|

Failure Mechanisms

Failure causes are defects in design, process, quality, or part application, which are the underlying cause of a failure or which initiate a process which leads to failure. Where failure depends on the user of the product or process, then human error must be considered. Component failure/failure modes A part failure mode is the way in which a component failed "functionally" on the component level. Often a part has only a few failure modes. For example, a relay may fail to open or close contacts on demand. The failure mechanism that caused this can be of many different kinds, and often multiple factors play a role at the same time. They include corrosion, welding of contacts due to an abnormal electric current, return spring fatigue failure, unintended command failure, dust accumulation and blockage of mechanism, etc. Seldom only one cause (hazard) can be identified that creates system failures. The real root causes can in theory in most cases be traced back to some kind of human ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Human Error

Human error is an action that has been done but that was "not intended by the actor; not desired by a set of rules or an external observer; or that led the task or system outside its acceptable limits".Senders, J.W. and Moray, N.P. (1991) Human Error: Cause, Prediction, and Reduction'. Lawrence Erlbaum Associates, p.25. . Human error has been cited as a primary cause and contributing factor in disasters and accidents in industries as diverse as Nuclear and radiation accidents and incidents, nuclear power (e.g., the Three Mile Island accident), Pilot error, aviation, List of spaceflight-related accidents and incidents, space exploration (e.g., the Space Shuttle Challenger disaster and Space Shuttle Columbia disaster), and Medical error, medicine. Prevention of human error is generally seen as a major contributor to Data integrity, reliability and safety of (complex) systems. Human error is one of the many contributing causes of risk events. Definition Human error refers to somethi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Model (abstract)

The term conceptual model refers to any model that is formed after a wikt:concept#Noun, conceptualization or generalization process. Conceptual models are often abstractions of things in the real world, whether physical or social. Semantics, Semantic studies are relevant to various stages of process of concept formation, concept formation. Semantics is fundamentally a study of concepts, the meaning that thinking beings give to various elements of their experience. Overview Concept models and conceptual models The value of a conceptual model is usually directly proportional to how well it corresponds to a past, present, future, actual or potential state of affairs. A concept model (a model of a concept) is quite different because in order to be a good model it need not have this real world correspondence. In artificial intelligence, conceptual models and conceptual graphs are used for building expert systems and knowledge-based systems; here the analysts are concerned to repres ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Forensic Electrical Engineering

Forensic electrical engineering is a branch of forensic engineering, and is concerned with investigating electrical failures and accidents in a legal context. Many forensic electrical engineering investigations apply to fires suspected to be caused by electrical failures. Forensic electrical engineers are most commonly retained by insurance companies or attorneys representing insurance companies, or by manufacturers or contractors defending themselves against subrogation by insurance companies. Other areas of investigation include accident investigation involving electrocution, and intellectual property disputes such as patent actions. Additionally, since electrical fires are most often cited as the cause for "suspect" fires, an electrical engineer is often employed to evaluate the electrical equipment and systems to determine whether the cause of the fire was electrical in nature. Goals The ultimate goal of these investigations is often to determine the legal liability for a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Failure Rate

Failure is the social concept of not meeting a desirable or intended objective, and is usually viewed as the opposite of success. The criteria for failure depends on context, and may be relative to a particular observer or belief system. One person might consider a failure what another person considers a success, particularly in cases of direct competition or a zero-sum game. Similarly, the degree of success or failure in a situation may be differently viewed by distinct observers or participants, such that a situation that one considers to be a failure, another might consider to be a success, a qualified success or a neutral situation. It may also be difficult or impossible to ascertain whether a situation meets criteria for failure or success due to ambiguous or ill-defined definition of those criteria. Finding useful and effective criteria or heuristics to judge the success or failure of a situation may itself be a significant task. Sociology Cultural historian Sco ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Failure Modes, Effects, And Diagnostic Analysis

Failure modes, effects, and diagnostic analysis (FMEDA) is a systematic analysis technique to obtain subsystem / device level failure rates, failure modes and diagnostic capability. The FMEDA technique considers: * All components of a design, * The functionality of each component, * The failure modes of each component, * The effect of each component failure mode on the product functionality, * The ability of any automatic diagnostics to detect the failure, * The design strength (de-rating, safety factors), * The impact of any latent fault tests, and * The operational profile (environmental stress factors). Given a component database calibrated with field failure data that is reasonably accurate, the method can predict device level failure rate per failure mode, useful life, automatic diagnostic effectiveness, and latent fault test effectiveness for a given application. The predictions have been shown to be more accurate than field warranty return analysis or even typical field f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Failure Mode And Effects Analysis

Failure is the social concept of not meeting a desirable or intended Goal, objective, and is usually viewed as the opposite of success. The criteria for failure depends on context, and may be relative to a particular observer or belief system. One person might consider a failure what another person considers a success, particularly in cases of direct competition or a zero-sum game. Similarly, the degree of success or failure in a situation may be differently viewed by distinct observers or participants, such that a situation that one considers to be a failure, another might consider to be a success, a qualified success or a neutral situation. It may also be difficult or impossible to ascertain whether a situation meets criteria for failure or success due to ambiguous or ill-defined definition of those criteria. Finding useful and effective criteria or heuristics to judge the success or failure of a situation may itself be a significant task. Sociology Cultural historian Sco ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Failure Analysis

Failure analysis is the process of collecting and analyzing data to determine the cause of a failure, often with the goal of determining corrective actions or liability. According to Bloch and Geitner, ”machinery failures reveal a reaction chain of cause and effect… usually a deficiency commonly referred to as the symptom…”. Failure analysis can save money, lives, and resources if done correctly and acted upon. It is an important discipline in many branches of manufacturing industry, such as the electronics industry, where it is a vital tool used in the development of new products and for the improvement of existing products. The failure analysis process relies on collecting failed components for subsequent examination of the cause or causes of failure using a wide array of methods, especially microscopy and spectroscopy. Nondestructive testing (NDT) methods (such as industrial computed tomography scanning) are valuable because the failed products are unaffected by analysis ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

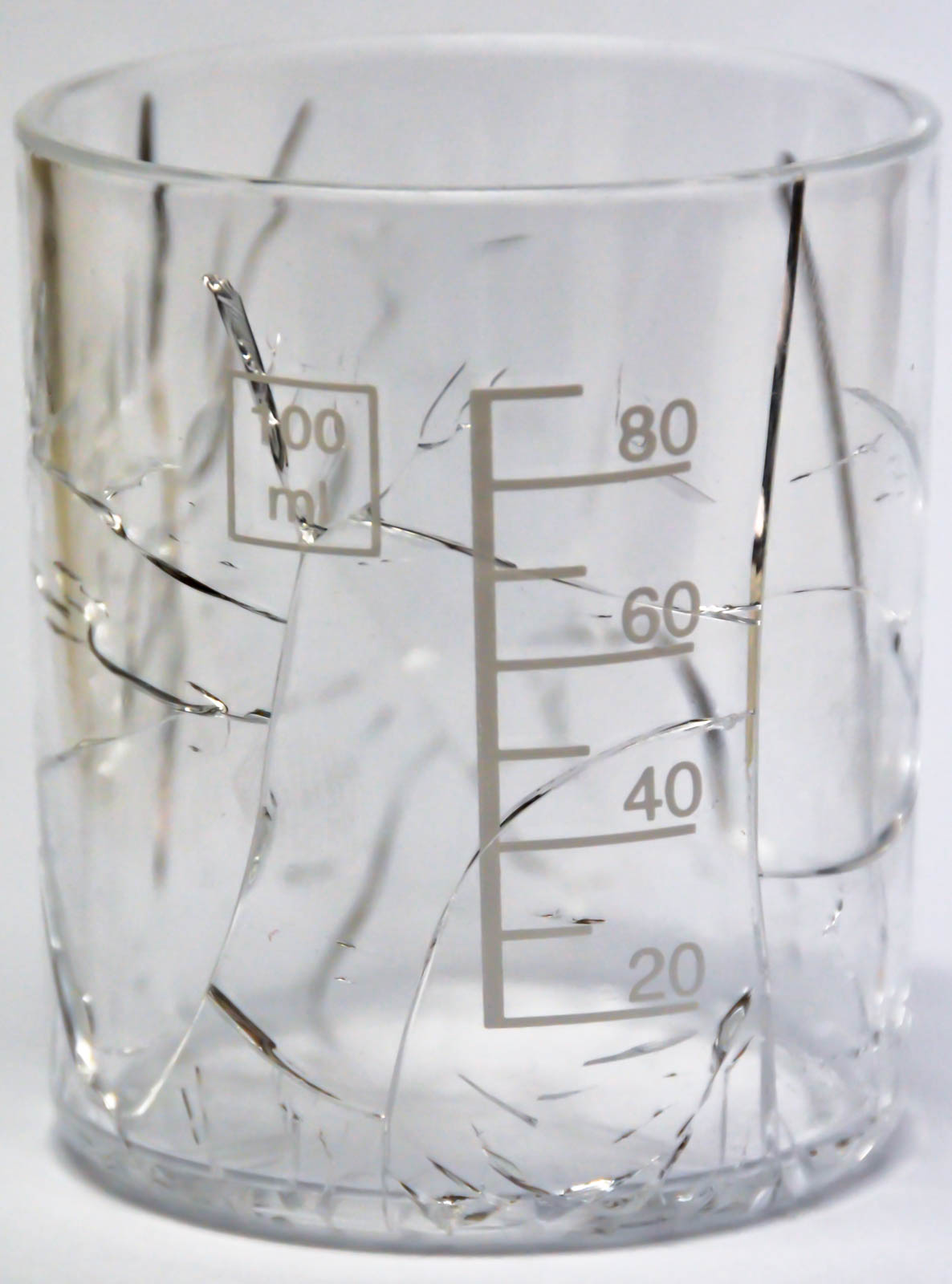

Environmental Stress Cracking

Environmental Stress Cracking (ESC) is one of the most common causes of unexpected brittle failure of thermoplastic (especially amorphous) polymers known at present. According to ASTM D883, stress cracking is defined as "an external or internal crack in a plastic caused by tensile stresses less than its short-term mechanical strength". This type of cracking typically involves brittle cracking, with little or no ductile drawing of the material from its adjacent failure surfaces. Environmental stress cracking may account for around 15-30% of all plastic component failures in service.H. F. Mark (2004). Encyclopedia of Polymers Science and Technology – 3rd Ed. Vol 12. John Miley & Sons Inc. This behavior is especially prevalent in glassy, amorphous thermoplastics. Amorphous polymers exhibit ESC because of their loose structure which makes it easier for the fluid to permeate into the polymer. Amorphous polymers are more prone to ESC at temperature higher than their glass tran ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stress Corrosion Cracking

Stress corrosion cracking (SCC) is the growth of crack formation in a corrosive environment. It can lead to unexpected and sudden failure of normally ductile metal alloys subjected to a tensile stress, especially at elevated temperature. SCC is highly chemically specific in that certain alloys are likely to undergo SCC only when exposed to a small number of chemical environments. The chemical environment that causes SCC for a given alloy is often one which is only mildly corrosive to the metal. Hence, metal parts with severe SCC can appear bright and shiny, while being filled with microscopic cracks. This factor makes it common for SCC to go undetected prior to failure. SCC often progresses rapidly, and is more common among alloys than pure metals. The specific environment is of crucial importance, and only very small concentrations of certain highly active chemicals are needed to produce catastrophic cracking, often leading to devastating and unexpected failure. The stresse ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Steel

Steel is an alloy of iron and carbon that demonstrates improved mechanical properties compared to the pure form of iron. Due to steel's high Young's modulus, elastic modulus, Yield (engineering), yield strength, Fracture, fracture strength and low raw material cost, steel is one of the most commonly manufactured materials in the world. Steel is used in structures (as concrete Rebar, reinforcing rods), in Bridge, bridges, infrastructure, Tool, tools, Ship, ships, Train, trains, Car, cars, Bicycle, bicycles, Machine, machines, Home appliance, electrical appliances, furniture, and Weapon, weapons. Iron is always the main element in steel, but other elements are used to produce various grades of steel demonstrating altered material, mechanical, and microstructural properties. Stainless steels, for example, typically contain 18% chromium and exhibit improved corrosion and Redox, oxidation resistance versus its carbon steel counterpart. Under atmospheric pressures, steels generally ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Iron

Iron is a chemical element; it has symbol Fe () and atomic number 26. It is a metal that belongs to the first transition series and group 8 of the periodic table. It is, by mass, the most common element on Earth, forming much of Earth's outer and inner core. It is the fourth most abundant element in the Earth's crust, being mainly deposited by meteorites in its metallic state. Extracting usable metal from iron ores requires kilns or furnaces capable of reaching , about 500 °C (900 °F) higher than that required to smelt copper. Humans started to master that process in Eurasia during the 2nd millennium BC and the use of iron tools and weapons began to displace copper alloys – in some regions, only around 1200 BC. That event is considered the transition from the Bronze Age to the Iron Age. In the modern world, iron alloys, such as steel, stainless steel, cast iron and special steels, are by far the most common industrial metals, due to their mechan ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rusting

Rust is an iron oxide, a usually reddish-brown oxide formed by the reaction of iron and oxygen in the catalytic presence of water or air moisture. Rust consists of hydrous iron(III) oxides (Fe2O3·nH2O) and iron(III) oxide-hydroxide (FeO(OH), Fe(OH)3), and is typically associated with the corrosion of refined iron. Given sufficient time, any iron mass, in the presence of water and oxygen, could eventually convert entirely to rust. Surface rust is commonly flaky and friable, and provides no passivational protection to the underlying iron unlike other metals such as aluminum, copper, and tin which form stable oxide layers. ''Rusting'' is the common term for corrosion of elemental iron and its alloys such as steel. Many other metals undergo similar corrosion, but the resulting oxides are not commonly called "rust". Several forms of rust are distinguishable both visually and by spectroscopy, and form under different circumstances. Other forms of rust include the result of r ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |