|

Plating

Plating is a finishing process in which a metal is deposited on a surface. Plating has been done for hundreds of years; it is also critical for modern technology. Plating is used to decorate objects, for corrosion inhibition, to improve solderability, to harden, to improve wearability, to reduce friction, to improve paint adhesion, to alter conductivity, to improve IR reflectivity, for radiation shielding, and for other purposes. Jewelry typically uses plating to give a silver or gold finish. Thin-film deposition has plated objects as small as an atom, therefore plating finds uses in nanotechnology. There are several plating methods, and many variations. In one method, a solid surface is covered with a metal sheet, and then heat and pressure are applied to fuse them (a version of this is Sheffield plate). Other plating techniques include electroplating, vapor deposition under vacuum and sputter deposition. Recently, plating often refers to using liquids. Metallizing refers ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electroplating

Electroplating, also known as electrochemical deposition or electrodeposition, is a process for producing a metal coating on a solid substrate through the redox, reduction of cations of that metal by means of a direct current, direct electric current. The part to be coated acts as the cathode (negative electrode) of an electrolytic cell; the electrolyte is a solution (chemistry), solution of a salt (chemistry), salt whose cation is the metal to be coated, and the anode (positive electrode) is usually either a block of that metal, or of some inert electrical conductor, conductive material. The current is provided by an external power supply. Electroplating is widely used in industry and decorative arts to improve the surface qualities of objects—such as resistance to abrasion (mechanical), abrasion and corrosion, lubrication, lubricity, reflectivity, electrical conductivity, or appearance. It is used to build up thickness on undersized or worn-out parts and to manufacture metal ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electroless Nickel Plating

Electroless Deposition, Electroless nickel-phosphorus plating, also referred to as ''E-nickel'', is a chemical engineering, chemical process that deposits an even layer of nickel-phosphorus alloy on the surface of a solid substrate, like metal or plastic. The process involves dipping the substrate in a water solution containing nickel salt (chemistry), salt and a phosphorus-containing reducing agent, usually a hypophosphite salt. It is the most common version of electroless nickel plating (EN plating) and is often referred by that name. A Electroless nickel-boron plating, similar process uses a borohydride reducing agent, yielding a nickel-boron coating instead. Unlike electroplating, processes in general do not require passing an electric current through the bath and the substrate; the redox reaction, reduction of the metal cations in solution to metallic is achieved by purely chemical means, through an autocatalysis, autocatalytic reaction. This creates an even layer of met ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gold Plating

Gold plating is a method of depositing a thin layer of gold onto the surface of another metal, most often copper or silver (to make silver-gilt), by a chemical or electrochemical (electroplating) process. Plating refers to modern coating methods, such as the ones used in the electronics industry, whereas gilding is the decorative covering of an object with gold, which typically involve more traditional methods and much larger objects. Gold plating chemistry There are five recognized classes of gold plating chemistry: # Alkaline gold cyanide, for gold and gold alloy plating # Neutral gold cyanide, for high-purity plating # Acid gold plating for bright hard gold and gold alloy plating # Non-cyanide, generally sulphite or chloride-based for gold and gold alloy plating # Miscellaneous Jewellery Gold plating of silver is used in the manufacture of jewellery. The thickness of gold plating on jewellery is noted in microns (or micro-meters). The microns of thickness determines h ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sheffield Plate

Old Sheffield Plate (or OSP) is the material developed by Thomas Boulsover in the 1740s, a fusion of copper and sterling silver which could be made into a range of items normally made in solid silver. The material rapidly gained popularity as a substitute for solid silver, as it was much cheaper to produce. Any object made in silver could be made in Old Sheffield Plate, although objects subject to heavy wear such as spoons and forks were not so satisfactory in plate. The characteristic identifying feature of OSP is the 'bleeding' or 'show through' of the copper base, especially on points of wear although there is also a subtle difference in colour from the pure silver of electro plating to the "very faintly bluish lustre" of OSP. In addition to having a distinct bluish cast, the alloy produced in OSP is also harder than electrodeposited silver. The material remained popular until being replaced by the electroplate process in the 1840s. Items produced in Old Sheffield Plate in ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metallizing

Metallizing is the general name for the technique of coating metal on the surface of objects. Metallic coatings may be decorative, protective or functional. Techniques for metallization started as early as mirror making. In 1835, Justus von Liebig discovered the process of coating a glass surface with metallic silver, making the glass mirror one of the earliest items being metallized. Plating other non-metallic objects grew rapidly with introduction of ABS plastic. Because a non-metallic object tends to be a poor electrical conductor, the object's surface must be made conductive before plating can be performed. The plastic part is first etched chemically by a suitable process, such as dipping in a hot chromic acid-sulfuric acid mixture. The etched surface is sensitised and activated by first dipping in tin(II) chloride solution, then palladium chloride solution. The processed surface is then coated with electroless copper or nickel before further plating. This process gives ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Printed Circuit Board

A printed circuit board (PCB), also called printed wiring board (PWB), is a Lamination, laminated sandwich structure of electrical conduction, conductive and Insulator (electricity), insulating layers, each with a pattern of traces, planes and other features (similar to wires on a flat surface) Chemical milling, etched from one or more sheet layers of copper laminated onto or between sheet layers of a non-conductive substrate. PCBs are used to connect or Electrical wiring, "wire" Electronic component, components to one another in an electronic circuit. Electrical components may be fixed to conductive pads on the outer layers, generally by soldering, which both electrically connects and mechanically fastens the components to the board. Another manufacturing process adds Via (electronics), vias, metal-lined drilled holes that enable electrical interconnections between conductive layers, to boards with more than a single side. Printed circuit boards are used in nearly all e ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Silver

Silver is a chemical element; it has Symbol (chemistry), symbol Ag () and atomic number 47. A soft, whitish-gray, lustrous transition metal, it exhibits the highest electrical conductivity, thermal conductivity, and reflectivity of any metal. Silver is found in the Earth's crust in the pure, free elemental form ("native metal, native silver"), as an alloy with gold and other metals, and in minerals such as argentite and chlorargyrite. Most silver is produced as a byproduct of copper, gold, lead, and zinc Refining (metallurgy), refining. Silver has long been valued as a precious metal. Silver metal is used in many bullion coins, sometimes bimetallism, alongside gold: while it is more abundant than gold, it is much less abundant as a native metal. Its purity is typically measured on a per-mille basis; a 94%-pure alloy is described as "0.940 fine". As one of the seven metals of antiquity, silver has had an enduring role in most human cultures. Other than in currency and as an in ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gold

Gold is a chemical element; it has chemical symbol Au (from Latin ) and atomic number 79. In its pure form, it is a brightness, bright, slightly orange-yellow, dense, soft, malleable, and ductile metal. Chemically, gold is a transition metal, a group 11 element, and one of the noble metals. It is one of the least reactivity (chemistry), reactive chemical elements, being the second-lowest in the reactivity series. It is solid under standard temperature and pressure, standard conditions. Gold often occurs in free elemental (native state (metallurgy), native state), as gold nugget, nuggets or grains, in rock (geology), rocks, vein (geology), veins, and alluvial deposits. It occurs in a solid solution series with the native element silver (as in electrum), naturally alloyed with other metals like copper and palladium, and mineral inclusions such as within pyrite. Less commonly, it occurs in minerals as gold compounds, often with tellurium (gold tellurides). Gold is resistant to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thin-film Deposition

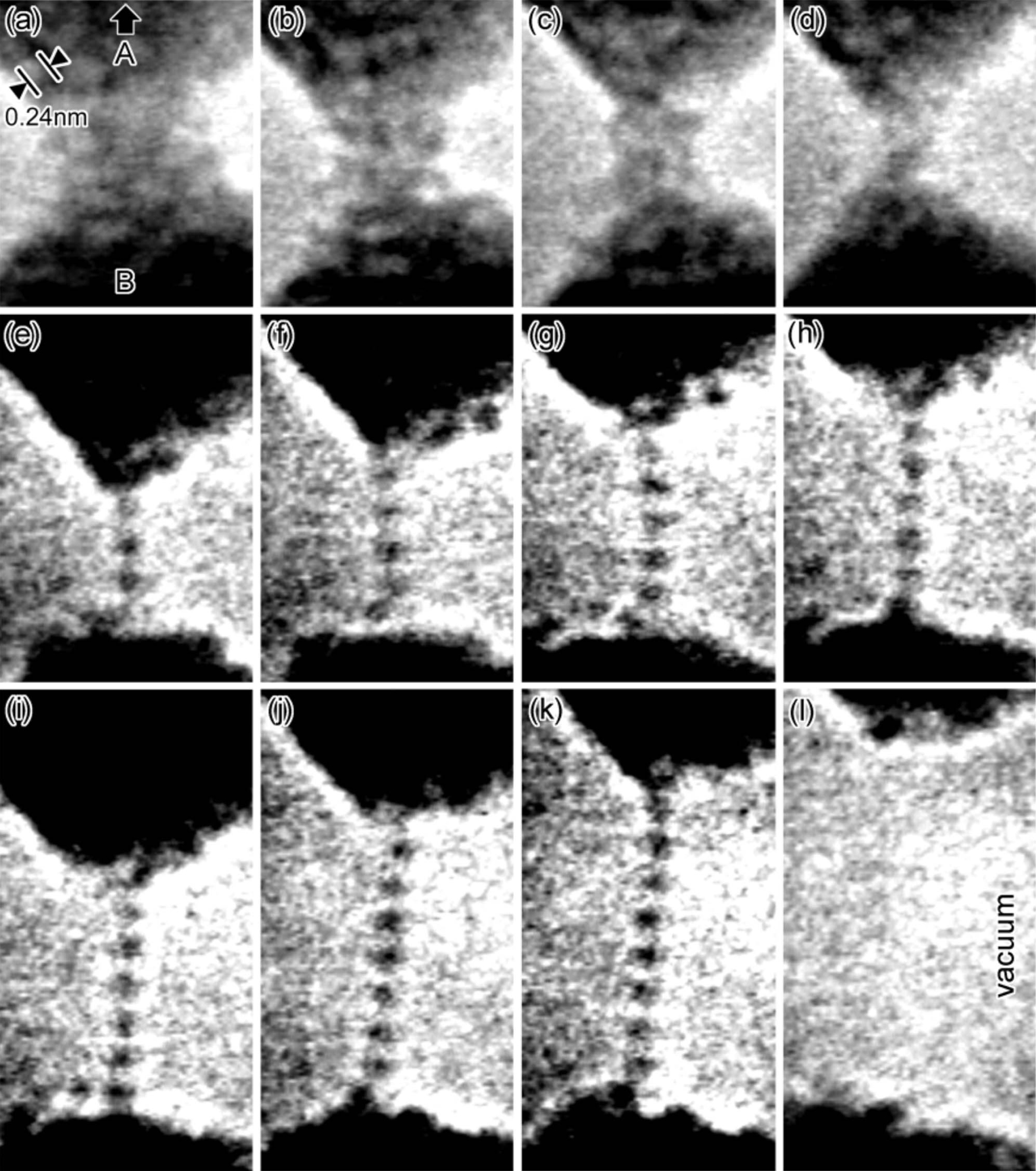

A thin film is a layer of materials ranging from fractions of a nanometer ( monolayer) to several micrometers in thickness. The controlled synthesis of materials as thin films (a process referred to as deposition) is a fundamental step in many applications. A familiar example is the household mirror, which typically has a thin metal coating on the back of a sheet of glass to form a reflective interface. The process of silvering was once commonly used to produce mirrors, while more recently the metal layer is deposited using techniques such as sputtering. Advances in thin film deposition techniques during the 20th century have enabled a wide range of technological breakthroughs in areas such as magnetic recording media, electronic semiconductor devices, integrated passive devices, light-emitting diodes, optical coatings (such as antireflective coatings), hard coatings on cutting tools, and for both energy generation (e.g. thin-film solar cells) and storage ( thin-film batterie ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Angel Gilding

Angel gilding is gilding glass or gold plating by electroless chemical deposition. Gold chloride is dissolved in water, mixed with other chemicals and poured on clean glass that has been treated with stannous chloride. The gold layer is delicate and usually translucent. To make an opaque, affordable and adherent mirror, a layer of silver is deposited over the gold. Glass gilders use the term ''angel gilding'' to distinguish the chemical process from gold leaf gilding also known as '' verre églomisé''. History Justus von Liebig, widely credited with inventing the modern process for silvering glass, also worked on gilding glass with gold chloride. James Pratt, a British glass worker, was the first to realize that he could make affordable gold mirrors by depositing a layer of silver on top of the gold. He was granted a British patent in 1885. Gold mirrors and gold mirrored signs were very popular in English public houses (pubs) in the late Victorian era and many wonderful exa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Galvanization

Galvanization ( also spelled galvanisation) is the process of applying a protective zinc coating to steel or iron, to prevent rusting. The most common method is hot-dip galvanizing, in which the parts are coated by submerging them in a bath of hot, molten zinc. Protective action The zinc coating, when intact, prevents corrosive substances from reaching the underlying iron. It's main function is to act as a sacrificial anode to prevent the iron from rusting by cathodic protection. Zinc is more reactive than iron, so the zinc coating preferentially oxidizes to zinc carbonate, preventing the iron from corroding, even if there are gaps in the zinc coating. Additional electroplating such as a chromate conversion coating may be applied to provide further surface passivation to the substrate material. History and etymology The process is named after the Italian physician, physicist, biologist and philosopher Luigi Galvani (9 September 1737 – 4 December 1798). The earliest kno ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Copper

Copper is a chemical element; it has symbol Cu (from Latin ) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pinkish-orange color. Copper is used as a conductor of heat and electricity, as a building material, and as a constituent of various metal alloys, such as sterling silver used in jewelry, cupronickel used to make marine hardware and coins, and constantan used in strain gauges and thermocouples for temperature measurement. Copper is one of the few metals that can occur in nature in a directly usable, unalloyed metallic form. This means that copper is a native metal. This led to very early human use in several regions, from . Thousands of years later, it was the first metal to be smelted from sulfide ores, ; the first metal to be cast into a shape in a mold, ; and the first metal to be purposely alloyed with another metal, tin, to create bronze, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |