circuit board (PCB) ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wave Soldering

Wave soldering is a bulk soldering process used in printed circuit board manufacturing. The circuit board is passed over a pan of molten solder in which a pump produces an upwelling of solder that looks like a standing wave. As the circuit board makes contact with this wave, the components become soldered to the board. Wave soldering is used for both through-hole printed circuit assemblies, and surface mount. In the latter case, the components are glued onto the surface of a printed circuit board (PCB) by placement equipment, before being run through the molten solder wave. Wave soldering is mainly used in soldering of through hole components. As through-hole components have been largely replaced by surface mount components, wave soldering has been supplanted by reflow soldering methods in many large-scale electronics applications. However, there is still significant wave soldering where surface-mount technology (SMT) is not suitable (e.g., large power devices and high pi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Numerical Control

Computer numerical control (CNC) or CNC machining is the automated control of machine tools by a computer. It is an evolution of numerical control (NC), where machine tools are directly managed by data storage media such as punched cards or punched tape. Because CNC allows for easier programming, modification, and real-time adjustments, it has gradually replaced NC as computing costs declined. A CNC machine is a motorized maneuverable tool and often a motorized maneuverable platform, which are both controlled by a computer, according to specific input instructions. Instructions are delivered to a CNC machine in the form of a sequential program of machine control instructions such as G-code and M-code, and then executed. The program can be written by a person or, far more often, generated by graphical computer-aided design (CAD) or computer-aided manufacturing (CAM) software. In the case of 3D printers, the part to be printed is "sliced" before the instructions (or the prog ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Infrared

Infrared (IR; sometimes called infrared light) is electromagnetic radiation (EMR) with wavelengths longer than that of visible light but shorter than microwaves. The infrared spectral band begins with the waves that are just longer than those of red light (the longest waves in the visible spectrum), so IR is invisible to the human eye. IR is generally (according to ISO, CIE) understood to include wavelengths from around to . IR is commonly divided between longer-wavelength thermal IR, emitted from terrestrial sources, and shorter-wavelength IR or near-IR, part of the solar spectrum. Longer IR wavelengths (30–100 μm) are sometimes included as part of the terahertz radiation band. Almost all black-body radiation from objects near room temperature is in the IR band. As a form of EMR, IR carries energy and momentum, exerts radiation pressure, and has properties corresponding to both those of a wave and of a particle, the photon. It was long known that fires e ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Surface Tension

Surface tension is the tendency of liquid surfaces at rest to shrink into the minimum surface area possible. Surface tension (physics), tension is what allows objects with a higher density than water such as razor blades and insects (e.g. Gerridae, water striders) to float on a water surface without becoming even partly submerged. At liquid–air interfaces, surface tension results from the greater attraction of liquid molecules to each other (due to Cohesion (chemistry), cohesion) than to the molecules in the air (due to adhesion). There are two primary mechanisms in play. One is an inward force on the surface molecules causing the liquid to contract. Second is a tangential force parallel to the surface of the liquid. This ''tangential'' force is generally referred to as the surface tension. The net effect is the liquid behaves as if its surface were covered with a stretched elastic membrane. But this analogy must not be taken too far as the tension in an elastic membrane i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |