Flux (metallurgy) on:

[Wikipedia]

[Google]

[Amazon]

In metallurgy, a flux () is a chemical

In metallurgy, a flux () is a chemical

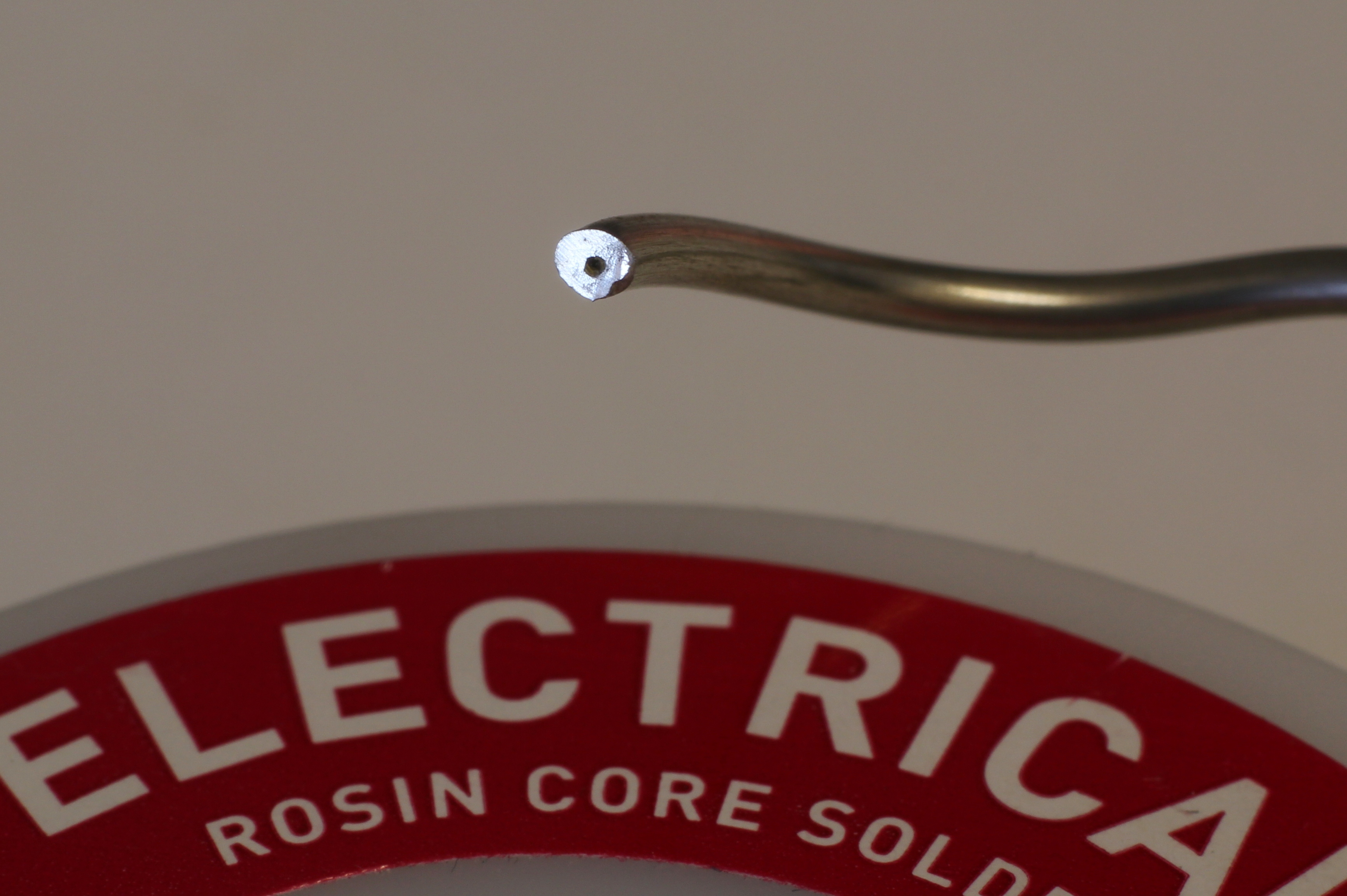

The terms resin flux and rosin flux are ambiguous and somewhat interchangeable, with different vendors using different assignments. Generally, fluxes are labeled as rosin if the vehicle they are based on is primarily natural

The terms resin flux and rosin flux are ambiguous and somewhat interchangeable, with different vendors using different assignments. Generally, fluxes are labeled as rosin if the vehicle they are based on is primarily natural

MetalShapers.Org

Tips & Tricks from the Pros: 'Aluminum Welding"'' (includes Filler Metal chart)

Solder Fume and You

{{DEFAULTSORT:Flux (Metallurgy) Metallurgy Brazing and soldering

In metallurgy, a flux () is a chemical

In metallurgy, a flux () is a chemical cleaning agent

Cleaning agents or hard-surface cleaners are substances (usually liquids, powders, sprays, or granules) used to remove dirt, including dust, stains, bad smells, and clutter on surfaces. Purposes of cleaning agents include health, beauty, removin ...

, flowing agent, or purifying agent. Fluxes may have more than one function at a time. They are used in both extractive metallurgy and metal joining.

Some of the earliest known fluxes were sodium carbonate, potash

Potash () includes various mined and manufactured salts that contain potassium in water-soluble form.

, charcoal, coke, borax, lime

Lime commonly refers to:

* Lime (fruit), a green citrus fruit

* Lime (material), inorganic materials containing calcium, usually calcium oxide or calcium hydroxide

* Lime (color), a color between yellow and green

Lime may also refer to:

Botany ...

, lead sulfide Lead sulfide refers to two compounds containing lead and sulfur:

* Lead(II) sulfide, PbS, containing lead in the +2 oxidation state, naturally occurring as the mineral galena

*Lead(IV) sulfide

Lead(IV) sulfide is a chemical compound with the formu ...

and certain minerals containing phosphorus

Phosphorus is a chemical element with the symbol P and atomic number 15. Elemental phosphorus exists in two major forms, white phosphorus and red phosphorus, but because it is highly reactive, phosphorus is never found as a free element on Ear ...

. Iron ore was also used as a flux in the smelting

Smelting is a process of applying heat to ore, to extract a base metal. It is a form of extractive metallurgy. It is used to extract many metals from their ores, including silver, iron, copper, and other base metals. Smelting uses heat and a ...

of copper. These agents served various functions, the simplest being a reducing agent, which prevented oxides from forming on the surface of the molten metal, while others absorbed impurities into the slag, which could be scraped off the molten metal.

Fluxes are also used in foundries

A foundry is a factory that produces metal castings. Metals are cast into shapes by melting them into a liquid, pouring the metal into a mold, and removing the mold material after the metal has solidified as it cools. The most common metals pr ...

for removing impurities from molten nonferrous metal

In metallurgy, non-ferrous metals are metals or alloys that do not contain iron (allotropes of iron, ferrite, and so on) in appreciable amounts.

Generally more costly than ferrous metals, non-ferrous metals are used because of desirable proper ...

s such as aluminium

Aluminium (aluminum in American and Canadian English) is a chemical element with the symbol Al and atomic number 13. Aluminium has a density lower than those of other common metals, at approximately one third that of steel. I ...

, or for adding desirable trace element

__NOTOC__

A trace element, also called minor element, is a chemical element whose concentration (or other measure of amount) is very low (a "trace amount"). They are classified into two groups: essential and non-essential. Essential trace elements ...

s such as titanium

Titanium is a chemical element with the Symbol (chemistry), symbol Ti and atomic number 22. Found in nature only as an oxide, it can be reduced to produce a lustrous transition metal with a silver color, low density, and high strength, resista ...

.

As cleaning agents, fluxes facilitate soldering, brazing, and welding

Welding is a fabrication process that joins materials, usually metals or thermoplastics, by using high heat to melt the parts together and allowing them to cool, causing fusion. Welding is distinct from lower temperature techniques such as bra ...

by removing oxidation from the metals to be joined. In some applications molten flux also serves as a heat-transfer medium, facilitating heating of the joint by the soldering tool or molten solder.

Uses

Metal joining

In high-temperature metal joining processes (welding

Welding is a fabrication process that joins materials, usually metals or thermoplastics, by using high heat to melt the parts together and allowing them to cool, causing fusion. Welding is distinct from lower temperature techniques such as bra ...

, brazing and soldering), flux is a substance that is nearly inert at room temperature, but which becomes strongly reducing at elevated temperatures, preventing oxidation of the base and filler materials. The role of flux is typically dual: dissolving the oxides already present on the metal surface, which facilitates wetting by molten metal, and acting as an oxygen barrier by coating the hot surface, preventing its oxidation.

For example, tin-lead solder attaches very well to copper, but poorly to the various oxides of copper, which form quickly at soldering temperatures. By preventing the formation of metal oxides, flux enables the solder to adhere to the clean metal surface, rather than forming beads, as it would on an oxidized surface.Soldering

In soldering of metals, flux serves a threefold purpose: it removes any oxidized metal from the surfaces to be soldered, seals out air thus preventing further oxidation, and by facilitating amalgamation, improves wetting characteristics of the liquid solder. Some fluxes arecorrosive

A corrosive substance is one that will damage or destroy other substances with which it comes into contact by means of a chemical reaction.

Etymology

The word ''corrosive'' is derived from the Latin verb ''corrodere'', which means ''to gnaw'', ...

, so the parts have to be cleaned with a damp sponge or other absorbent material after soldering to prevent damage. Several types of flux are used in electronics.

A number of standards exist to define the various flux types. The principal standard is J-STD-004.

Various tests, including the ROSE test, may be used after soldering to check for the presence of ionic or other contaminants that could cause short circuits or other problems.

Brazing and silver soldering

Brazing (sometimes known as silver soldering or hard soldering) requires a much higher temperature than soft soldering, sometimes over 850 °C. As well as removing existing oxides, rapid oxidation of the metal at the elevated temperatures has to be avoided. This means that fluxes need to be more aggressive and to provide a physical barrier. Traditionally borax was used as a flux for brazing, but there are now many different fluxes available, often using active chemicals such as fluorides as well as wetting agents. Many of these chemicals are toxic and due care should be taken during their use.Smelting

In the process ofsmelting

Smelting is a process of applying heat to ore, to extract a base metal. It is a form of extractive metallurgy. It is used to extract many metals from their ores, including silver, iron, copper, and other base metals. Smelting uses heat and a ...

, inorganic chlorides, fluorides (see fluorite

Fluorite (also called fluorspar) is the mineral form of calcium fluoride, CaF2. It belongs to the halide minerals. It crystallizes in isometric cubic habit, although octahedral and more complex isometric forms are not uncommon.

The Mohs sca ...

), limestone

Limestone ( calcium carbonate ) is a type of carbonate sedimentary rock which is the main source of the material lime. It is composed mostly of the minerals calcite and aragonite, which are different crystal forms of . Limestone forms whe ...

and other materials are designated as "fluxes" when added to the contents of a smelting furnace or a cupola for the purpose of purging the metal of chemical impurities such as phosphorus, and of rendering slag more liquid at the smelting temperature. The slag is a liquid mixture of ash, flux, and other impurities. This reduction of slag viscosity with temperature, increasing the flow of slag in smelting, is the origin of the word ''flux'' in metallurgy.

The flux most commonly used in iron and steel furnaces is limestone

Limestone ( calcium carbonate ) is a type of carbonate sedimentary rock which is the main source of the material lime. It is composed mostly of the minerals calcite and aragonite, which are different crystal forms of . Limestone forms whe ...

, which is charged in the proper proportions with the iron and fuel.

Drawbacks

Fluxes have several serious drawbacks: * Corrosivity, which is mostly due to the aggressive compounds of the activators; hygroscopic properties of the flux residues may aggravate the effects * Interference with test equipment, which is due to the insulating residues deposited on the test contacts on electronic circuit boards * Interference withmachine vision

Machine vision (MV) is the technology and methods used to provide imaging-based automatic inspection and analysis for such applications as automatic inspection, process control, and robot guidance, usually in industry. Machine vision refers to ...

systems when the layer of flux or its remains is too thick or improperly located

* Contamination of sensitive parts, e.g. facets of laser diodes, contacts of connectors and mechanical switches, and MEMS assemblies

* Deterioration of electrical properties of printed circuit boards, as soldering temperatures are above the glass transition temperature of the board material and flux components (e.g. glycols, or chloride and bromide ions) can diffuse into its matrix; e.g. water-soluble fluxes containing polyethylene glycol

Polyethylene glycol (PEG; ) is a polyether compound derived from petroleum with many applications, from industrial manufacturing to medicine. PEG is also known as polyethylene oxide (PEO) or polyoxyethylene (POE), depending on its molecular we ...

were demonstrated to have such impact

* Deterioration of high-frequency circuit performance by flux residues

* Deterioration of surface insulation resistance, which tends to be as much as three orders of magnitude lower than the bulk resistance of the material

* Electromigration and growth of whiskers between nearby traces, aided by ionic residues, surface moisture and a bias voltage

* The fumes liberated during soldering have adverse health effects, and volatile organic compounds

Volatile organic compounds (VOCs) are organic compounds that have a high vapour pressure at room temperature. High vapor pressure correlates with a low boiling point, which relates to the number of the sample's molecules in the surrounding air, a t ...

can be outgassed during processing

* The solvents required for post-soldering cleaning of the boards are expensive and may have adverse environmental impact

In special cases the drawbacks are sufficiently serious to warrant using fluxless techniques.

Dangers

Acid flux types (not used in electronics) may containhydrochloric acid

Hydrochloric acid, also known as muriatic acid, is an aqueous solution of hydrogen chloride. It is a colorless solution with a distinctive pungent smell. It is classified as a strong acid

Acid strength is the tendency of an acid, symbol ...

, zinc chloride or ammonium chloride, which are harmful to humans. Therefore, flux should be handled with gloves and goggles, and used with adequate ventilation.

Prolonged exposure to rosin fumes released during soldering can cause occupational asthma

Occupational asthma is new onset asthma or the recurrence of previously quiescent asthma directly caused by exposure to an agent at workplace. It is an occupational lung disease and a type of work-related asthma. Agents that can induce occupationa ...

(formerly called ''colophony disease'' in this context) in sensitive individuals, although it is not known which component of the fumes causes the problem.

While molten solder has low tendency to adhere to organic materials, molten fluxes, especially of the resin/rosin type, adhere well to fingers. A mass of hot sticky flux can transfer more heat to skin and cause more serious burn

A burn is an injury to skin, or other tissues, caused by heat, cold, electricity, chemicals, friction, or ultraviolet radiation (like sunburn). Most burns are due to heat from hot liquids (called scalding), solids, or fire. Burns occur ma ...

s than a comparable particle of non-adhering molten metal, which can be quickly shaken off. In this regard, molten flux is similar to molten hot glue.

Fluxless techniques

In some cases the presence of flux is undesirable; flux traces interfere with e.g. precision optics or MEMS assemblies. Flux residues also tend to outgas in vacuum and space applications, and traces of water, ions and organic compounds may adversely affect long-term reliability of non-hermetic packages. Trapped flux residues are also the cause of most voids in the joints. Flux-less techniques are therefore desirable there. For successful soldering and brazing, the oxide layer has to be removed from both the surfaces of the materials and the surface of the filler metal preform; the exposed surfaces also have to be protected against oxidation during heating. Flux-coated preforms can also be used to eliminate flux residue entirely from the soldering process. Protection of the surfaces against further oxidation is relatively simple, by using vacuum or inert atmosphere. Removal of the native oxide layer is more troublesome; physical or chemical cleaning methods have to be employed and the surfaces can be protected by e.g. gold plating. The gold layer has to be sufficiently thick and non-porous to provide protection for reasonable storage time. Thick gold metallization also limits choice of soldering alloys, as tin-based solders dissolve gold and form brittleintermetallic

An intermetallic (also called an intermetallic compound, intermetallic alloy, ordered intermetallic alloy, and a long-range-ordered alloy) is a type of metallic alloy that forms an ordered solid-state compound between two or more metallic eleme ...

s, embrittling the joint. Thicker gold coatings are usually limited to use with indium-based solders and solders with high gold content.

Removal of the oxides from the solder preform is also troublesome. Fortunately some alloys are able to dissolve the surface oxides in their bulk when superheated by several degrees above their melting point; the Sn-Cu1 and Sn-Ag4 require superheating by 18–19 °C, the Sn-Sb5 requires as little as 10 °C, but the Sn-Pb37 alloy requires 77 °C above its melting point to dissolve its surface oxide. The self-dissolved oxide degrades the solder's properties and increases its viscosity in molten state, however, so this approach is not optimal.

Solder preforms are preferred to be with high volume-to-surface ratio, as that limits the amount of oxide being formed. Pastes have to contain smooth spherical particles, preforms are ideally made of round wire. Problems with preforms can be also sidestepped by depositing the solder alloy directly on the surfaces of the parts or substrates, by chemical or electrochemical means for example.

A protective atmosphere with chemically reducing properties can be beneficial in some cases. Molecular hydrogen

Hydrogen is the chemical element with the symbol H and atomic number 1. Hydrogen is the lightest element. At standard conditions hydrogen is a gas of diatomic molecules having the formula . It is colorless, odorless, tasteless, non-toxic ...

can be used to reduce surface oxides of tin and indium at temperatures above 430 and 470 °C; for zinc the temperature is above 500 °C, where zinc is already becoming volatilized. (At lower temperatures the reaction speed is too slow for practical applications.) Very low partial pressures of oxygen and water vapor have to be achieved for the reaction to proceed.

Other reactive atmospheres are also in use. Vapors of formic acid and acetic acid are the most commonly used. Carbon monoxide

Carbon monoxide (chemical formula CO) is a colorless, poisonous, odorless, tasteless, flammable gas that is slightly less dense than air. Carbon monoxide consists of one carbon atom and one oxygen atom connected by a triple bond. It is the simple ...

and halogen gases (for example carbon tetrafluoride

Tetrafluoromethane, also known as carbon tetrafluoride or R-14, is the simplest perfluorocarbon ( C F4). As its IUPAC name indicates, tetrafluoromethane is the perfluorinated counterpart to the hydrocarbon methane. It can also be classified as a ...

, sulfur hexafluoride, or dichlorodifluoromethane) require fairly high temperatures for several minutes to be effective.

Atomic hydrogen is much more reactive than molecular hydrogen. In contact with surface oxides it forms hydroxides, water, or hydrogenated complexes, which are volatile at soldering temperatures. A practical dissociation method is an electrical discharge. Argon-hydrogen gas compositions with hydrogen concentration below the low flammable limit can be used, eliminating the safety issues. The operation has to be performed at low pressure, as the stability of atomic hydrogen at atmospheric pressure is insufficient. Such hydrogen plasma can be used for fluxless reflow soldering.

Active atmospheres are relatively common in furnace brazing; due to the high process temperatures the reactions are reasonably fast. The active ingredients are usually carbon monoxide (possibly in the form of combusted fuel gas) and hydrogen. Thermal dissociation of ammonia yields an inexpensive mixture of hydrogen and nitrogen.

Bombardment with atomic particle beams can remove surface layers at a rate of tens of nanometers per minute. The addition of hydrogen to the plasma augments the removal efficiency by chemical mechanisms.

Mechanical agitation is another possibility for disrupting the oxide layer. Ultrasound can be used for assisting tinning and soldering; an ultrasonic transducer can be mounted on the soldering iron, in a solder bath, or in the wave for wave soldering

Wave soldering is a bulk soldering process used for the manufacturing of printed circuit boards. The circuit board is passed over a pan of molten solder in which a pump produces an upwelling of solder that looks like a standing wave. As the ci ...

. The oxide disruption and removal involves cavitation effects between the molten solder and the base metal surface. A common application of ultrasound fluxing is in tinning of passive parts (active parts do not cope well with the mechanical stresses involved); even aluminium can be tinned this way. The parts can then be soldered or brazed conventionally.

Mechanical rubbing of a heated surface with molten solder can be used for coating the surface. Both surfaces to be joined can be prepared this way, then placed together and reheated. This technique was formerly used to repair small damages on aluminium aircraft skins.

A very thin layer of zinc can be used for joining aluminium parts. The parts have to be perfectly machined, or pressed together, due to the small volume of filler metal. At high temperature applied for long time, the zinc diffuses away from the joint. The resulting joint does not present a mechanical weakness and is corrosion-resistant. The technique is known as diffusion soldering.

Fluxless brazing of copper alloys can be done with self-fluxing filler metals. Such metals contain an element capable of reaction with oxygen, usually phosphorus

Phosphorus is a chemical element with the symbol P and atomic number 15. Elemental phosphorus exists in two major forms, white phosphorus and red phosphorus, but because it is highly reactive, phosphorus is never found as a free element on Ear ...

. A good example is the family of copper-phosphorus alloys.

Properties

Fluxes have several important properties: * Activity – the ability to dissolve existing oxides on the metal surface and promote wetting with solder. Highly active fluxes are often acidic or corrosive in nature. * Corrosivity – the promotion of corrosion by the flux and its residues. Most active fluxes tend to be corrosive at room temperatures and require careful removal. As activity and corrosivity are linked, the preparation of surfaces to be joined should allow use of milder fluxes. Some water-soluble flux residues are hygroscopic, which causes problems with electrical resistance and contributes to corrosion. Fluxes containing halides and mineral acids are highly corrosive and require thorough removal. Some fluxes, especially those based on borax used for brazing, form very hard glass-like coatings that are difficult to remove. * Cleanability – the difficulty of removal of flux and its residues after the soldering operation. Fluxes with higher content of solids tend to leave larger amount of residues; thermal decomposition of some vehicles also leads to formation of difficult-to-clean, polymerized and possibly even charred deposits (a problem especially for hand soldering). Some flux residues are soluble inorganic solvent

A solvent (s) (from the Latin '' solvō'', "loosen, untie, solve") is a substance that dissolves a solute, resulting in a solution. A solvent is usually a liquid but can also be a solid, a gas, or a supercritical fluid. Water is a solvent for ...

s, others in water, some in both. Some fluxes are no-clean, as they are sufficiently volatile or undergo thermal decomposition to volatile products, that they do not require the cleaning step. Other fluxes leave non-corrosive residues that can be left in place. However, flux residues can interfere with subsequent operations; they can impair adhesion of conformal coating

Conformal coating is a protective coating of thin polymeric film, applied to printed circuit boards (PCB). The coating is named conformal since it ''conforms'' to the contours of the PCB. Conformal coatings are typically applied at 25-250 μm to ...

s, or act as undesired insulation on connectors and contact pads for test equipment.

* Residue tack – the stickiness of the surface of the flux residue. When not removed, the flux residue should have smooth, hard surface. Tacky surfaces tend to accumulate dust and particulates, which causes issues with electrical resistance; the particles themselves can be conductive or they can be hygroscopic or corrosive.

* Volatility – this property has to be balanced to facilitate easy removal of solvents during the preheating phase but to not require too frequent replenishing of solvent in the process equipment.

* Viscosity – especially important for solder paste

Solder paste is used in the manufacture of printed circuit boards to connect surface mount components to pads on the board. It is also possible to solder through-hole pin in paste components by printing solder paste in and over the holes. The s ...

s, which have to be easy to apply but also thick enough to stay in place without spreading to undesired locations. Solder pastes may also function as a temporary adhesive for keeping electronic parts in place before and during soldering. Fluxes applied by e.g. foam require low viscosity.

* Flammability – relevant especially for glycol-based vehicles and for organic solvents. Flux vapors tend to have low autoignition temperature and present a risk of a flash fire

A flash fire is a sudden, intense fire caused by ignition of a mixture of air and a dispersed flammable substance such as a solid (including dust), flammable or combustible liquid (such as an aerosol or fine mist), or a flammable gas. It is charact ...

when the flux comes in contact with a hot surface.

* Solids – the percentage of solid material in the flux. Fluxes with low solids, sometimes as little as 1–2%, are called low solids flux, low-residue flux, or no clean flux. They are often composed of weak organic acids, with addition of small amount of rosin or other resins.

* Conductivity – some fluxes remain conductive after soldering if not cleaned properly, leading to random malfunctions on circuits with high impedances. Different types of fluxes are differently prone to cause these issues.

Composition

Fluxes for metal joining

The composition of fluxes is tailored for the required properties - the base metals and their surface preparation (which determine the composition and thickness of surface oxides), the solder (which determines the wetting properties and the soldering temperature), the corrosion resistance and ease of removal, and others. Fluxes for soft soldering are typically of organic nature, though inorganic fluxes, usually based on halogenides or acids, are also used in non-electronics applications. Fluxes for brazing operate at significantly higher temperatures and are therefore mostly inorganic; the organic compounds tend to be of supplementary nature, e.g. to make the flux sticky at low temperature so it can be easily applied. The surface of the tin-based solder is coated predominantly with tin oxides; even in alloys the surface layer tends to become relatively enriched by tin. Fluxes for indium and zinc based solders have different compositions than fluxes for ordinary tin-lead and tin-based solders, due to different soldering temperatures and different chemistry of the oxides involved. Organic fluxes are unsuitable for flame soldering and flame brazing, as they tend to char and impair solder flow. Some metals are classified as "unsolderable" in air, and have to be either coated with another metal before soldering or special fluxes or protective atmospheres have to be used. Such metals are beryllium, chromium,magnesium

Magnesium is a chemical element with the symbol Mg and atomic number 12. It is a shiny gray metal having a low density, low melting point and high chemical reactivity. Like the other alkaline earth metals (group 2 of the periodic ta ...

, titanium

Titanium is a chemical element with the Symbol (chemistry), symbol Ti and atomic number 22. Found in nature only as an oxide, it can be reduced to produce a lustrous transition metal with a silver color, low density, and high strength, resista ...

, and some aluminium alloys.

Fluxes for high-temperature soldering differ from the fluxes for use at lower temperatures. At higher temperatures even relatively mild chemicals have sufficient oxide-disrupting activity, but the metal oxidation rates become fairly high; the barrier function of the vehicle therefore becomes more important than the fluxing activity. High molecular weight hydrocarbons are often used for this application; a diluent with a lower molecular weight, boiling off during the preheat phase, is usually used to aid application.

Common fluxes are ammonium chloride or resin acids Resin acid refers to mixtures of several related carboxylic acids, primarily abietic acid, found in tree resins. Nearly all resin acids have the same basic skeleton: three fused rings having the empirical formula C19H29COOH. Resin acids are tacky, ...

(contained in rosin

Rosin (), also called colophony or Greek pitch ( la, links=no, pix graeca), is a solid form of resin obtained from pines and some other plants, mostly conifers, produced by heating fresh liquid resin to vaporize the volatile liquid terpene comp ...

) for soldering copper

Copper is a chemical element with the symbol Cu (from la, cuprum) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pinkis ...

and tin; hydrochloric acid

Hydrochloric acid, also known as muriatic acid, is an aqueous solution of hydrogen chloride. It is a colorless solution with a distinctive pungent smell. It is classified as a strong acid

Acid strength is the tendency of an acid, symbol ...

and zinc chloride for soldering galvanized

Galvanization or galvanizing ( also spelled galvanisation or galvanising) is the process of applying a protective zinc coating to steel or iron, to prevent rusting. The most common method is hot-dip galvanizing, in which the parts are submerged ...

iron

Iron () is a chemical element with Symbol (chemistry), symbol Fe (from la, Wikt:ferrum, ferrum) and atomic number 26. It is a metal that belongs to the first transition series and group 8 element, group 8 of the periodic table. It is, Abundanc ...

(and other zinc

Zinc is a chemical element with the symbol Zn and atomic number 30. Zinc is a slightly brittle metal at room temperature and has a shiny-greyish appearance when oxidation is removed. It is the first element in group 12 (IIB) of the periodi ...

surfaces); and borax for brazing, braze-welding ferrous

In chemistry, the adjective Ferrous indicates a compound that contains iron(II), meaning iron in its +2 oxidation state, possibly as the divalent cation Fe2+. It is opposed to " ferric" or iron(III), meaning iron in its +3 oxidation state, suc ...

metals, and forge welding

Forge welding (FOW), also called fire welding, is a solid-state welding process that joins two pieces of metal by heating them to a high temperature and then hammering them together. It may also consist of heating and forcing the metals together ...

.

Organic fluxes

Organic fluxes typically consist of four major components: * Activators – chemicals disrupting/dissolving the metal oxides. Their role is to expose unoxidized, easily wettable metal surface and aid soldering by other means, e.g. by exchange reactions with the base metals. ** Highly active fluxes contain chemicals that are corrosive at room temperature. The compounds used include metal halides (most often zinc chloride or ammonium chloride),hydrochloric acid

Hydrochloric acid, also known as muriatic acid, is an aqueous solution of hydrogen chloride. It is a colorless solution with a distinctive pungent smell. It is classified as a strong acid

Acid strength is the tendency of an acid, symbol ...

, phosphoric acid

Phosphoric acid (orthophosphoric acid, monophosphoric acid or phosphoric(V) acid) is a colorless, odorless phosphorus-containing solid, and inorganic compound with the chemical formula . It is commonly encountered as an 85% aqueous solution, w ...

, citric acid, and hydrobromic acid

Hydrobromic acid is a strong acid formed by dissolving the diatomic molecule hydrogen bromide (HBr) in water. "Constant boiling" hydrobromic acid is an aqueous solution that distills at and contains 47.6% HBr by mass, which is 8.77 mol/L. ...

. Salts of mineral acid

A mineral acid (or inorganic acid) is an acid derived from one or more inorganic compounds, as opposed to organic acids which are acidic, organic compounds. All mineral acids form hydrogen ions and the conjugate base when dissolved in water.

Cha ...

s with amine

In chemistry, amines (, ) are compounds and functional groups that contain a basic nitrogen atom with a lone pair. Amines are formally derivatives of ammonia (), wherein one or more hydrogen

Hydrogen is the chemical element wi ...

s are also used as aggressive activators. Aggressive fluxes typically facilitate corrosion

Corrosion is a natural process that converts a refined metal into a more chemically stable oxide. It is the gradual deterioration of materials (usually a metal) by chemical or electrochemical reaction with their environment. Corrosion engi ...

, require careful removal, and are unsuitable for finer work. Activators for fluxes for soldering and brazing aluminium often contain fluorides.

** Milder activators begin to react with oxides only at elevated temperature. Typical compounds used are carboxylic acids (e.g. fatty acids (most often oleic acid and stearic acid), dicarboxylic acids) and sometimes amino acid

Amino acids are organic compounds that contain both amino and carboxylic acid functional groups. Although hundreds of amino acids exist in nature, by far the most important are the alpha-amino acids, which comprise proteins. Only 22 alpha a ...

s. Some milder fluxes also contain halides or organohalide

Halocarbon compounds are chemicals in which one or more carbon atoms are linked by covalent bonds with one or more halogen atoms (fluorine, chlorine, bromine or iodine – ) resulting in the formation of organofluorine compounds, organochlori ...

s.

* Vehicles – high-temperature tolerant chemicals in the form of non-volatile liquids or solids with suitable melting point; they are generally liquid at soldering temperatures. Their role is to act as an oxygen barrier to protect the hot metal surface against oxidation, to dissolve the reaction products of activators and oxides and carry them away from the metal surface, and to facilitate heat transfer. Solid vehicles tend to be based on natural or modified rosin

Rosin (), also called colophony or Greek pitch ( la, links=no, pix graeca), is a solid form of resin obtained from pines and some other plants, mostly conifers, produced by heating fresh liquid resin to vaporize the volatile liquid terpene comp ...

(mostly abietic acid, pimaric acid

Pimaric acid is a carboxylic acid from the resin acid group, often found in the oleoresins of pine trees. It can be prepared by dehydration of abietic acid, which it usually accompanies in mixtures like rosin. It is soluble in alcohols, acetone, a ...

, and other resin acids) or natural or synthetic resin

In polymer chemistry and materials science, resin is a solid or highly viscous substance of plant or synthetic origin that is typically convertible into polymers. Resins are usually mixtures of organic compounds. This article focuses on n ...

s. Water-soluble organic fluxes tend to contain vehicles based on high-boiling polyol

In organic chemistry, a polyol is an organic compound containing multiple hydroxyl groups (). The term "polyol" can have slightly different meanings depending on whether it is used in food science or polymer chemistry. Polyols containing two, thr ...

s - glycol

A diol is a chemical compound containing two hydroxyl groups ( groups). An aliphatic diol is also called a glycol. This pairing of functional groups is pervasive, and many subcategories have been identified.

The most common industrial diol is e ...

s, diethylene glycol

Diethylene glycol (DEG) is an organic compound with the formula (HOCH2CH2)2O. It is a colorless, practically odorless, and hygroscopic liquid with a sweetish taste. It is a four carbon dimer of ethylene glycol. It is miscible in water, alcohol, ...

and higher polyglycols, polyglycol-based surfactants and glycerol.

* Solvents – added to facilitate processing and deposition to the joint. Solvents are typically dried out during preheating before the soldering operation; incomplete solvent removal may lead to boiling off and spattering of solder paste particles or molten solder.

* Additives – numerous other chemicals modifying the flux properties. Additives can be surfactants (especially nonionic), corrosion inhibitor

In chemistry, a corrosion inhibitor or anti-corrosive is a chemical compound that, when added to a liquid or gas, decreases the corrosion rate of a material, typically a metal or an alloy, that comes into contact with the fluid. The effectiveness ...

s, stabilizers and antioxidants, tackifier

Tackifiers are chemical compounds used in formulating adhesives to increase the tack, the stickiness of the surface of the adhesive. They are usually low-molecular weight compounds with high glass transition temperature. At low strain rate, they p ...

s, thickener

A thickening agent or thickener is a substance which can increase the viscosity of a liquid without substantially changing its other properties. Edible thickeners are commonly used to thicken sauces, soups, and puddings without altering their t ...

s and other rheological

Rheology (; ) is the study of the flow of matter, primarily in a fluid (liquid or gas) state, but also as "soft solids" or solids under conditions in which they respond with plastic flow rather than deforming elastically in response to an appli ...

modifiers (especially for solder paste

Solder paste is used in the manufacture of printed circuit boards to connect surface mount components to pads on the board. It is also possible to solder through-hole pin in paste components by printing solder paste in and over the holes. The s ...

s), plasticizer

A plasticizer ( UK: plasticiser) is a substance that is added to a material to make it softer and more flexible, to increase its plasticity, to decrease its viscosity, and/or to decrease friction during its handling in manufacture.

Plasticiz ...

s (especially for flux-cored solders), and dyes.

Inorganic fluxes

Inorganic fluxes contain components playing the same role as in organic fluxes. They are more often used in brazing and other high-temperature applications, where organic fluxes have insufficient thermal stability. The chemicals used often simultaneously act as both vehicles and activators; typical examples are borax,borate

A borate is any of several boron oxyanions, negative ions consisting of boron and oxygen, such as orthoborate , metaborate , or tetraborate ; or any salt with such anions, such as sodium metaborate, and disodium tetraborate . The name also re ...

s, fluoroborates, fluorides and chloride

The chloride ion is the anion (negatively charged ion) Cl−. It is formed when the element chlorine (a halogen) gains an electron or when a compound such as hydrogen chloride is dissolved in water or other polar solvents. Chloride sa ...

s. Halogenides are active at lower temperatures than borates, and are therefore used for brazing of aluminium and magnesium alloys; they are however highly corrosive.

Behavior of activators

The role of the activators is primarily disruption and removal of the oxide layer on the metal surface (and also the molten solder), to facilitate direct contact between the molten solder and metal. The reaction product is usually soluble or at least dispersible in the molten vehicle. The activators are usually either acids, or compounds that release acids at elevated temperature. The general reaction of oxide removal is: :Metal oxide + Acid → Salt + Water Salts are ionic in nature and can cause problems from metallic leaching or dendrite growth, with possible product failure. In some cases, particularly in high-reliability

Reliability, reliable, or unreliable may refer to:

Science, technology, and mathematics Computing

* Data reliability (disambiguation), a property of some disk arrays in computer storage

* High availability

* Reliability (computer networking), a ...

applications, flux residues must be removed.

The activity of the activator generally increases with temperature, up to a certain value where activity ceases, either due to thermal decomposition or excessive volatilization. However the oxidation rate of the metals also increases with temperature.

At high temperatures, copper oxide reacts with hydrogen chloride to water-soluble and mechanically weak copper chloride, and with rosin to salts of copper and abietic acid which is soluble in molten rosin.

Some activators may also contain metal ions, capable of exchange reaction with the underlying metal; such fluxes aid soldering by chemically depositing a thin layer of easier solderable metal on the exposed base metal. An example is the group of fluxes containing zinc

Zinc is a chemical element with the symbol Zn and atomic number 30. Zinc is a slightly brittle metal at room temperature and has a shiny-greyish appearance when oxidation is removed. It is the first element in group 12 (IIB) of the periodi ...

, tin or cadmium compounds, usually chlorides, sometimes fluorides or fluoroborates.

Inorganic activators

Common high-activity activators aremineral acid

A mineral acid (or inorganic acid) is an acid derived from one or more inorganic compounds, as opposed to organic acids which are acidic, organic compounds. All mineral acids form hydrogen ions and the conjugate base when dissolved in water.

Cha ...

s, often together with halides, amines, water or alcohols:

* hydrochloric acid

Hydrochloric acid, also known as muriatic acid, is an aqueous solution of hydrogen chloride. It is a colorless solution with a distinctive pungent smell. It is classified as a strong acid

Acid strength is the tendency of an acid, symbol ...

, most common

* phosphoric acid

Phosphoric acid (orthophosphoric acid, monophosphoric acid or phosphoric(V) acid) is a colorless, odorless phosphorus-containing solid, and inorganic compound with the chemical formula . It is commonly encountered as an 85% aqueous solution, w ...

, less common, use limited by its polymerization at higher temperatures

Inorganic acids are highly corrosive to metals even at room temperature, which causes issues during storage, handling and applications. As soldering involves high temperatures, compounds that decompose or react, with acids as products, are frequently used:

* zinc chloride, which at high temperatures reacts with moisture, forming oxychloride and hydrochloric acid

Hydrochloric acid, also known as muriatic acid, is an aqueous solution of hydrogen chloride. It is a colorless solution with a distinctive pungent smell. It is classified as a strong acid

Acid strength is the tendency of an acid, symbol ...

* ammonium chloride, thermally decomposing to ammonia and hydrochloric acid

* amine

In chemistry, amines (, ) are compounds and functional groups that contain a basic nitrogen atom with a lone pair. Amines are formally derivatives of ammonia (), wherein one or more hydrogen

Hydrogen is the chemical element wi ...

hydrochloride

In chemistry, a hydrochloride is an acid salt resulting, or regarded as resulting, from the reaction of hydrochloric acid with an organic base (e.g. an amine). An alternative name is chlorhydrate, which comes from French. An archaic alternative n ...

s, decomposing to the amine and hydrochloric acid

Rosin fluxes

rosin

Rosin (), also called colophony or Greek pitch ( la, links=no, pix graeca), is a solid form of resin obtained from pines and some other plants, mostly conifers, produced by heating fresh liquid resin to vaporize the volatile liquid terpene comp ...

. Some manufactures reserve "rosin" designation for military fluxes based on rosin (R, RMA and RA compositions) and label others as "resin".

Rosin has good flux properties. A mixture of organic acids ( resin acids, predominantly abietic acid, with pimaric acid

Pimaric acid is a carboxylic acid from the resin acid group, often found in the oleoresins of pine trees. It can be prepared by dehydration of abietic acid, which it usually accompanies in mixtures like rosin. It is soluble in alcohols, acetone, a ...

, isopimaric acid

Isopimaric acid (IPA) is a toxin which acts as a large conductance Ca2+-activated K+ channel (BK channel) opener.

Sources

IPA originates from many sorts of trees, especially conifers.

Chemistry

IPA is one of the members of the resin acid group ...

, neoabietic acid, dihydroabietic acid, and dehydroabietic acid), rosin is a glassy solid, virtually nonreactive and noncorrosive at normal temperature, but liquid, ionic and mildly reactive to metal oxides at molten state. Rosin tends to soften between 60–70 °C and is fully fluid at around 120 °C; molten rosin is weakly acidic and is able to dissolve thinner layers of surface oxides from copper without further additives. For heavier surface contamination or improved process speed, additional activators can be added.

There are several possible activator groups for rosins:

* halide activators (organic halide salts, e.g. dimethylammonium chloride and diethylammonium chloride)

* organic acids (monocarboxylic, e.g. formic acid, acetic acid, propionic acid, and dicarboxylic, e.g. oxalic acid, malonic acid

Malonic acid (IUPAC systematic name: propanedioic acid) is a dicarboxylic acid with structure CH2(COOH)2. The ionized form of malonic acid, as well as its esters and salts, are known as malonates. For example, diethyl malonate is malonic acid' ...

, sebacic acid

Sebacic acid is a naturally occurring dicarboxylic acid with the chemical formula . It is a white flake or powdered solid. ''Sebaceus'' is Latin for tallow candle, ''sebum'' is Latin for tallow, and refers to its use in the manufacture of candles. ...

)

There are three types of rosin: gum rosin (from pine tree oleoresin Oleoresins are semi-solid extracts composed of resin and essential or fatty oil, obtained by evaporation of the solvents used for their production. The oleoresin of conifers is known as crude turpentine or gum turpentine, which consists of oil of ...

), wood rosin (obtained by extraction of tree stumps), and tall oil rosin (obtained from tall oil, a byproduct of kraft paper

Kraft paper or kraft is paper or paperboard (cardboard) produced from chemical pulp produced in the kraft process.

Sack kraft paper (or just sack paper) is a porous kraft paper with high elasticity and high tear resistance, designed for packag ...

process). Gum rosin has a milder odor and lower tendency to crystallize from solutions than wood rosin, and is therefore preferred for flux applications. Tall oil rosin finds increased use due to its higher thermal stability and therefore lower tendency to form insoluble thermal decomposition residues. The composition and quality of rosin differs by the tree type, and also by location and even by year. In Europe, rosin for fluxes is usually obtained from a specific type of Portuguese pine, in America a North Carolina variant is used.

Natural rosin can be used as-is, or can be chemically modified by e.g. esterification

In chemistry, an ester is a compound derived from an oxoacid (organic or inorganic) in which at least one hydroxyl group () is replaced by an alkoxy group (), as in the substitution reaction of a carboxylic acid and an alcohol. Glycerides ar ...

, polymerization

In polymer chemistry, polymerization (American English), or polymerisation (British English), is a process of reacting monomer molecules together in a chemical reaction to form polymer chains or three-dimensional networks. There are many fo ...

, or hydrogenation

Hydrogenation is a chemical reaction between molecular hydrogen (H2) and another compound or element, usually in the presence of a catalyst such as nickel, palladium or platinum. The process is commonly employed to reduce or saturate organ ...

. The properties being altered are increased thermal stability, better cleanability, altered solution viscosity

The viscosity of a fluid is a measure of its resistance to deformation at a given rate. For liquids, it corresponds to the informal concept of "thickness": for example, syrup has a higher viscosity than water.

Viscosity quantifies the inte ...

, and harder residue (or conversely, softer and more tacky residue). Rosin can be also converted to a water-soluble rosin flux, by formation of an ethoxylated rosin amine

In chemistry, amines (, ) are compounds and functional groups that contain a basic nitrogen atom with a lone pair. Amines are formally derivatives of ammonia (), wherein one or more hydrogen

Hydrogen is the chemical element wi ...

, an adduct

An adduct (from the Latin ''adductus'', "drawn toward" alternatively, a contraction of "addition product") is a product of a direct addition of two or more distinct molecules, resulting in a single reaction product containing all atoms of all co ...

with a polyglycol and an amine.

One of the early fluxes was a mixture of equal amounts of rosin and vaseline

Vaseline ()Also pronounced with the main stress on the last syllable . is an American brand of petroleum jelly-based products owned by transnational company Unilever. Products include plain petroleum jelly and a selection of skin creams, soa ...

. A more aggressive early composition was a mixture of saturated solution of zinc chloride, alcohol, and glycerol.

Fluxes can be also prepared from synthetic resins, often based on esters of polyol

In organic chemistry, a polyol is an organic compound containing multiple hydroxyl groups (). The term "polyol" can have slightly different meanings depending on whether it is used in food science or polymer chemistry. Polyols containing two, thr ...

s and fatty acids. Such resins have improved fume odor and lower residue tack, but their fluxing activity and solubility tend to be lower than that of natural resins.

Rosin flux grades

Rosin fluxes are categorized by grades of activity: L for low, M for moderate, and H for high. There are also other abbreviations for different rosin flux grades: * R (Rosin) – pure rosin, no activators, low activity, mildest * WW (Water-White) – purest rosin grade, no activators, low activity, sometimes synonymous with R * RMA (Rosin Mildly Activated) - contains mild activators, typically no halides * RA (Rosin Activated) – rosin with strong activators, high activity, contains halides * OA (Organic Acid) – rosin activated with organic acids, high activity, highly corrosive, aqueous cleaning * SA (Synthetically Activated) – rosin with strong synthetic activators, high activity; formulated to be easily soluble in organic solvents (chlorofluorocarbon

Chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs) are fully or partly halogenated hydrocarbons that contain carbon (C), hydrogen (H), chlorine (Cl), and fluorine (F), produced as volatile derivatives of methane, ethane, and pro ...

s, alcohols) to facilitate cleaning

* WS (Water-Soluble) – usually based on inorganic or organic halides; highly corrosive residues

* SRA (Superactivated rosin) – rosin with very strong activators, very high activity

* IA (Inorganic Acid) – rosin activated with inorganic acids (usually hydrochloric acid or phosphoric acid), highest activities, highly corrosive

R, WW, and RMA grades are used for joints that can not be easily cleaned or where there is too high corrosion risk. More active grades require thorough cleaning of the residues. Improper cleaning can actually aggravate the corrosion by releasing trapped activators from the flux residues.

Special fluxes

Fluxes for soldering certain metals

Some materials are very difficult to solder. In some cases special fluxes have to be employed.Aluminum and its alloys

Aluminium and its alloys are difficult to solder due to the formation of the passivation layer of aluminium oxide. The flux has to be able to disrupt this layer and facilitate wetting by solder. Salts or organic complexes of some metals can be used; the salt has to be able to penetrate the cracks in the oxide layer. The metal ions, more noble than aluminium, then undergo a redox reaction, dissolve the surface layer of aluminium and form a deposit there. This intermediate layer of another metal then can be wetted with a solder. One example of such flux is a composition of triethanolamine, fluoroboric acid, and cadmium fluoroborate. More than 1% magnesium in the alloy impairs the flux action, however, as the magnesium oxide layer is more refractory. Another possibility is an inorganic flux composed of zinc chloride or tin(II) chloride, ammonium chloride, and a fluoride (e.g.sodium fluoride

Sodium fluoride (NaF) is an inorganic compound with the formula . It is used in trace amounts in the fluoridation of drinking water, in toothpaste, in metallurgy, and as a flux. It is a colorless or white solid that is readily soluble in water. I ...

). Presence of silicon

Silicon is a chemical element with the symbol Si and atomic number 14. It is a hard, brittle crystalline solid with a blue-grey metallic luster, and is a tetravalent metalloid and semiconductor. It is a member of group 14 in the periodic ta ...

in the alloy impairs the flux effectivity, as silicon does not undergo the exchange reaction aluminium does.

Magnesium alloys

Magnesium alloy

Magnesium alloys are mixtures of magnesium (the lightest structural metal) with other metals (called an alloy), often aluminium, zinc, manganese, silicon, copper, rare earths and zirconium. Magnesium alloys have a hexagonal lattice structure, w ...

s. A putative flux for soldering these alloys at low temperature is molten acetamide. Acetamide dissolves surface oxides on both aluminium and magnesium; promising experiments were done with its use as a flux for a tin-indium solder on magnesium.

Stainless steel

Stainless steel is material which is difficult to solder because of its stable, self-healing surface oxide layer and its low thermal conductivity. A solution of zinc chloride in hydrochloric acid is a common flux for stainless steels; it has however to be thoroughly removed afterwards as it would cause pitting corrosion. Another highly effective flux is phosphoric acid; its tendency to polymerize at higher temperatures however limits its applications.Metal salts as flux in hot corrosion

Hot corrosion can affectgas turbine

A gas turbine, also called a combustion turbine, is a type of continuous flow internal combustion engine. The main parts common to all gas turbine engines form the power-producing part (known as the gas generator or core) and are, in the directio ...

s operating in high salt environments (e.g., near the ocean). Salts, including chloride

The chloride ion is the anion (negatively charged ion) Cl−. It is formed when the element chlorine (a halogen) gains an electron or when a compound such as hydrogen chloride is dissolved in water or other polar solvents. Chloride sa ...

s and sulfate

The sulfate or sulphate ion is a polyatomic anion with the empirical formula . Salts, acid derivatives, and peroxides of sulfate are widely used in industry. Sulfates occur widely in everyday life. Sulfates are salts of sulfuric acid and many ...

s, are ingested by the turbines and deposited in the hot sections of the engine; other elements present in fuels also form salts, e.g. vanadate

In chemistry, a vanadate is an anionic coordination complex of vanadium. Often vanadate refers to oxoanions of vanadium, most of which exist in its highest oxidation state of +5. The complexes and are referred to as hexacyanovanadate(III) and no ...

s. The heat from the engine melts these salts which then can flux the passivating oxide layers on the metal components of the engine, allowing corrosion to occur at an accelerated rate.

List of fluxes

* Borax – for brazing * Beeswax * Citric Acid - for soldering copper/electronics. * Tallow and lead *Paraffin wax

Paraffin wax (or petroleum wax) is a soft colorless solid derived from petroleum, coal, or oil shale that consists of a mixture of hydrocarbon molecules containing between 20 and 40 carbon atoms. It is solid at room temperature and begins to ...

* Palm oil

* Zinc chloride ("Killed Spirits")

* Zinc chloride and Ammonium chloride

* Olive oil and Ammonium chloride – for iron

* Rosin

Rosin (), also called colophony or Greek pitch ( la, links=no, pix graeca), is a solid form of resin obtained from pines and some other plants, mostly conifers, produced by heating fresh liquid resin to vaporize the volatile liquid terpene comp ...

, tallow, olive oil, and zinc chloride - for aluminium

* Cryolite

Cryolite ( Na3 Al F6, sodium hexafluoroaluminate) is an uncommon mineral identified with the once-large deposit at Ivittuut on the west coast of Greenland, mined commercially until 1987.

History

Cryolite was first described in 1798 by Danish vete ...

(Sodium hexafluoroaluminate)

* Cryolite and phosphoric acid

Phosphoric acid (orthophosphoric acid, monophosphoric acid or phosphoric(V) acid) is a colorless, odorless phosphorus-containing solid, and inorganic compound with the chemical formula . It is commonly encountered as an 85% aqueous solution, w ...

* Phosphoric acid & alcohol

* Cryolite and barium chloride

Barium chloride is an inorganic compound with the formula Ba Cl2. It is one of the most common water-soluble salts of barium. Like most other water-soluble barium salts, it is white, highly toxic, and imparts a yellow-green coloration to a flame. ...

* Oleic acid

* Lithium chloride

Lithium chloride is a chemical compound with the formula Li Cl. The salt is a typical ionic compound (with certain covalent characteristics), although the small size of the Li+ ion gives rise to properties not seen for other alkali metal chlorid ...

* Magnesium chloride

Magnesium chloride is the family of inorganic compounds with the formula , where x can range from 0 to 12. These salts are colorless or white solids that are highly soluble in water. These compounds and their solutions, both of which occur in natu ...

* Sodium chloride

* Potassium chloride

* Unslaked lime

Flux recovery

During thesubmerged arc welding

Submerged arc welding (SAW) is a common arc welding process. The first SAW patent was taken out in 1935. The process requires a continuously fed consumable solid or tubular (metal cored) electrode. The molten weld and the arc zone are protec ...

process, not all flux turns into slag. Depending on the welding process, 50% to 90% of the flux can be reused.

Standards

Solder fluxes are specified according to several standards.ISO 9454-1 and DIN EN 29454-1

The most common standard in Europe isISO

ISO is the most common abbreviation for the International Organization for Standardization.

ISO or Iso may also refer to: Business and finance

* Iso (supermarket), a chain of Danish supermarkets incorporated into the SuperBest chain in 2007

* Iso ...

9454-1 (also known as DIN EN 29454-1).

This standard specifies each flux by a four-character code: flux type, base, activator, and form. The form is often omitted.

Therefore, 1.1.2 means rosin flux with halides.

DIN 8511

The older German DIN 8511 specification is still often in use in shops. In the table below, note that the correspondence between DIN 8511 and ISO 9454-1 codes is not one-to-one.J-STD-004

One standard increasingly used (e.g. in the United States) is J-STD-004. It is very similar to DIN EN 61190-1-1. Four characters (two letters, then one letter, and last a number) represent flux composition, flux activity, and whether activators include halides: * First two letters: Base ** RO: rosin ** RE: resin ** OR: organic ** IN: inorganic * Third letter: Activity ** L: low ** M: moderate ** H: high * Number: Halide content ** 0: less than 0.05% in weight (“halide-free”) ** 1: halide content depends on activity: *** less than 0.5% for low activity *** 0.5% to 2.0% for moderate activity *** greater than 2.0% for high activity Any combination is possible, e.g. ROL0, REM1 or ORH0. J-STD-004 characterizes the flux by reliability of residue from a surface insulation resistance (SIR) and electromigration standpoint. It includes tests for electromigration and surface insulation resistance (which must be greater than 100 MΩ after 168 hours at elevated temperature and humidity with a DC bias applied).MIL-F-14256 and QQ-S-571

The old MIL-F-14256 and QQ-S-571 standards defined fluxes as: Any of these categories may be no-clean, or not, depending on the chemistry selected and the standard that the manufacturer requires.See also

* Flux-cored arc welding *Gas metal arc welding

Gas metal arc welding (GMAW), sometimes referred to by its subtypes metal inert gas (MIG) and metal active gas (MAG) is a welding process in which an electric arc forms between a consumable MIG wire electrode and the workpiece metal(s), which hea ...

* Shielded metal arc welding

Shielded metal arc welding (SMAW), also known as manual metal arc welding (MMA or MMAW), flux shielded arc welding or informally as stick welding, is a manual arc welding process that uses a consumable electrode covered with a flux to lay the we ...

References

External links

MetalShapers.Org

Tips & Tricks from the Pros: 'Aluminum Welding"'' (includes Filler Metal chart)

Solder Fume and You

{{DEFAULTSORT:Flux (Metallurgy) Metallurgy Brazing and soldering