|

Plated

Plating is a surface covering in which a metal is deposited on a conductive surface. Plating has been done for hundreds of years; it is also critical for modern technology. Plating is used to decorate objects, for corrosion inhibition, to improve solderability, to harden, to improve wearability, to reduce friction, to improve paint adhesion, to alter conductivity, to improve IR reflectivity, for radiation shielding, and for other purposes. Jewelry typically uses plating to give a silver or gold finish. Thin-film deposition has plated objects as small as an atom, therefore plating finds uses in nanotechnology. There are several plating methods, and many variations. In one method, a solid surface is covered with a metal sheet, and then heat and pressure are applied to fuse them (a version of this is Sheffield plate). Other plating techniques include electroplating, vapor deposition under vacuum and sputter deposition. Recently, plating often refers to using liquids. Metallizin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electroplating

Electroplating, also known as electrochemical deposition or electrodeposition, is a process for producing a metal coating on a solid substrate through the reduction of cations of that metal by means of a direct electric current. The part to be coated acts as the cathode (negative electrode) of an electrolytic cell; the electrolyte is a solution of a salt of the metal to be coated; and the anode (positive electrode) is usually either a block of that metal, or of some inert conductive material. The current is provided by an external power supply. Electroplating is widely used in industry and decorative arts to improve the surface qualities of objects—such as resistance to abrasion and corrosion, lubricity, reflectivity, electrical conductivity, or appearance. It is used to build up thickness on undersized or worn-out parts, or to manufacture metal plates with complex shape, a process called electroforming. It is used to deposit copper and other conductors in forming pr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Printed Circuit Board

A printed circuit board (PCB; also printed wiring board or PWB) is a medium used in electrical and electronic engineering to connect electronic components to one another in a controlled manner. It takes the form of a laminated sandwich structure of conductive and insulating layers: each of the conductive layers is designed with an artwork pattern of traces, planes and other features (similar to wires on a flat surface) etched from one or more sheet layers of copper laminated onto and/or between sheet layers of a non-conductive substrate. Electrical components may be fixed to conductive pads on the outer layers in the shape designed to accept the component's terminals, generally by means of soldering, to both electrically connect and mechanically fasten them to it. Another manufacturing process adds vias: plated-through holes that allow interconnections between layers. Printed circuit boards are used in nearly all electronic products. Alternatives to PCBs include wire ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gold Plating

Gold plating is a method of depositing a thin layer of gold onto the surface of another metal, most often copper or silver (to make silver-gilt), by chemical or electrochemical plating. This article covers plating methods used in the modern electronics industry; for more traditional methods, often used for much larger objects, see gilding. Types There are several types of gold plating used in the electronics industry: * ''Soft, pure gold plating'' is used in the semiconductor industry. The gold layer is easily soldered and wire bonded. Its Knoop hardness ranges between 60 and 85. The plating baths have to be kept free of contamination. * ''Soft, pure gold'' is deposited from special electrolytes. Entire printed circuit boards can be plated. This technology can be used for depositing layers suitable for wire bonding. * ''Bright hard gold on contacts'', with Knoop hardness between 120–300 and purity of 99.7–99.9% gold. Often contains a small amount of nickel and/or cobalt ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Jewelry

Jewellery ( UK) or jewelry ( U.S.) consists of decorative items worn for personal adornment, such as brooches, rings, necklaces, earrings, pendants, bracelets, and cufflinks. Jewellery may be attached to the body or the clothes. From a western perspective, the term is restricted to durable ornaments, excluding flowers for example. For many centuries metal such as gold often combined with gemstones, has been the normal material for jewellery, but other materials such as glass, shells and other plant materials may be used. Jewellery is one of the oldest types of archaeological artefact – with 100,000-year-old beads made from '' Nassarius'' shells thought to be the oldest known jewellery.Study reveals 'oldest jewellery' , '' |

Silver

Silver is a chemical element with the symbol Ag (from the Latin ', derived from the Proto-Indo-European ''h₂erǵ'': "shiny" or "white") and atomic number 47. A soft, white, lustrous transition metal, it exhibits the highest electrical conductivity, thermal conductivity, and reflectivity of any metal. The metal is found in the Earth's crust in the pure, free elemental form ("native silver"), as an alloy with gold and other metals, and in minerals such as argentite and chlorargyrite. Most silver is produced as a byproduct of copper, gold, lead, and zinc refining. Silver has long been valued as a precious metal. Silver metal is used in many bullion coins, sometimes alongside gold: while it is more abundant than gold, it is much less abundant as a native metal. Its purity is typically measured on a per-mille basis; a 94%-pure alloy is described as "0.940 fine". As one of the seven metals of antiquity, silver has had an enduring role in most human cultures. Oth ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sheffield Plate

Sheffield plate is a layered combination of silver and copper that was used for many years to produce a wide range of household articles. Almost every article made in sterling silver was also crafted by Sheffield makers, who used this manufacturing process to produce nearly identical wares at far less cost. History The material was accidentally invented by Thomas Boulsover, of Sheffield's Cutlers Company, in 1743. While trying to repair the handle of a customer's decorative knife, he heated it too much and the silver started to melt. When he examined the damaged handle, he noticed that the silver and copper had fused together very strongly. Experiments showed that the two metals behaved as one when he tried to reshape them, even though he could clearly see the two different layers. Boulsover set up in business, funded by Strelley Pegge of Beauchief, and carried out further experiments in which he put a thin sheet of silver on a thick ingot of copper and heated the two toge ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gold

Gold is a chemical element with the symbol Au (from la, aurum) and atomic number 79. This makes it one of the higher atomic number elements that occur naturally. It is a bright, slightly orange-yellow, dense, soft, malleable, and ductile metal in a pure form. Chemically, gold is a transition metal and a group 11 element. It is one of the least reactive chemical elements and is solid under standard conditions. Gold often occurs in free elemental ( native state), as nuggets or grains, in rocks, veins, and alluvial deposits. It occurs in a solid solution series with the native element silver (as electrum), naturally alloyed with other metals like copper and palladium, and mineral inclusions such as within pyrite. Less commonly, it occurs in minerals as gold compounds, often with tellurium ( gold tellurides). Gold is resistant to most acids, though it does dissolve in aqua regia (a mixture of nitric acid and hydrochloric acid), forming a soluble tetrachloroaurate an ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

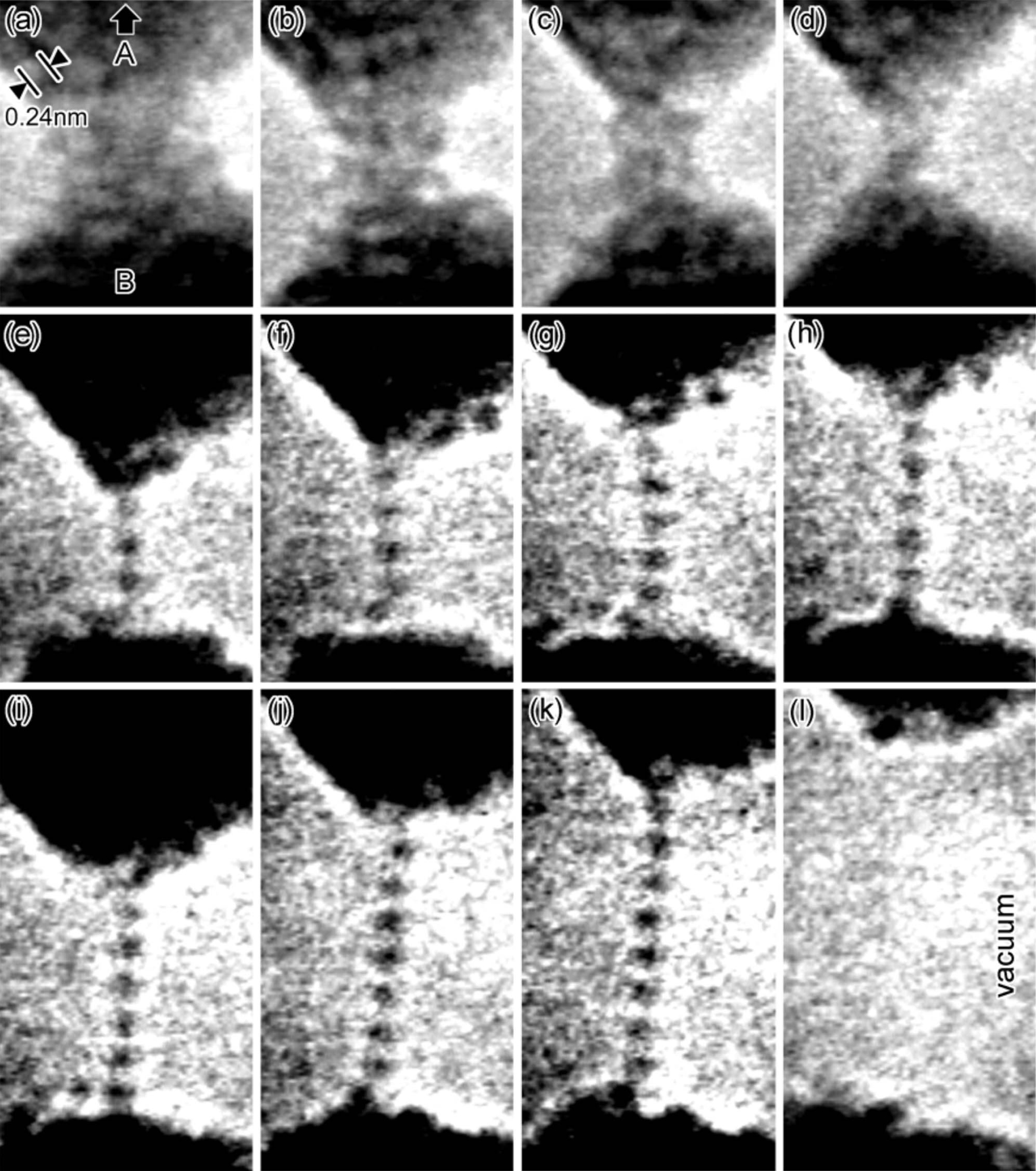

Electroless Nickel Plating

Electroless nickel-phosphorus plating is a chemical process that deposits an even layer of nickel-phosphorus alloy on the surface of a solid substrate, like metal or plastic. The process involves dipping the substrate in a water solution containing nickel salt and a phosphorus-containing reducing agent, usually a hypophosphite salt. It is the most common version of electroless nickel plating (EN plating) and is often referred by that name. A similar process uses a borohydride reducing agent, yielding a nickel-boron coating instead. Unlike electroplating, electroless plating processes in general do not require passing an electric current through the bath and the substrate; the reduction of the metal cations in solution to metallic is achieved by purely chemical means, through an autocatalytic reaction. Thus electroless plating creates an even layer of metal regardless of the geometry of the surface – in contrast to electroplating which suffers from uneven current density du ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metallizing

Metallizing is the general name for the technique of coating metal on the surface of objects. Metallic coatings may be decorative, protective or functional. Techniques for metallization started as early as mirror making. In 1835, Justus von Liebig discovered the process of coating a glass surface with metallic silver, making the glass mirror one of the earliest items being metallized. Plating other non-metallic objects grew rapidly with introduction of ABS plastic. Because a non-metallic object tends to be a poor electrical conductor, the object's surface must be made conductive before plating can be performed. The plastic part is first etched chemically by a suitable process, such as dipping in a hot chromic acid- sulfuric acid mixture. The etched surface is sensitised and activated by first dipping in tin(II) chloride solution, then palladium chloride solution. The processed surface is then coated with electroless copper or nickel before further plating. This process giv ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cathode

A cathode is the electrode from which a conventional current leaves a polarized electrical device. This definition can be recalled by using the mnemonic ''CCD'' for ''Cathode Current Departs''. A conventional current describes the direction in which positive charges move. Electrons have a negative electrical charge, so the movement of electrons is opposite to that of the conventional current flow. Consequently, the mnemonic ''cathode current departs'' also means that electrons flow ''into'' the device's cathode from the external circuit. For example, the end of a household battery marked with a + (plus) is the cathode. The electrode through which conventional current flows the other way, into the device, is termed an anode. Charge flow Conventional current flows from cathode to anode outside of the cell or device (with electrons moving in the opposite direction), regardless of the cell or device type and operating mode. Cathode polarity with respect to the anode can be positi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Corrosion

Corrosion is a natural process that converts a refined metal into a more chemically stable oxide. It is the gradual deterioration of materials (usually a metal) by chemical or electrochemical reaction with their environment. Corrosion engineering is the field dedicated to controlling and preventing corrosion. In the most common use of the word, this means electrochemical oxidation of metal in reaction with an oxidant such as oxygen, hydrogen or hydroxide. Rusting, the formation of iron oxides, is a well-known example of electrochemical corrosion. This type of damage typically produces oxide(s) or salt(s) of the original metal and results in a distinctive orange colouration. Corrosion can also occur in materials other than metals, such as ceramics or polymers, although in this context, the term "degradation" is more common. Corrosion degrades the useful properties of materials and structures including strength, appearance and permeability to liquids and gases. Many str ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electrical Connector

Components of an electrical circuit are electrically connected if an electric current can run between them through an electrical conductor. An electrical connector is an electromechanical device used to create an electrical connection between parts of an electrical circuit, or between different electrical circuits, thereby joining them into a larger circuit. Most electrical connectors have a genderi.e. the male component, called a ''plug'', connects to the female component, or ''socket''. The connection may be removable (as for portable equipment), require a tool for assembly and removal, or serve as a permanent electrical joint between two points. An adapter can be used to join dissimilar connectors. Thousands of configurations of connectors are manufactured for power, data, and audiovisual applications. Electrical connectors can be divided into four basic categories, differentiated by their function: * ''inline'' or ''cable'' connectors permanently attached to a cable, so ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |