|

Occam Process

The Occam process is a solder-free, Restriction of Hazardous Substances Directive (RoHS)-compliant method for use in circuit board manufacturing developed by Verdant Electronics. It combines the usual two steps of constructing printed circuit boards (PCBs) followed by the population process of placing various leaded and non-leaded electronic components into one process. The name "Occam" comes from a quotation by William of Ockham. Overview Electronic components are first positioned onto an adhesive layer of a temporary or permanent substrate, according to the design parameters. Then, the pre-tested, burned-in components are held firm in their positions by encapsulating them in insulating material, and the entire assembly is then inverted. The adhesive layer is then cut (after removing the temporary substrate if it exists) or drilled out over the component leads, mechanically or by laser ablation. These holes are then plated with a conductive, copper connection (a via) from t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Solder

Solder (; North American English, NA: ) is a fusible alloy, fusible metal alloy used to create a permanent bond between metal workpieces. Solder is melted in order to wet the parts of the joint, where it adheres to and connects the pieces after cooling. Metals or alloys suitable for use as solder should have a lower melting point than the pieces to be joined. The solder should also be resistant to oxidative and corrosive effects that would degrade the joint over time. Solder used in making electrical connections also needs to have favorable electrical characteristics. Soft solder typically has a melting point range of , and is commonly used in electronics, plumbing, and sheet metal work. Alloys that melt between are the most commonly used. Soldering performed using alloys with a melting point above is called "hard soldering", "silver soldering", or brazing. In specific proportions, some alloys are eutectic — that is, the alloy's melting point is the lowest possible for a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Restriction Of Hazardous Substances Directive

The Restriction of Hazardous Substances Directive 2002/95/EC (RoHS 1), short for Directive on the restriction of the use of certain hazardous substances in electrical and electronic equipment, was adopted in February 2003 by the European Union. The initiative was to limit the amount of hazardous chemicals in electronics. The RoHS 1 directive took effect on 1 July 2006, and is required to be enforced and became a law in each member state. This directive restricts (with exceptions) the use of ten hazardous materials in the manufacture of various types of electronic and electrical equipment. In addition to the exceptions, there are exclusions for products such as solar panels. It is closely linked with the Waste Electrical and Electronic Equipment Directive (WEEE) 2002/96/EC (now superseded) which sets collection, recycling and recovery targets for electrical goods and is part of a legislative initiative to solve the problem of huge amounts of toxic electronic waste. In s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Circuit Board Manufacturing

Printed circuit board manufacturing is the process of manufacturing bare printed circuit boards (PCBs) and populating them with electronic components. It includes all the processes to produce the full assembly of a board into a functional circuit board. In board manufacturing, multiple PCBs are grouped on a single panel for efficient processing. After assembly, they are separated (depaneled). Various techniques, such as silk screening and photoengraving, replicate the desired copper patterns on the PCB layers. Multi-layer boards are created by laminating different layers under heat and pressure. Holes for vias (vertical connections between layers) are also drilled. The final assembly involves placing components onto the PCB and soldering them in place. This process can include through-hole technology (in which the component goes through the board) or surface-mount technology (SMT) (in which the component lays on top of the board). Design Manufacturing starts from the fabricat ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Printed Circuit Board

A printed circuit board (PCB), also called printed wiring board (PWB), is a Lamination, laminated sandwich structure of electrical conduction, conductive and Insulator (electricity), insulating layers, each with a pattern of traces, planes and other features (similar to wires on a flat surface) Chemical milling, etched from one or more sheet layers of copper laminated onto or between sheet layers of a non-conductive substrate. PCBs are used to connect or Electrical wiring, "wire" Electronic component, components to one another in an electronic circuit. Electrical components may be fixed to conductive pads on the outer layers, generally by soldering, which both electrically connects and mechanically fastens the components to the board. Another manufacturing process adds Via (electronics), vias, metal-lined drilled holes that enable electrical interconnections between conductive layers, to boards with more than a single side. Printed circuit boards are used in nearly all e ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

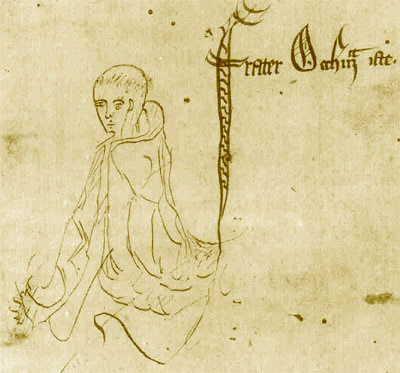

William Of Ockham

William of Ockham or Occam ( ; ; 9/10 April 1347) was an English Franciscan friar, scholastic philosopher, apologist, and theologian, who was born in Ockham, a small village in Surrey. He is considered to be one of the major figures of medieval thought and was at the centre of the major intellectual and political controversies of the 14th century. He is commonly known for Occam's razor, the methodological principle that bears his name, and also produced significant works on logic, physics and theology. William is remembered in the Church of England with a commemoration corresponding to the commonly ascribed date of his death on 10 April. Life William of Ockham was born in Ockham, Surrey, around 1287. He received his elementary education in the London House of the Greyfriars. It is believed that he then studied theology at the University of OxfordSpade, Paul Vincent (ed.). ''The Cambridge Companion to Ockham''. Cambridge University Press, 1999, p. 20.He has long been claim ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Laser Ablation

Laser ablation or photoablation (also called laser blasting) is the process of removing material from a solid (or occasionally liquid) surface by irradiating it with a laser beam. At low laser flux, the material is heated by the absorbed laser energy and evaporation, evaporates or Sublimation (chemistry), sublimates. At high laser flux, the material is typically converted to a Plasma (physics), plasma. Usually, laser ablation refers to removing material with a pulsed laser, but it is possible to ablate material with a continuous wave laser beam if the laser intensity is high enough. While relatively long laser pulses (e.g. nanosecond pulses) can heat and thermally alter or damage the processed material, ultrashort laser pulses (e.g. femtoseconds) cause only minimal material damage during processing due to the ultrashort light-matter interaction and are therefore also suitable for micromaterial processing. Excimer lasers of deep ultra-violet light are mainly used in photoabla ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Via (electronics)

A via (Latin, 'path' or 'way') is an electrical connection between two or more metal layers of a printed circuit boards (PCB) or integrated circuit. Essentially a via is a small drilled hole that goes through two or more adjacent layers; the hole is plated with metal (often copper) that forms an electrical connection through the insulating layers. Vias are an important concern in PCB manufacturing. As vertical structures crossing multiple layers, they are specified differently from most of the design, which increases the chance for errors. They place the strictest demands on registration (how closely aligned different layers are). They are manufactured with different tooling from other features -- tooling that typically has looser tolerances. If either the hole or any layer is slightly out of place, the wrong electrical connections may be made; this may not be visible from the surface. After the hole is drilled, it must also be lined with conductive material, as opposed to simpl ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Conformal Coating

Conformal coating is a protective, breathable coating of thin polymeric film applied to printed circuit boards (PCBs). Conformal coatings are typically applied with 25–250 μm thickness on electronic circuitry to protect against moisture and other substances. Coatings can be applied in many ways, including brushing, spraying, dispensing, and dip coating. Many materials can be used as conformal coatings depending on manufacturer needs, such as acrylic, silicone, urethane, and parylene. Many circuit board assembly firms apply a layer of transparent conformal coating to assemblies as an alternative to potting. Conformal coatings are used to protect electronic components from possible environmental exposure; they allow moisture to escape but protect against contamination. More recently, conformal coatings are being used to reduce the formation of whiskers and to prevent current bleed between closely positioned components. Applications Precision analogue circuitry may su ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Whisker (metallurgy)

Metal whiskering is a phenomenon that occurs in electrical devices when metals form long whisker-like projections over time. Tin whiskers were noticed and documented in the vacuum tube era of electronics early in the 20th century in equipment that used pure, or almost pure, tin solder in their production. It was noticed that small metal hairs or tendrils grew between metal solder pads, causing short circuits. Metal whiskers form in the presence of compressive stress. Germanium, zinc, cadmium, and even lead whiskers have been documented. Many techniques are used to mitigate the problem, including changes to the annealing (metallurgy), annealing process (heating and cooling), the addition of elements like copper and nickel, and the inclusion of conformal coatings. Traditionally, lead has been added to slow down whisker growth in tin-based solders. Following the RoHS, Restriction of Hazardous Substances Directive (RoHS), the European Union banned the use of lead in most consumer elec ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Reflow Soldering

Reflow soldering is a process in which a solder paste (a sticky mixture of powdered solder and flux (metallurgy), flux) is used to temporarily attach anywhere from one to thousands of tiny electrical components to their contact pads, after which the entire assembly is subjected to controlled heat. The solder paste reflows in a molten state, creating permanent solder joints. Heating may be accomplished by passing the assembly through a reflow oven, under an Infrared heater, infrared lamp, or (mainly for prototyping) by soldering individual joints with a hot air pencil. Reflow soldering with long industrial convection ovens is the preferred method of soldering surface mount technology (SMT) components to a printed circuit board (PCB). Each segment of the oven has a regulated temperature, according to the specific thermal requirements of each assembly. Reflow ovens meant specifically for the soldering of surface mount components may also be used for Through-hole technology, throu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Moisture Sensitivity Level

Moisture sensitivity level (MSL) relates to the packaging and handling precautions for some semiconductors and is a rating that shows a device's susceptibility to damage due to absorbed moisture when subjected to reflow soldering as defined in J-STD-020. The MSL is an electronic standard for the time period in which a moisture sensitive device can be exposed to ambient room conditions (30 °C/85%RH at Level 1; 30 °C/60%RH at all other levels) without taking measures to retard the absorption of moisture. Modern semiconductors are typically encapsulated in molded plastic. This plastic absorbs and retains moisture from ambient air. When a semiconductor package is soldered or de-soldered, it is subjected to rapid heating. The increase in temperature will cause trapped moisture to turn to vapor, seek to expand and escape the package. The process of moisture expansion and escape can be violent and result in internal separation (delamination) of the plastic from the die or le ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |