Printed circuit board on:

[Wikipedia]

[Google]

[Amazon]

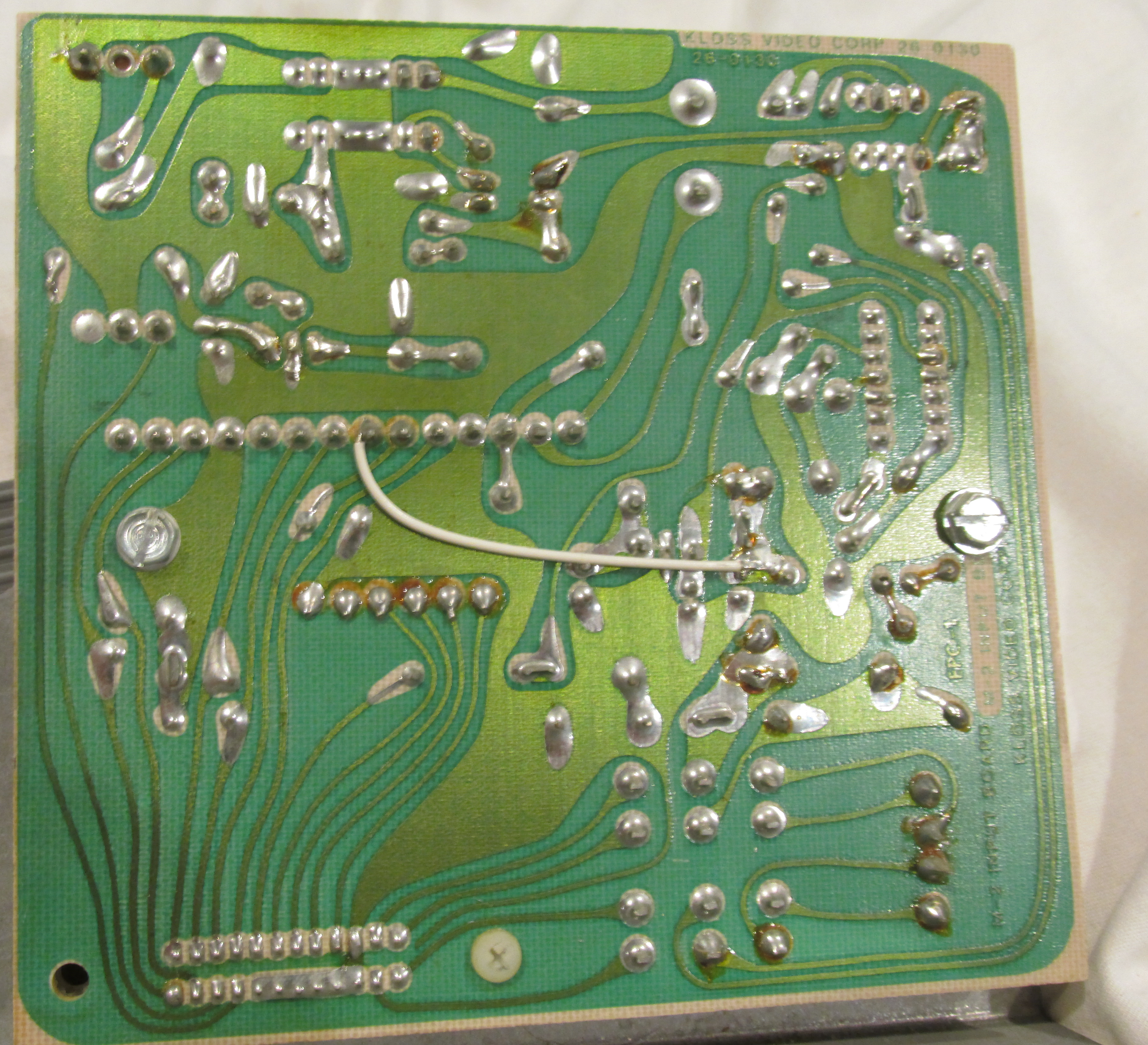

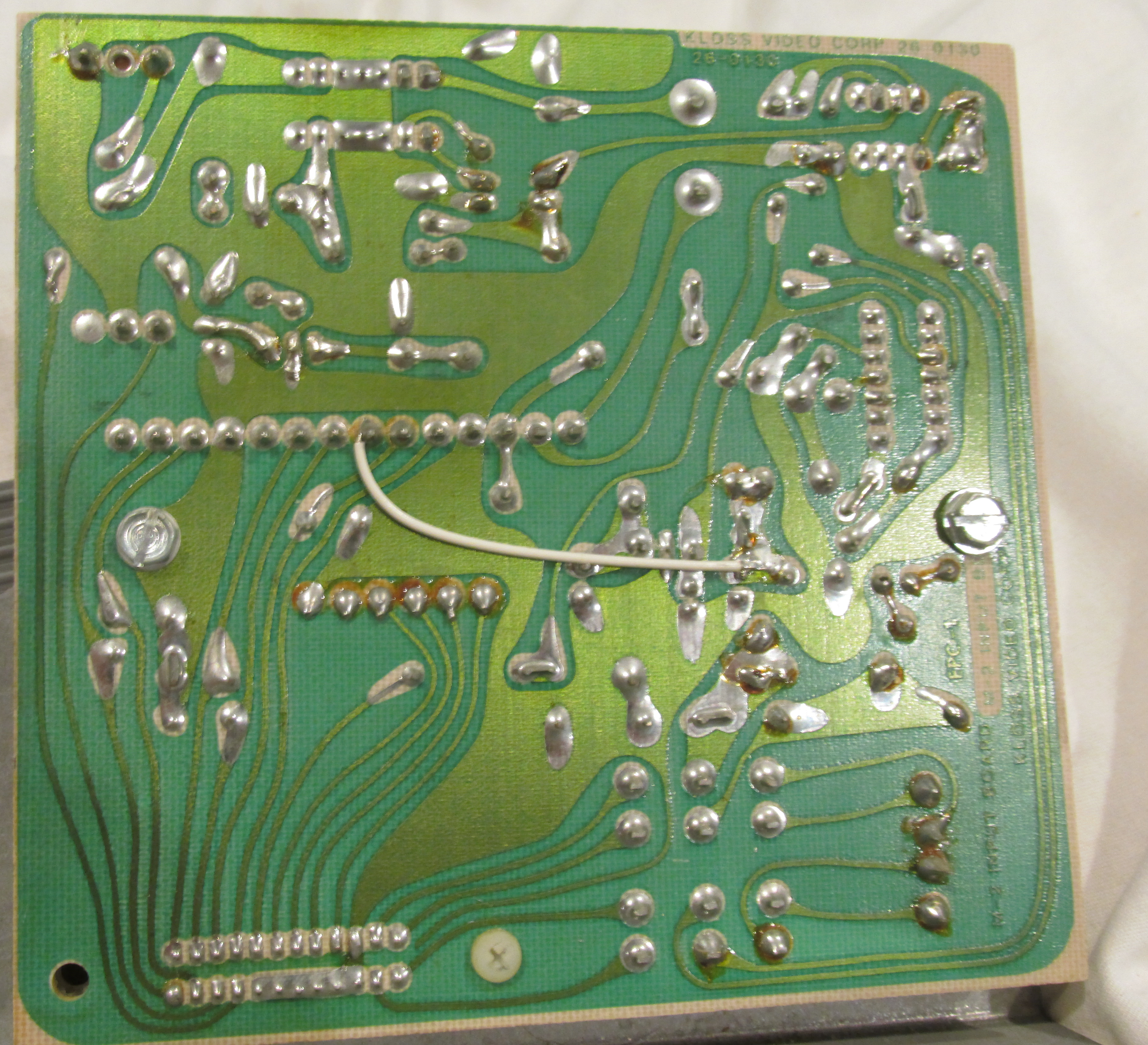

A printed circuit board (PCB), also called printed wiring board (PWB), is a laminated sandwich structure of

A printed circuit board (PCB), also called printed wiring board (PWB), is a laminated sandwich structure of

The Austrian engineer Paul Eisler invented the printed circuit as part of a radio set while working in the UK around 1936. In 1941 a multi-layer printed circuit was used in German magnetic influence naval mines.

Around 1943 the United States began to use the technology on a large scale to make

The Austrian engineer Paul Eisler invented the printed circuit as part of a radio set while working in the UK around 1936. In 1941 a multi-layer printed circuit was used in German magnetic influence naval mines.

Around 1943 the United States began to use the technology on a large scale to make

A basic PCB consists of a flat sheet of insulating material and a layer of copper

A basic PCB consists of a flat sheet of insulating material and a layer of copper

"Through hole" components are mounted by their wire leads passing through the board and soldered to traces on the other side. "Surface mount" components are attached by their leads to copper traces on the same side of the board. A board may use both methods for mounting components. PCBs with only through-hole mounted components are now uncommon. Surface mounting is used for

"Through hole" components are mounted by their wire leads passing through the board and soldered to traces on the other side. "Surface mount" components are attached by their leads to copper traces on the same side of the board. A board may use both methods for mounting components. PCBs with only through-hole mounted components are now uncommon. Surface mounting is used for

A minimal PCB for a single component, used for

A minimal PCB for a single component, used for

Cordwood construction can save significant space and was often used with wire-ended components in applications where space was at a premium (such as fuzes, missile guidance, and telemetry systems) and in high-speed

Cordwood construction can save significant space and was often used with wire-ended components in applications where space was at a premium (such as fuzes, missile guidance, and telemetry systems) and in high-speed

A printed circuit board (PCB), also called printed wiring board (PWB), is a laminated sandwich structure of

A printed circuit board (PCB), also called printed wiring board (PWB), is a laminated sandwich structure of conductive

In physics and electrical engineering, a conductor is an object or type of material that allows the flow of Electric charge, charge (electric current) in one or more directions. Materials made of metal are common electrical conductors. The flow ...

and insulating layers, each with a pattern of traces, planes and other features (similar to wires on a flat surface) etched from one or more sheet layers of copper laminated onto or between sheet layers of a non-conductive substrate. PCBs are used to connect or "wire" components

Component may refer to:

In engineering, science, and technology Generic systems

*System components, an entity with discrete structure, such as an assembly or software module, within a system considered at a particular level of analysis

* Lumped e ...

to one another in an electronic circuit

An electronic circuit is composed of individual electronic components, such as resistors, transistors, capacitors, inductors and diodes, connected by conductive wires or Conductive trace, traces through which electric current can flow. It is a t ...

. Electrical components may be fixed to conductive pads on the outer layers, generally by soldering, which both electrically connects and mechanically fastens the components to the board. Another manufacturing process adds vias, metal-lined drilled holes that enable electrical interconnections between conductive layers, to boards with more than a single side.

Printed circuit boards are used in nearly all electronic products today. Alternatives to PCBs include wire wrap and point-to-point construction, both once popular but now rarely used. PCBs require additional design effort to lay out the circuit, but manufacturing and assembly can be automated. Electronic design automation

Electronic design automation (EDA), also referred to as electronic computer-aided design (ECAD), is a category of software tools for designing Electronics, electronic systems such as integrated circuits and printed circuit boards. The tools wo ...

software is available to do much of the work of layout. Mass-producing circuits with PCBs is cheaper and faster than with other wiring methods, as components are mounted and wired in one operation. Large numbers of PCBs can be fabricated at the same time, and the layout has to be done only once. PCBs can also be made manually in small quantities, with reduced benefits.

PCBs can be single-sided (one copper layer), double-sided (two copper layers on both sides of one substrate layer), or multi-layer (stacked layers of substrate with copper plating sandwiched between each and on the outside layers). Multi-layer PCBs provide much higher component density, because circuit traces on the inner layers would otherwise take up surface space between components. The rise in popularity of multilayer PCBs with more than two, and especially with more than four, copper planes was concurrent with the adoption of surface-mount technology. However, multilayer PCBs make repair, analysis, and field modification of circuits much more difficult and usually impractical.

The world market for bare PCBs exceeded US$

The United States dollar (Currency symbol, symbol: Dollar sign, $; ISO 4217, currency code: USD) is the official currency of the United States and International use of the U.S. dollar, several other countries. The Coinage Act of 1792 introdu ...

60.2 billion in 2014, and was estimated at $80.33 billion in 2024, forecast to be $96.57 billion for 2029, growing at 4.87% per annum.

History

Predecessors

Before the development of printed circuit boards, electrical and electronic circuits were wired point-to-point on a chassis. Typically, the chassis was a sheet metal frame or pan, sometimes with a wooden bottom. Components were attached to the chassis, usually by insulators when the connecting point on the chassis was metal, and then their leads were connected directly or with jumper wires by soldering, or sometimes using crimp connectors, wire connector lugs on screw terminals, or other methods. Circuits were large, bulky, heavy, and relatively fragile (even discounting the breakable glass envelopes of the vacuum tubes that were often included in the circuits), and production was labor-intensive, so the products were expensive. Development of the methods used in modern printed circuit boards started early in the 20th century. In 1903, a German inventor, Albert Hanson, described flat foil conductors laminated to an insulating board, in multiple layers.Thomas Edison

Thomas Alva Edison (February11, 1847October18, 1931) was an American inventor and businessman. He developed many devices in fields such as electric power generation, mass communication, sound recording, and motion pictures. These inventions, ...

experimented with chemical methods of plating conductors onto linen paper in 1904. Arthur Berry in 1913 patented a print-and- etch method in the UK, and in the United States Max Schoop obtained a patent to flame-spray metal onto a board through a patterned mask. Charles Ducas in 1925 patented a method of electroplating circuit patterns.

Predating the printed circuit invention, and similar in spirit, was John Sargrove's 1936–1947 Electronic Circuit Making Equipment (ECME) that sprayed metal onto a Bakelite

Bakelite ( ), formally , is a thermosetting polymer, thermosetting phenol formaldehyde resin, formed from a condensation reaction of phenol with formaldehyde. The first plastic made from synthetic components, it was developed by Belgian chemist ...

plastic board. The ECME could produce three radio boards per minute.

Early PCBs

The Austrian engineer Paul Eisler invented the printed circuit as part of a radio set while working in the UK around 1936. In 1941 a multi-layer printed circuit was used in German magnetic influence naval mines.

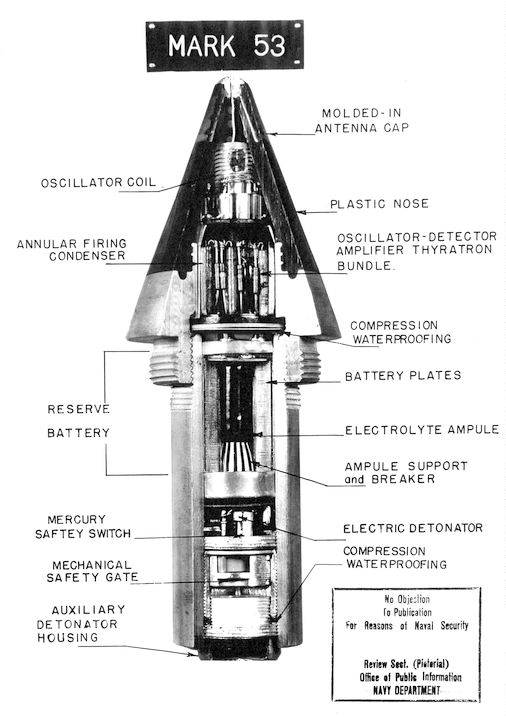

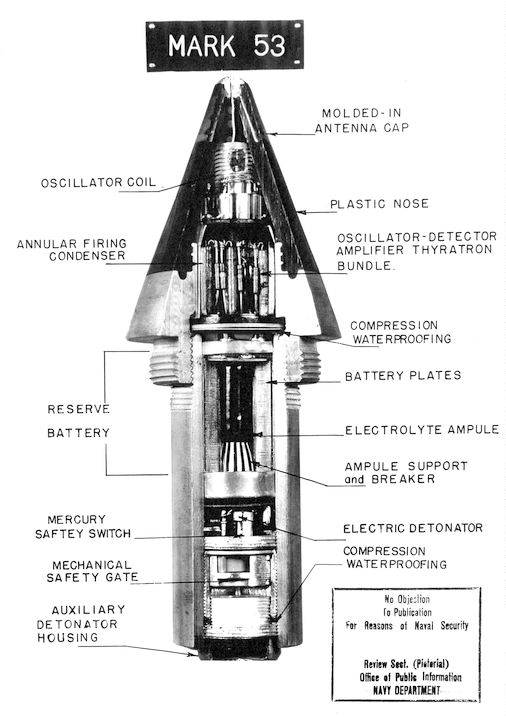

Around 1943 the United States began to use the technology on a large scale to make

The Austrian engineer Paul Eisler invented the printed circuit as part of a radio set while working in the UK around 1936. In 1941 a multi-layer printed circuit was used in German magnetic influence naval mines.

Around 1943 the United States began to use the technology on a large scale to make proximity fuze

A Proximity Fuse (also VT fuse or "variable time fuze") is a fuse that detonates an explosive device automatically when it approaches within a certain distance of its target. Proximity fuses are designed for elusive military targets such as air ...

s for use in World War II. Such fuzes required an electronic circuit that could withstand being fired from a gun, and could be produced in quantity. The Centralab Division of Globe Union submitted a proposal which met the requirements: a ceramic plate would be screenprinted with metallic paint for conductors and carbon material for resistor

A resistor is a passive two-terminal electronic component that implements electrical resistance as a circuit element. In electronic circuits, resistors are used to reduce current flow, adjust signal levels, to divide voltages, bias active e ...

s, with ceramic disc capacitors and subminiature vacuum tubes soldered in place. The technique proved viable, and the resulting patent on the process, which was classified by the U.S. Army, was assigned to Globe Union. It was not until 1984 that the Institute of Electrical and Electronics Engineers

The Institute of Electrical and Electronics Engineers (IEEE) is an American 501(c)(3) public charity professional organization for electrical engineering, electronics engineering, and other related disciplines.

The IEEE has a corporate office ...

(IEEE) awarded Harry W. Rubinstein its Cledo Brunetti Award for early key contributions to the development of printed components and conductors on a common insulating substrate. Rubinstein was honored in 1984 by his alma mater, the University of Wisconsin-Madison

A university () is an institution of tertiary education and research which awards academic degrees in several academic disciplines. ''University'' is derived from the Latin phrase , which roughly means "community of teachers and scholars". Uni ...

, for his innovations in the technology of printed electronic circuits and the fabrication of capacitors. This invention also represents a step in the development of integrated circuit

An integrated circuit (IC), also known as a microchip or simply chip, is a set of electronic circuits, consisting of various electronic components (such as transistors, resistors, and capacitors) and their interconnections. These components a ...

technology, as not only wiring but also passive components were fabricated on the ceramic substrate.

Post-war developments

In 1948, the US released the invention for commercial use. Printed circuits did not become commonplace in consumer electronics until the mid-1950s, after the ''Auto-Sembly'' process was developed by the United States Army. At around the same time in the UK work along similar lines was carried out by Geoffrey Dummer, then at the RRDE. Motorola was an early leader in bringing the process into consumer electronics, announcing in August 1952 the adoption of "plated circuits" in home radios after six years of research and a $1M investment. Motorola soon began using its trademarked term for the process, PLAcir, in its consumer radio advertisements. Hallicrafters released its first "foto-etch" printed circuit product, a clock-radio, on November 1, 1952. Even as circuit boards became available, the point-to-point chassis construction method remained in common use in industry (such as TV and hi-fi sets) into at least the late 1960s. Printed circuit boards were introduced to reduce the size, weight, and cost of parts of the circuitry. In 1960, a small consumer radio receiver might be built with all its circuitry on one circuit board, but a TV set would probably contain one or more circuit boards. Originally, every electronic component had wireleads

Lead () is a chemical element; it has Chemical symbol, symbol Pb (from Latin ) and atomic number 82. It is a Heavy metal (elements), heavy metal that is density, denser than most common materials. Lead is Mohs scale, soft and Ductility, malleabl ...

, and a PCB had holes drilled for each wire of each component. The component leads were then inserted through the holes and solder

Solder (; North American English, NA: ) is a fusible alloy, fusible metal alloy used to create a permanent bond between metal workpieces. Solder is melted in order to wet the parts of the joint, where it adheres to and connects the pieces aft ...

ed to the copper PCB traces. This method of assembly is called ''through-hole'' construction. In 1949, Moe Abramson and Stanislaus F. Danko of the United States Army Signal Corps developed the ''Auto-Sembly'' process in which component leads were inserted into a copper foil interconnection pattern and dip soldered. The patent they obtained in 1956 was assigned to the U.S. Army. With the development of board lamination and etching

Etching is traditionally the process of using strong acid or mordant to cut into the unprotected parts of a metal surface to create a design in intaglio (incised) in the metal. In modern manufacturing, other chemicals may be used on other type ...

techniques, this concept evolved into the standard printed circuit board fabrication process in use today. Soldering could be done automatically by passing the board over a ripple, or wave, of molten solder in a wave-soldering machine. However, the wires and holes are inefficient since drilling holes is expensive and consumes drill bits and the protruding wires are cut off and discarded.

Since the 1980s, surface mount parts have increasingly replaced through-hole components, enabling smaller boards and lower production costs, but making repairs more challenging.

In the 1990s the use of multilayer surface boards became more frequent. As a result, size was further minimized and both flexible and rigid PCBs were incorporated in different devices. In 1995 PCB manufacturers began using microvia technology to produce High-Density Interconnect (HDI) PCBs.

Recent advances

Recent advances in3D printing

3D printing, or additive manufacturing, is the construction of a three-dimensional object from a CAD model or a digital 3D model. It can be done in a variety of processes in which material is deposited, joined or solidified under computer ...

have meant that there are several new techniques in PCB creation. 3D printed electronics (PEs) can be utilized to print items layer by layer and subsequently the item can be printed with a liquid ink that contains electronic functionalities.

HDI (High Density Interconnect) technology allows for a denser design on the PCB and thus potentially smaller PCBs with more traces and components in a given area. As a result, the paths between components can be shorter. HDIs use blind/buried vias, or a combination that includes microvias. With multi-layer HDI PCBs the interconnection of several vias stacked on top of each other (stacked vías, instead of one deep buried via) can be made stronger, thus enhancing reliability in all conditions. The most common applications for HDI technology are computer and mobile phone components as well as medical equipment and military communication equipment. A 4-layer HDI microvia PCB is equivalent in quality to an 8-layer through-hole PCB, so HDI technology can reduce costs. HDI PCBs are often made using build-up film such as ajinomoto build-up film, which is also used in the production of flip chip packages. Some PCBs have optical waveguides, similar to optical fibers built on the PCB.

Composition

A basic PCB consists of a flat sheet of insulating material and a layer of copper

A basic PCB consists of a flat sheet of insulating material and a layer of copper foil

Foil may refer to:

Materials

* Foil (metal), a quite thin sheet of metal, usually manufactured with a rolling mill machine

* Metal leaf, a very thin sheet of decorative metal

* Aluminium foil, a type of wrapping for food

* Tin foil, metal foil ma ...

, laminated to the substrate. Chemical etching divides the copper

Copper is a chemical element; it has symbol Cu (from Latin ) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pinkish-orang ...

into separate conducting lines called tracks or ''circuit traces'', pads for connections, vias to pass connections between layers of copper, and features such as solid conductive areas for electromagnetic shielding or other purposes. The tracks function as wires fixed in place, and are insulated from each other by air and the board substrate material. The surface of a PCB may have a coating that protects the copper from corrosion

Corrosion is a natural process that converts a refined metal into a more chemically stable oxide. It is the gradual deterioration of materials (usually a metal) by chemical or electrochemical reaction with their environment. Corrosion engine ...

and reduces the chances of solder shorts between traces or undesired electrical contact with stray bare wires. For its function in helping to prevent solder shorts, the coating is called solder resist or solder mask.

The pattern to be etched into each copper layer of a PCB is called the "artwork". The etching is usually done using photoresist which is coated onto the PCB, then exposed to light projected in the pattern of the artwork. The resist material protects the copper from dissolution into the etching solution. The etched board is then cleaned. A PCB design can be mass-reproduced in a way similar to the way photograph

A photograph (also known as a photo, or more generically referred to as an ''image'' or ''picture'') is an image created by light falling on a photosensitivity, photosensitive surface, usually photographic film or an electronic image sensor. Th ...

s can be mass-duplicated from film negatives using a photographic printer.

FR-4 glass epoxy is the most common insulating substrate. Another substrate material is cotton paper impregnated with phenolic resin, often tan or brown.

When a PCB has no components installed, it is less ambiguously called a ''printed wiring board'' (''PWB'') or ''etched wiring board''. However, the term "printed wiring board" has fallen into disuse. A PCB populated with electronic components is called a ''printed circuit assembly'' (''PCA''), ''printed circuit board assembly'' or ''PCB assembly'' (''PCBA''). In informal usage, the term "printed circuit board" most commonly means "printed circuit assembly" (with components). The IPC preferred term for an assembled board is ''circuit card assembly'' (''CCA''), and for an assembled backplane

A backplane or backplane system is a group of electrical connectors in parallel with each other, so that each pin of each connector is linked to the same relative pin of all the other connectors, forming a computer bus. It is used to connect s ...

it is ''backplane assembly''. "Card" is another widely used informal term for a "printed circuit assembly".

For example, expansion card

In computing, an expansion card (also called an expansion board, adapter card, peripheral card or accessory card) is a printed circuit board that can be inserted into an electrical connector, or expansion slot (also referred to as a bus sl ...

.

A PCB may be printed with a legend identifying the components, test points, or identifying text. Originally, silkscreen printing was used for this purpose, but today other, finer quality printing methods are usually used. Normally the legend does not affect the function of a PCBA.

Layers

A printed circuit board can have multiple layers of copper which almost always are arranged in pairs. The number of layers and the interconnection designed between them (vias, PTHs) provide a general estimate of the board complexity. Using more layers allow for more routing options and better control of signal integrity, but are also time-consuming and costly to manufacture. Likewise, selection of the vias for the board also allow fine tuning of the board size, escaping of signals off complex ICs, routing, and long term reliability, but are tightly coupled with production complexity and cost. One of the simplest boards to produce is the two-layer board. It has copper on both sides that are referred to as external layers; multi layer boards sandwich additional internal layers of copper and insulation. After two-layer PCBs, the next step up is the four-layer. The four layer board adds significantly more routing options in the internal layers as compared to the two layer board, and often some portion of the internal layers is used as ground plane or power plane, to achieve better signal integrity, higher signaling frequencies, lower EMI, and better power supply decoupling. In multi-layer boards, the layers of material are laminated together in an alternating sandwich: copper, substrate, copper, substrate, copper, etc.; each plane of copper is etched, and any internal vias (that will not extend to both outer surfaces of the finished multilayer board) are plated-through, before the layers are laminated together. Only the outer layers need be coated; the inner copper layers are protected by the adjacent substrate layers.Component mounting

transistor

A transistor is a semiconductor device used to Electronic amplifier, amplify or electronic switch, switch electrical signals and electric power, power. It is one of the basic building blocks of modern electronics. It is composed of semicondu ...

s, diode

A diode is a two-Terminal (electronics), terminal electronic component that conducts electric current primarily in One-way traffic, one direction (asymmetric electrical conductance, conductance). It has low (ideally zero) Electrical resistance ...

s, IC chips, resistor

A resistor is a passive two-terminal electronic component that implements electrical resistance as a circuit element. In electronic circuits, resistors are used to reduce current flow, adjust signal levels, to divide voltages, bias active e ...

s, and capacitors. Through-hole mounting may be used for some large components such as electrolytic capacitor

An electrolyte is a substance that conducts electricity through the movement of ions, but not through the movement of electrons. This includes most soluble Salt (chemistry), salts, acids, and Base (chemistry), bases, dissolved in a polar solven ...

s and connectors.

The first PCBs used through-hole technology, mounting electronic components by lead inserted through holes on one side of the board and soldered onto copper traces on the other side. Boards may be single-sided, with an unplated component side, or more compact double-sided boards, with components soldered on both sides. Horizontal installation of through-hole parts with two axial leads (such as resistors, capacitors, and diodes) is done by bending the leads 90 degrees in the same direction, inserting the part in the board (often bending leads located on the back of the board in opposite directions to improve the part's mechanical strength), soldering the leads, and trimming off the ends. Leads may be soldered either manually or by a wave soldering machine.

Surface-mount technology emerged in the 1960s, gained momentum in the early 1980s, and became widely used by the mid-1990s. Components were mechanically redesigned to have small metal tabs or end caps that could be soldered directly onto the PCB surface, instead of wire leads to pass through holes. Components became much smaller and component placement on both sides of the board became more common than with through-hole mounting, allowing much smaller PCB assemblies with much higher circuit densities. Surface mounting lends itself well to a high degree of automation, reducing labor costs and greatly increasing production rates compared with through-hole circuit boards. Components can be supplied mounted on carrier tapes. Surface mount components can be about one-quarter to one-tenth of the size and weight of through-hole components, and passive components much cheaper. However, prices of semiconductor surface mount devices (SMDs) are determined more by the chip itself than the package, with little price advantage over larger packages, and some wire-ended components, such as 1N4148 small-signal switch diodes, are actually significantly cheaper than SMD equivalents.

Electrical properties

Each trace consists of a flat, narrow part of thecopper

Copper is a chemical element; it has symbol Cu (from Latin ) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pinkish-orang ...

foil that remains after etching. Its resistance, determined by its width, thickness, and length, must be sufficiently low for the current the conductor will carry. Power and ground traces may need to be wider than signal traces. In a multi-layer board one entire layer may be mostly solid copper to act as a ground plane for shielding and power return. For microwave

Microwave is a form of electromagnetic radiation with wavelengths shorter than other radio waves but longer than infrared waves. Its wavelength ranges from about one meter to one millimeter, corresponding to frequency, frequencies between 300&n ...

circuits, transmission line

In electrical engineering, a transmission line is a specialized cable or other structure designed to conduct electromagnetic waves in a contained manner. The term applies when the conductors are long enough that the wave nature of the transmis ...

s can be laid out in a planar form such as stripline or microstrip with carefully controlled dimensions to assure a consistent impedance. In radio-frequency and fast switching circuits the inductance

Inductance is the tendency of an electrical conductor to oppose a change in the electric current flowing through it. The electric current produces a magnetic field around the conductor. The magnetic field strength depends on the magnitude of the ...

and capacitance

Capacitance is the ability of an object to store electric charge. It is measured by the change in charge in response to a difference in electric potential, expressed as the ratio of those quantities. Commonly recognized are two closely related ...

of the printed circuit board conductors become significant circuit elements, usually undesired; conversely, they can be used as a deliberate part of the circuit design, as in distributed-element filter

A distributed-element filter is an electronic filter in which capacitance, inductance, and resistance (the elements of the circuit) are not localised in discrete capacitors, inductors, and resistors as they are in conventional filters. Its pu ...

s, antennae, and fuses, obviating the need for additional discrete components. High density interconnects (HDI) PCBs have tracks or vias with a width or diameter of under 152 micrometers.

Materials

Laminates

Laminates are manufactured by curing layers of cloth or paper withthermoset

In materials science, a thermosetting polymer, often called a thermoset, is a polymer that is obtained by irreversibly hardening (" curing") a soft solid or viscous liquid prepolymer (resin). Curing is induced by heat or suitable radiation and ...

resin under pressure and heat to form an integral final piece of uniform thickness. They can be up to in width and length. Varying cloth weaves (threads per inch or cm), cloth thickness, and resin

A resin is a solid or highly viscous liquid that can be converted into a polymer. Resins may be biological or synthetic in origin, but are typically harvested from plants. Resins are mixtures of organic compounds, predominantly terpenes. Commo ...

percentage are used to achieve the desired final thickness and dielectric

In electromagnetism, a dielectric (or dielectric medium) is an Insulator (electricity), electrical insulator that can be Polarisability, polarised by an applied electric field. When a dielectric material is placed in an electric field, electric ...

characteristics. Available standard laminate thickness are listed in

ANSI/IPC-D-275.

The cloth or fiber material used, resin

A resin is a solid or highly viscous liquid that can be converted into a polymer. Resins may be biological or synthetic in origin, but are typically harvested from plants. Resins are mixtures of organic compounds, predominantly terpenes. Commo ...

material, and the cloth to resin ratio determine the laminate's type designation (FR-4, CEM-1, G-10, etc.) and therefore the characteristics of the laminate produced. Important characteristics are the level to which the laminate is fire retardant, the dielectric constant

The relative permittivity (in older texts, dielectric constant) is the permittivity of a material expressed as a ratio with the electric permittivity of a vacuum. A dielectric is an insulating material, and the dielectric constant of an insul ...

(er), the loss tangent

In electrical engineering, dielectric loss quantifies a dielectric material's inherent dissipation of electromagnetic energy (e.g. heat). It can be parameterized in terms of either the loss angle or the corresponding loss tangent . Both refer ...

(tan δ), the tensile strength

Ultimate tensile strength (also called UTS, tensile strength, TS, ultimate strength or F_\text in notation) is the maximum stress that a material can withstand while being stretched or pulled before breaking. In brittle materials, the ultimate ...

, the shear strength, the glass transition temperature

The glass–liquid transition, or glass transition, is the gradual and reversible transition in amorphous materials (or in amorphous regions within semicrystalline materials) from a hard and relatively brittle "glassy" state into a viscous or rub ...

(Tg), and the Z-axis expansion coefficient (how much the thickness changes with temperature).

There are quite a few different dielectrics that can be chosen to provide different insulating values depending on the requirements of the circuit. Some of these dielectrics are polytetrafluoroethylene

Polytetrafluoroethylene (PTFE) is a synthetic fluoropolymer of tetrafluoroethylene, and has numerous applications because it is chemically inert. The commonly known brand name of PTFE-based composition is Teflon by Chemours, a corporate spin-of ...

(Teflon), FR-4, FR-1, CEM-1 or CEM-3. Well known pre-preg materials used in the PCB industry are FR-2 (phenolic cotton paper), FR-3 (cotton paper and epoxy), FR-4 (woven glass and epoxy), FR-5 (woven glass and epoxy), FR-6 (matte glass and polyester), G-10 (woven glass and epoxy), CEM-1 (cotton paper and epoxy), CEM-2 (cotton paper and epoxy), CEM-3 (non-woven glass and epoxy), CEM-4 (woven glass and epoxy), CEM-5 (woven glass and polyester). Thermal expansion is an important consideration especially with ball grid array (BGA) and naked die technologies, and glass fiber offers the best dimensional stability.

FR-4 is by far the most common material used today. The board stock with unetched copper on it is called "copper-clad laminate".

With decreasing size of board features and increasing frequencies, small non-homogeneities like uneven distribution of fiberglass or other filler, thickness variations, and bubbles in the resin matrix, and the associated local variations in the dielectric constant, are gaining importance.

Key substrate parameters

The circuit-board substrates are usually dielectric composite materials. The composites contain a matrix (usually an epoxy resin) and a reinforcement (usually a woven, sometimes non-woven, glass fibers, sometimes even paper), and in some cases a filler is added to the resin (e.g. ceramics; titanate ceramics can be used to increase the dielectric constant). The reinforcement type defines two major classes of materials: woven and non-woven. Woven reinforcements are cheaper, but the high dielectric constant of glass may not be favorable for many higher-frequency applications. The spatially non-homogeneous structure also introduces local variations in electrical parameters, due to different resin/glass ratio at different areas of the weave pattern. Non-woven reinforcements, or materials with low or no reinforcement, are more expensive but more suitable for some RF/analog applications. The substrates are characterized by several key parameters, chiefly thermomechanical (glass transition temperature

The glass–liquid transition, or glass transition, is the gradual and reversible transition in amorphous materials (or in amorphous regions within semicrystalline materials) from a hard and relatively brittle "glassy" state into a viscous or rub ...

, tensile strength

Ultimate tensile strength (also called UTS, tensile strength, TS, ultimate strength or F_\text in notation) is the maximum stress that a material can withstand while being stretched or pulled before breaking. In brittle materials, the ultimate ...

, shear strength, thermal expansion

Thermal expansion is the tendency of matter to increase in length, area, or volume, changing its size and density, in response to an increase in temperature (usually excluding phase transitions).

Substances usually contract with decreasing temp ...

), electrical (dielectric constant

The relative permittivity (in older texts, dielectric constant) is the permittivity of a material expressed as a ratio with the electric permittivity of a vacuum. A dielectric is an insulating material, and the dielectric constant of an insul ...

, loss tangent

In electrical engineering, dielectric loss quantifies a dielectric material's inherent dissipation of electromagnetic energy (e.g. heat). It can be parameterized in terms of either the loss angle or the corresponding loss tangent . Both refer ...

, dielectric breakdown voltage, leakage current, tracking resistance...), and others (e.g. moisture absorption).

At the glass transition temperature

The glass–liquid transition, or glass transition, is the gradual and reversible transition in amorphous materials (or in amorphous regions within semicrystalline materials) from a hard and relatively brittle "glassy" state into a viscous or rub ...

the resin in the composite softens and significantly increases thermal expansion; exceeding Tg then exerts mechanical overload on the board components - e.g. the joints and the vias. Below Tg the thermal expansion of the resin roughly matches copper and glass, above it gets significantly higher. As the reinforcement and copper confine the board along the plane, virtually all volume expansion projects to the thickness and stresses the plated-through holes. Repeated soldering or other exposition to higher temperatures can cause failure of the plating, especially with thicker boards; thick boards therefore require a matrix with a high Tg.

The materials used determine the substrate's dielectric constant

The relative permittivity (in older texts, dielectric constant) is the permittivity of a material expressed as a ratio with the electric permittivity of a vacuum. A dielectric is an insulating material, and the dielectric constant of an insul ...

. This constant is also dependent on frequency, usually decreasing with frequency. As this constant determines the signal propagation speed, frequency dependence introduces phase distortion in wideband applications; as flat a dielectric constant vs frequency characteristics as is achievable is important here. The impedance of transmission lines decreases with frequency, therefore faster edges of signals reflect more than slower ones.

Dielectric breakdown voltage determines the maximum voltage gradient the material can be subjected to before suffering a breakdown (conduction, or arcing, through the dielectric).

Tracking resistance determines how the material resists high voltage electrical discharges creeping over the board surface.

Loss tangent determines how much of the electromagnetic energy from the signals in the conductors is absorbed in the board material. This factor is important for high frequencies. Low-loss materials are more expensive. Choosing unnecessarily low-loss material is a common engineering error in high-frequency digital design; it increases the cost of the boards without a corresponding benefit. Signal degradation by loss tangent and dielectric constant can be easily assessed by an eye pattern.

Moisture absorption occurs when the material is exposed to high humidity or water. Both the resin and the reinforcement may absorb water; water also may be soaked by capillary forces through voids in the materials and along the reinforcement. Epoxies of the FR-4 materials are not too susceptible, with absorption of only 0.15%. Teflon has very low absorption of 0.01%. Polyimides and cyanate esters, on the other side, suffer from high water absorption. Absorbed water can lead to significant degradation of key parameters; it impairs tracking resistance, breakdown voltage, and dielectric parameters. Relative dielectric constant of water is about 73, compared to about 4 for common circuit board materials. Absorbed moisture can also vaporize on heating, as during soldering, and cause cracking and delamination, the same effect responsible for "popcorning" damage on wet packaging of electronic parts. Careful baking of the substrates may be required to dry them prior to soldering.

Common substrates

Often encountered materials: * FR-2, phenolic paper or phenolic cotton paper, paper impregnated with a phenol formaldehyde resin. Common in consumer electronics with single-sided boards. Electrical properties inferior to FR-4. Poor arc resistance. Generally rated to 105 °C. * FR-4, a wovenfiberglass

Fiberglass (American English) or fibreglass (English in the Commonwealth of Nations, Commonwealth English) is a common type of fibre-reinforced plastic, fiber-reinforced plastic using glass fiber. The fibers may be randomly arranged, flattened i ...

cloth impregnated with an epoxy resin. Low water absorption (up to about 0.15%), good insulation properties, good arc resistance. Very common. Several grades with somewhat different properties are available. Typically rated to 130 °C.

* Aluminum

Aluminium (or aluminum in North American English) is a chemical element; it has chemical symbol, symbol Al and atomic number 13. It has a density lower than that of other common metals, about one-third that of steel. Aluminium has ...

, or ''metal core board'' or insulated metal substrate (IMS), clad with thermally conductive thin dielectric - used for parts requiring significant cooling - power switches, LEDs. Consists of usually single, sometimes double layer thin circuit board based on e.g. FR-4, laminated on aluminum sheet metal, commonly 0.8, 1, 1.5, 2 or 3 mm thick. The thicker laminates sometimes also come with thicker copper metalization.

* Flexible substrates - can be a standalone copper-clad foil or can be laminated to a thin stiffener, e.g. 50–130 μm

** Kapton

file:Kaptonpads.jpg, Kapton insulating pads for mounting electronic parts on a heat sink

Kapton is a polyimide film used in flexible printed circuits (flexible electronics) and space blankets, which are used on spacecraft, satellites, and variou ...

or UPILEX, a polyimide foil. Used for flexible printed circuits, in this form common in small form-factor consumer electronics or for flexible interconnects. Resistant to high temperatures.

** Pyralux, a polyimide-fluoropolymer composite foil. Copper layer can delaminate during soldering.

Less-often encountered materials:

* FR-1, like FR-2, typically specified to 105 °C, some grades rated to 130 °C. Room-temperature punchable. Similar to cardboard. Poor moisture resistance. Low arc resistance.

* FR-3, cotton paper impregnated with epoxy. Typically rated to 105 °C.

* FR-5, woven fiberglass and epoxy, high strength at higher temperatures, typically specified to 170 °C.

* FR-6, matte glass and polyester

* G-10, woven glass and epoxy - high insulation resistance, low moisture absorption, very high bond strength. Typically rated to 130 °C.

* G-11, woven glass and epoxy - high resistance to solvents, high flexural strength retention at high temperatures. Typically rated to 170 °C.

* CEM-1, cotton paper and epoxy

* CEM-2, cotton paper and epoxy

* CEM-3, non-woven glass and epoxy

* CEM-4, woven glass and epoxy

* CEM-5, woven glass and polyester

* PTFE

Polytetrafluoroethylene (PTFE) is a synthetic fluoropolymer of tetrafluoroethylene, and has numerous applications because it is chemically inert. The commonly known brand name of PTFE-based composition is Teflon by Chemours, a spin-off fro ...

, ("Teflon") - expensive, low dielectric loss, for high frequency applications, very low moisture absorption (0.01%), mechanically soft. Difficult to laminate, rarely used in multilayer applications.

* PTFE, ceramic filled - expensive, low dielectric loss, for high frequency applications. Varying ceramics/PTFE ratio allows adjusting dielectric constant and thermal expansion.

* RF-35, fiberglass-reinforced ceramics-filled PTFE. Relatively less expensive, good mechanical properties, good high-frequency properties.

* Alumina, a ceramic. Hard, brittle, very expensive, very high performance, good thermal conductivity.

* Polyimide, a high-temperature polymer. Expensive, high-performance. Higher water absorption (0.4%). Can be used from cryogenic temperatures to over 260 °C.

Copper thickness

Copper thickness of PCBs can be specified directly or as the weight of copper per area (in ounce per square foot) which is easier to measure. One ounce per square foot is 1.344 mils or 34 micrometers thickness (0.001344 inches). ''Heavy copper'' is a layer exceeding three ounces of copper per ft2, or approximately 4.2 mils (105 μm) (0.0042 inches) thick. Heavy copper layers are used for high current or to help dissipate heat. On the common FR-4 substrates, 1 oz copper per ft2 (35 μm) is the most common thickness; 2 oz (70 μm) and 0.5 oz (17.5 μm) thickness is often an option. Less common are 12 and 105 μm, 9 μm is sometimes available on some substrates. Flexible substrates typically have thinner metalization. Metal-core boards for high power devices commonly use thicker copper; 35 μm is usual but also 140 and 400 μm can be encountered. In the US, copper foil thickness is specified in units of ounces per square foot (oz/ft2), commonly referred to simply as ''ounce''. Common thicknesses are 1/2 oz/ft2 (150 g/m), 1 oz/ft2 (300 g/m), 2 oz/ft2 (600 g/m), and 3 oz/ft2 (900 g/m). These work out to thicknesses of 17.05 μm (0.67thou

The word ''thou'' () is a second-person singular pronoun in English. It is now largely archaic, having been replaced in most contexts by the word '' you'', although it remains in use in parts of Northern England and in Scots (). ''Thou' ...

), 34.1 μm (1.34 thou

The word ''thou'' () is a second-person singular pronoun in English. It is now largely archaic, having been replaced in most contexts by the word '' you'', although it remains in use in parts of Northern England and in Scots (). ''Thou' ...

), 68.2 μm (2.68 thou), and 102.3 μm (4.02 thou), respectively.

1/2 oz/ft2 foil is not widely used as a finished copper weight, but is used for outer layers when plating for through holes will increase the finished copper weight Some PCB manufacturers refer to 1 oz/ft2 copper foil as having a thickness of 35 μm (may also be referred to as 35 μ, 35 micron, or 35 mic).

* 1/0 – denotes 1 oz/ft2 copper one side, with no copper on the other side.

* 1/1 – denotes 1 oz/ft2 copper on both sides.

* H/0 or H/H – denotes 0.5 oz/ft2 copper on one or both sides, respectively.

* 2/0 or 2/2 – denotes 2 oz/ft2 copper on one or both sides, respectively.

Manufacturing

Printed circuit board manufacturing involves manufacturing bare printed circuit boards and then populating them with electronic components. In large-scale board manufacturing, multiple PCBs are grouped on a single panel for efficient processing. After assembly, they are separated ( depaneled).Types

Breakout boards

A minimal PCB for a single component, used for

A minimal PCB for a single component, used for prototyping

A prototype is an early sample, model, or release of a product built to test a concept or process. It is a term used in a variety of contexts, including semantics, design, electronics, and software programming. A prototype is generally used to ...

, is called a breakout board. The purpose of a breakout board is to "break out" the leads of a component on separate terminals so that manual connections to them can be made easily. Breakout boards are especially used for surface-mount components or any components with fine lead pitch.

Advanced PCBs may contain components embedded in the substrate, such as capacitors and integrated circuits, to reduce the amount of space taken up by components on the surface of the PCB while improving electrical characteristics.

Multiwire boards

Multiwire is a patented technique of interconnection which uses machine-routed insulated wires embedded in a non-conducting matrix (often plastic resin). It was used during the 1980s and 1990s. Multiwire is still available through Hitachi. Since it was quite easy to stack interconnections (wires) inside the embedding matrix, the approach allowed designers to forget completely about the routing of wires (usually a time-consuming operation of PCB design): Anywhere the designer needs a connection, the machine will draw a wire in a straight line from one location/pin to another. This led to very short design times (no complex algorithms to use even for high density designs) as well as reducedcrosstalk

In electronics, crosstalk (XT) is a phenomenon by which a signal transmitted on one circuit or channel of a transmission system creates an undesired effect in another circuit or channel. Crosstalk is usually caused by undesired capacitive, ...

(which is worse when wires run parallel to each other—which almost never happens in Multiwire), though the cost is too high to compete with cheaper PCB technologies when large quantities are needed.

Corrections can be made to a Multiwire board layout more easily than to a PCB layout.

Cordwood construction

Cordwood construction can save significant space and was often used with wire-ended components in applications where space was at a premium (such as fuzes, missile guidance, and telemetry systems) and in high-speed

Cordwood construction can save significant space and was often used with wire-ended components in applications where space was at a premium (such as fuzes, missile guidance, and telemetry systems) and in high-speed computer

A computer is a machine that can be Computer programming, programmed to automatically Execution (computing), carry out sequences of arithmetic or logical operations (''computation''). Modern digital electronic computers can perform generic set ...

s, where short traces were important. In cordwood construction, axial-leaded components were mounted between two parallel planes. The name comes from the way axial-lead components (capacitors, resistors, coils, and diodes) are stacked in parallel rows and columns, like a stack of firewood. The components were either soldered together with jumper wire or they were connected to other components by thin nickel ribbon welded at right angles onto the component leads. To avoid shorting together different interconnection layers, thin insulating cards were placed between them. Perforations or holes in the cards allowed component leads to project through to the next interconnection layer. One disadvantage of this system was that special nickel

Nickel is a chemical element; it has symbol Ni and atomic number 28. It is a silvery-white lustrous metal with a slight golden tinge. Nickel is a hard and ductile transition metal. Pure nickel is chemically reactive, but large pieces are slo ...

-leaded components had to be used to allow reliable interconnecting welds to be made. Differential thermal expansion of the component could put pressure on the leads of the components and the PCB traces and cause mechanical damage (as was seen in several modules on the Apollo program). Additionally, components located in the interior are difficult to replace. Some versions of cordwood construction used soldered single-sided PCBs as the interconnection method (as pictured), allowing the use of normal-leaded components at the cost of being difficult to remove the boards or replace any component that is not at the edge.

Before the advent of integrated circuit

An integrated circuit (IC), also known as a microchip or simply chip, is a set of electronic circuits, consisting of various electronic components (such as transistors, resistors, and capacitors) and their interconnections. These components a ...

s, this method allowed the highest possible component packing density; because of this, it was used by a number of computer vendors including Control Data Corporation

Control Data Corporation (CDC) was a mainframe and supercomputer company that in the 1960s was one of the nine major U.S. computer companies, which group included IBM, the Burroughs Corporation, and the Digital Equipment Corporation (DEC), the N ...

.

Uses

Printed circuit boards have been used as an alternative to their typical use for electronic andbiomedical engineering

Biomedical engineering (BME) or medical engineering is the application of engineering principles and design concepts to medicine and biology for healthcare applications (e.g., diagnostic or therapeutic purposes). BME also integrates the logica ...

thanks to the versatility of their layers, especially the copper layer. PCB layers have been used to fabricate sensors, such as capacitive pressure sensors and accelerometers, actuators such as microvalves and microheaters, as well as platforms of sensors and actuators for Lab-on-a-chip (LoC), for example to perform polymerase chain reaction

The polymerase chain reaction (PCR) is a method widely used to make millions to billions of copies of a specific DNA sample rapidly, allowing scientists to amplify a very small sample of DNA (or a part of it) sufficiently to enable detailed st ...

(PCR), and fuel cells, to name a few.

Repair

Manufacturers may not support component-level repair of printed circuit boards because of the relatively low cost to replace compared with the time and cost of troubleshooting to a component level. In board-level repair, the technician identifies the board (PCA) on which the fault resides and replaces it. This shift is economically efficient from a manufacturer's point of view but is also materially wasteful, as a circuit board with hundreds of functional components may be discarded and replaced due to the failure of one minor and inexpensive part, such as a resistor or capacitor, and this practice is a significant contributor to the problem of e-waste.Legislation

In many countries (including allEuropean Single Market

The European single market, also known as the European internal market or the European common market, is the single market comprising mainly the member states of the European Union (EU). With certain exceptions, it also comprises Iceland, ...

participants, the United Kingdom

The United Kingdom of Great Britain and Northern Ireland, commonly known as the United Kingdom (UK) or Britain, is a country in Northwestern Europe, off the coast of European mainland, the continental mainland. It comprises England, Scotlan ...

, Turkey

Turkey, officially the Republic of Türkiye, is a country mainly located in Anatolia in West Asia, with a relatively small part called East Thrace in Southeast Europe. It borders the Black Sea to the north; Georgia (country), Georgia, Armen ...

, and China

China, officially the People's Republic of China (PRC), is a country in East Asia. With population of China, a population exceeding 1.4 billion, it is the list of countries by population (United Nations), second-most populous country after ...

), legislation restricts the use of lead

Lead () is a chemical element; it has Chemical symbol, symbol Pb (from Latin ) and atomic number 82. It is a Heavy metal (elements), heavy metal that is density, denser than most common materials. Lead is Mohs scale, soft and Ductility, malleabl ...

, cadmium

Cadmium is a chemical element; it has chemical symbol, symbol Cd and atomic number 48. This soft, silvery-white metal is chemically similar to the two other stable metals in group 12 element, group 12, zinc and mercury (element), mercury. Like z ...

, and mercury in electrical equipment. PCBs sold in such countries must therefore use lead-free manufacturing processes and lead-free solder, and attached components must themselves be compliant.

Safety Standard UL 796 covers component safety requirements for printed wiring boards for use as components in devices or appliances. Testing analyzes characteristics such as flammability, maximum operating temperature

An operating temperature is the allowable temperature range of the local ambient environment at which an electrical or mechanical device operates. The device will operate effectively within a specified temperature range which varies based on the de ...

, electrical tracking, heat deflection, and direct support of live electrical parts.

See also

* Breadboard * BT-Epoxy - resin used in PCBs * Certified interconnect designer - qualification for PCB designers * Occam process - solder-free circuit board manufacture methodReferences

Further reading

* *External links

* {{Authority control Electrical engineering Electronics substrates Electronics manufacturing Electronic engineering Printed circuit board manufacturing