|

Flux-cored

Flux-cored arc welding (FCAW or FCA) is a semi-automatic or automatic arc welding process. FCAW requires a continuously-fed consumable tubular electrode containing a flux and a constant-voltage or, less commonly, a constant-current welding power supply. An externally supplied shielding gas is sometimes used, but often the flux itself is relied upon to generate the necessary protection from the atmosphere, producing both gaseous protection and liquid slag protecting the weld. Types One type of FCAW requires no shielding gas. This is made possible by the flux core in the tubular consumable electrode. However, this core contains more than just flux. It also contains various ingredients that when exposed to the high temperatures of welding generate a shielding gas for protecting the arc. This type of FCAW is attractive because it is portable and generally has good penetration into the base metal. Also, windy conditions need not be considered. Some disadvantages are that this proces ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Arc Welding

Arc welding is a welding process that is used to join metal to metal by using electricity to create enough heat to melt metal, and the melted metals, when cool, result in a binding of the metals. It is a type of welding that uses a welding power supply to create an electric arc between a metal stick ("electrode") and the base material to melt the metals at the point of contact. Arc welders can use either direct (DC) or alternating (AC) current, and consumable or non-consumable electrodes. The welding area is usually protected by some type of shielding gas (e.g. an inert gas), vapor, or slag. Arc welding processes may be manual, semi-automatic, or fully automated. First developed in the late part of the 19th century, arc welding became commercially important in shipbuilding during the Second World War. Today it remains an important process for the fabrication of steel structures and vehicles. Power supplies To supply the electrical energy necessary for arc welding processes ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Flux (metallurgy)

In metallurgy, a flux () is a chemical cleaning agent, flowing agent, or purifying agent. Fluxes may have more than one function at a time. They are used in both extractive metallurgy and metal joining. Some of the earliest known fluxes were sodium carbonate, potash, charcoal, coke, borax, lime, lead sulfide and certain minerals containing phosphorus. Iron ore was also used as a flux in the smelting of copper. These agents served various functions, the simplest being a reducing agent, which prevented oxides from forming on the surface of the molten metal, while others absorbed impurities into the slag, which could be scraped off the molten metal. Fluxes are also used in foundries for removing impurities from molten nonferrous metals such as aluminium, or for adding desirable trace elements such as titanium. As cleaning agents, fluxes facilitate soldering, brazing, and welding by removing oxidation from the metals to be joined. In some applications molten flux a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

FCAW Drawing

Flux-cored arc welding (FCAW or FCA) is a semi-automatic or automatic arc welding process. FCAW requires a continuously-fed consumable tubular electrode containing a flux and a constant-voltage or, less commonly, a constant-current welding power supply. An externally supplied shielding gas is sometimes used, but often the flux itself is relied upon to generate the necessary protection from the atmosphere, producing both gaseous protection and liquid slag protecting the weld. Types One type of FCAW requires no shielding gas. This is made possible by the flux core in the tubular consumable electrode. However, this core contains more than just flux. It also contains various ingredients that when exposed to the high temperatures of welding generate a shielding gas for protecting the arc. This type of FCAW is attractive because it is portable and generally has good penetration into the base metal. Also, windy conditions need not be considered. Some disadvantages are that this proces ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electrode

An electrode is an electrical conductor used to make contact with a nonmetallic part of a circuit (e.g. a semiconductor, an electrolyte, a vacuum or air). Electrodes are essential parts of batteries that can consist of a variety of materials depending on the type of battery. The electrophore, invented by Johan Wilcke, was an early version of an electrode used to study static electricity. Anode and cathode in electrochemical cells Electrodes are an essential part of any battery. The first electrochemical battery made was devised by Alessandro Volta and was aptly named the Voltaic cell. This battery consisted of a stack of copper and zinc electrodes separated by brine-soaked paper disks. Due to fluctuation in the voltage provided by the voltaic cell it wasn't very practical. The first practical battery was invented in 1839 and named the Daniell cell after John Frederic Daniell. Still making use of the zinc–copper electrode combination. Since then many more batteries ha ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Voltage

Voltage, also known as electric pressure, electric tension, or (electric) potential difference, is the difference in electric potential between two points. In a static electric field, it corresponds to the work needed per unit of charge to move a test charge between the two points. In the International System of Units, the derived unit for voltage is named '' volt''. The voltage between points can be caused by the build-up of electric charge (e.g., a capacitor), and from an electromotive force (e.g., electromagnetic induction in generator, inductors, and transformers). On a macroscopic scale, a potential difference can be caused by electrochemical processes (e.g., cells and batteries), the pressure-induced piezoelectric effect, and the thermoelectric effect. A voltmeter can be used to measure the voltage between two points in a system. Often a common reference potential such as the ground of the system is used as one of the points. A voltage can represent either a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electric Current

An electric current is a stream of charged particles, such as electrons or ions, moving through an electrical conductor or space. It is measured as the net rate of flow of electric charge through a surface or into a control volume. The moving particles are called charge carriers, which may be one of several types of particles, depending on the conductor. In electric circuits the charge carriers are often electrons moving through a wire. In semiconductors they can be electrons or holes. In an electrolyte the charge carriers are ions, while in plasma, an ionized gas, they are ions and electrons. The SI unit of electric current is the ampere, or ''amp'', which is the flow of electric charge across a surface at the rate of one coulomb per second. The ampere (symbol: A) is an SI base unit. Electric current is measured using a device called an ammeter. Electric currents create magnetic fields, which are used in motors, generators, inductors, and transformers. In ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Welding Power Supply

A welding power supply is a device that provides or modulates an electric current to perform arc welding.- - There are multiple arc welding processes in common use ranging from relatively simple Shielded Metal Arc Welding (SMAW) to more complicated welding processes using inert shielding gas like Gas metal arc welding (GMAW) or Gas tungsten arc welding (GTAW). Welding power supplies primarily serve as devices that allow a welder to exercise control over whether current is alternating current (AC) or direct current (DC), as well as the amount of current and voltage. Power supplies for welding processes that use shielding gas also offer connections for gas and methods to control gas flow. The operator can set these factors to within the parameters as needed by the metal type, thickness, and technique to be used. The majority of welding power supplies do not generate power, instead functioning as controllable transformers that allow the operator to adjust electrical properties as ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Shielding Gas

Shielding gases are inert or semi-inert gases that are commonly used in several welding processes, most notably gas metal arc welding and gas tungsten arc welding (GMAW and GTAW, more popularly known as MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas), respectively). Their purpose is to protect the weld area from oxygen, and water vapour. Depending on the materials being welded, these atmospheric gases can reduce the quality of the weld or make the welding more difficult. Other arc welding processes use alternative methods of protecting the weld from the atmosphere as well – shielded metal arc welding, for example, uses an electrode covered in a flux that produces carbon dioxide when consumed, a semi-inert gas that is an acceptable shielding gas for welding steel. Improper choice of a welding gas can lead to a porous and weak weld, or to excessive spatter; the latter, while not affecting the weld itself, causes loss of productivity due to the labor needed to remove the scatter ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Slag (welding)

Welding slag is a form of slag, or vitreous material produced as a byproduct of some arc welding processes, most specifically shielded metal arc welding (also known as stick welding), submerged arc welding, and flux-cored arc welding. Slag is formed when flux, the solid shielding material used in the welding process, melts in or on top of the weld zone (also known as Dross). Slag is the solidified remaining flux after the weld area cools.Modern Welding Technology (6th Edition), Howard B. Cary& Scott Helzer, 2004, __TOC__ Flux Welding flux is a combination of carbonate and silicate materials used in welding processes to shield the weld from atmospheric gases. When the heat of the weld zone reaches the flux, the flux melts and outgasses. The gases produced push the atmospheric gas back, preventing oxidation (and reactions with nitrogen). The melted flux covers the molten metal in the weld zone. Flux materials are chosen so that the density of the melted flux / slag is lower ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

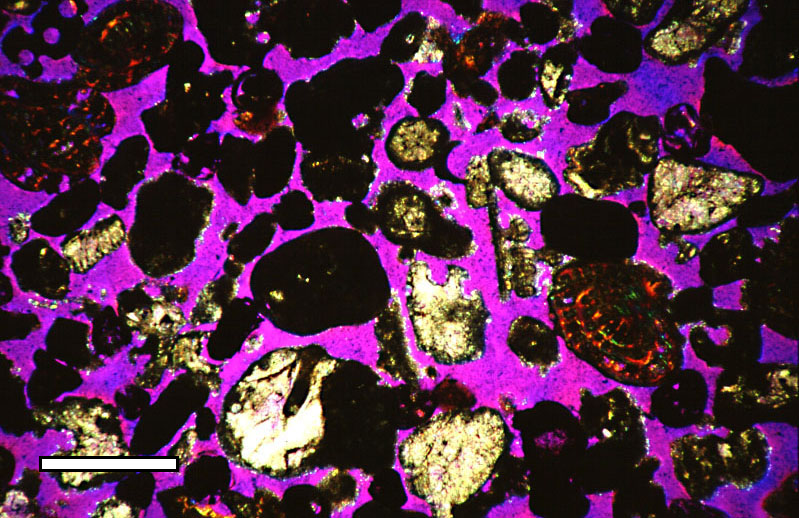

Porosity

Porosity or void fraction is a measure of the void (i.e. "empty") spaces in a material, and is a fraction of the volume of voids over the total volume, between 0 and 1, or as a percentage between 0% and 100%. Strictly speaking, some tests measure the "accessible void", the total amount of void space accessible from the surface (cf. closed-cell foam). There are many ways to test porosity in a substance or part, such as industrial CT scanning. The term porosity is used in multiple fields including pharmaceutics, ceramics, metallurgy, materials, manufacturing, petrophysics, hydrology, earth sciences, soil mechanics, and engineering. Void fraction in two-phase flow In gas-liquid two-phase flow, the void fraction is defined as the fraction of the flow-channel volume that is occupied by the gas phase or, alternatively, as the fraction of the cross-sectional area of the channel that is occupied by the gas phase. Void fraction usually varies from location to location in the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Slag

Slag is a by-product of smelting ( pyrometallurgical) ores and used metals. Broadly, it can be classified as ferrous (by-products of processing iron and steel), ferroalloy (by-product of ferroalloy production) or non-ferrous/base metals (by-products of recovering non-ferrous materials like copper, nickel, zinc and phosphorus). Within these general categories, slags can be further categorized by their precursor and processing conditions (e.g., Blast furnace (BF) slags, air-cooled blast furnace (ACBF) slag, basic oxygen furnace (BOF) slag, and electric arc furnace (EAF) slag) . Due to the large demand for these materials, slag production has also significantly increased throughout the years despite recycling (most notably in the iron and steelmaking industries) and upcycling efforts. The World Steel Association (WSA) estimates that 600 kg of by-products (~90 wt% is slags) are generated per tonne of steel produced. Composition Slag is usually a mixture of metal oxides and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |